Abstract

Vertical semiconducting fins integrated with high-κ oxide dielectrics have been at the centre of the key device architecture that has promoted advanced transistor scaling during the last decades. Single-fin channels based on two-dimensional (2D) semiconductors are expected to offer unique advantages in achieving sub-1 nm fin-width and atomically flat interfaces, resulting in superior performance and potentially high-density integration. However, multi-fin structures integrated with high-κ dielectrics are commonly required to achieve higher electrical performance and integration density. Here we report a ledge-guided epitaxy strategy for growing high-density, mono-oriented 2D Bi2O2Se fin arrays that can be used to fabricate integrated 2D multi-fin field-effect transistors. Aligned substrate steps enabled precise control of both nucleation sites and orientation of 2D fin arrays. Multi-channel 2D fin field-effect transistors based on epitaxially integrated 2D Bi2O2Se/Bi2SeO5 fin-oxide heterostructures were fabricated, exhibiting an on/off current ratio greater than 106, high on-state current, low off-state current, and high durability. 2D multi-fin channel arrays integrated with high-κ oxide dielectrics offer a strategy to improve the device performance and integration density in ultrascaled 2D electronics.

Similar content being viewed by others

Introduction

Over the past few decades, conventional field-effect transistors (FETs) based on three-dimensional (3D) semiconductors have continued to shrink in size according to Moore’s Law (the number of transistors in an integrated circuit doubles approximately every two years), enabling improvements in device performance and transistor density1,2. To sustain further increases in integration density and improvements in electrical performance, the fin field-effect transistor (FinFET) featuring a thin vertical fin channel surrounded by the gate electrodes was adopted at the 22 nm node3. This nonplanar transistor structure provides superior electrostatic control and marked reduction in energy consumption4,5,6,7, enabling the continuous downscaling of integrated circuits (ICs)3,7,8,9,10,11,12,13,14.

However, Si-based FinFETs are still struggling to achieve sub-3 nm nodes with minimum fin width of about 5 nm that reaches the physical limitation presented by quantum mechanical issues. In particular, the short-channel effect and sub-5 nm channel thickness ultimately limit Si-based FinFET downscaling. The reduced mobility, imperfect interfaces, and nonuniform electrostatic control associated with channel surface and fin shape are the main obstacles. On the one hand, the worsened surface roughness of thinning 3D channel material induces strong surface scattering of charge carriers15,16. Additionally, the tapered fin shape of Si FinFETs, which presumably originated from the top-down etching process of bulk Si17,18, leads to poorer electrostatic control at the fin bottom with larger width17,18,19 (Fig. 1a). In order to overcome these issues, efforts have been devoted to fabricate 3D transistor architectures using 2D semiconductors20,21,22,23,24,25,26,27, especially vertical 2D FinFETs20,21,22,23, which can be attributed to the unique advantages of 2D material with atomically flat surface28,29,30,31,32,33 and the rectangular fin shape originated from bottom-up growth method20. Remarkably, 2D Bi2O2Se/Bi2SeO5 fin/oxide heterostructure enables 2D single-fin FETs integrated with high-κ gate oxide, exhibiting comparable performance to industrial Si-based FinFETs23.

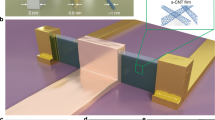

a Schematic illustration for 2D multi-fin FETs potentially applied in advanced integrated circuits. b–d Schematic (b) and corresponding scanning electron microscopy (SEM) images of 2D Bi2O2Se fins with two perpendicular orientations on pristine LaAlO3 (100) surface, including top view (c) and tilted view (d). e–g Schematic (e) and corresponding SEM images of ledge-guided epitaxial mono-oriented 2D Bi2O2Se fins on pre-treated LaAlO3 (100) surface, including top view (f) and tilted view (g).

In principle, the ultrascaled FinFETs tend to adopt uniform multi-fin arrays to achieve high-density integration and robust performance in terms of power gain and drive capability for logic chips34,35,36,37. As compared to single-fin FETs, multi-fin FETs might offer a larger total channel width, resulting in higher total drive current, transconductance, and lower noise35. Despite the advanced performance of 2D single-fin FETs, 2D multi-fin FETs are also highly desired for enhanced power gain and drive capability. Therefore, it is necessary to explore the growth of high-density 2D fin arrays for the fabrication of integrated 2D multi-fin FETs.

Here, we present a ledge-guided epitaxy approach to grow high-density, mono-oriented 2D fin arrays on diverse insulating substrates for the fabrication of integrated 2D multi-fin FETs. Remarkably, the ledge-guided epitaxy of mono-oriented 2D fin arrays is independent of the symmetry of substrate and differs to the recently reported defect-induced epitaxy which necessitates coworkers with two-fold symmetric substrates (e.g., MgO (110)) and defect-induced selective nucleation23. The pre-created aligned steps on the substrates assist in controlling the nucleation sites and orientation of 2D Bi2O2Se fin arrays via reducing the binding energy of nuclei at the step edge and lowering the substrate symmetry, enabling the growth of high-density parallel 2D fin arrays with a minimum fin spacing of sub-20 nm. As-grown 2D Bi2O2Se fin arrays were fabricated into multi-channel 2D FinFETs with integrated high-κ native-oxide Bi2SeO5, which exhibit superior electrical performance and good durability, including low off-state current (IOFF), large on/off current ratio (ION/IOFF) of >106, and high on-state current (ION). Compared with 2D single-fin FETs, 2D multi-fin FETs possess superior electrical performance, such as enhanced on-state current and transconductance, indicating the potential of high-density 2D fin-oxide heterostructure arrays for realizing ICs with high-density integration and improved performance.

