Abstract

Photochemical conversion of CO2 into high-value C2+ products is difficult to achieve due to the energetic and mechanistic challenges in forming multiple C-C bonds. Herein, an efficient photocatalyst for the conversion of CO2 into C3H8 is prepared by implanting Cu single atoms on Ti0.91O2 atomically-thin single layers. Cu single atoms promote the formation of neighbouring oxygen vacancies (VOs) in Ti0.91O2 matrix. These oxygen vacancies modulate the electronic coupling interaction between Cu atoms and adjacent Ti atoms to form a unique Cu-Ti-VO unit in Ti0.91O2 matrix. A high electron-based selectivity of 64.8% for C3H8 (product-based selectivity of 32.4%), and 86.2% for total C2+ hydrocarbons (product-based selectivity of 50.2%) are achieved. Theoretical calculations suggest that Cu-Ti-VO unit may stabilize the key *CHOCO and *CH2OCOCO intermediates and reduce their energy levels, tuning both C1-C1 and C1-C2 couplings into thermodynamically-favourable exothermal processes. Tandem catalysis mechanism and potential reaction pathway are tentatively proposed for C3H8 formation, involving an overall (20e− – 20H+) reduction and coupling of three CO2 molecules at room temperature.

Similar content being viewed by others

Introduction

Using sunlight to generate fuels from CO2 and water has the potential to reduce CO2 emissions and facilitate the large-scale storage of renewable energy1,2,3,4,5. Currently, light-driven reduction of CO2 is mainly limited to two-electron-reduced CO and further reduced C1 hydrocarbons such as methane (CH4)6,7 and C2 products such as ethene (C2H4)8 and ethane (C2H6)9 in few cases. However, the formation of C3 products by artificial photosynthesis is rare10,11 and generally relies on a higher-order reaction pathway that requires the sequential formation of multiple C-C bonds12, which involves the integration of two consecutive steps of CO2-to-CO and CO-to-C2+ at different catalytic centres13,14,15,16. These C-C couplings are usually challenging endothermic processes with huge uphill energy barriers owing to the high energy levels of the key *C2 and *C3 intermediates17,18,19,20. These energy barriers result from the lack of effective catalytic centres that can stabilize these multicarbon intermediates21,22.

Single-atom (SA) catalysts with maximum atom utilization efficiency and unique catalytic performance have emerged as an attractive frontier in heterogeneous catalysis23,24. Atomically thin two-dimensional (2D) materials are suitable platforms to anchor metal SAs25,26. These 2D single-layer (SL) materials can not only improve the activity of catalytic reactions27, but also provide ideal models to gain atomic-level insights into real active sites and reaction mechanisms of catalytic processes through experimental and theoretical techniques25,28.

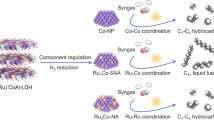

Herein, we report that implanting Cu SAs in Ti0.91O2 atomic SLs allows the construction of a unique Cu-Ti-VO/Ti0.91O2-SL photocatalyst for highly efficient and selective conversion of CO2 into C3H8. The Cu SA promotes the neighboring Ti0.91O2 to generate oxygen vacancies (VOs) and form a Cu-Ti-VO unit in the Ti0.91O2 matrix. The Cu-Ti-VO/Ti0.91O2-SL photocatalysis system efficiently converts CO2 into C2+ products at room temperature with high electron-based selectivity of 64.8% for C3H8 (product-based selectivity of 32.4%) and 86.2% for overall C2+ hydrocarbons (product-based selectivity of 50.2%). As suggested by theoretical calculations, the Cu-Ti-VO units may stabilize the key *CHOCO and *CH2OCOCO intermediates and reduce their energy levels, tuning both C1-C1 and C1-C2 couplings into thermodynamically favorable exothermal processes. Based on the simulation results, tandem catalytic mechanism and reaction pathway for the production of C2+ hydrocarbons are proposed, involving an overall 20 e—20 H+ reduction and two sequential C-C coupling processes of three CO2 molecules (3 CO2 + 20 e− + 20 H+→ C3H8 + 6 H2O). Our work provides an alternative paradigm for the photoconversion of CO2 into multicarbon solar fuels, and represents a progressive step toward imitating natural photosynthesis.

Results

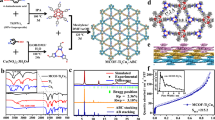

Formation and characterization of Cu-Ti-VO units

Atomically thin layers of Ti0.91O2-SL were synthesized by exfoliating the layered protonic lepidocrocite-type titanate of H0.7Ti1.825O429,30. The absence of peaks in the corresponding X-ray diffraction (XRD) pattern suggests the complete exfoliation into single layers31 (Supplementary Fig. 1). Cu SAs were then implanted in Ti0.91O2-SL to form Cu-Ti-VO/Ti0.91O2-SL through a modified wet-chemical route, followed by a rapid thermal treatment (RTT) in an Ar atmosphere32 (see Methods for details). The amount of Cu loading was detected to be 0.29 wt% by inductively coupled plasma–optical emission spectrometry (ICP-OES). The XRD pattern of Cu-Ti-VO/Ti0.91O2-SL was similar to that of pristine Ti0.91O2-SL (Supplementary Fig. 1). The thickness of Cu-Ti-VO/Ti0.91O2-SL was found to be 0.85 nm using atomic force microscopy (AFM) (Supplementary Fig. 2), which corresponded closely to the theoretical monolayer thickness (0.75 nm)30,33,34. Field emission-scanning electron microscopy (FE-SEM) and transmission electron microscopy (TEM) images show the ultrathin sheet-like morphology of Cu-Ti-VO/Ti0.91O2-SL without discernible nanoparticles (NPs) (Fig. 1a–c), potentially implying the atomic-scale size of the Cu embedded in the Ti0.91O2 matrix. The isolated bright dots in atomic resolution aberration-corrected high angle annular dark-field-scanning transmission electron microscopy (AC HADDF-STEM) images (Fig. 1e) directly confirm the atomic dispersion of the Cu in the matrix. Energy dispersive X-ray spectroscopy (EDS) mapping (Fig. 1f–i) indicates that Cu is evenly distributed throughout the atomically thin Ti0.91O2 matrix.

