Abstract

The development of facile tailoring approach to adjust the intrinsic activity and stability of atomically-precise metal nanoclusters catalysts is of great interest but remians challenging. Herein, the well-defined Au8 nanoclusters modified by single-atom sites are rationally synthesized via a co-eletropolymerization strategy, in which uniformly dispersed metal nanocluster and single-atom co-entrenched on the poly-carbazole matrix. Systematic characterization and theoretical modeling reveal that functionalizing single-atoms enable altering the electronic structures of Au8 clusters, which amplifies their electrocatalytic reduction of CO2 to CO activity by ~18.07 fold compared to isolated Au8 metal clusters. The rearrangements of the electronic structure not only strengthen the adsorption of the key intermediates *COOH, but also establish a favorable reaction pathway for the CO2 reduction reaction. Moreover, this strategy fixing nanoclusters and single-atoms on cross-linked polymer networks efficiently deduce the performance deactivation caused by agglomeration during the catalytic process. This work contribute to explore the intrinsic activity and stability improvement of metal clusters.

Similar content being viewed by others

Introduction

Catalysis with well-defined metal nanoclusters (NCs), at the borderline of small-molecule catalysis and heterogeneous metal catalysis, is a rising topic of interest1,2,3,4,5. Despite their structural appeal, the generally poor stability and catalytic properties of NCs put them out of reach of practical applications. Extensive research efforts have been devoted to improving the intrinsic catalytic properties of metal NCs by tailoring their compositions and structures, such as heterometallic doping6,7,8,9,10, ligand engineering9,11,12,13,14,15, and size regulating16,17,18. While a large number of studies have been released, the controllable synthesis of target metal NCs with well-defined structure still faces great challenges for the synthetic chemists because metal clusters are susceptible to external stimulus during the assembly process19,20,21. Thus, the goal of achieving a metal NCs-based catalyst with high activity and stability raises the necessity for the development of new tailoring approach.

Significant advances have been witnessed in the single-atom (SA) catalysts as efficient catalysts for various reactions22,23,24,25,26. Owing to the different electronic states between NCs and SAs27,28, recent research has found that integrating SAs and metal NCs into one system is an efficient strategy to improve catalytic performance27,28,29,30,31,32,33,34,35,36,37. Introducing SAs can result in the asymmetric electron distribution and moderate free energy for intermediates adsorption, thus optimizing the catalytic activity of metal NCs33,36. Therefore, modulating the electronic structures of metal NCs through SAs could achieve synergistic effects for a given reaction. However, strategies to prepare nanocluster-single atom (NC-SA) catalysts usually involve pyrolysis treatment27,29,30,32,33,34,35,37. The resulting catalyst with vague structure makes it difficult to decipher structure–activity relationships. To the best of our knowledge, studies of functionalizing atomically-precise metal NCs with extra SAs to pursue remarkable activity and stability are still in their infancy.

Herein, uniformly dispersed metal NCs modified with SA sites loaded in a poly-carbazole matrix (denoted as Poly-(Au8-DCP@M), M = Fe, Co, Ni, Cu, Zn) were achieved through an effective co-eletropolymerization strategy (Fig. 1a and Supplementary Fig. 1). The carbazole-substituted phenanthroline composed of chelated metal sites (DCP@Fe, DCP = 3,8-di(9H-carbazol-9-yl)-1,10-phenanthroline) enabled integrating isolated SAs into the hybrid material (Supplementary Fig. 2). Considering that gold-based nanomaterials are intrinsically active for catalyzing CO2 reduction reaction (CO2RR)16,17,38,39, Au8 NC [Au8(dppp)4(CzPA)2]2+ capped by bidentate pisphosphine (dppp = 1,3-bis(diphenylphosphino) propane) and alkynyl carbazole ligands (HCzPA, 9-(4-ethynylphenyl)carbazole) was chosen as the model NC. In comparison with previously reported NC-SA catalysts, the benefit of this strategy is the assembly of monomers will fully pre-disperse the well-defined metal NCs and SAs, thus making them evenly distributed in the resulting skeleton, which providing ideal platforms to understand the critical roles of NCs and SAs in catalytic processes. Remarkably, the as-prepared Poly-(Au8-DCP@Fe) catalysts exhibited much better catalytic efficiency than the pristine Au8 crystal, self-polymerized Poly-Au8, Poly-DCP@Fe and Poly-(Au8-DCP) (co-polymerized Au8 and DCP) toward electrochemical CO2RR. By combining the spectroscopy analysis and theoretical calculations, the introduction of isolated Fe SAs is capable of regulating the electronic structure of Au8 NCs, thus optimizing the adsorption of COOH* in the rate-determining step of CO2RR and accelerating the kinetic processes. This facile strategy of introduction extra SAs to manipulate the intrinsic activity of metal NCs provides valuable insights for designing highly active metal NCs-based catalysts.

a Schematic illustration of Poly-(Au8-DCP@M) catalysts fabricated by co-eletropolymerization strategy. b, c Atomic-resolution HAADF-STEM image of Poly-(Au8-DCP@Fe) revealing the atomically dispersed Au8 NCs and Fe SA. d Elemental mapping of overlapped images and Au (green), P (purple), Fe (cyan), and N (blue).

