Abstract

Atomically precise nanoclusters (NCs) provide opportunities for correlating the structure and electrocatalytic properties at atomic level. Herein, we report the single-atom doping effect and ligand effect on CO2 electroreduction (eCO2RR) by comparing monogold-doped Au1Cu24 and homocopper Cu25 NCs protected by triphenylphosphine or/and tris(4-fluorophenyl)phosphine. Catalytic results revealed that the electronic distribution of Cu25 NCs is enormously contracted by doping Au atoms, entitling it to exhibit the unique inhibition of hydrogen evolution reaction. And the inductive effect of ligand strongly favors the formation of formate in eCO2RR. Overall, this work will provide guidance for the rational design of the copper-based catalysts in the eCO2RR.

Similar content being viewed by others

Introduction

Electrochemical CO2 reduction reaction (eCO2RR) has been attracting intensive research efforts, as it can convert CO2 to value-added chemicals in a carbon neutral route1,2,3,4. Due to the chemical inertness of CO2, sufficient activation energy is necessarily needed for breaking C–O bond and producing new carbon chemicals. Therefore, it is imperative for us to develop efficient catalysts to lower activation energy. So far, several transition metal-based catalysts have been successfully synthesized with high activity, but the specific selectivity for reduction products is relatively poor5,6.

Ligand-protected atomically precise metal nanoclusters (NCs) have been widely used in the field of catalysis7,8,9,10,11,12, owing to their unique properties and well-defined structures13. Recently, the catalysis application has expanded to eCO2RR to explore the formation mechanism of the reduction products, involving morphology14, active center15,16,17,18,19,20, size effect21, alloy effect22,23,24,25, electronic structure26,27, ligand type28,29,30,31, and so on. To be specific, Wang and co-workers reported that [Au22H3(dppe)3(PPh3)8]3+ exhibited higher selectivity towards CO (FE = 92.7% at −0.6 V) than that of [Au11(dppe)5]3+ (FE = 70.6%), in which the former was consisted of two Au11 units, indicating the structure of NCs plays an important role in electrochemical performance32. For another case, Pt1Au37(SCH2PhtBu)24 (15 electrons) was fabricated by doping mono-Pt into the kernels of Au38(SCH2PhtBu)24 (14 electrons), leading to a broader HOMO-LUMO gap and increased selectivity of CO, while two Pt atoms doped Pt2Au37(SCH2PhtBu)24 (16 electrons) was less active than Pt1Au37 for eCO2RR26. Furthermore, fine tuning of the NCs surface by ligand modification could enhance the selectivity for eCO2RR. For instance, Jin’s group found that the thiolated Au25 NCs showed an excellent selectivity of CO2 to CO, while the selenolated Au25 with the same metal packing inclined to the HER process31. Recently, Zang et al. reported that, Au28(C2B10H11S)12(C4H8S)4Cl4 exhibited higher FE of CO (98.5%) than that of the alkynyl protected Au28 due to the stripping of surface ligand to expose more active sites28.

Cu-based catalysts are considered to be the most promising eCO2RR catalysts because of their suitable adsorption energy for CO2 with H33,34. However, to our best knowledge, only a few cases about Cu NCs being used in eCO2RR have been reported. For example, Jiang and co-works used Cu32H20{S2P(OiPr)2}12 as catalyst showing high selectivity of CO2 to HCOOH (FE = ~90%), further verified that the HCOOH formation proceeds via the lattice-hydride mechanism through density functional theory calculations and experiments35. Subsequently, Zang’s group found that the ditetrahedron-shaped Cu8 NCs exhibited ultra-high selectivity of HCOOH (FE = ~92%), which was twice as high as that of the cube-shaped Cu8 NCs isomers36. Recently, our group reported that, the formation of surface hydride played a significant role in triggering the formation and stabilization of HCOO* on the Ag-Cu active center, leading to the exclusive formation of formate in the Cu-containing NCs37. However, hydrogen evolution reaction (HER), as the competing reaction of eCO2RR, is inevitable in electroreduction with Cu-based NCs. Therefore, will the electronic distribution of NCs impact the composition of reduction products? How to effectively inhibit HER meanwhile promote eCO2RR? What is the relationship between the selectivity of C1 products (CO vs. HCOOH) and NCs structure? These questions form the aim and motivation of the current investigation.

Herein, we investigated the effects of the metal kernel and ligand on eCO2RR at the atomic level by employing four different [M@Cu24H22(PR3)12]+ (M = Au or Cu; R = -PPh3 or -p-FPPh3) NCs covered by two kinds of phosphine ligands, including [Cu25H22(Ph3P)12]+ (Cu25-(Ph)3P hereafter), [Cu25H22(p-FPh3P)12]+ (Cu25-(p-FPh)3P hereafter), [AuCu24H22(Ph3P)12]+ (AuCu24-(Ph)3P hereafter) and [AuCu24H22(p-FPh3P)12]+ (AuCu24-(p-FPh)3P hereafter). The Au-doped M@Cu24 NCs show preference towards the products of the eCO2RR, whereas homogeneous parent copper NCs tend to HER, indicating the metal dopants play a significant role in the electrochemical reactions. The kind of ligands also influences the selectivity of product in eCO2RR. As a comparison, the NCs catalysts protected by fluoro-substituted phosphonate ligands gave rise to a more enhanced activity for the electrochemical process of CO2-to-formate conversion at more positive potential. This work will provide guidance for the rational design of the copper-based catalysts for the eCO2RR.