Fourier transforms of the Cu K-edge extended X-ray absorption fine structure (EXAFS) spectra of Cu-Ti-VO/Ti0.91O2-SL (Fig. 2a) contain a prominent peak at ~1.56 Å, assigned to Cu-O coordination in the first shell with a coordination number of 4 according to the EXAFS fitting analysis (Supplementary Fig. 3 and Supplementary Table 1). The characteristic metallic Cu-Cu bonding at ~2.24 Å is not observed, further validating the single-atom distribution of Cu. A minor scattering peak at ~2.42 Å is attributed to Cu-Ti coordination in the second shell based on the EXAFS fitting results34,35. The presence of Cu-Ti coordination, originating from the strong electronic interaction between Cu and adjacent Ti atoms, suggests that Cu is present in the atomically dispersed Cu-Ti dual-metal coordination form36.

a Fourier transforms of EXAFS spectra at the Cu K-edge. b EPR spectra. Normalized XANES spectra at the c Cu K-edge and d Ti K-edge. e, f The atomic structure configuration (colour codes: light blue (Ti), blue (Cu), and red (O)). g PDOS and d-band centres of Cu 3d and Ti 3d orbitals. h, i COHP between Cu and adjacent Ti. j, k Charge density differences (yellow represents electron accumulation, and purple denotes electron depletion).

The normalized Cu K-edge X-ray absorption near-edge structure (XANES) spectra show that the near-edge absorption energy of Cu-Ti-VO/Ti0.91O2-SL is higher than that of Cu foil and lies between the energies of Cu2O and CuO (Fig. 2c), indicating that the average oxidation state of Cu is between +1 and +2, which is verified by Cu LMM Auger electron spectra (AES) and Cu 2p X-ray photoelectron spectra (XPS) as well as the theoretical results (Supplementary Fig. 4a, c). The near-edge absorption energy and white-line intensity of Ti K-edge XANES for Cu-Ti-VO/Ti0.91O2-SL are higher than those for Ti0.91O2-SL (Fig. 2d), suggesting the presence of Ti species with lower electronic density, which is confirmed by the Tiδ+ (δ > 4) species in Ti 2p XPS spectra37,38 (Supplementary Fig. 4b). The formation of these electron-poor Ti centres and the partially oxidized Cu centres proves the electron donation to Cu SAs from the coordinated Ti atoms as a result of the strong electronic interaction in the Cu-Ti dual-metal coordination.

The O 1 s XPS spectrum of Cu-Ti-VO/Ti0.91O2-SL displays a peak attributed to VO at 531.6 eV39,40 (Supplementary Fig. 5). The electron paramagnetic resonance (EPR) spectra also show a VO signal at a g value of 2.00340 (Fig. 2b), suggesting the formation of VOs in Cu-Ti-VO/Ti0.91O2-SL. In contrast, no VO signal is observed for Ti0.91O2-SL (Fig. 2b and Supplementary Fig. 5). Density functional theory (DFT) computations reveal that the formation energy of VO is 5.66 eV in Ti0.91O2-SL, while the value sharply decreases to 2.39 eV with Cu anchoring, implying that the introduction of Cu SAs can facilitate the formation of neighboring VOs in the Ti0.92O2 matrix.

The strong coordination interaction of the anchored Cu SA with neighboring Ti atoms originates from the presence of VOs. A control sample without VOs (denoted as Cu-O/Ti0.91O2-SL) was synthesized through a similar RTT in an air atmosphere (see Methods, Fig. 2b, f and Supplementary Fig. 6 for details). The projected density of states (PDOS) of Cu-Ti-VO/Ti0.91O2-SL (Fig. 2g) demonstrates that the d-band centre (ɛd) of Cu (−2.52 eV) is in good agreement with adjacent Ti (−2.58 eV), inducing a strong electronic coupling effect in the dual-metal sites36. The crystal orbital Hamilton population (COHP) between Cu SAs and the closest Ti atoms was then calculated to quantitatively study the intensity of Cu-Ti interactions with and without VOs. The less antibonding orbital populations and a more negative value of integrated-crystal orbital Hamilton population (ICOHP) for Cu-Ti-VO/Ti0.91O2-SL than Cu-O/Ti0.91O2-SL prove that the Cu-Ti electronic interaction is much stronger when VOs are present (Fig. 2h, i). Charge density differences and Bader charge analysis (Fig. 2j) suggest that 0.3 e− directly transfers to Cu SAs from the neighboring Ti atoms in Cu-Ti-VO/Ti0.91O2-SL, which causes notable electron accumulation at Cu sites and substantial electron depletion at Ti sites, revealing the asymmetric electron distribution at Cu-Ti coordination. In comparison, without VOs, Cu-O/Ti0.91O2-SL displays no discernible electron perturbation at Ti sites, and electrons are localized within Cu-O coordination (Fig. 2k), demonstrating that Cu SAs share negligible interactions with Ti atoms and are in a relatively isolated single-metal form, confirmed by XPS and EPR (Fig. 2b and Supplementary Fig. 6). Therefore, both experimental and theoretical analyses indicate that Cu-Ti-VO units are formed in the Ti0.91O2 matrix for Cu-Ti-VO/Ti0.91O2-SL. In contrast, isolated Cu-O sites are formed in the Ti0.91O2 matrix without VOs for Cu-O/Ti0.91O2-SL.