Results

Synthesis and characterization of nanocluster-single atom catalysts

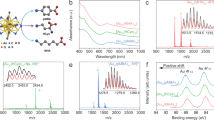

The preparation of Poly-(Au8-DCP@M) is schematically depicted in Fig. 1a. Specifically, alkynyl carbazole ligand (HCzPA) modified Au8 nanoclusters were successfully synthesized via solvent evaporation method. Supplementary Fig. 3 and Supplementary Tables 1–3 shows its identical atomic structure solved by single-crystal X-ray diffraction (SCXRD). The Au8 core contained a di-edge-bridged bitetrahedral unit. Each of the two terminal gold atoms accommodates one phosphine and one alkynyl group. The highly electro-active group “carbazole” in the CzPAs endow Au8 clusters excellent polymerization capability. The bulk phase purity of this crystal was verified by powder X-ray diffraction (PXRD) (Supplementary Fig. 4). Another carbazole-substituted phenanthroline monomer chelated with different single site metals (DCP@M, M = Fe, Co, Ni, Cu, Zn) was successively electrochemically polymerized with Au8 crystal via multi-cycled cyclic voltammetry(CV) methods in the potential range of 0 to 2 V (vs. Ag/Ag+) to obtain Poly-(Au8-DCP@M). For comparison, a series of control samples, including co-polymerization of Au8 and DCP (Poly-(Au8-DCP)), as well as self-polymerization of monomers Au8 (Poly-Au8) and DCP@M (Poly-DCP@M) were prepared via the same procedure (Supplementary Fig. 5). Taking Poly-(Au8-DCP@Fe) as a representative sample, we conducted a series of characterizations. In the first cycle of the positive CV scan, Poly-(Au8-DCP@Fe) displayed two obvious oxidation peaks at 1.36 V and 1.50 V, which are attributed to the oxidation of carbazole groups in both the Au8 crystal and DCP@Fe. The reduction peak of Poly-(Au8-DCP@Fe) appeared at 1.68 V in the negative CV scan cycle is completely different from that of Au8 (1.44 V) and DCP@Fe (1.42 V), suggesting that the new dimeric carbazole cations formed by carbazole cations coupling in Au8 and DCP@Fe were reduced (Fig. 2a). In the FT-IR spectra, the generation of new peaks at 801 cm−1 was attributed to the vibrational bands of C–H bonds of the tri-substituted carbazole ring as well as the disappearance of the di-substituted carbazole ring at 716 and 723 cm−1 (Fig. 2b), thus indicating the formation of the biscarbazole network40,41,42.

a CV profiles of co-eletropolymerization recorded for first scan cycles at 100 mV s–1 (the electropolymerization potential range was set between 0 V and 2.0 V. Carbon paper, Ag/Ag+ and platinum foil were used as the working electrode, reference electrode and counter electrode, respectively). b FT-IR spectra of the Poly-(Au8-DCP@Fe), DCP@Fe, and Au8 crystal, as well as their peak assignments. c Au L3-edge EXAFS of Au foil, Poly-Au8, and Poly-(Au8-DCP@Fe). d Fe K-edge EXAFS of Poly-(Au8-DCP@Fe), FePc, and Fe foil. Wavelet transform of (e) Au L3-edge and (f) Fe K-edge EXAFS for Poly-(Au8-DCP@Fe).

High-resolution transmission electron microscopy (TEM) image confirmed that the Au8 NCs were uniformly dispersed in the Poly-(Au8-DCP@Fe) (Supplementary Fig. 6). The co-existence of metal NCs and single metal sites on Poly-(Au8-DCP@Fe) was confirmed by atomic-resolution high-angle annular dark-field scanning TEM (HAADF-STEM). Figure 1b, c clearly showed the highly dispersed dots with heavier image contrast, thus showing the presence of ultrafine Au8 clusters. The size (~1.0 nm) is close to the X-ray crystallographically measured value of an Au8 nanocluster (0.98 nm). This indicates that this strategy efficiently prevents cluster agglomeration. Closer observation further shows that numerous single metal sites were homogeneously presented on the hybrid material. Energy dispersive X-ray spectroscopy (EDS) mapping analysis of STEM images confirmed that the Fe single sites were homogeneously distributed over Poly-(Au8-DCP@Fe), while the specific elements (Au and P) of Au8 were uniformly dispersed on Poly-(Au8-DCP@Fe) in the form of clusters (Fig. 1d). As a control sample, TEM analysis and HAADF-STEM imaging of Poly-DCP@Fe confirmed the absence of metal nanoparticles, showcasing the uniform dispersion of atomically dispersed Fe species (Supplementary Figs. 7, 8). Quantitative analysis of Fe and Au contents in Poly-(Au8-DCP@Fe) and other control samples (Au8 crystal, Poly-Au8, Poly-(Au8-DCP), DCP@Fe and Poly-DCP@Fe) were determined via inductively coupled plasma optical emission spectrometer (ICP-OES) (Supplementary Table 4). The result revealed Au and Fe contents of 5.99 wt% and 4.00 wt%, respectively, in Poly-(Au8-DCP@Fe).

Furthermore, the local coordination environment and chemical states of Fe and Au species in Poly-(Au8-DCP@Fe) were investigated via X-ray absorption spectroscopy. The Au L3-edge X-ray absorption near-edge structure (XANES) results showed that the white lines of Poly-Au8, Poly-(Au8-DCP), and Poly-(Au8-DCP@Fe) are very close to each other, indicating that the average oxidation state of the cluster is close to a metallic state. The near-edge of the Au L3-edge spectra for Poly-(Au8-DCP@Fe) displayed a discernible shift towards the high-energy region compared to that of Poly-(Au8-DCP), indicating an elevated oxidation state of Au atoms in Poly-(Au8-DCP@Fe) following the introduction of Fe single atoms (Supplementary Fig. 9). This observation aligns with the findings obtained from X-ray photoelectron spectroscopy (XPS) analysis. Fourier transformed (FT) extended X-ray adsorption fine structure (EXAFS) spectra showed a peak at around 1.5 Å in the R space for Poly-Au8 and Poly-(Au8-DCP@Fe), which was ascribed to the Au–C bond. The broad peaks appearing in the range of 1.8–3.2 Å were attributed to Au–P and Au−Au bonds (Fig. 2c and Supplementary Table 5). Wavelet transform (WT) EXAFS plots in K space further confirm the presence of Au–Au, Au–P, and Au–C bond in the Poly-(Au8-DCP@Fe) and Poly-Au8 (Fig. 2e and Supplementary Fig 10). These results collaborated that the pristine coordination bond of Au8 NCs after polymerization is well-preserved. The Fe K-edge XANES spectra showed that the absorption edges of Poly-(Au8-DCP@Fe) is close to Fe3O4, indicating that the valence states of Fe in the Poly-(Au8-DCP@Fe) was between +2 and +3 (Supplementary Fig. 11). The EXAFS spectrum of Fe K-edge for Poly-(Au8-DCP@Fe) in R space displays only a major peak identified at 1.50 Å. The position of this peak is analogous to that of iron phthalocyanine (FePc) references, signifying the existence of Fe-N coordination. The absence of Fe-Fe bonding in Poly-(Au8-DCP@Fe) verified the atomic distribution of the Fe species (Fig. 2d). WT EXAFS plots also demonstrate the existence of Fe SAs configurations in catalysts (Fig. 2f and Supplementary Fig. 12). These results demonstrated the successful fabrication of Au8 NC and Fe SA hybrid material.