Results and discussion

Synthesis and characterization of [M@Cu24H22(PR3)12]+ (M = Au or Cu; R = -PPh3 or -p-FPPh3) NCs

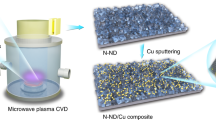

The four titled M@Cu24 NCs were synthesized through our previously reported methods with minor modifications38. The [Cu25H22(PPh3)12]Cl was firstly emerged as the by-product of Cu18 in C6H6 solvent reported by Hayton group39. In this work, compared with our previously reported method, we have improved the selectivity of these four target M@Cu24 NCs through the synthetic modification, which was a high-temperature reduction method using sodium borohydride under inert atmosphere. Note that the minor modifications, which were critical for the formation of these four M@Cu24 NCs with high yield. And we recorded the time-resolved UV–vis absorbance spectra of the four NCs to monitor the formation process, respectively. Note that, the absorption feature of Cu25-(Ph)3P and AuCu24-(Ph)3P are appeared at 1 h from the beginning (Supplementary Fig. 1a and 1b). Moreover, the four NCs could be controlled synthetized apace at 40 oC with high yields. For instance, the fingerprint absorbance peaks of tris(4-fluorophenyl) phosphine-protected AuCu24-(p-FPh)3P (423 nm and 535 nm) and Cu25-(p-FPh)3P (454 and 619 nm) are observed within 1 h of the reaction (Supplementary Fig. 1c and 1d). Polyhydrido copper clusters with Cu(0) character obtained by high-temperature reduction, which may be due to the Cu–H bond heterolysis and Cu atoms nucleation promoted by the fast Pedesis.

In our previous work, the crystal structure and optical properties of the four NCs have been compared38. According to these reported crystallographic information and X-ray crystallography analysis of four clusters38,39, the four NCs have quite similar M@Cu12@Cu12 metal framework and surface motif arrangements (Fig. 1), providing an ideal platform to probe the electronic structure effect of the catalysts on the eCO2RR. All the four NCs share the same 13-atom M@Cu12 (M = Cu or Au) icosahedron kernel, which is covered by four Cu3(R3P)3 units (i.e., Cu3(Ph3P)3 or Cu3(p-FPh3P)3). The detailed synthetic procedure can be found in the “Methods” section, and the relevant characterization elucidation will be discussed next.

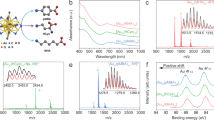

The electron distribution and composition of the four NCs can be revealed by UV–vis spectra and X-ray photoelectron spectroscopy (XPS). As displayed in Supplementary Fig. 2a and 2c, Cu25-(Ph)3P shows two distinct absorption peaks located at around 459 and 635 nm, while Cu25-(p-FPh)3P presents a little bit blue-shift (454 and 619 nm), due to electron-withdrawing ligands leading to an increased band gap. Similar absorption peak blue-shift also occurs in AuCu24-(Ph)3P (437 and 580 nm) and AuCu25-(p-FPh)3P (423 and 535 nm) (Supplementary Fig. 2b and 2d). Moreover, the two mono-Au-doping alloy NCs are brown in dichloromethane, in contrast with both Cu25-(Ph)3P and Cu25-(p-FPh)3P presenting a light green visible to the naked eye. The electronic structures of these four NCs were subsequently probed by X-ray photoelectron spectroscopy (XPS), and the results are presented in Supplementary Figs. 3, 4 and Supplementary Table 1. As depicted in Supplementary Figs. 3a, 3c, 4a and 4c, the XPS survey scan profiles confirmed the co-existence of the Cu, P, and C elements in Cu25-(Ph)3P; the Au, Cu, P, and C elements in AuCu24-(Ph)3P; Cu, P, F and C elements in Cu25-(p-FPh)3P; Au, Cu, P, F and C elements in AuCu24-(p-FPh)3P, respectively. The Au/Cu atomic ratio of AuCu24-(Ph)3P and AuCu24-(p-FPh)3P were estimated as 1.03/24.15 and 1.16/24.21, in good agreement with the theoretical value (1/24). As illustrated in Supplementary Figs. 3b, 3d, 4b and 4d, the binding energies of Cu 2p3/2 peaks in AuCu24-(Ph)3P (932.56 eV) and AuCu24-(p-FPh)3P (932.62 eV) are much higher than that of Cu25-(Ph)3P (932.42 eV) and Cu25-(p-FPh)3P (932.48 eV), suggesting that one gold atom doped can significantly affect the electron distribution of the parent homogenous Cu25 NCs. Compared with homogenous Cu25 NCs, the free valence electrons of the AuCu12 core enormously shrunk inward by one gold doping, leading to a fact that Cu on the surface were electropositive. Furthermore, the binding energy of relatively electron-withdrawing ligands covered AuCu24-(p-FPh)3P (932.62 eV) was slightly higher than that of AuCu24-(Ph)3P (932.56 eV), and it means that more electropositive Cu atoms could be observed in relatively electron-withdrawing ligands coved M@Cu24 NCs. Meanwhile, the binding energies of the Au 4f7/2 peaks in AuCu24-(p-FPh)3P (84.14 eV) and AuCu24-(p-FPh)3P (84.48 eV) are on a higher-energy side (oxidation side) relative to that of Au(0) (84.0 eV), demonstrating that the incorporated Au is partially oxidized (Supplementary Figs. 3e and 4e).