Photocatalytic CO2 reduction performance

All of the photocatalytic CO2 reduction metrics reported in this study were measured in CO2-saturated acetonitrile aqueous solution (acetonitrile: water = 5:1 by volume) unless otherwise specified, and the testing details are described in the Methods section (Supplementary Fig. 7). Unexfoliated layered titanate (denoted as Ti0.91O2-B) mainly produces CO, with a formation rate of 7.0 μmol g−1 h−1 (Fig. 3b). Ti0.91O2-SL displays an enhanced CO production rate of 67.0 μmol g−1 h−1, indicating that the atomically thin 2D geometry is favorable for the improvement of CO2 activity through the potential exposure of many rich active sites and a shortened charge-transfer distance from the interior to the surface26,41. Both CO and CH4 were detected on Cu-O/Ti0.91O2-SL with yields of 61.0 and 11.3 μmol g−1 h−1, respectively. Cu-Ti-VO/Ti0.91O2-SL exhibit significant yields of C2H4 (7.6 μmol g−1h−1) and C3H8 (13.8 μmol g−1h−1), together with a small amount of CH4 and trace C2H6/C3H6, in addition to CO (18.6 μmolg−1h−1) (Fig. 3a, b), showing a strong capability of C-C coupling. No H2 production was detected (Supplementary Fig. 8), and O2 was generated roughly stoichiometrically (Supplementary Fig. 9). The quantum efficiency (QE) was obtained 0.48%, 0.15%, and 0.06% at the wavelength of 385, 415, and 520 nm, respectively. A high electron-based selectivity of C3H8 of 64.8% was achieved (32.4% of the product-based selectivity), and that of total C2+ products was as high as 86.2% (50.2% of the product-based selectivity) (Fig. 3c and Table 1). The photocatalytic performance of Cu-Ti-VO/Ti0.91O2-SL was also tested in pure water. The production rates of all carbon-based products decreased in pure water as compared with those (Supplementary Fig. 10). Moreover, the overall selectivity of C2+ products becomes lower in pure water, and the selectivity of C3H8 is less than C2H4 (Supplementary Fig. 11). H2 is detected with a formation rate of ~2.2 μmol g−1 h−1 in pure water. The improved activity and selectivity are most likely due to the high CO2 solubility in acetonitrile, which largely increases the local accessibility of CO2, thus enhancing the contact between the catalyst and CO2 molecules to facilitate C-C coupling. To the best of our knowledge, the efficiency and selectivity of C3H8 production in our work outperform most of the reported photocatalysts in acetonitrile medium, and also rank among the top of the reported C2+ production photocatalysts in non-acetonitrile medium (Supplementary Table 3).

The substantially suppressed CO production and increased C2+ production on Cu-Ti-VO/Ti0.91O2-SL, compared with pristine Ti0.91O2-SL, imply that the formation of C2+ products is potentially derived from the coupling depletion of the *CO intermediate. CO was used to substitute CO2 as the starting reactant on Cu-Ti-VO/Ti0.91O2-SL, and a considerable amount of C3H8 and C2H4 was indeed detected (Supplementary Fig. 12), further confirming *CO as an important intermediate for the present C2+ products. The distinctive CO2 photoreduction activity and high selectivity of C3H8 and total C2+ products are still well maintained after three-cycle tests of 15 h in total (Supplementary Figs. 13 and 14), and the post-reaction characterizations of Cu-Ti-VO/Ti0.91O2-SL display no obvious structural and morphological changes (Supplementary Figs. 15–17), demonstrating the excellent stability of the catalyst. Notably, with the decrease in the Cu loading amount, the C2+ yield declines as the lower Cu loading reasonably reduces the number of Cu-Ti-VO units, restraining C-C coupling (Supplementary Figs. 18 and 19). Moreover, higher Cu loading results in Cu aggregation into nanoclusters (NCs) and nanoparticles (NPs), subsequently lowering the selectivity of C2+ products, which is probably due to the weaker coupling interaction between Cu and the Ti0.91O2 matrix as the metal particle size increases42,43 (Supplementary Fig. 18). A series of control experiments were performed in the absence of illumination, the catalyst or CO2, and no detectable CO or other hydrocarbon products were detected. The 13CO2 isotope labeling experiment and the time profile of relative abundance of 13C labeled products confirm that the carbon source for CO and other hydrocarbon products originates from the input CO2 gas44 (Supplementary Figs. 20 and 21, and Supplementary Table 4).

The light utilization and the charge carrier dynamics of the as-prepared catalysts were studied. The absorption edge of single-layer Ti0.91O2-SL displays a blue shift compared with layered Ti0.91O2-B due to the quantum confinement effect of monolayer structure, while the light absorption is enhanced after implantation of Cu single atoms (Supplementary Fig. 22). Photoelectrochemical (PEC) measurements confirm the enhanced charge separation and migration efficiency of Cu-Ti-VO/Ti0.91O2-SL, ascribed to the 2D atomically-thin structure, which effectively shortens the charge transfer distance from body to surface and lowers charge recombination possibility (Supplementary Fig. 23). The fast charge carrier dynamics of Cu-Ti-VO/Ti0.91O2-SL is kinetically favorable for the multi-electron reactions of generating C2+ products. Moreover, CO2 adsorption isotherms reveal that Cu-Ti-VO/Ti0.91O2-SL possesses the highest CO2 uptake capacity, which is a priority for CO2 activation and reduction (Supplementary Fig. 24).