To explore the interaction between Au8 clusters and Fe single sites, the electronic states of Au species in Poly-(Au8-DCP@Fe) were studied by XPS. Compared to Poly-(Au8-DCP), the Au 4f7/2 of Poly-(Au8-DCP@Fe) shift to higher binding energy, indicating an increasing Auδ+ species after the introduction of Fe sites. The high oxidation state of Au species could promote the stabilization of reaction intermediates *COOH and *CO, which could make the transformation from CO2 to the *COOH intermediate more favorable in CO2RR43. Similarly, the Au 4f7/2 binding energy of Poly-Au8 was 85.48 eV, which was about 0.48 eV higher than the binding energy of Au8 crystal (Fig. 3a). For the Fe charge state, the negative shift of the binding energies of Fe 2p in Poly-(Au8-DCP@Fe) than that of Poly-DCP@Fe indicated an decreasing valance state of Fe SA (Supplementary Fig. 13). The change of the electronic state of Poly-(Au8-DCP@Fe), Poly-(Au8-DCP) and Poly-(DCP@Fe) was further probed by diffuse reflectance infrared Fourier transform spectroscopy under a CO atmosphere (CO-DRIFTS). The adsorbed CO peak position is considered as a cue for determining the electron cloud density of accessible Au site44,45,46,47. As shown in Fig. 3b, compared with Poly-(Au8-DCP), a red-shift of CO molecules adsorbed onto the Au8 NCs is observed for Poly-(Au8-DCP@Fe), suggesting a decrease in electron density and increasing valance state of Au8 NCs. In contrast, blue-shift occurred for Fe sites in Poly-(Au8-DCP@Fe) compared to the peak of Poly-DCP@Fe, suggesting an increase in the electron density of Fe SA. The peak at around 2150–2250 cm−1 was assigned to gaseous CO45,47,48.

a XPS spectra of Au 4f for Poly-(Au8-DCP@Fe), Poly-(Au8-DCP), Poly-Au8, and Au8 crystal. b Spectra of CO-DRIFTS on Poly-(Au8-DCP@Fe), Poly-(Au8-DCP), and Poly-DCP@Fe at 298 K. c Differential charge density distributions of Au8 crystal, Poly-Au8, Poly-(Au8-DCP), and Poly-(Au8-DCP@Fe). The yellow and blue regions correspond to the charge accumulation and depletion, respectively. d The partial density of states (PDOS) for Au8 crystal, Poly-Au8, Poly-(Au8-DCP), and Poly-(Au8-DCP@Fe).

To further reveal the electron redistribution behavior, charge density difference and Bader charge analyses were performed. The relaxed atomic structural models of Au8 crystal, Poly-Au8, Poly-(Au8-DCP), and Poly-(Au8-DCP@Fe) were constructed based on the structural analysis. Once the Fe SA site was introduced into the hybrid system, the electron around the Au8 cluster active site transfers to the peripheral ligands, thus making the Au8 cluster center in Poly-(Au8-DCP@Fe) more positive and strengthening the adsorption of the intermediate in CO2RR (Fig. 3c). In addition, the Bader charge for Au8 cluster of Poly-(Au8-DCP) and Poly-(Au8-DCP@Fe) was calculated to be 0.126 and 0.101, respectively. Compared to Poly-(Au8-DCP), the electron cloud density of Au8 in Poly-(Au8-DCP@Fe) towards the electron-deficient state, which is consistent with the XPS results. The partial density of states (PDOS) diagrams in Fig. 3d illustrate that the d-band center of Poly-(Au8-DCP@Fe) (−3.39 eV) was much closer to the Fermi level than that of Au8 crystal (−4.19 eV), Poly-Au8 (−4.44 eV) and Poly-(Au8-DCP) (−3.85 eV), thus indicating that the introduction of SAs can result in more stable adsorption with the intermediate. This optimizes the catalytic performance of Au8 NCs. The above analysis indicated that the functionalizing SAs induces the electron redistribution around the Au8 NCs, which modulates the electronic structure of Au8 NCs and therefore greatly influences their inherent catalytic performance.

Electrocatalytic activity study of Poly-(Au8-DCP@Fe): electrocatalytic CO2 reduction

Encouraged by the regulated electronic state of Au8 cluster, the electrochemical CO2RR catalytic performances of Poly-(Au8-DCP@M) were next examined in 0.5 M KHCO3 using a three-electrode H-type cell. The gaseous and liquid products were determined by gas chromatography (GC) and 1H nuclear magnetic resonance (NMR) spectroscopy, respectively. No liquid products were found, and the gas products were CO and H2 for all samples (Supplementary Fig. 14). Figure 4a and Supplementary Fig. 15 show that the maximum CO Faradaic efficiency (FE) of Poly-(Au8-DCP@M) was 90.89% (Fe, −0.57 V), 87.23% (Co, −0.67 V), 74.14% (Ni, −0.57 V), 50.01% (Cu, −0.47 V) and 9.25% (Zn, −0.57 V), respectively. Of these, Poly-(Au8-DCP@Fe) exhibited highest CO2RR performance. Although Co functionalized catalyst Poly-(Au8-DCP@Co) exhibited high comparable CO FE, more negative reduction potentials implied more energy required for the catalytic reactions to proceed. Then, a series of control experiments were conducted to understand the origination of high activity of Poly-(Au8-DCP@Fe). Linear scanning voltammetry (LSV) curves showed a greater current density and a more positive onset potential of Poly-(Au8-DCP@Fe) compared to the other four control catalysts: Au8 crystal, Poly-(Au8-DCP), Poly-Au8, and Poly-DCP@Fe (Fig. 4b and Supplementary Fig. 16). Moreover, at −0.57 V, Poly-(Au8-DCP@Fe) exhibited a higher CO FE (90.89%) than Au8 crystal (0.60%), Poly-Au8 (12.56%), Poly-(Au8-DCP) (69.06%) and Poly-DCP@Fe (1.16%) (Fig. 4c and Supplementary Figs. 17–21). The remarkable enhancement in CO FE of Poly-Au8 beyond −0.57 V is attributed to a sharp increase in current density49,50 (Supplementary Fig. 22). Quasi-in situ XPS analysis further indicated that the enhanced performance post −0.57 V is influenced by the partial exposure of catalytic sites of Poly-Au8 (Supplementary Fig. 23). Additionally, the catalytic performance evaluation of DCP@Fe, as shown in Supplementary Fig. 24, demonstrates the production of H2 as the primary gas in a broad potential range from −0.47 to −0.87 V, with H2 FE near 100%, mirroring the behavior of Poly-DCP@Fe. These findings collectively indicated that Fe SAs in these catalytic systems are inactive in the electrocatalytic CO2 to CO reaction. The higher activity of Poly-(Au8-DCP@Fe) than that of Poly-(Au8-DCP) between −0.47 to −0.87 V indicated that the introduction of single Fe sites promotes the CO2RR. Interestingly, Poly-(Au8-DCP) showed significantly increased catalytic efficiency than isolated Au8 cluster and Poly-Au8. This may be due to the introduction of the DCP component to promote electron and mass transfer of Poly-(Au8-DCP). Moreover, the poorer catalytic performance of Poly-DCP@Fe than of Poly-Au8 suggests that Au8 NC rather than Fe SA is likely the main active site. To substantiate this inference, 4,4’-Di(9H-carbazol-9-yl)-1,1’-biphenyl (BCP), featuring two carbazole groups akin to Au8 clusters, was employed as a comonomer for dispersing Fe SAs by co-eletropolymerization with DCP@Fe (Supplementary Figs. 25 and 26). The obtained Poly-(DCP@Fe-BCP) predominantly produces H2 as the main gas across a broad potential range from −0.47 to −0.87 V, with H2 FE near 100% (Supplementary Fig. 25b). On the contrary, Poly-(Au8-BCP), prepared by co-electropolymerization of Au8 clusters with BCP, exhibited significantly higher CO2RR activity (CO FEmaximum = 78.32% at −0.57 V) (Supplementary Fig. 25c and Supplementary Fig. 27). Taken together, these results underscore that sufficiently dispersed Au8 cluster, rather than Fe SA, are more likely to serve as catalytic active sites, driving the catalyst’s activity for CO2-to-CO conversion.