Results

Ledge-guided epitaxy of 2D fin arrays

As an emerging 2D semiconductor, Bi2O2Se has unique layered structure and superior properties, including ultrahigh carrier mobility, moderate band gap, great air stability38,39. Notably, Bi2O2Se has a high-κ (κ ≈ 21) competitive native-oxide dielectric, Bi2SeO5, which works as effectively as SiO2 does with Si40,41,42. Bi2O2Se has a tetragonal crystal structure (I4/mmm, a = 3.88 Å, c = 12.16 Å and Z = 2), and consists of positively charged [Bi2O2]n2n+ layers sandwiched by negatively charged Sen2n- layers (Supplementary Fig. 1). There are relatively weak electrostatic interactions between the [Bi2O2]n2n+ layers and the Sen2n− layers, while within the [Bi2O2]n2n+ layers are strong covalent bonds. The high density of dangling bonds at an edge of layered [Bi2O2]n2n+ greatly enhances the bonding between the edge and the substrate and allows vertical 2D Bi2O2Se fins to be efficiently grown on diverse insulating substrates (such as LaAlO3, MgO and CaF2). On the other hand, the in-plane orientation of 2D fins depends on the symmetry matching between the substrate and 2D fin. On pristine [LaO]+-terminated LaAlO3 (100) surface with 4-fold symmetry (Fig. 1 b–d), the 2-fold symmetric 2D Bi2O2Se fins have two equivalent energy-minimum orientations (that is, 0° and 90° orientations) and were found randomly aligned along two perpendicular directions of the substrate. Due to the two different in-plane orientations and the nature of random nucleation, the as-grown 2D fins were discrete, which impedes further high-density integration of 2D multiple fin channels.

To grow unidirectionally aligned 2D fin arrays, we first prepared high-density, aligned steps on insulating substrates, which had been confirmed effective for the growth of aligned 2D single crystals43. Taking the adopted LaAlO3 (100) as a presentative example, several artificially self-aligned steps with specific orientation on the LaAlO3 (100) surface can be easily pre-created with parallel or perpendicular the [001] or [010] direction by using a less-sharp diamond scraper before the growth of 2D fin arrays (Supplementary Fig. 2). Remarkably, the self-aligned step edges formed with an “atomic” resolution originate from brittle fractures along the [001] or [010] direction of the LaAlO3 lattice from the (010) or (001) cleavage plane. From the experimental epitaxial results, despite the fact that the formed step edges are not perpendicular to the scratches, a mono-oriented 2D fin array is still obtained (Supplementary Fig. 2). With the assistance of these aligned steps, the vertical 2D Bi2O2Se nucleus are anchored along the pre-patterned step edges to site-specifically grow unidirectionally aligned 2D fin arrays (Fig. 1e–g and Supplementary Fig. 3). The whole ledge-guided epitaxy towards the energetically favorable growth of aligned 2D fin arrays mainly involves the following four processes (taking LaAlO3 as a representative example): (i) a single-crystal epitaxy substrate with exposed ledges is adopted; (ii) exposed ledges on the substrate surface preferentially trap precursor atoms and thereby serve as nucleation sites; (iii) 2D fin seeds with energetic minimum nucleate at the ledge, breaking the symmetry and selectively stabilizing a preferred orientation; (iv) mono-oriented seeds grow anisotropically into well-aligned 2D fins (Supplementary Fig. 4). Remarkably, after combining a micromachined arm and a diamond scrape, the spacing of 2D fin arrays is controllable by controlling the spacing of step arrays (Supplementary Fig. 2).

Structure characterization of ledge-guided epitaxial 2D fins

To elucidate the interfacial microstructures and nucleation mechanism of vertical 2D Bi2O2Se fin arrays grown by the ledge-guided epitaxy, we have performed aberration-corrected scanning transmission electron microscopy (AC-STEM) investigations. The 2D Bi2O2Se fin/LaAlO3 slices were initially fabricated using focused ion beam (FIB) milling, followed by extensive cross-sectional AC-STEM observations. Figure 2a shows a typical 2D Bi2O2Se fin grown by ledge-guided epitaxy, which is strictly perpendicular to the LaAlO3 substrate surface with a smooth surface along its fin height. The aspect ratio (i.e., height/thickness) of this particular 2D fin is as high as ~37 (~30 nm in thickness, ~1.1 μm in height), which may help boost the electrical performance of 2D FinFETs44. High-resolution (HR) AC-STEM image of the vertical 2D Bi2O2Se fin from the side view (Fig. 2b) indicates the layered structure of 2D Bi2O2Se with a layer spacing of ~0.61 nm, consistent with the (002) planes of layered Bi2O2Se. The corresponding Fast Fourier Transform (FFT) diffraction spots of the interface further indicate the epitaxial relationships where the (100) and (001) planes of epitaxial Bi2O2Se are parallel to (100) and (001) planes of LaAlO3, respectively (Fig. 2c). Note that atomically sharp steps exist on the LaAlO3 substrate surface (Fig. 2b), allowing for guided growth of vertical 2D Bi2O2Se fin. Interestingly, the interface strain of 2D fin around the substrate step is clearly identified (Fig. 2d), which can be almost completely relaxed along the vertical direction of the 2D fin within ~1.0 nm. Furthermore, the enlarged image of interface microstructure as shown in Fig. 2e exhibits the atomically sharp interface and perfect epitaxial growth between Bi2O2Se fin and the step edge of [LaO]+ terminated LaAlO3 (100) surface.

a Cross-sectional low-magnification transmission electron microscopy (TEM) image of a vertical Bi2O2Se fin grown by ledge-guided epitaxy. b Cross-sectional high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) image showing clear steps on the surface of the substrate, where the fin nucleated. The dashed line means Bi2O2Se/LaAlO3 interface. c Fast Fourier Transform (FFT) diffraction spots of (b). d Strain mapping (ɛxx) estimated from a filtered version of the panel (b). e High-magnification HAADF-STEM image with atomic resolution and corresponding schematic of Bi2O2Se/LaAlO3 interface. The dashed line represents actual interface. f, g The binding energies and optimized structures of Bi/Se atoms (f) and Bi-O monomers (g) adsorbed at the step edge and the terrace of the LaAlO3 substrate, respectively. h The binding energies and optimized structures of a 2D Bi2O2Se nucleus at the step edge and terrace, demonstrate that nucleation at the step edge is energetically favorable. ΔE is the energy difference between two nucleation sites.