Electrocatalytic CO2 reduction performance

Electrochemical CO2 reduction reaction (shorted for eCO2RR) was envisioned to measure the catalytic performances of these title NCs. Given the abundant surface defects and functional groups of acid multi-walled carbon nanotubes (CNTs), the four NCs were deposited onto CNTs with 50% wt. loading to form the AuCu24-(Ph)3P/CNTs, Cu25-(Ph)3P/CNTs, AuCu24-(p-FPh)3P/CNTs and Cu25-(p-FPh)3P/CNTs electrocatalysts. Noted that, no nanoparticles were observed on the surface of four electrocatalysts, which corresponds to the X-ray diffraction (XRD) pattern (Supplementary Fig. 5). It was found that CO and H2 were the only two gaseous products under all applied potential (without IR correction) versus the reversible hydrogen electrode (RHE) by gas chromatography (GC). In addition, 1H-NMR spectra verified liquid products (Supplementary Fig. 6). The linear scanning voltammetry (LSV) were first conducted for the four catalysts. As depicted in Supplementary Fig. 7, both AuCu24-(Ph)3P/CNTs and AuCu24-(p-FPh)3P/CNTs exhibit a much higher current density and a more positive onset potential in CO2 saturated aqueous 0.5 M KHCO3 solution than in the one of N2 purged, indicating that the two mono-Au-doped clusters have much higher CO2 reduction activity. Cu25-(Ph)3P/CNTs and Cu25-(p-FPh)3P/CNTs, almost the same current density are observed at all of the test potentials, implying that HER rather than eCO2RR is the major reduction process for both Cu25 NCs electrocatalysts.

For these four electrocatalysts, one-metal-atom and ligand difference can cause remarkable eCO2RR catalytic performance discrepancy, and a strong metal core effect (Cu13 vs. AuCu12) and ligand effect (Ph3P vs. FPh3P) is observed. As illustrated in Fig. 2a–c, AuCu24-(Ph)3P/CNTs exhibits the highest CO faradaic efficiency (FECO) of 45.6% at −1.0 V, while H2 is the main product (FEH2 >80%) of the Cu25-(Ph)3P/CNTs in all tested potential ranges and the FE of CO and formate is only ~0–3.7% and ~6.1–10.1% at −0.8 to −1.0 V. It was due to the core effect (Au vs. Cu), suggesting that the mono-gold doped AuCu24 can selectively reduce CO2 to high value-added carbon products. In contrast, the homogeneous Cu-based NCs, because of the high Cu-H binding energy, could be the active center for HER. Similarly, AuCu24-(p-FPh)3P/CNTs and Cu25-(p-FPh)3P/CNTs, which had only one-metal-atom difference from each other, displayed FECO content only 11.8% to 20.6% and 2.1% to 8.2% in the entire tested potential, respectively (Fig. 2d). However, compared with triphenylphosphine covered NCs, AuCu24-(p-FPh)3P/CNTs (FEformate = 30.6%) and Cu25-(p-FPh)3P/CNTs (FEformate = 20.3%) have higher FE of formate, which were several times more than that of AuCu24-(Ph)3P and Cu25-(Ph)3P (Fig. 2e). Futhermore, the selectivity btween C1 and H2 product of Cu25-(p-FPh)3P/CNTs (FEH2 = 80.2 to 90.4%) and AuCu24-(p-FPh)3P/CNTs (FEH2 = 59.3–70.6%) are similiar with triphenylphosphine counterparts (Fig. 2f). As shown in the Fig. 2g, the FECO+formate on AuCu24-(Ph)3P/CNTs of 55.9% is almost four times more than that of Cu25-(Ph)3P/CNTs (FECO+formate = 14.8%) at the tested potential of −0.8 V, while the Cu25-(p-FPh)3P/CNTs had lower FECO+formate (20.8%), which were about a half that of AuCu24-(p-FPh)3P/CNTs (FECO+formate = 40.5%) (Fig. 2h). Noted that, the formate selectivity on the two tris(4-fluorophenyl)phosphine protected NCs were two times more than that of AuCu24-(Ph)3P/CNTs and Cu25-(Ph)3P/CNTs, indicating that the ligand effect had a momentous effect on selectively reducing CO2 to C1 products.

a, d CO, b, e formate and c, f H2 faradaic efficiency of AuCu24-(Ph)3P, Cu25-(Ph)3P, and Cu25-(p-FPh)3P, AuCu24-(p-FPh)3P, respectively. FEs for various eCO2RR products obtained on g AuCu24-(Ph)3P, Cu25-(Ph)3P, and h AuCu24-(p-FPh)3P, Cu25-(p-FPh)3P. The error bars represent the standard deviation of three tests at the same test potential.

