Abstract

The catalytic combustion of methane at a low temperature is becoming increasingly key to controlling unburned CH4 emissions from natural gas vehicles and power plants, although the low activity of benchmark platinum-group-metal catalysts hinders its broad application. Based on automated reaction route mapping, we explore main-group elements catalysts containing Si and Al for low-temperature CH4 combustion with ozone. Computational screening of the active site predicts that strong Brønsted acid sites are promising for methane combustion. We experimentally demonstrate that catalysts containing strong Bronsted acid sites exhibit improved CH4 conversion at 250 °C, correlating with the theoretical predictions. The main-group catalyst (proton-type beta zeolite) delivered a reaction rate that is 442 times higher than that of a benchmark catalyst (5 wt% Pd-loaded Al2O3) at 190 °C and exhibits higher tolerance to steam and SO2. Our strategy demonstrates the rational design of earth-abundant catalysts based on automated reaction route mapping.

Similar content being viewed by others

Introduction

The past decades have witnessed the widespread utilization of natural gas as a clean fuel for vehicles and power plants. The catalytic combustion of methane (CH4) into carbon dioxide (CO2) is becoming an increasingly valuable strategy for addressing the emissions of unburned CH4, which exerts a greenhouse gas effect that is 22 times higher than that of CO21,2,3. Different types of heterogeneous catalysts, such as platinum-group-metal (PGM-)4,5,6,7 and metal-oxide-based catalysts8,9,10, have been reported. Among them, PGM-based catalysts, such as Pd- and Pt-loaded Al2O3, exhibited the highest catalytic activities11. However, the Pd-based catalysts suffer from high operating temperatures (>500 °C) under humidity conditions, as well as irreversible deactivation by sulfation during the co-feeding of steam and SO22,12,13,14. Moreover, large amounts of PGMs (200–266 g) must be utilized to achieve the combustion of CH4 in a natural-gas-fueled heavy-duty vehicle15. Additionally, the mining and purification of PGMs extensively impact the environment (the productions of 1 kg each of Pt and Pd generate 12,500 and 3880 kg of CO2 equivalents, respectively). Conversely, the production of main-group elements generates significantly lower CO2 equivalents (e.g., 8.2 kg of Al)16,17. Thus, it is highly desirable (economically and ecologically) to develop main-group catalysts that can function at <200 °C in the co-presence of steam and SO2.

Conventional catalyst screening, which is based on trial-and-error experiments, may not yield discontinuous discoveries, such as the main-group-facilitated catalytic combustion of CH4 at low temperatures. The computational reaction route mapping of the unexplored chemical reaction space can benefit the discovery of different catalytic reactions18,19,20,21,22,23. Generally, the computations of the elementary steps in combustion reactions are considered challenging because of the abundant intermediates and products that exhibit similar formation energies and activation barriers (Ea)24. To comprehensively explore the various reaction routes, density functional theory (DFT)-based automated methods for predicting reaction pathways are promising because they link the theoretical prediction to the practical designs of catalysts25,26,27,28,29,30. Maeda et al. developed an efficient automated path-searching method, namely the artificial force-induced reaction (AFIR) method, which involves pressing the atoms in given reactant molecules together by applying artificial force to form new structures (products) and assigning their transition states (TS)30,31,32,33,34,35,36,37,38,39,40,41. Via AFIR, they elucidated the entire reaction pathways of uncatalyzed reactions32,37,39,40. The automated reaction route mapping of heterogeneous catalysis systems is still formidable owing to the complexity of the surface reactions on solid materials, where the adsorption/desorption of the reactants and products, diffusion/migration of the adsorbates, and bond rearrangements proceed simultaneously35,36,41.

Ozone (O3), a strong oxidant42, is generated onsite by a commercial ozonizer. O3 has been employed to enhance the catalytic performance of the gas-phase combustion of volatile organic compounds, including toluene43,44,45, acetone46,47, and benzene48,49. Regarding the combustion of CH4 with O350,51,52, zeolite-based catalysts, such as Pd53−, Fe54−, Co55−, and proton56-type zeolites, have demonstrated efficiencies at low temperatures. However, the reported studies only considered the catalytic performance; thus, the strategy for designing the catalysts based on the detailed mechanism and elementary steps must still need to be addressed.

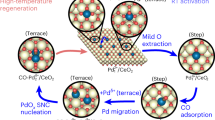

Herein, based on a computational design concept employing the AFIR method, we report a main-group catalyst for driving catalytic combustion of CH4 with O3 at low temperatures. First, we explored the CH4 + O3 reaction network toward generating CO2 (Fig. 1a), confirming that the formation of methanol (CH3OH), CH4 + O3 → CH3OH + O2, was the rate-determining step (RDS) of CH4 combustion. Thereafter, we performed the virtual screening of the active sites for RDS to propose the following concept: stronger Brønsted acid sites (BASs) exhibit higher catalytic activities (Fig. 1b). This concept was experimentally verified via CH4 combustion tests employing O3 at 250 °C in the presence of different BAS catalysts exhibiting different acid strengths (Fig. 1c). Finally, we demonstrated that a proton-type beta zeolite with Si/Al = 8.5 (Hß8.5) exhibited a reaction rate that was three orders of magnitude higher than that of a PGM-based benchmark catalyst, 5 wt% Pd-loaded Al2O3 (Pd5Al2O3). The developed catalyst exhibited very high resistance to steam and SO2 poisoning during the 170-h reaction test.

a Employing single-component (SC)-AFIR, CH4 combustion with O3 was comprehensively explored to determine the key intermediates and elementary steps. b Different active sites were evaluated regarding the decrease in Ea of the key elementary step. c Heterogeneous catalyst comprising the predicted active site was tested experimentally.