Ledge-guided epitaxy mechanism of 2D fin arrays

Density functional theory (DFT) calculations were performed to gain a better understanding of the ledge-guided epitaxy mechanism. As shown in Fig. 2f, g, the binding energy of a Bi/Se atom or Bi-O monomer at the step edge and terrace of [LaO]+ terminated LaAlO3 substrate surface was calculated, respectively. The results showed that the binding energy of Bi atom at the terrace is 0.48 eV, while it decreases to −0.26 eV at the step edge. For Se atom adsorption, the binding energy is −0.45 eV at the terrace and it decreases to −1.06 eV at the step edge. Supplementary Fig. 5 illustrates additional adsorption structures of Bi and Se, which further confirm that Bi and Se atoms tend to preferentially absorb at the step edge site rather than the terrace site. Similarly, the Bi–O monomer has lower binding energy at the step edge than terrace, indicating that the exposed step edges preferentially trap precursor Bi–O monomers (Fig. 2g).

We further optimized the structure and calculated the binding energy of the 2D Bi2O2Se nucleus at the step edge and the terrace of LaAlO3, respectively (Fig. 2g). The calculations clearly reveal that the nucleation of vertical 2D Bi2O2Se fins at the step edge of LaAlO3 substrate is highly preferred than that on terrace. The 2D Bi2O2Se fin nucleus exhibite a lower binding energy of −10.40 eV at the step edge than that on the terrace, −9.62 eV. The energy difference (ΔE) between two nucleation sites reache 0.78 eV and thermodynamic probability of the 2D Bi2O2Se fin nucleation at the step edge can be roughly estimated to be 1/(1 + exp(ΔE/kBT)) > 99.99%, in which kB is the Boltzmann constant and T = 903 K is the growth temperature of 2D fin arrays. Considering that the step edges on the substrate serve as active lines to initiate the nucleation of 2D Bi2O2Se fins, the site-specific epitaxy of 2D fin arrays can be well controlled via the ledge-guided epitaxy.

Orientation and density control of 2D fin arrays

Besides controlling the nucleation sites, the aligned step edges of the substrate also enable the mono-orientation alignment of 2D fins on the substrate. The 2-fold symmetric 2D Bi2O2Se fins vertically grown on a 4-fold symmetric LaAlO3 substrate have two energy-degenerated orientations, which are perpendicular to each other. However, by introducing high-density aligned steps on the LaAlO3 substrates, the substrate symmetry was reduced from C4V to C2V. According to the principle of symmetry matching45,46,47, the nucleated C2V symmetric Bi2O2Se fins can be mono-oriented on a pretreated C2 symmetric LaAlO3 substrate, resulting in the vertical growth of aligned 2D fin arrays at the controlled nucleation sites.

In addition to artificial step edges, reducing the substrate symmetry by applying a miscut angle can also be used to tune the in-plane orientation of 2D Bi2O2Se fin arrays (Fig. 3a). Miscut toward [100] produces nanoscale steps on LaAlO3 (100) surface with their edges along [010]. On well-cut LaAlO3 (100) surface with a tunable miscut angle and step density, the orientation of vertical 2D Bi2O2Se fin arrays can be adjusted from two perpendicular orientations to mono-orientation as the miscut angle toward the [100] direction increases from 0.1° to 10° (Fig. 3b). As the miscut angle increases, the correspondingly increased step density inhibits the across-terrace growth of 2D Bi2O2Se fins, forming mono-oriented 2D fins. When miscut angle of LaAlO3 (100) substrates reaches ~10°, purely mono-oriented 2D Bi2O2Se fin arrays were obtained (Figs. 3a, b). Remarkably, we used high-density aligned steps of LaAlO3 (100) substrate to further increase the density of aligned 2D fins via the ledge-guided epitaxy (Fig. 3c).

a Schematic and SEM images showing the effect of the step density on the orientation of 2D Bi2O2Se fin arrays. b Statistic for mono-oriented fin percentage of 2D Bi2O2Se fin arrays growth with miscut angle of the epitaxial substrate. Error bars indicate standard deviations of mono-oriented fin percentage for different miscut angle. c–e SEM images of high-density 2D Bi2O2Se fin arrays grown by ledge-guided epitaxy on LaAlO3 (100) surface (c), MgO (110) surface (d) and CaF2 (110) surface (e). Insets: corresponding tilted-view high-magnification SEM images. LFS represents fin spacing. f Statistical minimum fin pitch and fin spacing of different vertical 2D Bi2O2Se fin arrays grown by ledge-guided epitaxy on various substrates. Error bars indicate standard deviations of minimum fin spacing and fin pitch for different 2D fin arrays.

This strategy is also applicable for other insulated substrates, such as MgO and CaF2. Unidirectionally aligned 2D Bi2O2Se fins nucleate randomly and grow anisotropically on pristine 2-fold symmetric MgO (110) and CaF2 (110) surfaces (Supplementary Fig. 6). With the introduction of high-density aligned steps on the surface of MgO (110) and CaF2 (110) slices, high-density 2D Bi2O2Se fin arrays are achievable (Fig. 3d, e). Figure 3f presents the statistic result of the minimum fin spacing and fin pitch in various 2D fin arrays on different substrates. As-grown 2D fin arrays generally exhibit small fin spacing of less than 80 nm and fin pitch of less than 200 nm (Supplementary Fig. 7), among which some 2D fin arrays even achieve a minimum fin spacing of less than 20 nm (Fig. 3f). Given more precise and controllable preparation of substrate steps, it will be possible to fabricate ordered high-density 2D fin arrays that meet the material requirement of advanced sub-1 nm technology node, as projected by International Roadmap for Devices and Systems (IRDS)48.