a The maximum CO FE of Poly-(Au8-DCP@M). b The LSV curves of Au8 crystal, Poly-(Au8-DCP@Fe), Poly-(Au8-DCP), Poly-Au8, and Poly-DCP@Fe measured in CO2-saturated 0.5 M KHCO3, (c) CO FE of Poly-(Au8-DCP@Fe), Poly-(Au8-DCP), Poly-Au8, Au8 crystal, and Poly-DCP@Fe. d Plots of the current density versus the scan rate for Poly-(Au8-DCP@Fe), Poly-(Au8-DCP), Poly-Au8 and Au8 crystal, the linear fit determined the specific capacitance. e Chronoamperometry of the Poly-(Au8-DCP@Fe) in CO2 saturated 0.5 M KHCO3 at –0.57 V. f GC-MS of 13CO generation using Poly-(Au8-DCP@Fe) as electrocatalyst in CO2RR reaction under 13CO2 atmosphere.

To estimate the electrochemical active surface areas (ECSAs) of these samples and further discuss the potential influencing factors, we calculated the electrochemical double-layer capacitance (Cdl). The Cdl values of these samples decreased in the following order: Poly-(Au8-DCP@Fe) (0.275 mF cm−2) > Poly-(Au8-DCP) (0.271 mF cm−2) > Poly-Au8 (0.197 mF cm−2) > Au8 crystal (0.01 mF cm−2). After polymerization, the larger ECSA of Poly-(Au8-DCP@Fe), Poly-(Au8-DCP), and Poly-Au8 than that of pristine Au8 cluster implied more accessible active sites for CO2RR. These differences originated from the specific polymerized network building the high electron transfer pathway to the catalytic sites. Since the ECSA of Poly-(Au8-DCP@Fe) is similar to that of Poly-(Au8-DCP), but its current density is much larger, thus demonstrating the much better intrinsic high activity of Poly-(Au8-DCP@Fe) (Fig. 4d and Supplementary Fig. 28). Besides, the Tafel slopes were calculated from a characteristic curve of the overpotential versus a logarithm of the steady partial current density of CO. The Tafel slope value of Poly-(Au8-DCP@Fe) was 218 mV decade−1, which is successively lower than that of Poly-(Au8-DCP) (237 mV decade−1), Poly-Au8 (240 mV decade−1) and Au8 crystal (381 mV decade−1), thus illustrating its faster CO2RR kinetics (Supplementary Fig. 29). In short, the enhanced intrinsic catalytic activity and kinetics of Poly-(Au8-DCP@Fe) fully demonstrate the activation effect of the decorating isolated Fe atoms on the Au8 cluster for enhanced CO2RR activity. The long-term CO2RR catalytic stability of Poly-(Au8-DCP@Fe) was studied at a fixed potential of −0.57 V. The corresponding CO FE can be retained at values above 80% over the entire experiment, and the current density also remained stable in the later stage after 6 h of testing (Fig. 4e). The marginal degradation in CO FE observed in Poly-(Au8-DCP@Fe) can be primarily ascribed to the formation of a limited number of larger-sized Au8 nanoclusters after the long-term reaction (Supplementary Fig. 30). The structure of post-test Poly-(Au8-DCP@Fe) was confirmed by HAADF-STEM and XPS (Supplementary Figs. 31 and 32). The well-maintained morphology and electronic states underscored its high stability. To identify the carbon source of the reduction products, 13CO2 isotopic experiment was carried out. The peak at m/z = 29 assigned to 13CO indicates that the reduction product was indeed from the reactant CO2 (Fig. 4f). In comparison with recently reported Au NCs-based catalysts, such as Au22H3 (CO FEmaximum = 92.7% at −0.60 V)51 and Au24H3 (CO FEmaximum > 90% at 10 mA/cm−2)52, Poly-(Au8-DCP@Fe) (CO FEmaximum = 90.89% at −0.57 V) demonstrated comparable CO2RR performance in terms of CO FE and the applied potential. A comprehensive comparison, presented in Supplementary Fig. 33 and Supplementary Table 6, showcased the CO2RR performance of Poly-(Au8-DCP@Fe) against reported Au NCs and bimetallic Au NCs-based catalysts, underscoring the exceptional activity of Poly-(Au8-DCP@Fe).