Results

Computation of the reaction pathways toward CH4 combustion by O3

We explored the reaction pathway of CH4 and O3 (CH4 + O3) via SC-AFIR, which was an automated method for searching for reaction paths, as implemented in the GRRM program. Employing this method, the reaction routes of the non-catalytic oxidation of CH4 into CO2 by O3 are automatically mapped. Figure 2a shows the reaction pathways with the corresponding values of their relative energies (ΔE) and Ea. In the first reaction, CH4 is oxidized by O3 to yield CH3OH and O2 with strong exothermicity (243.0 kJ/mol). In the TS structure, one O atom of O3 extracts one H atom of CH4 to yield CH3 and OOOH fragments, where the evaluated Ea is 142.7 kJ/mol. This value is comparable to the reported experimental value for gas-phase CH4 combustion by O3 (148 kJ/mol)57. Next, the reactivity of CH3OH with O3 is assessed by exploring the reaction pathway via the SC-AFIR method (see Supplementary Fig. S1). Although CH3OH is oxidized into formaldehyde (CH2O), H2O, and O2 by O3, CH3OH + O3 \(\to\) CH2O + H2O + O2, via an exothermic reaction (210.1 kJ/mol), the process requires a very high Ea (255.1 kJ/mol). Alternatively, the oxidation of CH3OH by O2 produces CH2O and H2O2, CH3OH + O2 \(\to\) CH2O + H2O2, via a low Ea of 76.1 kJ/mol (Fig. 2a). The subsequent oxidation of CH2O by H2O2 yields formic acid (CH2O2) and H2O, CH2O + H2O2 \(\to\) CH2O2 + H2O, with an Ea of 124.2 kJ/mol. The decomposition of the produced CH2O2 yields CO2 and H2, CH2O2 \(\to\) CO2 + H2, or CO and H2O molecules, CH2O2 \(\to\) CO + H2O. However, these decomposition processes require high Ea to produce CO2 and CO (264.3 and 296.3 kJ/mol, respectively) because of the high stability of CH2O2. As an alternative reaction path, we explored the oxidation of CH2O by O2, which was abundantly present in the practical systems, via SC-AFIR (see Supplementary Fig. S2). Thus, the oxidation of CH2O by O2 represents a facile process for producing CO and H2O2 via an Ea of 113.7 kJ/mol. The CO was oxidized into CO2 + O2 by O3 through an Ea of 84.9 kJ/mol (see Supplementary Fig. S3). For comparison, Nitrous oxide (N2O) and H2O2 were assessed as alternative oxidants to oxidize CH4 into CH3OH (see Supplementary Fig. S4). The evaluated Ea of the CH4 + N2O and CH4 + H2O2 reactions are 269 and 177 kJ/mol, respectively, indicating that O3 is the most efficient oxidant for producing CH3OH.

a Calculated reaction pathway of CH4 + O3, as well as the values of relative energies (ΔEs). The values written in dark red represent Ea. b Energy profile of CH4 combustion to yield CO2. The reaction path shown by the red lines is the most plausible for CO2 formation. The result of the Bader charge analyses of the TS structures of CH4 + O3 and CH3OH + O3 is shown together. ΔEs are provided under each bar, and the Ea are described employing the bold italic style (Unit: kJ/mol).

Employing the explored reaction pathways (Fig. 2b), the reaction, CH4 + O3 \(\to\) CH3OH + O2, was determined as the crucial process, with the highest Ea in the CH4 oxidation reaction (the RDS). To further elucidate the TS structure of this reaction, Bader charge analysis was performed to investigate the distribution of charge on each atom in the TS structure (Fig. 2b). The total atomic charges in the CH3 fragment are almost neutral (+0.12), indicating that it is a radical-like fragment. Regarding the OOOH fragment, the structure is divided into two parts: (I) the part comprising the H and O atoms that are closer to the CH3 fragment (denoted as O1) and (II) that comprising the other two O atoms (denoted as O2 and O3). In the former part, the determined atomic charges of the H and O1 atoms are +0.56 and −0.58, respectively, while those of the O2 and O3 atoms in the latter part are +0.06 and −0.12, respectively. This charge distribution indicates that the OOOH fragment comprises a OH radical and O2 molecular species.

Virtual screening of catalytic sites for the reaction of CH4 + O3 to produce CH3OH + O2

The oxidation of CH4 by O3 into CH3OH and O2 was determined as the key reaction during CH4 combustion (Computation of the reaction pathways toward CH4 combustion by O3). To conduct the virtual screening of the catalytically active sites that effectively decrease the Ea, we carried out SC-AFIR calculations for the CH4 + O3 reaction on the following model active sites: (a) a Cu(0) atom as a redox site, (b) an NO molecule as a radical species, (c) pyridine (C5H5N) as a Brønsted and Lewis base site, and (d) sulfuric acid (H2SO4) as a Brønsted acid site (Fig. 3). Lewis acid site is not considered here because it is known that Lewis acid sites are rapidly deactivated in the presence of H2O and SO2, which are abundantly contained in the exhaust gases and produced by the CH4 combustion reaction. Figure 3a shows the reaction path of CH4 + O3 over Cu(0). First, the C–H bond of CH4 is cleaved by the O atom of O3 over the Cu atom to yield OH and CH3 groups on the Cu(II) cation (Cu(OH)(CH3)), as well as adsorbed O2 molecules through a high Ea (318.2 kJ/mol). Subsequently, the adsorbed O2 molecule interacts with the neighboring CH3 group to form CH3OO species on the Cu(II) cation (Cu(OH)(CH3OO)) via an Ea of 115.4 kJ/mol, while the extraction of the H atom of the OH group (Cu(O)(OOH)(CH3)) is determined as an unfavorable path. Finally, the Cu(OH)2 species and CH2O are produced with a moderate barrier (108.7 kJ), although the Cu(II) cation was not reduced back into the Cu(0) atom. The maximum barrier was higher than that of the uncatalyzed reaction (142.7 kJ/mol). Hence, the Cu(0) atom was not a suitable catalyst for the CH4 + O3 reaction. Further, the NO molecules as a representative radical site reacted with O3 to yield O2 and NO2, where the H atom of CH4 was subsequently extracted to yield the CH3 radical species that were bound to the nitrous acid (HONO) species (Fig. 3b). Although the evaluated Ea of this step was relatively low (122.7 kJ/mol), that of the reverse reaction (CH3• + HONO → CH4 + NO2) was very low (2.0 kJ/mol). Additionally, the reaction, NO2 + CH4, to yield CH3OH + O2 shows only a low exothermicity (−21.1 kJ/mol). These results indicate that NO is also an inefficient catalyst for the CH4 + O3 reaction. To compare the result above with more realistic models, the reaction route mappings on the Cu metal cluster and FeO species in ZSM-5 zeolite were carried out only for the first step of CH4 activation (supplementally Fig. S5). Note that the CH4 activation on FeO species in ZSM-5 zeolite is known to proceed via the formation of CH3 radical, similar to the case of the NO molecule in Fig. 3b58. The results indicate that, although Ea for CH4 are different, the tendency of each active site is similar (high Ea of reducing back and low Ea of reverse-reaction for metal and radical sites, respectively). In the case of C5H5N as a base site, O3 slightly interacted with the basic site (the N atom) of C5H5N before reacting with CH4; thus, O3 was not decomposed by the active site (Fig. 3c). Thereafter, CH3OH was produced through a similar TS structure to the gas-phase one, and the product, which was weakly bound to the base site, was slightly more stable than that in the gas phase (ΔE = − 264 kJ (on the base site) vs −243 kJ (in the gas phase)), while their Ea were comparable (Ea = 134.9 vs 142.7 kJ/mol). Finally, H2SO4 was assessed as an acid site. CH3OH was produced via an Ea of 126.2 kJ/mol, which was lower than that of the gas-phase reaction (142.7 kJ/mol), with very high exothermicity (ΔE = − 279.3 kJ/mol; Fig. 3d). As representative PGMs, Pd atom was also assessed as a potential active site for CH4 + O3 reaction (Supplementary Fig. S6). The result shows that the highest activation barrier in the reaction coordinates toward CH2O is 109.3 kJ/mol. Since Pd-based catalysts are known to be efficient catalysts for CH4 combustion by O2, our result agrees with the previous reports3,53,57,59. Thus, the activity of Pd-based catalysts (Pd-loaded Al2O3 and Pd-exchanged zeolite) for CH4 + O3 reaction will be experimentally tested later. Consequently, we predicted that BASs were the most effective among the virtually screened active sites for CH4 + O3. In the next section, we discussed the preferable property of BAS, as well as the detailed mechanism of decreasing Ea.