Electrical performance of 2D multi-fin FETs

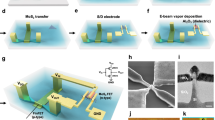

High-density aligned 2D fin arrays facilitate the fabrication of 2D multi-fin FETs that integrate multiple fin channels, which have the potential to boost electrical performance with higher drive capability. As illustrated in Fig. 4a–e, conformal formation of epitaxial native-oxide Bi2SeO5 layer and atomic layer deposition of HfO2 film are both used as high-κ bilayer dielectrics of 2D multi-fin FETs. Epitaxial Bi2SeO5 dielectric (κ ≈ 21) was created by intercalation oxidation of 2D Bi2O2Se fin with the assistance of ultraviolet, where Sen2n− layers underwent intercalative oxidation to SeO32− groups while the layered [Bi2O2]n2n+ framework structures remain intact (Supplementary Fig. 8). In the space between two [Bi2O2]n2n+ layers, a SeO32− group has four equivalent orientations. Our DFT calculations indicate that the SeO32− groups between two [Bi2O2]n2n+ layers tend to be aligned along one direction, while tuning the orientations of SeO32− groups in neighboring layers only results in very small energy difference and lattice constant change. For example, the three structures of Bi2SeO5 shown in Supplementary Fig. 9 have nearly equivalent lattice constants and stability. Notably, the fin-oxide heterostructure with atomically smooth interface, formed by the 2D Bi2O2Se fin integrated high-κ native-oxide Bi2SeO5 epilayer, acts as the workhorse architecture for 2D multi-fin FETs (Supplementary Fig. 8d). On the one hand, controllable oxidation is an effective approach to thinning 2D fins in the fin-oxide heterostructures, which enables 2D fin as thin as 3 nm (Supplementary Fig. 8e). In addition, combining oxidation and selective etching via diluted HF acid (~0.2 %), the downscaling of total thickness of 2D fins can possibly be further realized (Supplementary Fig. 10).

a Schematic diagram of 2D Bi2O2Se/Bi2SeO5/HfO2 FinFET with three fins. b Cross-sectional STEM image of fin arrays. c–e Low-magnification STEM image (c), Energy-dispersive X-ray spectroscopy (EDS) image (d), and high-magnification STEM image (e) of Bi2O2Se/Bi2SeO5 fin-oxide heterostructures covered with HfO2 dielectric layer. f Tilted SEM image of a 3-fin FinFET. g Typical output curves of the 2D multi-fin FET in (f). IDS is the source-drain current. VDS is the source-drain voltage and VG is the gate voltage. Lch represents the channel length of the devices. h Transfer curves of the 2D multi-fin FET in (f) and the repeated transfer curve measurement results for 50 cycles of the 2D multi-fin FET. IG is the gate leakage current, Vth is the threshold voltage and ΔVth means the shift of threshold voltage. The intersection of the two dashed lines is the threshold voltage of the device, represented by a solid line. i Statistical on-state current (ION) and off-state current (IOFF) measured over 50 cycles for different multiple-channel 2D FinFETs. j, k Transfer curves (j) and statistical ION and IOFF (k) of the 2D multi-fin FET in (f) operated under different temperatures. l Comparison of normalized current of the fabricated 2D multi-fin FETs with 2D MoS2 FET49, 2D InSe FET50, 2D MoS2 FinFETs20 and Intel’s 14 nm-node Si FinFETs51 under low gate-voltage modulation. L is the channel length and Weff is the effective width of device.

2D multi-fin FET with channel length of about 1 μm was fabricated based on three Bi2O2Se fins with relatively consistent shapes (Fig. 4f). The 2D Bi2O2Se fin channel is ~250 nm high and 24 nm thick, surrounded by a 5.5 nm-thick epitaxial high-κ Bi2SeO5 and 7.2 nm-thick HfO2 dielectric (Supplementary Fig. 12). The fin spacing of about 1 μm was chosen for the convenience in device fabrication processing. The typical output and transfer curves are plotted in Fig. 4g, h, exhibiting a high electron mobility of up to 267 cm2 V−1 s−1. The off-current is lower than 0.01 nA and the on-state current reaches 645 μA at VDS of 2 V and VG of 3 V, resulting in a large on/off current ratio (ION/IOFF) of >106. The high on-state current is attributed to the multiple high-quality Bi2O2Se fins, indicating that uniform multiple-fin arrays can work independently and collaboratively. It is worth noting that the native-oxide Bi2SeO5 can act as the sole gate dielectric and enable remarkable gate control for the long channel 2D FinFETs (Supplementary Fig. 11). To obtain high-performance 2D FinFETs by shrinking channel length, HfO2 layer was introduced into the devices. The additional HfO2 layer acted as an insulating spacer to isolate the source/drain and gate electrodes and also served as dielectric because of its high dielectric constant (κ ≈ 16).

For different transistors, the electrical properties are similar, indicating the great reliability and reproducibility of 2D multi-fin FETs (Supplementary Fig. 13). The average on-state current (Ion) is 760 ± 60 uA, mobility (μ) is 165 ± 20 cm2 V−1 s−1, and subthreshold swing (SS) is 200 ± 40 mV dec−1, respectively. Note that the as-fabricated 2D FinFETs exhibit superior durability with almost no degradation in its electrical performance after performing repeated measurements for 50 times (Fig. 4h). The on/off current ratio remains almost constant and the threshold voltage (Vth) remains stable at around −0.46 V with a slight shift about 0.02 V in transfer curves (Fig. 4h, i). Remarkably, under the operating temperature of around 400 K, the multi-fin FinFET can still maintain an on/off ratio of more than 105, and the slightly increased off-state current can be recovered after cooling down to room temperature (Fig. 4j, k).