In situ characterization and theoretical analysis of intermediates for the overall process of CO2RR

To probe possible intermediates and reaction pathways during CO2RR, in situ attenuated total reflectance Fourier transform infrared (ATR-FTIR) spectroscopy of Poly-Au8, Poly-(Au8-DCP) and Poly-(Au8-DCP@Fe) at different application potentials were recorded, respectively. As shown in Fig. 5a–c, all samples exhibited the characteristic peaks of *COOH signal located at 1400 cm−1. Notably, the intensity of *COOH peaks of Poly-(Au8-DCP) and Poly-(Au8-DCP@Fe) was obviously stronger than that of Poly-Au8, thus suggesting the facilitated *COOH formation on these two materials. The peaks ranging from 1800 to 1900 cm−1 correspond to the bridge-adsorbed *CO (*COB) on Au surfaces. Obviously, Poly-(Au8-DCP@Fe) displayed a stronger *COB band intensity than Poly-(Au8-DCP) and Poly-Au8. The red shift of such peaks for Poly-(Au8-DCP@Fe) at more negative potentials is caused by the Stark tuning effect53,54. In addition, Poly-(Au8-DCP@Fe) showed an additional absorption peak at 2000-2100 cm−1 owing to the linear-adsorbed *CO (*COL) on Fe SA. These results confirmed that Poly-(Au8-DCP@Fe) is more efficient in converting CO2 into CO than Poly-(Au8-DCP) and Poly-Au8.

In situ ATR-FTIR spectra of (a) Poly-Au8, (b) Poly-(Au8-DCP) and (c) Poly-(Au8-DCP@Fe) in CO2 saturated 0.5 M KHCO3 between −0.47 V and −0.97 V. The free energy diagram of the (d) CO2RR and (e) HER over Au8 crystal, Poly-Au8, Poly-(Au8-DCP), and Poly-(Au8-DCP@Fe). f The values of UL(CO2)-UL(H2) for Au8 crystal, Poly-Au8, Poly-(Au8-DCP), and Poly-(Au8-DCP@Fe). g Conceptual illustration of the electronic structure of Au8 cluster modulated by SA in Poly-(Au8-DCP@Fe).

Density functional theory (DFT) calculations were carried out to further shed light on the critical role of Fe SAs in boosting the CO2RR activity of Au8 clusters. Figure 5d, e depicts the reaction-free energy pathway for the electrochemical CO2RR and competitive side hydrogen evolution reaction (HER) over four materials. The Au8, Poly-Au8, Poly-(Au8-DCP), and Poly-(Au8-DCP@Fe) displayed the required free energy changes (ΔG) of 1.81, 1.38, 1.12, and 0.81 eV, respectively, for the rate-limiting step of reduction of CO2 to *COOH. These calculations suggest that Poly-(Au8-DCP@Fe) had a more optimal ΔG, thus leading to a lower barrier forming *COOH, from the thermodynamic point. Moreover, the energy barriers of HER are significantly increasing for Poly-(Au8-DCP@Fe), which inhibits the production of H2 (Fig. 5e). In addition, the higher energy barrier for electrochemical CO2RR and the lower energy barrier for HER exhibited by Fe SA sites than Au8 NCs sites in Poly-(Au8-DCP@Fe), indicate that the Au8 NC sites in Poly-(Au8-DCP@Fe) were more responsible for the high catalytic efficiency of CO2RR (Supplementary Fig. 34). We also calculated the free energy of CO2RR and HER for catalysts chelating different single atoms (M = Co, Ni, Cu, Zn), and all catalysts showed a consistent trend, mirroring that observed in Poly-(Au8-DCP@Fe) (Supplementary Fig. 35). The corresponding reaction pathway and the free energy diagram of each intermediate over the Au8 NC sites are shown in Supplementary Fig. 36. Synthetically, the difference between thermodynamic limiting potentials for the CO2RR and HER (UL(CO2)−UL(H2)) reflects the selectivity for CO2-to-CO. It is shown that Poly-(Au8-DCP@Fe) present more positive value (0.39 eV) among all catalysts, explaining its highest CO2RR selectivity (Fig. 5f). These are identical to the experimental results. Therefore, the experimental and theoretical evidences indicate regulate the electronic structure of NCs by introducing extra SAs is a feasible method to improve the inherent catalytic performance of NCs (Fig. 5g). Electrostatic potential (ESP) analysis of Poly-(Au8-DCP@Fe) revealed negative ESP regions around the organic moieties of surface ligands, fostering robust interactions with CO2 molecules and elevating CO2 concentration near active sites55,56. Furthermore, DFT calculations showed that *COOH intermediate adsorption site on Poly-(Au8-DCP@Fe) to be No. 9 Au atom, suggesting that the catalytic site for CO2 reduction predominantly resides at this specific location (Supplementary Fig. 37).

Discussion

In summary, we have successfully constructed a highly homogeneous NC-SA hybrid catalyst Poly-(Au8-DCP@Fe) by facile co-eletropolymerization strategy. The obtained Poly-(Au8-DCP@Fe) featured a considerably enhanced catalytic performance toward CO2RR—a 90.89% CO FE at −0.57 V, than that of SA or metal NC components. The detailed analysis revealed that the high catalytic activity of Poly-(Au8-DCP@Fe) derive from the effective regulation of the electronic structure of the Au8 NCs by the Fe SAs, in which the Fe SA showed a positive modulation on the charge density and projected density of states of the metal cluster sites. This work creatively presented a new strategy to regulate the inherent catalytic activity of metal NCs via the introduction of SAs.

Methods

Synthesis of ligand 9-(4-ethynylphenyl)carbazole (HCzPA)

The ligand 9-(4-ethynylphenyl)carbazole (HCzPA) was synthesized according to the previous report57. 1H NMR of HCzPA. (600 MHz, CDCl3): δ 8.16–8.12 (m, 2H), 7.75–7.71 (m, 2H), 7.58–7.51 (m, 2H), 7.46–7.38 (m, 4H), 7.34–7.26 (m, 2H), 3.18 (s, 1H).

Synthesis of Au8 crystal

The taget [Au8(dppp)4(CzPA)2]2+ clsuters were synthesized using [Au8(dppp)4](NO3)258 as precursor. A methanolic solution (50 mL) of [Au8(dppp)4](NO3)2 (30.0 mg, 9 µmol) was added to HCzPA (5.0 mg, 18 µmol) and sodium methoxide (145 mg, 2.7 mmol), and the mixture was stirred at room temperature for 10 h. The obtained mixture was treated with water and then extracted with dichloromethane (20 mL × 3). The combined organic phase was dried over anhydrous Na2SO4, filtered and evaporated to dryness to give a pinkish solid, which was further purified by vapor diffusion of ether into a cluster solution in dichloromethane to give Au8 crystal as red crystals.