Theoretical calculations for CO2 photoreduction mechanism

The substantial suppression of CO production and promotion of C2+ production by Cu-Ti-VO/Ti0.91O2-SL, in sharp contrast to pristine Ti0.91O2-SL, has demonstrated the key role of Cu-Ti-VO units in coupling *CO intermediates into C2+ products. In fact, our in situ diffuse reflectance Fourier transform infrared spectroscopy (DRIFTS) characterization using 12CO2 and 13CO2 has detected the formation of the key *COOH, *CO, *CHO, and *CHOCO intermediates on Cu-Ti-VO/Ti0.91O2-SL (Fig. 4a, Supplementary Figs. 25 and 26, and Supplementary Note 1), indicating the coupling of *CO into *CHOCO intermediates. However, it is not feasible to experimentally establish a direct spatial correlation between the active sites and the evolution of reaction intermediates to allow for deeper understanding on CO2 photoreduction mechanism on atomic level. For this reason, density functional theory (DFT) calculations with a computational hydrogen electrode (CHE) model45,46 was employed in an attempt to describe one potential mechanism for the reaction of CO2-to-C2+ products on Cu-Ti-VO/Ti0.91O2-SL.

In the calculations, Cu-Ti-VO/Ti0.91O2-SL are featured with two types of catalytic centres for CO2 reduction: the Cu atom-free Ti0.91O2 matrix domain and the Cu-Ti-VO unit domain. On Ti0.91O2 domain, CO2 is reduced to *CO through *COOH intermediate47 (Fig. 4b and Supplementary Fig. 27). DFT results suggest the easy desorption of *CO on Ti0.91O2 matrix rather than further hydrogenation or C-C coupling (Supplementary Note 2), consistent with the experimental observation of the dominant CO product on pristine Ti0.91O2-SL. On Cu-Ti-VO unit domain, the absorbed CO2 is firstly converted to *CHO through *COOH and *CO intermediates48 (Supplementary Fig. 27). Then, the *CHO at Cu-Ti-VO unit may couple with the CO diffusing from neighboring Ti0.91O2 domain to generate *CHOCO49,50,51 with free energy change of −1.63 eV (see Supplementary Note 3 for more details about potential pathways). The following C1-C2 coupling (*CH2OCO + *CO → *CH2OCOCO) is also calculated to be a thermodynamically-favorable exergonic reaction (−0.13 eV) (Supplementary Note 3). As a contrast, it is worth noting that on the Cu-O site without Vos, C-C coupling processes are found to be challenging owing to the large uphill energy changes, while the hydrogenation of *CO into CH4 is more preferred (Fig. 4c)52,53. Meanwhile, for Cu-Ti-VO unit, some of the *C2 species will continue to hydrogenate through a series of proton-electron steps to form C2H4. The free energy change of the potential determining step (PDS) is calculated as 0.62 eV for the C3H8 formation pathway (Fig. 4d) and 0.90 eV for the C2H4 formation pathway (Supplementary Fig. 28), suggesting the easier formation of C3H8 than C2H4. This is in accordance with our photocatalytic experimental observation of the higher yield of C3H8 than C2H4 on Cu-Ti-VO/Ti0.91O2-SL. The overall reaction pathway for the reduction of CO2 to C3H8 and C2H4 over Cu-Ti-VO/Ti0.91O2-SL is tentatively described in Supplementary Fig. 29. In summary, the above results suggest a tandem catalysis mechanism13,14,15,16,54,55,56, where the Cu-free Ti0.91O2 matrix may be preferential to participate in the reduction of CO2 to CO, and Cu-Ti-VO unit is more beneficial to the exergonic C-C coupling to C2+ products (Supplementary Fig. 30).

The above result suggests favorable exergonic reactions for both C1-C1 and C1-C2 couplings on Cu-Ti-VO unit, which is in sharp contrast with Cu-O sites and other previously-reported catalysts with challenging endergonic C-C couplings17,18,19,20. Such downhill energy changes of C-C coupling on Cu-Ti-VO unit are probably owing to the low energy levels of the *CHOCO and *CH2OCOCO intermediates (Supplementary Fig. 31). A stable multiple-bonding configuration containing one Cu-C bond and two Ti-O bonds is built for the adsorption of *CHOCO on Cu-Ti-VO unit (Supplementary Fig. 32). Moreover, a five-membered ring is formed between *CH2OCOCO and Cu-Ti-VO unit, largely alleviating the electron accumulation and relaxing the intermolecular and intramolecular electrostatic repulsion (Supplementary Fig. 33). The electronic and geometric effect of Cu-Ti-VO unit may jointly stabilize these key *C2+ intermediates and lower their adsorption energy levels to promote C-C couplings.

Discussion

A unique Cu-Ti-VO unit in atomically thin Ti0.91O2 monolayer nanosheets was developed for highly efficient and selective photoconversion of CO2 to C3H8. Theoretical calculations suggested that the Cu-Ti-VO unit, as a favorable reaction centre for both C1-C1 and C1-C2 couplings, can effectively facilitate the multistep photocatalytic reduction of CO2 by reducing the energy levels of the key *CHOCO and *CH2OCOCO intermediates via electronic and geometric effects. A tandem mechanism and possible reaction pathway are proposed for the conversion of CO2 to C3H8. The results of our study may open an alternative avenue for designing and synthesizing tandem photocatalysts with dual-metal active sites and coordination vacancies that modulate the behavior of reaction intermediates for the production of multicarbon fuels driven by light.