Promotion effect of BAS on the CH4 + O3 reaction

We investigated the effect of the acid strength of BASs of the mineral acids on the Ea of CH4 + O3. H2SO4, perchloric acid (HClO4), nitric acid (HNO3), and phosphoric acid (H3PO4) were evaluated as BASs exhibiting different acidities. The initial structure (IS), final structure (FS), and TS are shown in Supplementary Fig. S7. The Ea of the strong acids (128.4 and 126.2 kJ/mol for HClO4 and H2SO4, respectively) are lower than that of the uncatalyzed reaction (142.7 kJ/mol), which is close to the value for a weak acid (142.2 and 138.8 kJ/mol for H3PO4 and HNO3, respectively).

To quantitatively evaluate the impact of the acid property, the Ea of the CH4 + O3 reaction are plotted as a function of the stabilization energy of C5H5N on BASs (Epyr), as determined by DFT calculations. Notably, the adsorption of C5H5N on BAS of solid material has been widely applied to experimentally and theoretically analyze its acidity60,61,62. The values of Epyr for HClO4, H2SO4, HNO3, and H3PO4 are −94.3, −91.1, −70.9, and −76.2 kJ/mol, respectively. This result corresponds to their experimentally obtained deprotonation enthalpies (see Supplementary Table S1). Figure 4d shows that the Ea of the CH4 + O3 reaction on BASs decreased with the increasing acid strengths, indicating that relatively strong BASs correspond to higher reaction rates for the CH4 + O3 reaction. To understand the activation mechanism within the frontier orbital theory, the projected crystal orbital Hamilton population (pCOHP) of an isolated O3 molecule was analyzed and described in Fig. 5a. There are two anti-bonding orbitals around the Fermi level (EF) in the pCOHP curve of O–O bond. In the visualization of their orbitals, lower and higher energies show π* and σ* characters, respectively. Since they have anti-bonding character, it is expected that more electron charge transfer to them induces weakening of the O–O bond. Figure 5b, c shows the Bader charge of O1 atom and the bond length of O1–O2 bond, respectively, against Epyr in TS structure of CH4 + O3 reaction (the representative TS structure is shown in Fig. 5d and others are shown in supplementary Fig. S8). By increasing Epyr, the charge of O1 atom increases while O1–O2 bond is elongated, indicating that the O3 molecule was more activated on the acids with higher Epyr. A schematic description of the activation scheme is shown in Fig. 5e. By the electrostatic interaction between BAS and O1 atom, the charge transfer to O1 atom occurs, resulting in the elongation of O1–O2 bond, and thus, the BASs with high Epyr efficiently decrease the Ea of CH4 + O3 reaction.

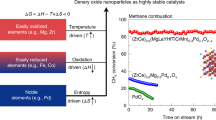

a Employed periodic model of the ß zeolite. b Structure of the adsorption of C5H5N on BAS of ß zeolite. c TS calculations of the CH4 + O3 reaction on BAS of the ß zeolite. ΔE is reported in the kJ/mol unit. Ea is shown in dark red. d Plot of Ea of the CH4 + O3 reaction as a function of the C5H5N-stabilization energy (Epyr) of the acids. e CH4 consumption rate of the samples in 0.1% CH4 + 0.7% O3 at 250 °C (He balance, total flow: 100 ml/min) as a function of Epyr.

a The projected crystal orbital Hamilton population (pCOHP) curve for the O–O bond in the isolated O3 molecule. b Bader charge of O1 atom and c O1–O2 bond length in TS structures against Epyr (shown in supplementary Fig. S8). d TS structure of CH4 + O3 reaction over H2SO4 molecule. Bader charge of O1 atom and bond lengths are shown together. e The schematic description of O–O bond activation scheme.

Inspired by the gained insight into BASs as active sites, a proton-type zeolite (ß-type) was theoretically examined for the adsorption of C5H5N (Fig. 4a, b). The result indicates the higher Epyr of the zeolite (Epyr = −199.8 kJ/mol) than that of H2SO4 (−91.1 kJ/mol). Note that Epyr reflects not only the strength of acidity but also the confinement effect of the zeolite cage that also probably affects the CH4 combustion reaction63,64. The extrapolation of the linear relationship between Epyr and Ea of the mineral acids indicates that the zeolite might achieve an extremely low Ea (~60 kJ/mol). To verify this hypothesis, we conducted TS calculations for the CH4 + O3 reaction on the BAS of the zeolite. Figure 4c shows the optimized structures of IS, TS, and FS. As expected from the strong acidity of the zeolite, the computed Ea (71.2 kJ/mol) is considerably lower than those for the mineral acids (126.2–142.2 kJ/mol).

Next, we experimentally verified the theoretically predicted relationship between the Ea and Epyr of the CH4 + O3 reaction. The mineral acid (3 wt% H2SO4, HClO4, HNO3, or H3PO4) was loaded onto an SiO2 support and tested for the reaction in a 0.1% CH4 + 0.7% O3 flow (total flow: 100 ml/min, He balance) at 250 °C employing a fixed-bed flow reactor (the volatility of the acid was examined by H2O on-off switching test; Fig. S10). The concentrations of CH4 and O3 in the outlet gas were monitored by a gas cell that was equipped with an infrared spectroscope (Supplementary Fig. S9 shows the illustration of the experimental setup). Their CH4 conversion was maintained for 30 min. The obtained CH4 consumption rates are plotted as a function of Epyr (Fig. 4e). Interestingly, the observed consumption rates correlate moderately with Epyr. Next, an Hß zeolite with a relatively low Si/Al ratio (8.5) (Hß8.5) was tested via the same reaction. Therein, Hß8.5 achieves an extremely higher consumption rate than H2SO4, demonstrating the highest rate among the tested catalysts. The above results demonstrate that the high CH4-combustion activity of a strong BAS-based catalyst, Hß8.5, could be rationally predicted based on computational mapping of the reaction network, as well as TS calculations. In the next section (Performance of the Hß-catalyzed CH4 combustion with O3), we experimentally demonstrate the superior performance of Hß8.5 by comparing it with Pd5Al2O3 as a conventional catalyst.