Synthesis of 3,8-di(9H-carbazol-9-yl)-1,10-phenanthroline (DCP)

3,8-Di(9H-carbazol-9-yl)-1,10-phenanthroline was prepared according to literature procedures59. 1H NMR of DCP. (600 MHz, DMSO): δ 9.45 (s, 2H,), 8.98 (s, 2H), 8.35 (d, 4H, J = 8.0 Hz), 8.28 (s, 2H), 7.61 (d, 4H, J = 8.0 Hz), 7.53 (t, 4H, J = 8.0 Hz), 7.39 (t, 4H, J = 8.0 Hz).

Synthesis of DCP@M (M=Fe, Co, Ni, Cu, Zn)

DCP (30 mg, 0.06 mmol) was refluxed with FeCl3 (9.54 mg, 0.06 mmol) in N,N-dimethylformamide under argon overnight. After cooling to room temperature, the mixture was evaporated to dryness and washed with water to give a red solid (DCP@Fe).

The DCP@Co, DCP@Ni, DCP@Cu and DCP@Zn were similarly prepared in methanol following the procedure for DCP@Fe by using Co(NO3)2·6H2O, NiCl2·6H2O, Cu(NO3)2·3H2O and ZnCl2, respectively.

Preparation of Poly-(Au8-DCP@M) (M=Fe, Co, Ni, Cu, Zn)

The preparation of Poly-(Au8-DCP@Fe) was given as a typical example for the preparation of Poly-(Au8-DCP@M). The co-electropolymerization of Au8 crystal and DCP@Fe was performed using a standard three-electrode system attached to an CH660E B14145 Electrochemical Workstation. Platinum foil (Pt) was used as the counter electrode, carbon paper/indium-doped tin oxide (ITO) glass as the working electrode, and Ag/AgCl electrode as the reference electrode. Co-eletropolymerization of Au8 crystal and DCP@Fe was carried out in CH3CN/CH2Cl2 (2/1 v/v) by using 0.1 M LiClO4 as electrolyte via multi-cycled cyclic voltammetry (CV) methods in the potential range of 0 to 2 V, and the scan rate was 100 mV s–1. After the electropolymerization process (20 cycles), the resulting Poly-(Au8-DCP@Fe) was washed with CH2Cl2 to remove unreacted precursors.

Preparation of Poly-(Au8-DCP), Poly-Au8, and Poly-DCP@Fe

Poly-(Au8-DCP) was similarly prepared following the procedure for Poly-(Au8-DCP@M) by using Au8 crystal and DCP. Poly-Au8 and Poly-DCP@Fe were fabricated by self-polymerization of Au8 crystal and DCP@Fe, which similarly to the procedure for Poly-(Au8-DCP@M).

Evaluation of electrochemical CO2 reduction (CO2RR) performance

The electrochemical CO2RR was carried out using a CH660E B14145 electrochemical workstation in an H-type electrolytic cell separated by a proton membrane. The Poly-(Au8-DCP@M)/Poly-(Au8-DCP)/Poly-Au8/Poly-DCP@Fe/Au8 crystal was used as the working electrode, which had a controlled surface area of 1 cm2. The Ag/AgCl (saturated with KCl) and platinum foil (Pt) were used as the reference electrode and counter electrode, respectively. 0.5 M KHCO3 solution (pH = 7.3) was evenly distributed to the cathode and anode compartments. CO2 gas was delivered at an average rate of 20 mL min−1 (at room temperature and ambient pressure), and the separated gas products were analyzed by Agilent GC7820 Gas Chromatograph. The liquid products were analyzed afterwards by quantitative NMR (Bruker AVIII HD 600) All the potentials in this study were converted to values with respect to a reversible hydrogen electrode (RHE) by E (vs. RHE) = E (vs. Ag/AgCl) + 0.0591 × pH +0.197.

The Poly-(Au8-DCP@M), Poly-(Au8-DCP), Poly-Au8, and Poly-DCP@Fe for CO2RR were deposited on carbon paper as work electrode. As a control, catalyst inks were prepared by dissolving 1 mg Au8 crystal into 0.5 mL solution including 0.46 mL dichloromethane and 40 μL Nafion solution, dripped on the carbon paper (1 × 1 cm−2) and then dried at room temperature.

The faradaic efficiency (FE) for CO production was calculated according to the following equation.

where xg is the molar flow of gas from the electrochemical cell (mol mol−1), fCO2 is the CO2 flow rate (mol s−1), Zg is the number of electron transferred for product formation, which is 2 for CO and H2, the itot is the total current in the electroreduction process. F is the Faradaic constant (96,485 C mol−1).

Cyclic voltammetry (CV) curves in electrochemical double-layer capacitance (Cdl) determination were measured in a potential window nearly without the faradaic process at different scan rates of 10, 20, 30, 40, and 50 mV s−1. The plot of current density at set potential against scan rate has a linear relationship and its slope is the Cdl.

TEM sample preparation

The obtained Poly-(Au8-DCP@Fe) was dispersed in 1 mL ethanol by ultrasound to form a suspension, which was then dropped on carbon film. The carbon film was dried under air within a few seconds and further used for TEM characterizations.

In situ ATR-FTIR experiments

In-situ ATR-FTIR tests were implemented by Bruker INVENIO S FT-IR spectrophotometer equipped with a liquid N2-cooled MCT detector. To enhance the in situ ATR-FTIR signal and electronic conduction, the ultra-thin gold foil was chemically deposited on the silicon. The working electrode for the in situ ATR-FTIR test was prepared by dropping the electrocatalyst on Au membrane.

In situ CO-DRIFTS experiments

In situ CO-DRIFTS was performed on a Bruker INVENIO S FT-IR spectrophotometer equipped with an MCT narrow-band detector and a modified in situ reaction cell with a drier device. The detailed pretreatment and test conditions are given as follows. Firstly, the sample was carefully put into the support sheet of reaction cell, and a pure Ar stream (50 mL min−1) was introduced for 20 min to remove the gaseous impurities in the cell. Subsequently, the sample was pre-reduced in a 5% H2/Ar flow (50 mL min−1) at 300 °C for 2 h, followed cooled 1.0 h to 25 °C in a pure Ar stream, and the background spectrum was collected in this process. Finally, the DRIFTS spectra was collected after introducing the 2% CO/N2 (50 mL min−1) to the cell for 1.0 h.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request. All data needed to evaluate the conclusions in the paper are present in the paper and/or the Supplementary Materials (including Supplementary Figs. 1–37). The X-ray crystallographic coordinates for structure reported in this article (see Supplementary Table 1) have been deposited at the Cambridge Crystallographic Data Centre (CCDC) under deposition number CCDC: 2290525 for Au8. These data can be obtained free of charge from the Cambridge Crystallographic Data Centre via http://www.ccdc.cam.ac.uk/ data_request/cif.