In order to evaluate the performance and energy efficiency of the 2D multi-fin FETs against that of the traditional Si and newly developed 2D semiconductor counterparts, we compared the normalized current of the fabricated 2D multi-fin FETs with 2D MoS2 FinFETs and Intel’s 14 nm-node Si FinFETs. Notably, owing to the different feature sizes of those transistors, the normalized current per level is employed as the comparison parameter to remove the effect of size. As illustrated in Fig. 4l, the drive current increases with the increase of VDS. The 2D multi-fin FET can achieve a larger drive current per level of up to 230 μA μm μm−1 (VDS = 1 V) under relative low gate-voltage modulation, surpassing that of 2D MoS2 FET49, 2D InSe FET50, 2D MoS2 FinFET20 and Si-based FinFET51, and revealing a potential for high-performance applications. More noteworthy is that 2D-semiconductor-based FinFET shows a strong advantage at energy efficiency that is remarkable for electronic devices with ultralow power consumption. The off-state current of as-fabricated 2D multi-fin FET is as low as 21.7 pA μm μm−1 (VDS = 1 V), which is comparable with 2D MoS2 FinFET and only 9.4% of that of Si-based FinFET.

To investigate the effect of fin number on 2D FinFET performance, we constructed 1-fin and 2-fin FETs using adjacent fins (Fig. 5a). In comparison with the 1-fin FET, the 2-fin FET exhibits a significant increase in on-state current, while maintaining superior electrostatic gate control (Fig. 5b and Supplementary Fig. 14). Meanwhile, the transconductance of the 2-fin FET is 1.7 times that of the 1-fin FET (Fig. 5c). As the number of fins increases further to 5, the FinFETs demonstrate even larger on-state current and transconductance, indicating improved drive capability (Fig. 5d and Supplementary Fig. 14). In particularly, the multi-fin FET with 5 fins delivers a high on-state current of up to 1 mA (Fig. 5e). The on-state current not only represents the drive capability, but also determines the intrinsic gate delay of transistors, which means the switching speed. Such high on-state current in 2D multi-fin FETs provides low gate delay of about 30 ps (Fig. 5f and Supplementary Table 1), which is comparable to Si-based metal-oxide-semiconductor (MOS) FETs at similar channel length. These remarkable performances of 2D muti-fin FETs highlight the potential of integrated 2D Bi2O2Se/Bi2SeO5 fin-oxide heterostructures as a promising candidate for next-generation advanced technology nodes.

a Top SEM image of FinFETs with single fin and two fins, respectively, which share one fin. b Transfer curves of 2D FinFETs with single fin and two fins. c Comparison of the transconductance of 2D FinFETs with single fin and two fins. The different data symbols were obtained from different devices. d Comparison of on-state current and transconductance of 2D FinFETs with different number of fins, demonstrating that multiple-channel FinFETs possess higher electrical performance. e Typical output curves of the 2D FinFETs with five fins. f Benchmarking of the gate delay of 2D multi-fin FETs versus the channel length (Lch) with Si MOS57, Ge MOS58, MoS2 FET59,60,61 and WS2 FET59 (Part of data of MoS2 and WS2 are calculated from ref. 59,60). IRDS 2017–2033 targets62 for high-performance (HP) transistors are also plotted.

Discussion

In summary, we developed ledge-guided epitaxy as a versatile approach for the preparation of high-density mono-oriented 2D Bi2O2Se fin arrays on various insulating substrates. We demonstrated that atomically sharp steps of growth substrates play a crucial role in controlling the nucleation sites and in-plane orientation of vertical 2D Bi2O2Se fins. As-fabricated 2D multi-fin FETs based on the epitaxially integrated 2D Bi2O2Se/Bi2SeO5 fin-oxide arrays exhibit high on-state current and remarkable device durability, even during repeated measurements and at high operating temperatures. By further optimizing the preparation of high-density aligned steps with precise spacing control by ion beam etching, it is possible to achieve ordered higher-density 2D Bi2O2Se fin arrays. This advancement will facilitate large-scale integration of 2D multi-fin FETs, thus allowing for further 2D transistor scaling.

Methods

Preparation of substrates with high-density steps

The growth substrates of LaAlO3 (100), MgO (110), and CaF2 (110) single crystals are scratched by diamond scraper to fabricate high-density aligned steps. The step direction is determined by the crystal structure of the substrate.

Synthesis of high-density aligned 2D Bi2O2Se fin arrays

High-density aligned 2D Bi2O2Se fin arrays were synthesized in a homemade chemical vapor deposition (CVD) system. Bi2O3 powder (Alfa Aesar, 99.999%) was placed in hot center of the furnace and Bi2Se3 powder (Alfa Aesar, 99.999%) was placed upstream 3.5 cm. The heating temperature was controlled at 610–650 oC. The total pressure of the growth chamber was kept at 400 Torr with the high-purity Ar gas serving as carrier gas, whose flow rate was 100 sccm (sccm: standard-state cubic centimeter per minute). The growth substrates were directly placed above the intersection of Bi2O3 and Bi2Se3 precursors with a gap of ~4 mm. The growth time was 10–60 s.

Characterizations

The morphology of as-synthesized aligned 2D Bi2O2Se fin arrays was characterized by scanning electron microscopy (SEM, Hitachi S4800 field emission electron microscope). The tilted SEM images were obtained by means of a sample holder tilted at 45o angle. To characterize the relationship between the location of 2D fins and the steps, the guided 2D Bi2O2Se fins were characterized using the atomic force microscopy (AFM, Bruker dimension icon, ScanAsyst mode).