Methods

Synthesis of catalysts

Cu-Ti-VO/Ti0.91O2-SL: Single-layer Ti0.91O2 nanosheets were synthesized according to previous literature29, and the specific procedure is presented below. The parent Cs compound, Cs0.7Ti1.825O4, was obtained by repeating twice the heat treatment (800 °C, 20 h) for the mixture of 10 mmol Cs2CO3 and 53 mmol anatase TiO2. The interlayer Cs ions were extracted by stirring 5 g of the as-prepared Cs0.7Ti1.825O4 in 500 mL of 1 M HCl solution for 24 h. After four cycles of acid exchange, the solid was washed with DI water to remove excess acid and then dried in a freeze dryer. Layered protonic lepidocrocite-type titanate of H0.7Ti1.825O4 was obtained.

0.4 g of the as-prepared layered H0.7Ti1.825O4 was shaken with 100 mL of 0.08 M tetrabutylammonium (TBA) hydroxide aqueous solution for a week to produce stable colloidal suspensions of atomically thin Ti0.91O2 single layers. The colloidal suspensions were then dried in a freeze dryer.

The Cu-en precursor was prepared by mixing 30 mL of 0.025 g/L CuCl2‧2H2O aqueous solution with 360 μL of ethanediamine (en) at room temperature. Then, this Cu-en precursor was added to 7 g of the as-prepared colloidal suspensions of single-layer Ti0.91O2. After stirring for 5 h, the solid was filtrated, washed with deionized water, and dried in a freeze dryer to obtain a single-layer Cu-en/Ti0.91O2 sample. Then, the Cu-Ti-VO/Ti0.91O2-SL sample was prepared by rapid thermal treatment (RTT) of single-layer Cu-en/Ti0.91O2 in an Ar atmosphere at 500 °C for 1 min32. Briefly, the powders were put into a quartz tube, which was then inserted into a tube furnace preheated to 500 °C. Under Ar flow, the powders were kept at that temperature for 1 min, and then the quartz tube was quickly removed and rapidly cooled to room temperature.

Cu-O/Ti0.91O2-SL: The sample was prepared by the same method as Cu-Ti-VO/Ti0.91O2-SL, except that the RTT process was conducted in an air atmosphere.

Cu-Ti-VO/Ti0.91O2-SL (lower): The sample was prepared by the same method as Cu-Ti-VO/Ti0.91O2-SL, except that an aqueous solution of 0.0125 g/L CuCl2‧2H2O was used.

Cu NC/Ti0.91O2-SL: The sample was prepared by the same method as Cu-Ti-VO/Ti0.91O2-SL, except that an aqueous solution of 0.1 g/L CuCl2‧2H2O was used.

Cu NP/Ti0.91O2-SL: The sample was prepared by the same method as Cu-Ti-VO/Ti0.91O2-SL, except that an aqueous solution of 0.2 g/L CuCl2‧2H2O aqueous was used, and RTT was maintained at 10 min.

Ti0.91O2-B: The sample was prepared by treating layered protonic lepidocrocite-type titanate of H0.7Ti1.825O4 with the same RTT process as used for Cu-Ti-VO/Ti0.91O2-SL.

Characterization

XRD data were measured on an X-ray diffractometer (Rigaku Ultima III, Japan) by Cu-Kα radiation (λ = 0.154178 nm) at 40 kV and 40 mA with a scan rate of 5° min−1. AFM analysis was performed on an MFP3D microscope (Asylum Research, MFP-3D-SA, USA) with a cantilever operating in tapping mode. The morphology was characterized by FE-SEM (FEI NOVA NANOSEM 230). TEM images were taken on an FEI Tecnai F20 TEM apparatus. Atomic-resolution STEM-HAADF images were obtained on a double spherical aberration-corrected STEM/TEM FEI Titan3 Cubed 60–300, and the samples were suspended on micron-scale carbon grids of Mo mesh. The Cu concentration was determined by ICP–OES with an Avio200 instrument. The XAFS spectra (Cu K-edge and Ti K-edge) were collected at the 1W1B station at the Beijing Synchrotron Radiation Facility (BSRF). The storage rings at BSRF were operated at 2.5 GeV with an average current of 250 mA. Using a Si (111) double-crystal monochromator, the data collection was conducted in transmission/fluorescence mode using an ionization chamber. All spectra were collected under ambient conditions. The EXAFS data were processed according to standard procedures using the ATHENA module implemented in the IFEFFIT software package. The k3-weighted EXAFS spectra were obtained by subtracting the postedge background from the overall absorption and then normalizing with respect to the edge jump step. Subsequently, k3-weighted χ(k) data of the Cu K-edge underwent Fourier transform to real (R) space using Hanning windows (dk = 1.0 Å−1) to separate the EXAFS contributions from different coordination shells. To obtain the quantitative structural parameters around the central atoms, least squares curve parameter fitting was performed using the ARTEMIS module of IFEFFIT software packages. The chemical states of the samples were detected by XPS and AES, which were equipped with an ultrahigh vacuum Thermo Fisher Scientific electron spectrometer by using Al Kα radiation (1486.6 eV) as the X-ray source, and the binding energies were calibrated according to the C 1 s peak of adventitious carbon at 284.6 eV. The in situ DRIFTS spectra were obtained on a Bruker IFS 66 v FT spectrometer with Harrick diffuse reflectance with ZnSe and quartz windows at BL01B in NSRL, Hefei.