References

Du, Y.-X., Sheng, H.-T., Astruc, D. & Zhu, M.-Z. Atomically precise noble metal nanoclusters as efficient catalysts: a bridge between structure and properties. Chem. Rev. 120, 526–622 (2020).

Tang, Q., Hu, G., Fung, V. & Jiang, D. E. Insights into interfaces, stability, electronic properties, and catalytic activities of atomically precise metal nanoclusters from first principles. Acc. Chem. Res. 51, 2793–2802 (2018).

Yan, J.-Z., Teo, B. K. & Zheng, N.-F. Surface chemistry of atomically precise coinage-metal nanoclusters: from structural control to surface reactivity and catalysis. Acc. Chem. Res. 51, 3084–3093 (2018).

Jin, R., Li, G., Sharma, S., Li, Y. & Du, X. Toward active-site tailoring in heterogeneous catalysis by atomically precise metal nanoclusters with crystallographic structures. Chem. Rev. 121, 567–648 (2021).

Yang, D. et al. Catalytic conversion of C1 molecules on atomically precise metal nanoclusters. CCS Chem. 4, 66–94 (2022).

Li, W. et al. Catalytic CO oxidation using bimetallic MxAu25–x clusters: a combined experimental and computational study on doping. Eff. J. Phys. Chem. C. 120, 10261–10267 (2016).

Zhuang, S. et al. Hard-sphere random close-packed Au47Cd2(TBBT)31 nanoclusters with a faradaic efficiency of up to 96% for electrocatalytic CO2 reduction to CO. Angew. Chem. Int. Ed. 59, 3073–3077 (2020).

Li, S. et al. Monopalladium substitution in gold nanoclusters enhances CO2 electroreduction activity and selectivity. ACS Catal. 10, 12011–12016 (2020).

Ding, M., Tang, L., Ma, X., Song, C. & Wang, S. Effects of ligand tuning and core doping of atomically precise copper nanoclusters on CO2 electroreduction selectivity. Commun. Chem. 5, 172 (2022).

Ghosh, A., Mohammed, O. F. & Bakr, O. M. Atomic-level doping of metal clusters. Acc. Chem. Res. 51, 3094–3103 (2018).

Yuan, S. F., Lei, Z., Guan, Z. J. & Wang, Q. M. Atomically precise preorganization of open metal sites on gold nanoclusters with high catalytic performance. Angew. Chem. Int. Ed. 60, 5225–5229 (2021).

Guan, Z. J. et al. Ligand engineering toward the trade-off between stability and activity in cluster catalysis. Angew. Chem. Int. Ed. 61, e202116965 (2022).

Narouz, M. R. et al. N-heterocyclic carbene-functionalized magic-number gold nanoclusters. Nat. Chem. 11, 419–425 (2019).

Wan, Xian-Kai, Wang, Jia-Qi, Nan, Zi-Ang & Wang, Q.-M. Ligand effects in catalysis by atomically precise gold nanoclusters. Sci. Adv. 3, e1701823 (2017).

Li, G. et al. Tailoring the electronic and catalytic properties of Au25 nanoclusters via ligand engineering. ACS Nano 10, 7998–8005 (2016).

Seong, H. et al. Atomically precise gold nanoclusters as model catalysts for identifying active sites for electroreduction of CO2. Angew. Chem. Int. Ed. 60, 14563–14570 (2021).

Li, S. et al. Dissecting critical factors for electrochemical CO2 reduction on atomically precise Au nanoclusters. Angew. Chem. Int. Ed. 61, e202211771 (2022).

Zhou, M. et al. Evolution from the plasmon to exciton state in ligand-protected atomically precise gold nanoparticles. Nat. Commun. 7, 13240 (2016).

Deng, G. et al. Body-centered-cubic-kernelled Ag15Cu6 nanocluster with alkynyl protection: synthesis, total structure, and CO2 electroreduction. J. Am. Chem. Soc. 145, 3401–3407 (2023).

Guan, Z. J. et al. Isomerization in alkynyl-protected gold nanoclusters. J. Am. Chem. Soc. 142, 2995–3001 (2020).

Lee, S. et al. [Pt2Cu34(PET)22Cl4]2-: an atomically precise, 10-electron PtCu bimetal nanocluster with a direct Pt-Pt bond. J. Am. Chem. Soc. 143, 12100–12107 (2021).

Geng, Z. et al. Achieving a record-high yield rate of 120.9 μgNH3 mgcat −1 h−1 for N2 electrochemical reduction over Ru single-atom catalysts. Adv. Mater. 30, 1803498 (2018).

Long, R. et al. Isolation of Cu atoms in Pd lattice: forming highly selective sites for photocatalytic conversion of CO2 to CH4. J. Am. Chem. Soc. 139, 4486–4492 (2017).

Kyriakou, G. et al. Isolated metal atom geometries as a strategy for selective heterogeneous hydrogenations. Science 335, 1209–1212 (2012).

Liu, J. et al. Tackling CO poisoning with single-atom alloy catalysts. J. Am. Chem. Soc. 138, 6396–6399 (2016).

Jiang, K. et al. Transition-metal single atoms in a graphene shell as active centers for highly efficient artificial photosynthesis. Chem 3, 950–960 (2017).

Huang, H. et al. Clusters induced electron redistribution to tune oxygen reduction activity of transition metal single-atom for metal-air batteries. Angew. Chem. Int. Ed. 61, e202116068 (2022).

Han, A. et al. Construction of Co4 atomic clusters to enable Fe-N4 motifs with highly active and durable oxygen reduction performance. Angew. Chem. Int. Ed. 62, e202303185 (2023).

Lin, J. et al. Boosting energy efficiency and stability of Li-CO2 batteries via synergy between Ru atom clusters and single-atom Ru-N4 sites in the electrocatalyst cathode. Adv. Mater. 34, e2200559 (2022).

Ao, X. et al. Markedly enhanced oxygen reduction activity of single-atom Fe catalysts via integration with Fe nanoclusters. ACS Nano 13, 11853–11862 (2019).

Ding, X. et al. Remote synergy between heterogeneous single atoms and clusters for enhanced oxygen evolution. Nano Lett. 23, 3309–3316 (2023).