Meanwhile, the CO partial current density (jCO) increased with the increasement of applied potential for the four electrocatalysts (Supplementary Fig. 8a and 8d). Both of mono-gold-doped NCs had a much larger jCO value than those of Cu25-(Ph)3P/CNTs and Cu25-(p-FPh)3P/CNTs at all potentials, further manifesting unique advantage of Au-doped NCs for converting CO2 into CO exclusively. Furthermore, the partial current density of formate (jformate) for AuCu24-(Ph)3P/CNTs and Cu25-(Ph)3P/CNTs increased with the increasement of tested potential (Supplementary Fig. 8b). However, the jformate of the two tris(4-fluorophenyl)phosphine covered NCs exhibited the same trend with each other, that is, it first increased then decreased, and the maximal value is 3.2 mA cm−2 for Cu25-(p-FPh)3P/CNTs and 2.6 mA cm−2 for AuCu24-(p-FPh)3P/CNTs at −1.1 V, which is much higher than that of triphenylphosphine counterparts (Supplementary Fig. 8e). This is mainly attributed to that the HER process became dominant at more negative potentials. Note that, both of Au-doped NCs had smaller partial current density of H2 (jH2) than that of corresponding Cu25 NCs, indicating that one gold atom doping could increase the selectivity for deducing CO2 to C1 product (Supplementary Fig. 8c and 8f).

Stability is a significant index for evaluating well-defined NCs electrocatalysts in eCO2RR, hence the long-term stability of the four catalysts were tested at −0.8 V, respectively. As illustrated in Fig. 3a, d, the current density and corresponding FE value of two mono-Au doped NCs remained almost unchanged (jtotal = −7.13 to −6.91 mA cm−2 for AuCu24-(Ph)3P/CNTs; jtotal from −7.05 to −6.90 mA cm−2 for AuCu24-(p-FPh)3P/CNTs) after 12 hours of continuous operation, indicating robust long-term durability. However, under the same conditions, the current density of Cu25-(Ph)3P/CNTs and Cu25-(p-FPh)3P/CNTs decreased about 5.7% (from −4.04 to −3.81 mA cm−2) and 4.3% (from −4.90 to −4.69 mA cm−2), respectively. Meanwhile, the FECO+formate and FEH2 of the four electrocatalysts are almost unchanged during the whole time (Fig. 3b, c, e, f). Furthermore, the morphologies of these NCs after eCO2RR are almost the same as before (Supplementary Fig. 9). These results indicate that, the majority of NCs electrocatalysts can be well preserved during the eCO2RR process. Using the fingerprint absorbance peak (635 nm for Cu25-(Ph)3P/CNTs; 580 nm for AuCu24-(Ph)3P/CNTs; 619 nm for Cu25-(p-FPh)3P/CNTs; 535 nm for AuCu24-(p-FPh)3P/CNTs) as the metric, the absorbance change can be quantified and employed to estimate the recovery rate (Supplementary Fig. 10). Notably, the entire absorbance feature of the four NCs kept constantly, though the intensity of the characteristic peaks was decreased at varying degrees under different potentials. At the −0.8 V, all the recovery rate of four catalysts were over 50%, which was in good agreement with the finding in the i-t test and the calculated results as summarized in Supplementary Table 2.

The electrochemically active surface area (ECSA) was measured to further reveal the reason for the difference in the catalytic performance of the four clusters in eCO2RR. The current density of Cu25-(Ph)3P, AuCu24-(Ph)3P, Cu25-(p-FPh)3P, and AuCu24-(p-FPh)3P at different scan rate ranging from 20 to 100 mV s−1 were recorded and shown in Supplementary Fig. 11, and based on that, the double-layer capacitance (Cdl) of the four NCs were evaluated to be 1.27, 1.21, 0.99 and 0.94 mF, respectively. Thus, the ECSA of Cu25-(Ph)3P, AuCu24-(Ph)3P, Cu25-(p-FPh)3P, and AuCu24-(p-FPh)3P were calculated to be 31.75, 30.25, 24.75 and 23.50 cm2, respectively. Therefore, the number of active sites of the three clusters can be arranged in descending order as Cu25-(Ph)3P > AuCu24-(Ph)3P > Cu25-(p-FPh)3P > AuCu24-(p-FPh)3P, which was attributed to the number of active sites scales with the ligand removal. Furthermore, the electrochemical impedance (EIS) was carried out to explore the charge transport properties of the four NCs at the electrode/electrolyte interface (Supplementary Fig. 12). The Nyquist plot of both homogeneous Cu25 NCs exhibited a much smaller the semicircular diameters than that of mono-gold-doped AuCu24, and the former have a conductivity with lower interfacial charge-transfer resistance.