Performance of the Hß-catalyzed CH4 combustion with O3

We conducted catalytic tests to experimentally demonstrate the catalytic performance of Hß8.5. Figure 6a shows the conversions of CH4 over Hß8.5 and a benchmark catalyst (Pd5Al2O3) in a flow of 0.1% CH4 + 5.95% O2 + 0.7% O3 at different temperatures. In 0.1% CH4 + 10% O2, Hß8.5 did not achieve CH4 conversion in the entire temperature range, indicating the necessity of O3 as the oxidant. In 0.1% CH4 + 5.95% O2 + 0.7% O3, Hß8.5 achieved the high conversion of CH4 at 200 °C, while Pd5Al2O3 required a temperature of >400 °C to achieve comparable performance. At >250 °C, the conversion of CH4 over Hß8.5 decreased because O3 conversion had reached 100% via self-decomposition (Fig. 5b). To evaluate the effect of Pd loading into zeolites, Pd-exchanged ß8.5 zeolite (Pdß8.5) was prepared and then tested, resulting in low CH4 conversion in the low-temperature region due to full decomposition of O3 similar to the result of Pd5Al2O3 (Supplementally Fig. S11). The effect of BAS on the self-decomposition of O3 into O2 (2O3 → 3O2) was theoretically investigated because this reaction represented an obstacle to the practical application of O3 as an oxidant. Supplementary Fig. S12 compares the optimized TS structures of the uncatalyzed and Hß-catalyzed decompositions of O3. The calculated Ea of the uncatalyzed and Hß-catalyzed reactions are 42.3 and 69.5 kJ/mol, respectively, indicating that BAS in zeolite do not promote the self-decomposition of O3. This property is desirable in catalysts for CH4 combustion by O3. Dissimilar to Hß8.5, Pd5Al2O3 exhibited high activity toward O3 decomposition (complete conversion even at 50 °C); hence, the addition of O3 did not increase the CH4 combustion activity of Pd5Al2O3.

a CH4 and b O3 conversions over 40 mg of the Hß zeolite with an Si/Al ratio of 8.5 (Hß8.5) and 40 mg of 5 wt% Pd-loaded Al2O3 (Pd5Al2O3) in 0.1% CH4 + 5.95% O2 + 0.7% O3 and 0.1% CH4 + 10% O2 flows as functions of the reaction temperature. c Conversions of CH4 and O3 over 40 mg of the Hß zeolite with different Si/Al ratios (8.5, 12.5, 20, and 255) in a 0.1% CH4 + 5.95% O2 + 0.7% O3 flow at 150 °C, together with the amount of BAS in the ß zeolite, as evaluated via NH3-adsorption measurements. d Arrhenius plots for the combustions of CH4 over Hß8.5 in 0.1% CH4 + 5.95% O2 + 0.7% O3 at 160–190 °C, as well as over Pd5Al2O3 in 0.1% CH4 + 10% O2 at 170–220 °C. The reaction rates (VCH4) at 190 °C over Hß8.5 and Pd5Al2O3 are shown together (R2 = 0.99 for both catalyst). e Time course of CH4 conversion over 40 mg of Pd5Al2O3 (at 400 °C) and Hß8.5 (at 200 °C) in 0.1% CH4 + 3% H2O + 40 ppm SO2 + 10% O2 or 5.95% O2 + 0.7% O3 for Pd5Al2O3 and Hß8.5, respectively, with He balance (total flow: 100 ml/min). f Long-term reaction test for 10 mg of Hß8.5 in 0.1% CH4 + 5.95% O2 + 0.7% O3 + 3% H2O + 40 ppm SO2 at 200 °C.

Figure 5c shows a plot of the conversions of CH4 and O3, as well as the BAS amounts, as evaluated by NH3-adsorption measurement as a function of the Si/Al ratio of the utilized ß zeolites (Si/Al = 8.5, 12.5, 20, and 255). Evidently, the Al-rich ß zeolites with more BASs exhibited higher CH4 conversions, which is consistent with the proposal from DFT calculation above. The Arrhenius plot of the Hß8.5-catalyzed CH4 combustion with O3 (Fig. 5d) revealed an apparent barrier (Ea) of 75 kJ/mol, which agrees with the theoretical value of the CH4 + O3 reaction to yield CH3OH (Ea = 71.2 kJ/mol). The Ea of Hß8.5 was considerably lower than that of Pd5Al2O3 (Ea = 95 kJ/mol) in 0.1% CH4 + 10% O2. Supplementary Fig. S13 shows the results of the kinetic analyses for estimating the reaction orders. The reaction orders of CH4 (0.2) and O3 (0.2) were positive. Further, the reaction rates per weight of the catalyst (for Hß8.5 and Pd5Al2O3) for CH4 conversion (VCH4) at 190 °C were compared, and the result indicated that VCH4 of Hß8.5 (57.5 mmol h−1 gcat−1) was 442 times higher than that of Pd5Al2O3 (0.13 mmol h−1 gcat−1), demonstrating that the found main-group catalyst (Hß8.5) exhibited considerably higher activity toward CH4 combustion than the PGM-based benchmark catalyst (scientific literature on the same reaction using proton-type zeolite are limited, and thus, it is difficult to compare with the previous reports.).

Further, Hß8.5 and Pd5Al2O3 were tested for CH4 combustion in the co-presence of H2O and SO2 to compare their resistance to steam and SOx poisoning. Figure 5f shows the time course of CH4 combustion over 40 mg of Hß8.5 (5.95% O2 + 0.7% O3 at 200 °C) and Pd5Al2O3 (10% O2 at 400 °C) in 0.1% CH4 + 3% H2O + 40 ppm SO2. By feeding H2O and SO2, the CH4 conversion at 400 °C over Pd5Al2O3 decreased with the reaction time, reaching almost zero after 10 h. Conversely, the CH4 conversion over Hß8.5 did not decrease at 200 °C even after 15 h, indicating that Hß8.5 was highly resistant to steam and SO2 poisoning. Finally, 10 mg of Hß8.5 was examined for the long-term reaction test in 0.1% CH4 + 5.95% O2 + 0.7% O3 + 3% H2O + 40 ppm SO2 at 200 °C, and the result indicated that the catalyst did not significantly decrease the CH4 conversion for 170 h of reaction time.