Cross-section STEM characterization of fin-substrate interface and FinFETs

The fin was thinned by focused ion beam (FEI Scios 2 Dual Beam SEM/FIB system) and cross-section TEM sample was obtained for characterizing the interface structure. Then the atomical structure of Bi2O2Se fin/LaAlO3 interface can be clearly demonstrated by an aberration-corrected scanning transmission electron microscope (AC-STEM) (FEI Titan Cubed Themis G2 300, operated at 300 kV acceleration voltage). The cross-section structure of FinFETs was also characterized by the same method.

Density functional theory (DFT) calculations

All calculations were carried out using density functional theory (DFT) via the Vienna ab initio simulation Package (VASP)52,53. The projector augmented wave method was employed to describe the interaction between valence electrons and nuclei54, and the Perdew–Burke–Ernzerhof (PBE) functional with generalized gradient approximation (GGA) was utilized to describe the exchange-correlation interaction55. The DFT-D3 dispersion-correction method56 was adopted to describe the van der Waals interactions. A kinetic energy cutoff of 500 eV was used for the plane wave basis set. Energy convergence criteria for electronic and ionic iterations were set to be 10−5 and 10−4 eV, respectively. A vacuum layer was set as ~15 Å.

The binding energy between a Bi/Se atom/Bi-O monomer/2D Bi2O2Se fin nucleus and the LaAlO3 substrate at different nucleation sites is defined as:

Where \({E}_{{{{{{\rm{t}}}}}}}\), \({E}_{{{{{{\rm{sub}}}}}}}\) and \({E}_{{{{{{{\rm{Bi}}}}}}/{{{{{\rm{Se}}}}}}/{{{{{\rm{BiO}}}}}}/{{{{{\rm{Bi}}}}}}}_{2}{{{{{{\rm{O}}}}}}}_{2}{{{{{\rm{Se}}}}}}}\) are the total energy, the energy of the substrate, and the energy of Bi/Se/Bi-O/Bi2O2Se adsorbed on the substrate, respectively.

The relative stabilities of Bi2O2Se, Bi2SeO5, and O2 are compared by their formation energies, which are calculated by using

where \({E}_{{{{{{\rm{t}}}}}}}\) is the total energy, \(N\) is the number of atoms.

Fabrication and measurements of 2D FinFETs

Aligned 2D fin arrays were used to fabricate FinFETs via the following device fabrication process. Firstly, in order to prevent 2D fin arrays from collapsing during processing, patterned Au film was adopted to encapsulate 2D Bi2O2Se fins. The pattern was processed with electron beam lithography (EBL) and the metal deposition (Au, 100 nm) was performed by magnetron sputtering coater (QAM-4W-STS, ULVAC) subsequently. Then, the channel windows were exposed by EBL processes and wet chemical etching to remove Au film. The etchant was an aqueous solution consisting I2, KI, and H2O in the ratio of 0.5:1:30. To remove the etchant residues, the slices were quickly transferred into hot water (90 oC) after being etched for 4–8 s. When the Au film on the channel window was completely etched, the remaining Au film acted as source and drain electrodes.

Next, high-κ native-oxide gate Bi2SeO5 (5.5 nm) prepared by intercalative oxidation and high-κ dielectric HfO2 (7.2 nm) deposited by atomic layer deposition (ALD) were used as the dielectrics. Finally, the top-gated electrodes were achieved by EBL exposure and subsequent deposition of Ti/Au films (50 nm/100 nm).

The electrical measurements of the as-fabricated 2D Bi2O2Se FinFETs were carried out by a Keithley SCS-4200 semiconductor parameter analyzer combined with a micromanipulator 6200 probe under ambient conditions.

Strain mapping

Strain mapping was estimated according to the displacement of bright spots in the STEM image shown in Fig. 2. The strain (ɛxx) was calculated by a peak-pair algorithm, and the formula is as follows:

Where \({u}_{{xx}}\) and \({u}_{{yy}}\) are the displacements of the bright spots in the in-plane <001> direction and the vertical <100> direction, respectively. \({u}_{{xx}}\) and \({u}_{{yy}}\) are calculated by \({u}_{{xx}}=\Delta x-{a}_{{{{{{{\rm{LaAlO}}}}}}}_{3}(x)}\) and \({u}_{{yy}}=\Delta y-{a}_{{{{{{{\rm{LaAlO}}}}}}}_{3}(y)}\). Here \(\Delta x\) and \(\Delta y\) represent the displacements of the bright spots in each direction, and \({a}_{{{{{{{\rm{LaAlO}}}}}}}_{3}(x)}\) and \({a}_{{{{{{{\rm{LaAlO}}}}}}}_{3}(y)}\) are lattice constants of the in-plane and vertical direction of the LaAlO3 (100) substrate.

Calculations of field-effect mobility and intrinsic gate delay for 2D Bi2O2Se FinFETs

The field-effect mobility of Bi2O2Se FinFETs was extracted from the linear region of transfer curves. The field-effect electron mobility was calculated according to the following relations:

Where CG is the top-gate oxide capacitance, Lch is the channel length of the devices, Weff represents the effective width of the devices, i.e., the sum of the width and twice the height of all 2D Bi2O2Se fins (Weff = (fin width + 2 × fin height) × fin number). The ɛr for Bi2SeO5 and HfO2 is adopted 21 and 16, respectively. Here, the tri-gate dielectrics are composed of 5.5 nm-thick Bi2SeO5 and 7.2 nm-thick HfO2, the \({C}_{{{\mbox{G}}}}^{*}\) equals 1.243 × 10−2 F m−2.

The intrinsic gate delay is defined as57

in which \({V}_{{{{{{\rm{DD}}}}}}}\) is the supplied voltage of operation and \({I}_{{{{{{\rm{on}}}}}}}\) is the on-state current. C is the total gate capacitance.