Measurements of photocatalytic CO2 reduction

Photocatalytic CO2 reduction experiments were performed in a Pyrex reaction vessel with a top irradiation window. Typically, 10 mg of photocatalyst powder was suspended in a 15 mL CO2-saturated solution containing 12.5 mL acetonitrile and 2.5 mL H2O in a 166 mL quartz reaction cell. Before illumination, the system was filled with CO2 (purity >99.999%) to 1 atm. The reactor was then irradiated by a 300 W Xe lamp (PerfectLight, PLS-SXE300). During irradiation, 0.1 mL of gas was collected from the reaction headspace every hour, and the gaseous products were analysed by using gas chromatography (GC-2014C, Shimadzu Corp., Japan). The isotope experiment was conducted using 13CO2 as feedstock, and the products were analysed using gas chromatography–mass spectrometry (7890 A and 5975 C, Agilent). The quantum efficiency was evaluated using a LED lamp (PerfectLight) with the wavelength of 385,415, or 520 nm as the light source.

The electron-based selectivity of C3H8 was calculated using (1):

The product-based selectivity of C3H8 was calculated using (2):

The electron-based selectivity of C2+ products was calculated using (3):

The product-based selectivity of C2+ products was calculated using (4):

where n is the formation rate.

The quantum efficiency was calculated using (5):

where N is the number of evolved gas molecules or incident photons.

Computational details

All calculations were performed based on density functional theory (DFT) through the Vienna ab initio Simulation Package (VASP)57. Projector-augmented-wave (PAW) pseudopotentials58 were used to treat the core electrons, while interactions between electrons were described by the Perdew-Burke-Ernzerhof (PBE)59 exchange-correlation functional of the generalized gradient approximation (GGA). For all the calculations, the vacuum space in the z-direction was 20 Å to avoid potential interactions between periodic surfaces. The DFT-D3 method of Grimme60 was applied to describe the van der Waals dispersion forces. DFT + U approach61,62 with U = 3.5 eV was considered to evaluate the influence of strongly correlated d electrons on the calculated free energies. According to our previous report63, the results of calculated free energies obtained from DFT + U and DFT are consistent. Therefore, regular DFT was employed in this work. The Monkhorst-Pack k-point grid with 3 × 3 × 1 mesh was applied until the maximal forces on each ion were smaller than 0.02 eV/Å. The convergence criterion of the energy was set to 10−4 eV, and a cut-off energy of 450 eV was used for the plane wave expansion. The Gibbs free energy change (ΔG) was defined as follows45,64:

where ΔE is the energy difference between the reactants and product obtained through DFT calculations. ΔEZPE and ΔS are the changes in the zero-point energies (ZPE) and entropy65. T represents the temperature and was set as 298.15.

Statistics & reproducibility

No statistical method was used to predetermine the sample size. No data were excluded from the analyses. The experiments were not randomized.

Data availability

The data that support the findings of this study are available within the paper and its supplementary information files or are available from the corresponding authors upon reasonable request. Source data are provided with this paper.

Code availability

All related codes regarding DFT simulations in this study are provided in the Source Data file.

References

Rao, H., Schmidt, L. C., Bonin, J. & Robert, M. Visible-light-driven methane formation from CO2 with a molecular iron catalyst. Nature 548, 74–77 (2017).

Hepburn, C. et al. The technological and economic prospects for CO2 utilization and removal. Nature 575, 87–97 (2019).

Bushuyev, O. S. et al. What should we make with CO2 and how can we make it? Joule 2, 825–832 (2018).

Cestellos-Blanco, S., Zhang, H., Kim, J. M., Shen, Y.-X. & Yang, P. Photosynthetic semiconductor biohybrids for solar-driven biocatalysis. Nat. Catal. 3, 245–255 (2020).

Loh, J. Y. Y., Kherani, N. P. & Ozin, G. A. Persistent CO2 photocatalysis for solar fuels in the dark. Nat. Sustain. 4, 466–473 (2021).

Tu, W., Zhou, Y. & Zou, Z. Photocatalytic conversion of CO2 into renewable hydrocarbon fuels: state-of-the-art accomplishment, challenges, and prospects. Adv. Mater. 26, 4607–4626 (2014).

Jiang, Z. et al. Filling metal-organic framework mesopores with TiO2 for CO2 photoreduction. Nature 586, 549–554 (2020).

Gao, W. et al. Vacancy-defect modulated pathway of photoreduction of CO2 on single atomically thin AgInP2S6 sheets into olefiant gas. Nat. Commun. 12, 4747 (2021).

Tu, W. et al. An in situ simultaneous reduction-hydrolysis technique for fabrication of TiO2-graphene 2D sandwich-like hybrid nanosheets: Graphene-promoted selectivity of photocatalytic-driven hydrogenation and coupling of CO2 into methane and ethane. Adv. Funct. Mater. 23, 1743–1749 (2013).

Yu, S. & Jain, P. K. Plasmonic photosynthesis of C1-C3 hydrocarbons from carbon dioxide assisted by an ionic liquid. Nat. Commun. 10, 2022 (2019).

Li, N. et al. Toward high-value hydrocarbon generation by photocatalytic reduction of CO2 in water vapor. ACS Catal. 9, 5590–5602 (2019).

Wang, X. et al. Efficient upgrading of CO to C3 fuel using asymmetric C-C coupling active sites. Nat. Commun. 10, 5186 (2019).

Zhang, H. et al. Computational and experimental demonstrations of one-pot tandem catalysis for electrochemical carbon dioxide reduction to methane. Nat. Commun. 10, 3340 (2019).

Meng, D. L. et al. Highly selective tandem electroreduction of CO2 to ethylene over atomically isolated nickel-nitrogen site/copper nanoparticle catalysts. Angew. Chem. Int. Ed. 60, 25485–25492 (2021).

Zhang, T. et al. Highly selective and productive reduction of carbon dioxide to multicarbon products via in situ CO management using segmented tandem electrodes. Nat. Catal. 5, 202–211 (2022).

Chen, C. et al. Cu-Ag tandem catalysts for high-rate CO2 electrolysis toward multicarbons. Joule 4, 1688–1699 (2020).