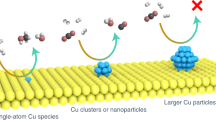

Effect on electron-density distribution modulating of copper catalyst on the selectivity of C1 products (CO vs. formate) from eCO2RR

According to the catalytic performance above, we find that the metal core plays an important role in the two competitive reactions (HER vs. eCO2RR) in electroreduction selectivity, further, achieving the formation selectivity for C1 products (formate vs. CO) in eCO2RR by changing the ligand type. Get insight in the electron-density distribution of the M@Cu24 (Au/ Cu), as displayed in Fig. 4, core and ligand effect could be observed: (i) the Cu atom on the surface of mono-gold-doped AuCu24 have lower electron cloud density (δ+) and is more prone to eCO2RR, caused by the free valence electrons of the AuCu12 core to shrink inward; (ii) The more electropositive Cu atoms banding with electrophilic ligand are preferable to bind the O atom of CO2, and showing selectivity for formate. Experimentally, the XPS results reflected the positive charge distribution among the four NCs. By mono-gold doping, the exterior Cu atoms of AuCu24-(Ph)3P (932.56 eV) and AuCu24-(p-FPh)3P (932.62 eV) are much more electropositive than that of Cu25-(Ph)3P (932.42 eV) and Cu25-(p-FPh)3P (932.48 eV) (Supplementary Figs. 3b, 3d, 4b and 4d). It was noting that, HER was inevitable for the polyhydrido Cu NCs catalysts in electrochemical reduction, however, it was advisable to increase the selectivity toward to eCO2RR and reduce the H-source supply in the solution by electron-contracted element such as Au, Pt, Pd, etc. More importantly, using electrophilic ligand could not only raise the stability of NCs, and promote the selectivity of formate in eCO2RR.

Conclusion

In summary, these four polyhydrido M@Cu24 (M = Au or Cu) NCs were controllably synthesized and used as electrocatalysts to probe the core and ligand effect for electroreduction selectivity. Significantly, the inert metal doping was propitious to eCO2RR, and the modification of the electrophilic ligand was efficient to enhance the selectivity for formate in eCO2RR. This work not only provides an efficient and simple strategy to prepare the polyhydrido Cu-based NCs, but also highlights the unique advantages of employing metal NCs as model catalysts to advance the fundamental mechanistic understanding toward electroreduction and beyond.

Methods

Chemicals and materials

The cupric (II) acetylacetonate (C10H14O4Cu), tetrachloroauric (III) acid (HAuCl4·3H2O, >99.99% metals basis), triphenylphosphine (Ph3P, ≥99%), tris(4-fluorophenyl)phosphine ((p-FPh)3P, ≥99%), NaBH4 (>98%) were received from Aldrich (Shanghai, China). Methanol, dichloromethane, and n-hexane were purchased from Aldrich (Shanghai, China). All reagents and solvents were commercially available and used without further purification. Pure water was purchased from Wahaha Co. Ltd. All glassware was thoroughly cleaned with aqua regia (HCl:HNO3 = 3:1, v-v), rinsed with copious pure water.

Synthesis of [Cu25H22(Ph3P)12]+ nanoclusters (Cu25-(Ph)3P)

Firstly, Cu25-(Ph)3P NCs were prepared according to a reported protocol with some minor modifications38. Briefly, at 40 oC under Ar atmosphere, a solution of cupric(II) acetylacetonate (60 mg) dissolved in a mixed solvent of methanol and dichloromethane in a volume ratio of 3:1. The color of the solution was ink blue. After 30 min, triphenylphosphine (100 mg) was added, and the solution changed slowly from ink blue to light blue. After that, 2 mL freshly aqueous NaBH4 (0.66 M in ice-cold water) was quickly added under vigorous stirring. The color of the solution slowly changed from light blue to yellow-green within 10 min. The reaction was aged for 2.5 h at room temperature. The solvent was then evaporated to give a yellow-green solid. After the reaction, the volume of the mixture was evaporated to dryness to give a black solid, which was successively washed with n-hexane and diethyl ether to remove the byproducts and excess triphenylphosphine, followed by extraction with dichloromethane and then dried by rotary evaporation. After diffusion of n-hexane to a dichloromethane solution at −4 oC for about one week, black crystals were obtained (yield: ~40% based on copper salt).

Synthesis of the [Cu25H22((p-FPh)3P)12]+ nanoclusters (Cu25-(p-FPh)3P)

The synthesis of Cu25-(p-FPh)3P was similar to that of Cu25-(Ph)3P and the synthetic procedures are identical until the addition of ligand, which triphenylphosphine was replaced with tris(4-fluorophenyl)phosphine. After that, 2 mL freshly aqueous NaBH4 (0.66 M in ice-cold water) was quickly added under vigorous stirring. The reaction was aged for 10 h at room temperature. After the reaction, the volume of the mixture was evaporated to dryness to give black solid, which was successively washed with n-hexane and diethyl ether to remove the byproducts and excess ligands, followed by extraction with dichloromethane and then dried by rotary evaporation. After diffusion of n-hexane to a dichloromethane solution at −4 oC for about two days, black crystals were obtained (yield: ~70% based on copper salt).