Data availability

Relevant data supporting the key findings of this study are available within the article and the Supplementary Information file. All raw data generated during the current study are available from the corresponding authors upon request.

References

Lundstrom, M. S. & Alam, M. A. Moore’s law: the journey ahead. Science 378, 722–723 (2022).

Liu, C. et al. Two-dimensional materials for next-generation computing technologies. Nat. Nanotechnol. 15, 545–557 (2020).

Hu, C. 3D FinFET and other sub-22 nm transistors. In Proc. 19th IEEE International Symposium on the Physical and Failure Analysis of Integrated Circuits 1–5 (2012).

International Roadmap For Devices And Systems 2022 Edition. https://irds.ieee.org/ (2022).

Liu, Y. et al. Promises and prospects of two-dimensional transistors. Nature 591, 43–53 (2021).

Datta, S., Chakraborty, W. & Radosavljevic, M. Toward attojoule switching energy in logic transistors. Science 378, 733–740 (2022).

Liu, J. C. et al. A reliability enhanced 5 nm CMOS technology featuring 5th generation FinFET with fully-developed EUV and high mobility channel for mobile SoC and high-performance computing application. In Proc. IEEE International Electron Devices Meeting 9.2.1–9.2.4 (2020).

Lin, C. et al. High performance 14 nm SOI FinFET CMOS technology with 0.0174 μm2 embedded DRAM and 15 Levels of Cu metallization. In Proc. IEEE International Electron Devices Meeting 3.8.1–3.8.3 (2014).

Gupta, S., Moroz, V., Smith, L., Lu, Q. & Saraswat, K. 7-nm FinFET CMOS design enabled by stress engineering using Si, Ge, and Sn. IEEE Trans. Electron Devices 61, 1222–1230 (2014).

Hisamoto, D. et al. A folded-channel MOSFET for deep-sub-tenth micron era. In Proc. IEEE International Electron Devices Meeting 1032–1034 (1998).

Hisamoto, D. et al. FinFET-a self-aligned double-gate MOSFET scalable to 20 nm. IEEE Trans. Electron Devices 47, 2320–2325 (2000).

Huang, X. et al. Sub 50 nm FinFET: PMOS. In Proc. IEEE International Electron Devices Meeting 67–70 (1999).

Yu, B. et al. FinFET scaling to 10 nm gate length. Digest. In Proc. IEEE International Electron Devices Meeting 251–254 (2002).

Lee, H. et al. Sub-5 nm all-around gate FinFET for ultimate scaling. In Proc. Symposium on VLSI Technology 58–59 (2006).

Hu, C. Thin-body FinFET as scalable low voltage transistor. IEEE VLSI-TSA. 1–4 (2012).

Wang, S., Liu, X. & Zhou, P. The road for 2D semiconductors in the silicon age. Adv. Mater. 34, 2106886 (2022).

Mehrotra, S., Paul, A., Cho, J., Povolotskyi, M. & Klimeck, G. Effect of Fin Tapering In Nanoscale Si FinFETs. In Proc. 16th International Workshop On Computational Electronics 182–183 (2013).

Kurniawan, E. D., Yang, H., Lin, C.-C. & Wu, Y.-C. Effect of fin shape of tapered FinFETs on the device performance in 5-nm node CMOS technology. Microelectron. Reliab. 83, 254–259 (2018).

Chen, C.-H., Fang, Y.-C., Chiang, C.-H. & Chu, S.-Y. Rounding and taper fin effect of FinFET varactors observed using three-dimensional simulation model. Jpn. J. Appl. Phys. 53, 078001 (2014).

Chen, M.-C. et al. TMD FinFET with 4 nm thin body and back gate control for future low power technology. In Proc. IEEE International Electron Devices Meeting 32.2.1–32.2.4 (2015).

Lan, Y.-W. et al. Scalable fabrication of a complementary logic inverter based on MoS2 fin-shaped field effect transistors. Nanoscale Horiz. 4, 683–688 (2019).

Chen, M.-L. et al. A FinFET with one atomic layer channel. Nat. Commun. 11, 1205 (2020).

Tan, C. et al. 2D fin field-effect transistors integrated with epitaxial high-k gate oxide. Nature 616, 66–72 (2023).

Huang, X. et al. Ultrathin multibridge channel transistor enabled by van der Waals assembly. Adv. Mater. 33, 2102201 (2021).

Tong, L. et al. Heterogeneous complementary field-effect transistors based on silicon and molybdenum disulfide. Nat. Electron. 6, 37–44 (2022).

Xiong, X. et al. Demonstration of vertically-stacked Cvd monolayer channels: MoS2 nanosheets GAA-FET with ion>700 µA/µm and MoS2/WSe2 CFET. In Proc. IEEE International Electron Devices Meeting 7.5.1–7.5.4 (2021).

Chung, Y. et al. First demonstration of GAA monolayer-MoS2 nanosheet nFET with 410 μA/μm ID at 1V VD at 40 nm gate length. In Proc. International Electron Devices Meeting 34.5.1–34.5.4 (2022).

Wang, S. et al. Two-dimensional devices and integration towards the silicon lines. Nat. Mater. 21, 1225–1239 (2022).

Li, M.-Y., Su, S.-K., Philip Wong, H.-S. & Li, L.-J. How 2D semiconductors could extend Moore’s law. Nature 567, 169–170 (2019).

Liu, L. et al. Uniform nucleation and epitaxy of bilayer molybdenum disulfide on sapphire. Nature 605, 69–75 (2022).

Wu, Z. et al. Large-scale growth of few-layer two-dimensional black phosphorus. Nat. Mater. 20, 1203–1209 (2021).

Akinwande, D. et al. Graphene and two-dimensional materials for silicon technology. Nature 573, 507–518 (2019).

Knobloch, T. et al. The performance limits of hexagonal boron nitride as an insulator for scaled CMOS devices based on two-dimensional materials. Nat. Electron. 4, 98–108 (2021).