To investigate the mechanism of the catalytic CH4 combustion by O3 in the realistic condition, ab initio molecular dynamics (AIMD) was additionally carried out for CH4 and O3 separately. During the simulation, the O3 molecule frequently interacted with BASs and was present near the sites. In contrast, the CH4 molecule diffused throughout the zeolite cage and less frequently interacted with BASs. In fact, the calculated mean diffusion coefficient of the O3 molecule is 5.0 × 10−4 Å2/fs in the simulation, while that of the CH4 molecule is 8.4 × 10−4 Å2/fs. These results indicate that, in realistic conditions, the O3 molecule is present near BASs, and once CH4 reaches the sites, CH4 and O3 react to form CH3OH and O2.

Discussion

In this study, we rationally designed a catalyst for low-temperature O3-driven catalytic combustion of CH4 based on the elucidation of an unexplored reaction network. The CH4 + O3 reaction toward generating CO2 was explored via SC-AFIR, and the formation of CH3OH via CH4 + O3 (CH4 + O3 → CH3OH + O2) was determined as RDS of CH4 combustion (Ea = 142.7 kJ/mol). To assess the various types of active sites (acid, base, redox, and radical sites), model molecules (H2SO4, C5H5N, a Cu atom, and HNO3) were introduced into the system, and reaction route was calculated. Among the examined active sites, H2SO4 effectively decreased the reaction (Ea = 126.2 kJ/mol); thus, different Brønsted acid catalysts with different acid strengths were examined for the TS calculation. The relationship between the acidity and calculated Ea of the CH4 + O3 reaction (CH3OH formation) availed a facile catalyst design concept; the stronger the BASs afford the higher the catalytic activity. Thereafter, the theory-driven concept was experimentally verified by CH4 combustion with O3 at 250 °C. An Hß zeolite, which was the most effective candidate, as predicted by this concept, was experimentally tested for the CH4 + O3 reaction. The apparent activation energy (75 kJ/mol), which was estimated by the kinetic experiment, was consistent with the computed value (71.2 kJ/mol). Hß exhibited a very high reaction rate, which was 442 times higher than that of the benchmark catalyst, Pd5Al2O3, at 190 °C. During the catalytic tests in the presence of SO2 and H2O, Hß achieved the full conversion of CH4 at 190 °C, whereas Pd5Al2O3 was completely deactivated even at a higher temperature (400 °C) owing to the poisoning of its active sites by water and SO2. Finally, the developed catalyst (Hß zeolite) was tested in a 170-h long-term reaction that exhibited very high resistance against water and SO2.

In summary, O3, which was determined as an efficient oxidant, oxidized CH4 into CH3OH as the RDS. Among the considered active sites, BAS in H2SO4 molecule efficiently decreased the activation barrier of CH3OH formation. After stronger BASs were evaluated to be promising theoretically and experimentally, proton-type zeolite, comprising strong BASs, was experimentally tested; Hß zeolite exhibited the superior CH4 combustion rate in the presence of O3. These results demonstrated that a computationally designed catalysis based on earth-abundant metal elements (Si and Al) and alternative oxidants could achieve higher activities and durabilities compared with their PGM-based ones for low-temperature CH4 combustion.

Methods

DFT calculations

Spin-polarized DFT calculations were performed employing the generalized-gradient approximation of Perdew–Burke–Ernzerhof functional65, as implemented in the Vienna Ab Initio Simulation Package66,67 (VASP), and the projected augmented waves68,69 method was employed for the Kohn–Sham equations with cut-off energy of 500 eV. The Γ point was employed for the Brillouin-zone sampling70. DFT-D3 dispersion correction with the Becke–Johnson damping was employed for all the calculations71. To simulate the gas-phase reaction, calculations were conducted within a large cubic cell (a = b = c = 15 Å). The structure of the β zeolite was obtained from the International Zeolite Association database72, and the lattice constants were fixed at initial values (a = b = 12.632 Å, c = 26.186 Å, α = β = γ = 90.0°) during the calculations. The SC-AFIR method, as implemented in the GRRM17 program38, was applied for reaction route mapping with a model collision energy parameter of 1000 kJ/mol. Only a positive force was applied for the AFIR calculations. The H, O, and C atoms in the CH4 and O3 molecules were considered the targets of SC-AFIR. The locally updated plane method availed the path top points, which were subsequently optimized as TS structures and determined by the following intrinsic reaction coordinate calculation73. To calculate for the β zeolite, the atoms of the zeolitic framework, except for the Al atom, as well as the Si atoms adjacent to the Al and O atoms connecting to the adjacent Si, and H atoms of BAS were fixed at the crystallographic position (Fig. 4b). The stabilization energy of C5H5N was defined, as follows:

Thus, the total energies of the models including a C5H5N molecule, acid molecules, and C5H5N interacting with the acid molecules were described as EC5H5N, EBAS, and EC5H5N on BAS, respectively. The pCOHP74 was calculated by LOBSTER software75. The molecular orbitals were visualized with the VASPMO code76. The structures are visualized by VESTA software77. AIMD simulation was performed within the periodic-boundary condition as implemented in CP2K package78. The spin-unrestricted DFT calculation was carried out using the Perdew–Burke–Ernzerhof functional65 within the generalized-gradient approximation. The valence electrons were described by the double-ζ valence plus polarization basis sets of the MOLOPT type79, and the core electrons were represented by the Goedecker–Teter–Hutter pseudopotentials80,81. The energy cutoff was set to 500 Ry. Only the Γ-point was employed for the Brillouin zone integration. The Born–Oppenheimer MD simulation was carried out with the canonical (NVT) ensemble condition using the Nóse−Hoover thermostat to control the temperature. The time step was set to 1 fs. After equilibrating for 1 ps, 50 ps of the simulation was performed for each model comprising one CH4 or O3 molecule, respectively.