Synthesis of [AuCu24H22(Ph3P)12]+ nanoclusters (AuCu24-(Ph)3P)

Firstly, AuCu24-(Ph)3P was synthesized following the methods reported by us previously with some minor modifications38. Briefly, at 40 oC under Ar, a solution of cupric(II) acetylacetonate (60 mg) and HAuCl4·3H2O (5 mg) dissolved in mixed solvent of methanol and dichloromethane in a volume ratio of 3:1. The color of the solution was ink blue. After 30 min, triphenylphosphine (100 mg) was added and the solution changed slowly from ink blue to light blue. After that, 2 mL freshly aqueous NaBH4 (0.66 M in ice-cold water) was quickly added under vigorous stirring. The color of the solution quickly turned reddish brown. The reaction was aged for 10 h at room temperature. The solvent was then evaporated to give a yellow-green solid. After the reaction, the volume of the mixture was evaporated to dryness to give black solid, which was successively washed with n-hexane and diethyl ether to remove the byproducts and excess triphenylphosphine, followed by extraction with dichloromethane and then dried by rotary evaporation. After diffusion of n-hexane to a dichloromethane solution at −4 oC for about three days, black crystals were obtained (yield: ~30% based on copper salt).

Synthesis of [AuCu24H22(p-FPh3P)12]+ nanoclusters (AuCu24-(p-FPh)3P)

The synthesis of AuCu24-(p-FPh)3P was similar to that of AuCu24-(Ph)3P and the synthetic procedures are identical until the addition of ligand, which triphenylphosphine was replaced with tris(4-fluorophenyl)phosphine. Then, 2 mL freshly aqueous NaBH4 (0.66 M in ice-cold water) was quickly added under vigorous stirring. The color of the solution quickly turned reddish brown. The reaction was aged for 10 h at 40 oC. The solvent was then evaporated to give a reddish-brown solid. After the reaction, the volume of the mixture was evaporated to dryness to give a black solid, which was successively washed with n-hexane and diethyl ether to remove the byproducts and excess ligands, followed by extraction with dichloromethane and then dried by rotary evaporation. After diffusion of n-hexane to a dichloromethane solution at −4 oC for about three days, black crystals were obtained (yield: ~80% based on copper salt).

Electrochemical measurements

To prepare the catalyst sample, these four as-prepared M@Cu24 (M = Au/Cu) were loading on acidic multi-walled carbon (CNTs) with a mass ratio of 1 (5 mg NC and 5 mg CNTs). The catalyst ink was prepared by dispersing the sample in isopropyl alcohol under sonication for 5 min. Then 1 mL catalyst suspension and 10 μL Nafion (5 wt.%) were uniformly mixed as the final catalyst ink. Then, 40 μL catalytic ink was dropwise cast onto the carbon cloth (1.0 × 1.0 cm2) and dried at room temperature as the working electrode. All electrochemical measurements were carried out in a custom gas-tight H-cell with two compartments separated by Nafion 117 membrane. Each compartment contained 25 mL electrolyte (0.5 M KHCO3: pH = 7.2 when saturated with CO2, pH = 8.8 when saturated with N2) with ~10 mL headspace. The electrochemical measurements were carried out on an electrochemical workstation (CHI 760E) with Pt sheet as counter electrode and Ag/AgCl electrodes (KCl saturated) as reference electrode. All the potentials were calibrated to a reversible hydrogen electrode (RHE) according to the Nernst equation:

The output of the gas flow from the cathode chamber was directed into a gas chromatograph instrument (GC3900Plus, RUI NENG) for identification and quantification of the gaseous products, which was purged for 30 min with an average rate of 10 mL min−1 (at room temperature and ambient pressure) prior to the test. The GC was installed with a thermal conductivity detector (TCD) to detect H2 and flame ionization detector (FID) to detect hydrocarbons. A methanizer (Agilent) was equipped in front of the FID for CO detection. High-purity Argon (99.9999%) was used as the carrier gas for all compartments of the GC.

The faradaic efficiency (FEX) and corresponding partial current density (jX) of X (X = CO or H2 or formate) were calculated as below:

Where

Qt = total charge consumed in the electrochemical reaction

Ni = the number of moles of the product (measured GC) n = the number of electrons transferred in the elementary reaction (n is 2 for CO, H2 and formate) F = the Faradaic constant (96485 C mol−1)

t = reaction time (s)

Area = geometry area of the electrode (1 cm2)

The electrochemically active surface area (ECSA) of the catalyst was obtained via the linear fit of the corresponding current density with respect to the scan rate (Fig. S10). The results show that double layer capacitance of electrode (CdI) for Cu25-(Ph)3P, AuCu24-(Ph)3P, Cu25-(p-FPh)3P and AuCu24-(p-FPh)3P are 1.27, 1.21, 0.99 and 0.94 mF, respectively. The ESCA can be calculated based on the following formula:

where CS is the specific capacitance of the sample or capacitance of an atomically smooth planar surface of the material per unit area under identical electrolyte conditions. And the average CS value of 0.04 mF cm−2 for an ideal flat surface of the metal catalyst in alkaline solution reported by McCrory was chosen for the ECSA evaluation40.