Zhu, J. et al. Asymmetric triple-atom sites confined in ternary oxide enabling selective CO2 photothermal reduction to acetate. J. Am. Chem. Soc. 143, 18233–18241 (2021).

Wang, W. et al. Photocatalytic C-C coupling from carbon dioxide reduction on copper oxide with mixed-valence copper(I)/copper(II). J. Am. Chem. Soc. 143, 2984–2993 (2021).

Wang, T. et al. Engineering catalytic interfaces in Cuδ+/CeO2-TiO2 photocatalysts for synergistically boosting CO2 reduction to ethylene. ACS Nano 16, 2306–2318 (2022).

Zhu, S. et al. Selective CO2 photoreduction into C2 product enabled by charge-polarized metal pair sites. Nano Lett. 21, 2324–2331 (2021).

Peng, C. et al. Double sulfur vacancies by lithium tuning enhance CO2 electroreduction to n-propanol. Nat. Commun. 12, 1580 (2021).

Diercks, C. S., Liu, Y., Cordova, K. E. & Yaghi, O. M. The role of reticular chemistry in the design of CO2 reduction catalysts. Nat. Mater. 17, 301–307 (2018).

Chen, Y. et al. Single-atom catalysts: synthetic strategies and electrochemical applications. Joule 2, 1242–1264 (2018).

Zhang, Y., Xia, B., Ran, J., Davey, K. & Qiao, S. Z. Atomic‐level reactive sites for semiconductor‐based photocatalytic CO2 reduction. Adv. Energy Mater. 10, 1903879 (2020).

Wang, Y. et al. Catalysis with two-dimensional materials confining single atoms: Concept, design, and applications. Chem. Rev. 119, 1806–1854 (2019).

Jiao, X. et al. Fundamentals and challenges of ultrathin 2D photocatalysts in boosting CO2 photoreduction. Chem. Soc. Rev. 49, 6592–6604 (2020).

Di, J. et al. Isolated single atom cobalt in Bi3O4Br atomic layers to trigger efficient CO2 photoreduction. Nat. Commun. 10, 2840 (2019).

Zhang, B., Fan, T., Xie, N., Nie, G. & Zhang, H. Versatile applications of metal single-atom@2D material nanoplatforms. Adv. Sci. 6, 1901787 (2019).

Sasaki, T., Watanabe, M., Hashizume, H., Yamada, H. & Nakazawa, H. Macromolecule-like aspects for a colloidal suspension of an exfoliated titanate. Pairwise association of nanosheets and dynamic reassembling process initiated from it. J. Am. Chem. Soc. 118, 8329–8335 (1996).

Wang, L., Sasaki, T., Ebina, Y., Kurashima, K. & Watanabe, M. Fabrication of controllable ultrathin hollow shells by layer-by-layer assembly of exfoliated titania nanosheets on polymer templates. Chem. Mater. 14, 4827–4832 (2002).

Song, Y. et al. Photocatalytic hydrogen evolution over monolayer H1.07Ti1.73O4·H2O nanosheets: Roles of metal defects and greatly enhanced performances. Appl. Catal. B: Environ. 221, 473–481 (2018).

Ren, Y. et al. Unraveling the coordination structure-performance relationship in Pt1/Fe2O3 single-atom catalyst. Nat. Commun. 10, 4500 (2019).

Geng, F. et al. Unusually stable ~100-fold reversible and instantaneous swelling of inorganic layered materials. Nat. Commun. 4, 1632 (2013).

Yi, D. et al. Regulating charge transfer of lattice oxygen in single-atom-doped titania for hydrogen evolution. Angew. Chem. Int. Ed. 59, 15855–15859 (2020).

Lee, B. H. et al. Reversible and cooperative photoactivation of single-atom Cu/TiO2 photocatalysts. Nat. Mater. 18, 620–626 (2019).

Gao, R. et al. Pt/Fe2O3 with Pt–Fe pair sites as a catalyst for oxygen reduction with ultralow Pt loading. Nat. Energy 6, 614–623 (2021).

Wang, Q. et al. Ultrahigh-loading of Ir single atoms on NiO matrix to dramatically enhance oxygen evolution reaction. J. Am. Chem. Soc. 142, 7425–7433 (2020).

Zhang, F.-F. et al. Iridium oxide modified with silver single stom for boosting oxygen evolution reaction in acidic media. ACS Energy Lett. 6, 1588–1595 (2021).

Xiao, M. et al. Molten-salt-mediated synthesis of an atomic nickel co-catalyst on TiO2 for improved photocatalytic H2 evolution. Angew. Chem. Int. Ed. 59, 7230–7234 (2020).

Chen, Y. et al. Engineering the atomic interface with single platinum atoms for enhanced photocatalytic hydrogen production. Angew. Chem. Int. Ed. 59, 1295–1301 (2020).

Bi, W., Wu, C. & Xie, Y. Atomically thin two-dimensional solids: an emerging platform for CO2 electroreduction. ACS Energy Lett. 3, 624–633 (2018).

van Deelen, T. W., Hernández Mejía, C. & de Jong, K. P. Control of metal-support interactions in heterogeneous catalysts to enhance activity and selectivity. Nat. Catal. 2, 955–970 (2019).

Guo, Y. et al. Low-Temperature CO2 methanation over CeO2-supported Ru single atoms, nanoclusters, and nanoparticles competitively tuned by strong metal–support interactions and H-spillover effect. ACS Catal. 8, 6203–6215 (2018).

Jiang, H. et al. Photocatalytic reduction of CO2 on Cu2O-loaded Zn-Cr layered double hydroxides. Appl. Catal. B: Environ. 224, 783–790 (2018).