Catalysts preparations

1 g of proton-type (H) β zeolite with a Si/Al ratio of 8.5 (Hβ 8.5) was obtained via the calcination of an NH4+-type β zeolite that was purchased from Tosoh Co. (HSZ-920NHA) in the air at 500 °C. The 1 g of Hβ zeolites with Si/Al ratios of 20 and 255 (HSZ-940HOA and HSZ-980HOA, respectively) were supplied by Tosoh Co., and another with a Si/Al ratio of 12.5 was supplied by the Catalysis Society of Japan (JRC-Z-HΒ25). Note that the impurity of Hβ8.5 was checked by ICP measurement, and Fe, Co, Ni, Cu, and Zn were not detected (<0.01 wt%). Acid-load SiO2 was prepared via impregnation method. 0.2 g of SiO2 (CARiACT G–6, Fuji Silysia, SBET = ca. 500 m2 g–1) was suspended in an 0.5 M aqueous solution of H2SO4, HClO4, H3PO4, and HNO3 at room temperature. The water was evaporated at 50 °C from the mixture and dried in an oven at 90 °C. 1 g of Al2O3 was prepared by calcining γ-AlOOH (Catapal B Alumina, Sasol) for 3 h at 900 °C. Next, 1.05 g of 5 wt% Pd-loaded Al2O3 was prepared by impregnating 1 g of Al2O3 with an 0.005 M aqueous HNO3 solution Pd(NH3)2(NO3)2. 0.5 g of Pd-exchanged ß zeolite (Pdß8.5) was prepared by exchanging NH4+− ß8.5 with an 0.005 M aqueous solution of [Pd(NH3)4]Cl2 at room temperature for 20 h, followed by centrifuging and washing with deionized water, drying (100 °C, 20 h), and by calcining (500 °C, 1 h, in the air).

Catalytic test

The catalytic test was conducted under in 0.1% CH4 + 0.7% O3 + 5.95% O2 (He balance, total flow:100 ml/min) as a typical condition. 40 mg of catalyst powder was set in the fixed-bed reactor using quartz wool and the outlet was directly connected to a JASCO FT/IR-4600 spectrometer that was equipped with a triglycine sulfate (TGS) detector, in which a homemade infrared (IR) gas cell, which was equipped with KBr windows, was placed to monitor the concentrations of CH4 and O3. For kinetic analysis, 5 mg of Hβ 8.5 was used to keep CH4 conversion under 40%. The IR area of O3 was calibrated employing an O3 analyzer (EG-550, EcoDesign Inc.) to convert the area into concentration. To feed O3 into the system, an O2 flow was passed through an ozonizer (F0G-AC5G, EcoDesign Inc.) that was placed before the mainstream. The whole view of the employed setup is shown in Supplementary Fig. S9. The NH3-adsorption measurement was carried out by Infrared spectroscopy (JASCO FT/IR-4200 spectrometer using a home-made in situ IR cell. The catalyst disc of the zeolite sample (40 mg,) was dehydrated under He flow at 500 °C before a background spectrum was recorded under a flow of He at 200 °C. Then, NH3 (1%) flowed to the sample, followed by He purging before IR spectrum was taken at 200 °C.

Statistics and reproducibility

The experiments were not randomized.

Data availability

The source data, which support the result of this study, can be found in the manuscript and Supplementary information. Data are available from the corresponding author upon request.

Code availability

The VASP code package used in this work can be accessible after a user license is authorized by the VASP company (https://www.vasp.at). LOBSTER, VASPMO, VESTA, and CP2K codes can be freely accessible from the websites (LOBSTER: http://www.cohp.de, VASPMO: https://sourceforge.net/projects/vaspmo/, VESTA: https://jp-minerals.org/vesta/en/, and CP2K: https://www.cp2k.org). AIMD simulation was carried out using Quickstep module in CP2K code.

References

Petrov, A. W. et al. Stable complete methane oxidation over palladium based zeolite catalysts. Nat. Commun. 9, 2545 (2018).

Petrov, A. W., Ferri, D., Tarik, M., Kröcher, O. & van Bokhoven, J. A. Deactivation aspects of methane oxidation catalysts based on palladium and ZSM-5. Top. Catal. 60, 123–130 (2017).

Jiang, D., Khivantsev, K. & Wang, Y. Low-temperature methane oxidation for efficient emission control in natural gas vehicles: Pd and beyond. ACS Catal. 10, 14304–14314 (2020).

Mahara, Y., Tojo, T., Murata, K., Ohyama, J. & Satsuma, A. Methane combustion over Pd/CoAl2O4 /Al2O3 catalysts prepared by galvanic deposition. RSC Adv. 7, 34530–34537 (2017).

Colussi, S., Fornasiero, P. & Trovarelli, A. Structure-activity relationship in Pd/CeO2 methane oxidation catalysts. Chin. J. Catal. 41, 938–950 (2020).

Xiong, H. et al. Engineering catalyst supports to stabilize PdOx two-dimensional rafts for water-tolerant methane oxidation. Nat. Catal. 4, 830–839 (2021).

Losch, P. et al. Modular Pd/zeolite composites demonstrating the key role of support hydrophobic/hydrophilic character in methane catalytic combustion. ACS Catal. 9, 4742–4753 (2019).

Arai, H., Yamada, T., Eguchi, K. & Seiyama, T. Catalytic combustion of methane over various perovskite-type oxides. Appl Catal. 26, 265–276 (1986).

Ferri, D. & Forni, L. Methane combustion on some perovskite-like mixed oxides. Appl Catal. B 16, 119–126 (1998).

Tao, F. F. et al. Understanding complete oxidation of methane on spinel oxides at a molecular level. Nat. Commun. 6, 7798 (2015).

He, L., Fan, Y., Bellettre, J., Yue, J. & Luo, L. A review on catalytic methane combustion at low temperatures: catalysts, mechanisms, reaction conditions and reactor designs. Renew. Sustain. Energ. Rev. 119, 109589 (2020).

Goodman, E. D. et al. Catalyst deactivation via decomposition into single atoms and the role of metal loading. Nat. Catal. 2, 748–755 (2019).

Yang, W. et al. A review on the impact of SO2 on the oxidation of NO, hydrocarbons, and CO in diesel emission control catalysis. ACS Catal. 11, 12446–12468 (2021).

Hou, Z. et al. Electronically engineering water resistance in methane combustion with an atomically dispersed tungsten on PdO catalyst. Angew. Chem. Int. Ed. 61, e202201655 (2022).

Keenan, M. et al. The catalytic challenges of implementing a Euro VI heavy duty emissions control system for a dedicated lean operating natural gas engine. Top. Catal. 62, 273–281 (2019).

Nuss, P. & Eckelman, M. J. Life cycle assessment of metals: a scientific synthesis. PLoS One 9, 1–12 (2014).

Bullock, R. M. et al. Using nature’s blueprint to expand catalysis with Earth-abundant metals. Science 369, 2020 (1979).

Stocker, S., Csányi, G., Reuter, K. & Margraf, J. T. Machine learning in chemical reaction space. Nat. Commun. 11, 1–11 (2020).

Kreitz, B. et al. Quantifying the impact of parametric uncertainty on automatic mechanism generation for CO2 hydrogenation on Ni(111). JACS Au 1, 1656–1673 (2021).