Yeh, W.-K., Zhang, W., Chen, P.-Y. & Yang, Y.-L. The impact of Fin number on device performance and reliability for multi-Fin Tri-gate n- and p-type FinFET. IEEE Trans. Device Mater. Reliab. 18, 555–560 (2018).

Sonkusare, R. S. & Rathod, S. S. Analysis of multifin n-FinFET for analog performance at 30 nm gate length. In Proc. International Conference on Communication and Electronics Systems (ICCES) 1–7 (2016).

Das, R. R., Maity, S., Chowdhury, A. & Chakraborty, A. RF/Analog performance of GaAs Multi-Fin FinFET with stress effect. Microelectron. J. 117, 105267 (2021).

Cheng, H.-W. & Li, Y. Electrical characteristics dependence on the channel fin aspect ratio of multi-fin field effect transistors. Semicond. Sci. Technol. 24, 115021 (2009).

Wu, J. et al. High electron mobility and quantum oscillations in non-encapsulated ultrathin semiconducting Bi2O2Se. Nat. Nanotechnol. 12, 530–534 (2017).

Tan, C. et al. Strain-free layered semiconductors for 2D transistors with on-state current density exceeding 1.3 mA μm–1. Nano. Lett. 22, 3770–3776 (2022).

Zhang, Y. et al. A single-crystalline native dielectric for two-dimensional semiconductors with an equivalent oxide thickness below 0.5 nm. Nat. Electron. 5, 643–649 (2022).

Li, T. et al. A native oxide high-κ gate dielectric for two-dimensional electronics. Nat. Electron. 3, 473–478 (2020).

Zhang, C. et al. Single-crystalline van der Waals layered dielectric with high dielectric constant. Nat. Mater. 22, 832–837 (2023).

Aljarb, A. et al. Ledge-directed epitaxy of continuously self-aligned single-crystalline nanoribbons of transition metal dichalcogenides. Nat. Mater. 19, 1300–1306 (2020).

Choi, K. et al. Reliability on evolutionary FinFET CMOS technology and beyond. In Proc. IEEE International Electron Devices Meeting 9.3.1–9.3.4 (2020).

Dong, J., Zhang, L., Dai, X. & Ding, F. The epitaxy of 2D materials growth. Nat. Commun. 11, 5862 (2020).

Fu, J. et al. Oriented lateral growth of two-dimensional materials on c-plane sapphire. Nat. Nanotechnol. 18, 1289–1294 (2023).

Fu, J. et al. Pieces of 2D materials: the next step to crystallize the polycrystalline domains. Matter 6, 2136–2152 (2023).

International Roadmap for Devices and Systems 2021 Edition. https://irds.ieee.org/ (2021).

Huang, J.-K. et al. High-κ perovskite membranes as insulators for two-dimensional transistors. Nature 605, 262–267 (2022).

Jiang, J., Xu, L., Qiu, C. & Peng, L.-M. Ballistic two-dimensional inse transistors. Nature 616, 470–475 (2023).

Natarajan, S. et al. A 14 nm logic technology featuring 2nd-generation FinFET, air-gapped interconnects, self-aligned double patterning and a 0.0588 μm2 SRAM cell size. In Proc. IEEE International Electron Devices Meeting 3.7.1–3.7.3 (2014).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Let 77, 3865–3868 (1996).

Grimme, S., Antony, J., Ehrlich, S. & Krieg, H. A consistent and accurate ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H-Pu. J. Chem. Phys. 132, 154104 (2010).

Chau, R. et al. Benchmarking nanotechnology for high-performance and low-power logic transistor applications. IEEE Trans. Nanotechnol. 4, 153–158 (2005).

Nicholas, G. et al. High-performance deep submicron Ge pMOSFETs with halo implants. IEEE Trans. Electron Devices 54, 2503–2511 (2007).

Sebastian, A., Pendurthi, R., Choudhury, T. H., Redwing, J. M. & Das, S. Benchmarking monolayer MoS2 and WS2 field-effect transistors. Nat. Commun. 12, 693 (2021).

Li, T. Epitaxial growth of wafer-scale molybdenum disulfide semiconductor single crystals on sapphire. Nat. Nanotechnol. 16, 1201–1207 (2021).

Liu, L., Lu, Y. & Guo, J. On monolayer MoS2 field-effect transistors at the scaling limit. IEEE Trans. Electron Devices 60, 4133–4139 (2013).

International Roadmap for Devices and Systems 2017 Edition. https://irds.ieee.org/ (2017).

Acknowledgements

We acknowledge the Molecular Materials and Nanofabrication Laboratory (MMNL) in the College of Chemistry at Peking University for the use of instruments. This work was supported by the National Natural Science Foundation of China (21920102004, 22205011, and 92164205), the National Key Research & Development Program of China (2021YFA1202901), Beijing National Laboratory for Molecular Sciences (BNLMS-CXTD-202001), and the New Cornerstone Science Foundation through the XPLORER PRIZE.

Author information

Authors and Affiliations

Contributions

H.P., C.T. and M.Y. conceived for the project and designed the experiments. M.Y. and C.T. performed the synthesis of high-density 2D fin arrays guided by steps and corresponding SEM characterizations. M.Y., C.T. and X.G. conducted the STEM and analyzed the results. C.T. and J.T. performed the device fabrication and electrical characterization. F.D. and Y.Y. conducted the theoretical calculations. H.P. supervised this research. M.Y., C.T. and H.P. co-wrote the manuscript. H.L. and other authors contributed to discussions.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Yuxuan Cosmi Lin and the other, anonymous, reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yu, M., Tan, C., Yin, Y. et al. Integrated 2D multi-fin field-effect transistors. Nat Commun 15, 3622 (2024). https://doi.org/10.1038/s41467-024-47974-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-47974-2

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.