For the morphology of four catalysts before and after eCO2RR, the NCs/CNTs loaded work electrodes were directly conducted by SEM measurement. For stability, the NCs/CNTs loaded carbon fibers were as work electrodes. The eCO2RR was allowed to proceed at −0.8 V (vs. RHE) for 30 min. After the test, the samples were rinsed with dichloromethane and collected for UV–vis characterization.

General characterization

The surface chemical compositions and valence states were examined by X-ray photoelectron spectroscopy (XPS, Phi X-tool instrument). Scanning electronic microscopic (SEM) images were collected with a field-emission scanning electron microscope (FESEM, Merlin). UV–visible absorption spectra of clusters, dimer and tetramer were recorded on a Shimadzu 2600/2700 spectrophotometer.

Data availability

All data generated or analyzed during this study are included in this article (and its Supplementary Information files).

References

Wagner, A., Sahm, C. D. & Reisner, E. Towards molecular understanding of local chemical environment effects in electro- and photocatalytic CO2 reduction. Nat. Catal. 3, 775–786 (2020).

Birdja, Y. Y. et al. Advances and challenges in understanding the electrocatalytic conversion of carbon dioxide to fuels. Nat. Energy 4, 732–745 (2019).

Wu, J., Sharifi, T., Gao, Y., Zhang, T. & Ajayan, P. M. Emerging carbon-based heterogeneous catalysts for electrochemical reduction of carbon dioxide into value-added chemicals. Adv. Mater. 31, e1804257 (2019).

Quan, Y., Zhu, J. & Zheng, G. Electrocatalytic reactions for converting CO2 to value‐added products. Small Sci. 1, 2100043 (2021).

Nitopi, S. et al. Progress and perspectives of electrochemical CO2 reduction on copper in aqueous electrolyte. Chem. Rev. 119, 7610–7672 (2019).

Zou, Y. & Wang, S. An investigation of active sites for electrochemical CO2 reduction reactions: from in situ characterization to rational design. Adv. Sci. 8, 2003579 (2021).

Du, Y., Sheng, H., Astruc, D. & Zhu, M. Atomically precise noble metal nanoclusters as efficient catalysts: a bridge between structure and roperties. Chem. Rev. 120, 526–622 (2020).

Yan, J., Teo, B. K. & Zheng, N. Surface chemistry of atomically precise coinage-metal nanoclusters: from structural control to surface reactivity and catalysis. Acc. Chem. Res. 51, 3084–3093 (2018).

Yang, M. et al. Highly dispersed Bi clusters for efficient rechargeable Zn-CO2 batteries. Appl. Catal. B: Environ. 307, 121145 (2022).

Li, S. et al. The precise editing of surface sites on a molecular-like gold catalyst for modulating regioselectivity. Chem. Sci. 11, 8000–8004 (2020).

Jin, R., Zeng, C., Zhou, M. & Chen, Y. Atomically precise colloidal metal nanoclusters and nanoparticles: fundamentals and opportunities. Chem. Rev. 116, 10346–10413 (2016).

Jin, M. et al. Highly dispersed Ag clusters for active and stable hydrogen peroxide production. Nano Res. 15, 5842–5847 (2022).

Yao, Q. F. et al. Molecular reactivity of thiolate-protected noble metal nanoclusters: synthesis, self-assembly, and applications. Chem. Sci. 12, 99–127 (2021).

Zhao, S. et al. Influence of atomic-level morphology on catalysis: the case of sphere and rod-like gold nanoclusters for CO2 electroreduction. ACS Catal. 8, 4996–5001 (2018).

Qin, L. et al. Homoleptic alkynyl-protected Ag15 nanocluster with atomic precision: structural analysis and electrocatalytic performance toward CO2 reduction. Angew. Chem. Int. Ed. 60, 26136–26141 (2021).

Li, S. et al. Boosting CO2 electrochemical reduction with atomically precise surface modification on gold nanoclusters. Angew. Chem. Int. Ed. 60, 6351–6356 (2021).

Austin, N., Zhao, S., McKone, J. R., Jin, R. & Mpourmpakis, G. Elucidating the active sites for CO2 electroreduction on ligand-protected Au25 nanoclusters. Catal. Sci. Technol. 8, 3795–3805 (2018).

Alfonso, D. R., Kauffman, D. & Matranga, C. Active sites of ligand-protected Au25 nanoparticle catalysts for CO2 electroreduction to CO. J. Chem. Phys. 144, 184705 (2016).

Wan, X. K., Wang, J. Q. & Wang, Q. M. Ligand-protected Au55 with a novel structure and remarkable CO2 electroreduction performance. Angew. Chem. Int. Ed. 60, 20748–20753 (2021).

Sun, Y. N., Liu, X., Xiao, K., Zhu, Y. & Chen, M. Y. Active-site tailoring of gold cluster catalysts for electrochemical CO2 reduction. ACS Catal. 11, 11551–11560 (2021).

Seong, H. et al. Atomically precise gold nanoclusters as model catalysts for identifying active sites for electroreduction of CO2. Angew. Chem. Int. Ed. 60, 14563–14570 (2021).