Lan, T. & An, Q. Discovering catalytic reaction networks using deep reinforcement learning from first-principles. J. Am. Chem. Soc. 143, 16804–16812 (2021).

Nakao, A., Harabuchi, Y., Maeda, S. & Tsuda, K. Leveraging algorithmic search in quantum chemical reaction path finding. Phys. Chem. Chem. Phys. 24, 10305–10310 (2022).

Xu, J., Cao, X. M. & Hu, P. Perspective on computational reaction prediction using machine learning methods in heterogeneous catalysis. Phys. Chem. Chem. Phys. 23, 11155–11179 (2021).

Fu, X., Li, J., Long, J., Guo, C. & Xiao, J. Understanding the product selectivity of syngas conversion on ZnO surfaces with complex reaction network and structural evolution. ACS Catal. 11, 12264–12273 (2021).

He, Z., Li, X. B., Liu, L. M. & Zhu, W. The intrinsic mechanism of methane oxidation under explosion condition: a combined ReaxFF and DFT study. Fuel 124, 85–90 (2014).

Hannagan, R. T. et al. First-principles design of a single-atom—alloy propane dehydrogenation catalyst. Science 372, 1444–1447 (2021).

Ulissi, Z. W., Medford, A. J., Bligaard, T. & Nørskov, J. K. To address surface reaction network complexity using scaling relations machine learning and DFT calculations. Nat. Commun. 8, 1–7 (2017).

Latimer, A. A. et al. Understanding trends in C-H bond activation in heterogeneous catalysis. Nat. Mater. 16, 225–229 (2017).

Schweitzer, J.-M. et al. Multiscale modeling as a tool for the prediction of catalytic performances: the case of n-heptane hydroconversion in a large-pore zeolite. ACS Catal. 12, 1068–1081 (2022).

Bruix, A., Margraf, J. T., Andersen, M. & Reuter, K. First-principles-based multiscale modelling of heterogeneous catalysis. Nat. Catal. 2, 659–670 (2019).

Ohno, K. & Maeda, S. Global reaction route mapping on potential energy surfaces of formaldehyde, formic acid, and their metal-substituted analogues. J. Phys. Chem. A 110, 8933–8941 (2006).

Maeda, S., Ohno, K. & Morokuma, K. Systematic exploration of the mechanism of chemical reactions: the global reaction route mapping (GRRM) strategy using the ADDF and AFIR methods. Phys. Chem. Chem. Phys. 15, 3683–3701 (2013).

Maeda, S., Komagawa, S., Uchiyama, M. & Morokuma, K. Finding reaction pathways for multicomponent reactions: the passerini reaction is a four-component reaction. Angew. Chem. - Int. Ed. 50, 644–649 (2011).

Maeda, S., Taketsugu, T., Ohno, K. & Morokuma, K. From roaming atoms to hopping surfaces: mapping out global reaction routes in photochemistry. J. Am. Chem. Soc. 137, 3433–3445 (2015).

Maeda, S., Harabuchi, Y., Ono, Y., Taketsugu, T. & Morokuma, K. Intrinsic reaction coordinate: calculation, bifurcation, and automated search. Int J. Quantum Chem. 115, 258–269 (2015).

Maeda, S., Sugiyama, K., Sumiya, Y., Takagi, M. & Saita, K. Global reaction route mapping for surface adsorbed molecules: a case study for H2O on Cu(111) surface. Chem. Lett. 47, 396–399 (2018).

Sugiyama, K., Sumiya, Y., Takagi, M., Saita, K. & Maeda, S. Understanding CO oxidation on the Pt(111) surface based on a reaction route network. Phys. Chem. Chem. Phys. 21, 14366–14375 (2019).

Yoshimura, T. et al. Exploring the full catalytic cycle of rhodium(i)-BINAP-catalysed isomerisation of allylic amines: a graph theory approach for path optimisation. Chem. Sci. 8, 4475–4488 (2017).

Maeda, S. et al. Implementation and performance of the artificial force induced reaction method in the GRRM17 program. J. Comput. Chem. 39, 233–250 (2018).

Hayashi, H. et al. Synthesis of difluoroglycine derivatives from amines, difluorocarbene, and CO2: computational design, scope, and applications. Chem. Eur. J. 27, 1–9 (2021).

Mita, T., Harabuchi, Y. & Maeda, S. Discovery of a synthesis method for a difluoroglycine derivative based on a path generated by quantum chemical calculations. Chem. Sci. 11, 7569–7577 (2020).

Sugiyama, K., Saita, K. & Maeda, S. A reaction route network for methanol decomposition on a Pt(111) surface. J. Comput. Chem. 42, 2163–2169 (2021).

Oyama, S. T. Chemical and catalytic properties of ozone. Catal. Rev. Sci. Eng. 42, 279–322 (2000).

Sugasawa, M. & Ogata, A. Effect of different combinations of metal and zeolite on ozone-assisted catalysis for toluene removal. Ozone Sci. Eng. 33, 158–163 (2011).

Kim, H. H. et al. Ozone-assisted catalysis of toluene with layered ZSM-5 and Ag/ZSM-5 zeolites. Plasma Chem. Plasma Process. 33, 1083–1098 (2013).

Chao, C. Y. H., Kwong, C. W. & Hui, K. S. Potential use of a combined ozone and zeolite system for gaseous toluene elimination. J. Hazard. Mater. 143, 118–127 (2007).

Xi, Y., Reed, C., Lee, Y. K. & Oyama, S. T. Acetone oxidation using ozone on manganese oxide catalysts. J. Phys. Chem. B 109, 17587–17596 (2005).

Reed, C., Xi, Y. & Oyama, S. T. Distinguishing between reaction intermediates and spectators: a kinetic study of acetone oxidation using ozone on a silica-supported manganese oxide catalyst. J. Catal. 235, 378–392 (2005).

Einaga, H. & Futamura, S. Catalytic oxidation of benzene with ozone over alumina-supported manganese oxides. J. Catal. 227, 304–312 (2004).

Einaga, H., Maeda, N. & Teraoka, Y. Effect of catalyst composition and preparation conditions on catalytic properties of unsupported manganese oxides for benzene oxidation with ozone. Appl. Catal. B 142–143, 406–413 (2013).

Božović, A. et al. Conversion of methane to methanol: Nickel, palladium, and platinum (d 9) cations as catalysts for the oxidation of methane by ozone at room temperature. Chem. Eur. J. 16, 11605–11610 (2010).

McDonald, D. C. et al. Temperature and isotope dependent kinetics of nickel-catalyzed oxidation of methane by ozone. J. Phys. Chem. A 122, 6655–6662 (2018).