Nørskov, J. K. et al. Origin of the overpotential for oxygen reduction at a fuel-cell cathode. J. Phys. Chem. B 108, 17886–17892 (2004).

Liu, X. et al. Understanding trends in electrochemical carbon dioxide reduction rates. Nat. Commun. 8, 15438 (2017).

Ran, L. et al. Engineering single-atom active sites on covalent organic frameworks for boosting CO2 Photoreduction. J. Am. Chem. Soc. 144, 17097–17109 (2022).

Calle-Vallejo, F. & Koper, M. T. M. Accounting for bifurcating pathways in the screening for CO2 reduction catalysts. ACS Catal. 7, 7346–7351 (2017).

Birdja, Y. Y. et al. Advances and challenges in understanding the electrocatalytic conversion of carbon dioxide to fuels. Nat. Energy 4, 732–745 (2019).

Garza, A. J., Bell, A. T. & Head-Gordon, M. Mechanism of CO2 reduction at copper surfaces: Pathways to C2 products. ACS Catal. 8, 1490–1499 (2018).

Liu, Q. et al. Regulating the *OCCHO intermediate pathway towards highly selective photocatalytic CO2 reduction to CH3CHO over locally crystallized carbon nitride. Energy Environ. Sci. 15, 225–233 (2022).

Li, X. et al. Selective visible-light-driven photocatalytic CO2 reduction to CH4 mediated by atomically thin CuIn5S8 layers. Nat. Energy 4, 690–699 (2019).

Wang, Z.-W. et al. Selective photocatalytic reduction CO2 to CH4 on ultrathin TiO2 nanosheet via coordination activation. Appl. Catal. B: Environ. 288, 120000 (2021).

Cao, B., Li, F.-Z. & Gu, J. Designing Cu-based tandem catalysts for CO2 electroreduction based on mass transport of CO intermediate. ACS Catal. 12, 9735–9752 (2022).

Li, Z. et al. Highly selective conversion of carbon dioxide to aromatics over tandem catalysts. Joule 3, 570–583 (2019).

Meng, S. L., Ye, C., Li, X. B., Tung, C. H. & Wu, L. Z. Photochemistry journey to multielectron and multiproton chemical transformation. J. Am. Chem. Soc. 144, 16219–16231 (2022).

Kresse, G. & Hafner, J. Ab initio molecular dynamics for liquid metals. Phys. Rev. B 47, 558–561 (1993).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Grimme, S., Antony, J., Ehrlich, S. & Krieg, H. A consistent and accurate ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H-Pu. J. Chem. Phys. 132, 154104 (2010).

Anisimov, V. I., Zaanen, J. & Andersen, O. K. Band theory and Mott insulators: hubbard U instead of stoner I. Phys. Rev. B 44, 943–954 (1991).

Dudarev, S. L., Botton, G. A., Savrasov, S. Y., Humphreys, C. J. & Sutton, A. P. Electron-energy-loss spectra and the structural stability of nickel oxide: An LSDA+U study. Phys. Rev. B 57, 1505–1509 (1998).

Ren, C. et al. A universal descriptor for complicated interfacial effects on electrochemical reduction reactions. J. Am. Chem. Soc. 144, 12874–12883 (2022).

Peterson, A. A., Abild-Pedersen, F., Studt, F., Rossmeisl, J. & Nørskov, J. K. How copper catalyzes the electroreduction of carbon dioxide into hydrocarbon fuels. Energy Environ. Sci. 3, 1311–1315 (2010).

Wang, V., Xu, N., Liu, J.-C., Tang, G. & Geng, W.-T. VASPKIT: A user-friendly interface facilitating high-throughput computing and analysis using VASP code. Comput. Phys. Commun. 267, 108033 (2021).

Acknowledgements

The authors wish to acknowledge the support of the National Key R &D Program of China (2018YFE0208500, 2021YFA1500700), the NSF of China (21972065, 22033002, 92261112), the NSF of Jiangsu Province (No. BK20220006), the Hefei National Laboratory for Physical Sciences at the Microscale (KF2020006), the Program for Guangdong Introducing Innovative and Entrepreneurial Team (2019ZL08L101), the University Development Fund (UDF01001159) and Cross-Subject Project of Chemistry Discipline of Yangzhou University (yzuxk202014).

Author information

Authors and Affiliations

Contributions

Y.S, Y.Zho., Y.X, J.W, Q.S., and Z.Z conceived the idea and designed the present work. C.R. performed the DFT calculations. Y.S., X.X., Y.Zha., Yi.Y., and H.C. conducted the experiments. L.Z. performed the XANES and EXAFS measurements. R.L. and W.Z. performed the in situ DRIFTS test. Yo.Y. contributed to the 13CO2 isotope labeling experiment.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shen, Y., Ren, C., Zheng, L. et al. Room-temperature photosynthesis of propane from CO2 with Cu single atoms on vacancy-rich TiO2. Nat Commun 14, 1117 (2023). https://doi.org/10.1038/s41467-023-36778-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-023-36778-5

This article is cited by

-

The reformation of catalyst: From a trial-and-error synthesis to rational design

Nano Research (2024)

-

Cu-Based Materials for Enhanced C2+ Product Selectivity in Photo-/Electro-Catalytic CO2 Reduction: Challenges and Prospects

Nano-Micro Letters (2024)

-

Single-atomic activation on ZnIn2S4 basal planes boosts photocatalytic hydrogen evolution

Nano Research (2024)

-

Dual activation and C-C coupling on single atom catalyst for CO2 photoreduction

npj Computational Materials (2023)

-

Photocatalytic reduction of CO2 with H2O into C2H6 mediated by dual metalation strategy

Science China Chemistry (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.