Zhai, W. et al. Simultaneously integrate iron single atom and nanocluster triggered tandem effect for boosting oxygen electroreduction. Small 18, e2107225 (2022).

Wu, S. et al. Single Cu–N4 sites enable atomic Fe clusters with high-performance oxygen reduction reactions. Energy Environ. Sci. 16, 3576–3586 (2023).

Chen, D. et al. A tandem strategy for enhancing electrochemical CO2 reduction activity of single-atom Cu-S(1) N(3) catalysts via integration with Cu nanoclusters. Angew. Chem. Int. Ed. 60, 24022–24027 (2021).

Wei, X. et al. Tuning the spin state of Fe single atoms by Pd nanoclusters enables robust oxygen reduction with dissociative pathway. Chem 9, 181–197 (2023).

Luo, W. et al. Modulating electronic structures of iron clusters through orbital rehybridization by adjacent single copper sites for efficient oxygen reduction. Angew. Chem. Int. Ed. 62, e202308344 (2023).

Liu, H. et al. Decorating single-atomic Mn sites with FeMn clusters to boost oxygen reduction reaction. Angew. Chem. Int. Ed. 62, e202214988 (2023).

Kim, B. et al. Over a 15.9% solar-to-CO conversion from dilute CO2 streams catalyzed by gold nanoclusters exhibiting a high CO2 binding affinity. ACS Energy Lett. 5, 749–757 (2019).

Zhao, S. et al. Influence of atomic-level morphology on catalysis: the case of sphere and rod-like gold nanoclusters for CO2 electroreduction. ACS Catal. 8, 4996–5001 (2018).

Gu, C. et al. In situ electrochemical deposition and doping of C60 films applied to high-performance inverted organic photovoltaics. Adv. Mater. 24, 5727–5731 (2012).

Liu, H. et al. Dendrimer‐based, high‐luminescence conjugated microporous polymer films for highly sensitive and selective volatile organic compound sensor arrays. Adv. Funct. Mater. 30, 1910275 (2020).

Zhou, Z. et al. Electropolymerization of robust conjugated microporous polymer membranes for rapid solvent transport and narrow molecular sieving. Nat. Commun. 11, 5323 (2020).

Sun, X. C. et al. Au3+ species-induced interfacial activation enhances metal–support interactions for boosting electrocatalytic CO2 reduction to CO. ACS Catal. 12, 923–934 (2021).

Wang, H. et al. Surface-clean Au25 nanoclusters in modulated microenvironment enabled by metal–organic frameworks for enhanced catalysis. J. Am. Chem. Soc. 144, 22008–22017 (2022).

Sun, Y. et al. The evolution in catalytic activity driven by periodic transformation in the inner sites of gold clusters. Adv. Funct. Mater. 29, 1904242 (2019).

Liu, Y. et al. Central doping of a foreign atom into the silver cluster for catalytic conversion of CO2 toward C-C bond formation. Angew. Chem. Int. Ed. 57, 9775–9779 (2018).

Xu, J., Xu, S., Chen, M. & Zhu, Y. Unlocking the catalytic activity of an eight-atom gold cluster with a Pd atom. Nanoscale 12, 6020–6028 (2020).

Li, G. et al. Reactivity and recyclability of ligand-protected metal cluster catalysts for CO2 transformation. Angew. Chem. Int. Ed. 62, e202216735 (2023).

Gu, J. et al. Modulating electric field distribution by alkali cations for CO2 electroreduction in strongly acidic medium. Nat. Catal. 5, 268–276 (2022).

Ma, T. et al. Graphene-based materials for electrochemical CO2 reduction. J. CO2 Util. 30, 168–182 (2019).

Gao, Z. H. et al. A heteroleptic gold hydride nanocluster for efficient and selective electrocatalytic reduction of CO2 to CO. J. Am. Chem. Soc. 144, 5258–5262 (2022).

Kulkarni, V. K. et al. N-Heterocyclic carbene-stabilized hydrido Au24 nanoclusters: synthesis, structure, and electrocatalytic reduction of CO2. J. Am. Chem. Soc. 144, 9000–9006 (2022).

Wu, Z. Z. et al. Identification of Cu(100)/Cu(111) interfaces as superior active sites for CO dimerization during CO2 electroreduction. J. Am. Chem. Soc. 144, 259–269 (2022).

Wuttig, A., Yaguchi, M., Motobayashi, K., Osawa, M. & Surendranath, Y. Inhibited proton transfer enhances Au-catalyzed CO2-to-fuels selectivity. Proc. Natl Acad. Sci. USA 113, E4585–E4593 (2016).

Frey, T. et al. Prediction of CO2 adsorption properties of azo, azoxy and azodioxy-linked porous organic polymers guided by electrostatic potential. CrystEngComm 25, 3870–3884 (2023).

Jiang, Y. et al. Metal–organic frameworks with target‐specific active sites switched by photoresponsive motifs: efficient adsorbents for tailorable CO2 capture. Angew. Chem. Int. Ed. 58, 6600–6604 (2019).

So, G. K. et al. Efficient color-tunable copper(I) complexes and their applications in solution-processed organic light-emitting diodes. Chem. Asian J. 12, 1490–1498 (2017).

Kobayashi, N., Kamei, Y., Shichibu, Y. & Konishi, K. Protonation-induced chromism of pyridylethynyl-appended [core+exo]- type Au8 clusters. resonance-coupled electronic perturbation through π-conjugated group. J. Am. Chem. Soc. 135, 16078–16081 (2013).

Chen, Q. et al. Efficient and selective methane borylation through pore size tuning of hybrid porous organic-polymer-based iridium catalysts. Angew. Chem. Int. Ed. 58, 10671–10676 (2019).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos. 22275168, 21825106, and 22175155).

Author information

Authors and Affiliations

Contributions

S.-Q.Z. proposed the research direction. S.W. guided the whole experiment. Y.-M.W. synthesized the catalysts, conducted the structure analysis and the catalytic studies. Q.-Y.W., C.-X.D., and F.-Q.Y. assisted in the completion of the whole experiment. L.-Y.W. and B.L. contributed to the revision process. All authors were active in writing this paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, YM., Yan, FQ., Wang, QY. et al. Single-atom tailored atomically-precise nanoclusters for enhanced electrochemical reduction of CO2-to-CO activity. Nat Commun 15, 1843 (2024). https://doi.org/10.1038/s41467-024-46098-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-46098-x

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.