Dillemuth, F. J., Skidmore, D. R. & Schubert, C. C. The reaction of ozone with methane. J. Phys. Chem. 64, 1496–1499 (1960).

Hui, K. S., Kwong, C. W. & Chao, C. Y. H. Methane emission abatement by Pd-ion-exchanged zeolite 13X with ozone. Energy Environ. Sci. 3, 1092–1098 (2010).

Keenan, M., Nicole, J. & Poojary, D. Ozone as an enabler for low temperature methane control over a current production Fe-BEA catalyst. Top. Catal. 62, 351–355 (2019).

Jin, S. M., Lee, K. Y. & Lee, D. W. Ozone-induced lean methane oxidation over cobalt ion-exchanged BEA catalyst under dry reaction conditions. J. Ind. Eng. Chem. 112, 296–306 (2022).

Ito, Y. Methane purification method and methance purification system. JPA P2017-170309A (2017).

Wan, M. P., Hui, K. S., Chao, C. Y. H. & Kwong, C. W. Catalytic combustion of methane with ozone using Pd-exchanged zeolite X: experimental investigation and kinetics model. Combust. Sci. Technol. 182, 1429–1445 (2010).

Mahyuddin, M. H., Shiota, Y., Staykov, A. & Yoshizawa, K. Theoretical investigation of methane hydroxylation over isoelectronic [FeO]2+- and [MnO]+-exchanged zeolites activated by N2O. Inorg. Chem. 56, 10370–10380 (2017).

Gannouni, A., Michel, C., Delbecq, F., Zina, M. S. & Sautet, P. DFT investigations for the catalytic reaction mechanism of methane combustion occurring on Pd(ii)/Al-MCM-41. Phys. Chem. Chem. Phys. 20, 25377–25386 (2018).

Liu, C., Tranca, I., van Santen, R. A., Hensen, E. J. M. & Pidko, E. A. Scaling relations for acidity and reactivity of zeolites. J. Phys. Chem. C. 121, 23520–23530 (2017).

Sandoval-Díaz, L. E., González-Amaya, J. A. & Trujillo, C. A. General aspects of zeolite acidity characterization. Microporous Mesoporous Mater. 215, 229–243 (2015).

Farneth, W. E. & Gorte, R. J. Methods for characterizing zeolite acidity. Chem. Rev. 95, 615–635 (1995).

Boronat, M. & Corma, A. What is measured when measuring acidity in zeolites with probe molecules? ACS Catal. 9, 1539–1548 (2019).

Grifoni, E. et al. Confinement effects and acid strength in zeolites. Nat. Commun. 12, 2630 (2021).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Kresse, G. & Hafner, J. Ab initio molecular dynamics for open-shell transition metals. Phys. Rev. B 48, 13115–13118 (1993).

Kresse, G. & Hafner, J. Ab initio molecular-dynamics simulation of the liquid-metal–amorphous-semiconductor transition in germanium. Phys. Rev. B 49, 14251–14269 (1994).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Kresse, G., Joubert, D., Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188–5192 (1976).

Grimme, S., Ehrlich, S. & Goerigk, L. Effect of the damping function in dispersion corrected density functional theory. J. Comput Chem. 32, 1456–1465 (2011).

Baerlocher, C., McCusker, L.B., van Koningsveld, H. Database of zeolite structures; http://www.iza-structure.org/databases/ (accessed Jun 2021).

Fukui, K. The path of chemical reactions—the IRC Approach. Acc. Chem. Res. 14, 363 (1981).

Dronskowski, R. & Blochl, P. E. Crystal orbital hamilton populations (COHP). Energy-resolved visualization of chemical bonding in solids based on density-functional calculations. J. Phys. Chem. 97, 8617–8624 (1993).

Maintz, S., Deringer, V. L., Tchougréeff, A. L. & Dronskowski, R. LOBSTER: a tool to extract chemical bonding from plane-wave based DFT. J. Comput. Chem. 37, 1030–1035 (2016).

Wang, Y. VASPMO, version 0.41., 2021.

Momma, K. & Izumi, F. VESTA 3 for three-dimensional visualization of crystal, volumetric and morphology data. J. Appl. Crystallogr. 44, 1272–1276 (2011).

Vandevondele, J. et al. Quickstep: Fast and accurate density functional calculations using a mixed Gaussian and plane waves approach. Comput. Phys. Commun. 167, 103–128 (2005).

VandeVondele, J. & Hutter, J. Gaussian basis sets for accurate calculations on molecular systems in gas and condensed phases. J. Chem. Phys. 127, 114105 (2007).

Goedecker, S. & Teter, M. Separable dual-space Gaussian pseudopotentials. Phys. Rev. B Condens. Matter Mater. Phys. 54, 1703–1710 (1996).

Hartwigsen, C., Goedecker, S. & Hutter, J. Relativistic separable dual-space Gaussian pseudopotentials from H to Rn. Phys. Rev. B 58, 3641–3662 (1998).

Acknowledgements

This research was financially supported by JST-CREST (JPMJCR17J3) and JSPS KAKENHI (21H04626) grants. Some of the calculations were conducted employing the supercomputing resources at the Cyberscience Center of Tohoku University. This research was also supported by the Joint Usage/Research Center for Catalysis. S.Y. is grateful to the MANABIYA system of the Institute for Chemical Reaction Design and Discovery (ICReDD) of Hokkaido University, which was established by the World Premier International Research Initiative (WPI), MEXT, Japan, to support the learning of the GRRM program techniques for DFT calculations. This research is one of the projects promoted by the Research Association of Automotive Internal Combustion Engines (AICE) and is financially supported by the Japan Ministry of Economy, Trade, and Industry. The authors acknowledge the Technical Division of the Institute for Catalysis of Hokkaido University. S.Y. acknowledges the Grant-in-Aid for JSPS Fellows (21J11744, DC2).

Author information

Authors and Affiliations

Contributions

S.Y. wore the draft and carried out DFT calculations as well as the most of experiments. K.Sa. and T.Ta. deeply discussed the applied computational approach and critically supported for utilization of GRRM program. T.M. and K.N. conducted the kinetic analysis for CH4 combustion reaction. K.K. prepared the catalysts and performed NH3 adsorption measurements. K.Sa, T.Ta, T.To., and Z.M. critically revised the manuscript. K.Sh. designed and supervised the whole project.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Qi An and the other, anonymous, reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Yasumura, S., Saita, K., Miyakage, T. et al. Designing main-group catalysts for low-temperature methane combustion by ozone. Nat Commun 14, 3926 (2023). https://doi.org/10.1038/s41467-023-39541-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-023-39541-y

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.