Tang, S., Xu, J., Liu, X. & Zhu, Y. Ag doped Au44 nanoclusters for electrocatalytic conversion of CO2 to CO. Chem. -Eur. J. 28, e202201262 (2022).

Zhuang, S. et al. Hard-sphere random close-packed Au47Cd2(TBBT)31 nanoclusters with a Faradaic efficiency of up to 96 % for electrocatalytic CO2 reduction to CO. Angew. Chem. Int. Ed. 59, 3073–3077 (2020).

Lin, X. et al. [AuAg26(SR)18S]- nanocluster: open shell structure and high Faradaic efficiency in electrochemical reduction of CO2 to CO. J. Phys. Chem. Lett. 12, 552–557 (2020).

Li, S. et al. Monopalladium substitution in gold nanoclusters enhances CO2 electroreduction activity and selectivity. ACS Catal. 10, 12011–12016 (2020).

Liu, X. et al. Asymmetrically doping a platium atom into a Au38 nanocluster for changing the electron configuration and reactivity in electrocatalysis. Angew. Chem. Int. Ed. 61, e202207685 (2022).

Xu, J. Y. et al. Evolution from superatomic Au24Ag20 monomers into molecular-like Au43Ag38 dimeric nanoclusters. Chem. Sci. 13, 2778–2782 (2022).

Wang, J., Xu, F., Wang, Z. Y., Zang, S. Q. & Mak, T. C. W. Ligand-shell engineering of a Au28 nanocluster boosts electrocatalytic CO2 reduction. Angew. Chem. Int. Ed. 61, e202207492 (2022).

Yuan, S. F. et al. Robust gold nanocluster protected with amidinates for electrocatalytic CO2 reduction. Angew. Chem. Int. Ed. 60, 14345–14349 (2021).

Kulkarni, V. K. et al. N-heterocyclic carbene-stabilized hydrido Au24 nanoclusters: synthesis, structure, and electrocatalytic reduction of CO2. J. Am. Chem. Soc. 144, 9000–9006 (2022).

Li, S. et al. The role of ligands in atomically precise nanocluster-catalyzed CO2 electrochemical reduction. Nanoscale 13, 2333–2337 (2021).

Gao, Z. H. et al. A heteroleptic gold hydride nanocluster for efficient and selective electrocatalytic reduction of CO2 to CO. J. Am. Chem. Soc. 144, 5258–5262 (2022).

Zhang, J.-N. et al. Copper as a single metal atom based photo-, electro- and photoelectrochemical catalyst decorated on carbon nitride surface for efficient CO2 reduction: a review. Nano Res. Energy 1, e9120015 (2022).

Ahmad, T. et al. Electrochemical CO2 reduction to C2+ products using Cu-based electrocatalysts: a review. Nano Res. Energy 1, e9120021 (2022).

Tang, Q. et al. Lattice-hydride mechanism in electrocatalytic CO2 reduction by structurally precise copper-hydride nanoclusters. J. Am. Chem. Soc. 139, 9728–9736 (2017).

Liu, L. J. et al. Mediating CO2 electroreduction activity and selectivity over atomically precise copper clusters. Angew. Chem. Int. Ed. 61, e202205626 (2022).

Ma, X. et al. Electrochemical CO2 reduction catalyzed by atomically precise alkynyl-protected Au7Ag8, Ag9Cu6, and Au2Ag8Cu5 nanoclusters: probing the effect of multi-metal core on selectivity. Chem. Sci. 13, 10149–10158 (2022).

Chen, A. et al. Gram-scale preparation of stable hydride M@Cu24 (M = Au/Cu) nanoclusters. J. Phys. Chem. Lett. 10, 6124–6128 (2019).

Nguyen, T. A. et al. A Cu25 nanocluster with partial Cu(0) character. J. Am. Chem. Soc. 137, 13319–13324 (2015).

McCrory, C. C., Jung, S., Peters, J. C. & Jaramillo, T. F. Benchmarking heterogeneous electrocatalysts for the oxygen evolution reaction. J. Am. Chem. Soc. 135, 16977–16987 (2013).

Acknowledgements

We thank the financial support provided by the National Natural Science Foundation of China (22171156, 52072194 and 21803001), Taishan Scholar Foundation of Shandong Province (China), and Startup Funds from Qingdao University of Science and Technology.

Author information

Authors and Affiliations

Contributions

S.W., C.S. and X.M. guided the whole experiment and conceived the idea. X.M. drafted the manuscript, M.D. conducted most of the experiments, L.T. gave some advice for the characterization and analysis, and C.S. and S.W. provided the funding support, and all the authors contributed to the final polishing of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Chemistry thanks Zhenghua Tang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ding, M., Tang, L., Ma, X. et al. Effects of ligand tuning and core doping of atomically precise copper nanoclusters on CO2 electroreduction selectivity. Commun Chem 5, 172 (2022). https://doi.org/10.1038/s42004-022-00779-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s42004-022-00779-0

This article is cited by

-

The road to the electroreduction of CO2

Communications Chemistry (2024)

-

Single-atom tailored atomically-precise nanoclusters for enhanced electrochemical reduction of CO2-to-CO activity

Nature Communications (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.