Abstract

Cuδ+ sites on the surface of oxide-derived copper (OD-Cu) are of vital importance in electrochemical CO2 reduction reaction (CO2RR). However, the underlying reason for the dynamically existing Cuδ+ species, although thermodynamically unstable under reductive CO2RR conditions, remains uncovered. Here, by using electron paramagnetic resonance, we identify the highly oxidative hydroxyl radicals (OH•) formed at room temperature in HCO3- solutions. In combination with in situ Raman spectroscopy, secondary ion mass spectrometry, and isotope-labelling, we demonstrate a dynamic reduction/reoxidation behavior at the surface of OD-Cu and reveal that the fast oxygen exchange between HCO3- and H2O provides oxygen sources for the formation of OH• radicals. In addition, their continuous generations can cause spontaneous oxidation of Cu electrodes and produce surface CuOx species. Significantly, this work suggests that there is a “seesaw-effect” between the cathodic reduction and the OH•-induced reoxidation, determining the chemical state and content of Cuδ+ species in CO2RR. This insight is supposed to thrust an understanding of the crucial role of electrolytes in CO2RR.

Similar content being viewed by others

Introduction

Conversion of CO2 into value-added chemicals through renewable electricity-powered electrochemical CO2 reduction reaction (CO2RR) has been recognized as a promising strategy to achieve “carbon-neutral”1,2,3. Oxide-derived copper (OD-Cu) has been proven as a group of efficient electrocatalysts for CO2RR, especially for multi-carbon products (C2+)4,5,6. The precise mechanism remains unknown and different views have been proposed7,8,9,10,11,12,13,14. Specifically, both experiments and theoretical calculations demonstrated that the Cuδ+/Cu0 interface can activate the inert CO2 molecules and promote CO-CO coupling10,11. To regulate the selectivity of C2+ products, many efficient OD-Cu catalysts with characteristic Cuδ+ sites have been achieved through constructing various oxidized pre-catalysts or employing CO2-pulsed electrolysis7,8,9,12.

Thermodynamically, CuOx phases should be removed under the CO2RR conditions thereby the loss of the active Cuδ+ species15. While some studies have demonstrated the reduction of CuOx phases to metallic Cu during CO2RR16,17,18,19,20. Interestingly, despite these, the Cuδ+ species has been frequently detected in CO2RR8,9,21,22,23. This puzzling phenomenon leads to divergent views of the presence of Cuδ+ species. Cuenya et al. demonstrated that the O2 plasma-treated CuOx is resistant to reduction24. Yu et al. found that in situ generated CO2RR intermediates on the surface of OD-Cu stabilize Cuδ+ species8. Chen et al. pointed out that the chemical states of Cu are associated with the oxidation caused by an uncertain oxidative species in the electrolytes25,26,27. We took the view that the Cuδ+ species should be dynamically existing, and we propose that the redox conditions provided by electrochemical cathodic reduction and oxidative species in electrolytes should be crucial. Understanding the reduction/reoxidation behavior of OD-Cu in commonly used CO2-saturated KHCO3 electrolytes is a grand challenge but vital to identifying what is the oxidative species.

Here, using in situ Raman spectroscopy, we observe the rapid reoxidation phenomenon of Cu to Cu2O species within a very short time scale (10 s) upon stopping the cathodic potential, and we record the dynamically existing Cuδ+ species at the surface of OD-Cu during the CO2RR. We further identify that the rapid reoxidation is caused by strongly oxidative OH• radicals existing in KHCO3 solutions, by using electron paramagnetic resonance (EPR). With the isotope-labeling technique, we point out that the OH• radicals are generated from both HCO3− and H2O upon oxygen exchange in HCO3− aqueous solutions at room temperature. In addition, owing to the continuous generation of OH• radicals, we observe higher degrees of oxidizing corrosion of Cu electrodes in CO2- or Ar-saturated KHCO3 solution under open circuit potential (OCP) relative to those electrolytes without OH• radicals, giving a hint of oxidative KHCO3 electrolytes. This work demonstrates unexpected OH• radicals as the oxidative species, and it guides the fundamental understanding of the origin of Cuδ+ species in CO2RR.

Results

Dynamic reduction/reoxidation behavior

To enhance in situ Raman signals, a surface roughened OD-Cu electrode was selected as a model catalyst for this study4,28. It was prepared via depositing the micro-nano Cu particles onto the surface of the Cu mesh substrate (Supplementary Fig. 1), by using a modified electrodeposition method29. The as-prepared Cu electrodes show a mainly metallic Cu state, with surfaces being oxidized to Cu2O phases owing to the exposure to air after electrodeposition and KHCO3 electrolytes before applying potentials for CO2RR (Supplementary Fig. 1).

We implemented potential-dependent Raman spectra to investigate the stability of surface Cu2O species under cathodic potentials in CO2-saturated 0.5 M KHCO3 solution (Supplementary Fig. 2). The vibration bands of surface Cu2O were observed at ~216, ~520, and ~620 cm−1 at >0.0 V versus reversible hydrogen electrode (VRHE)28,30,31. While, at <−0.2 VRHE, the typical Cu2O signals disappear, indicating the surface Cu+ species was reduced to metallic Cu. This result is supported by the prediction of the Pourbaix diagram for Cu and the previous reports15,16,17,18,19,20. In addition, the peaks at 282, 360, 2070–2100 cm−1 are related to the frustrated ρ(Cu–C–O) rotational mode, ν(Cu–CO) stretching mode, and intramolecular C≡O stretching vibration of CO intermediates, respectively. The bands at 2820–2950 cm−1 are assigned to the -CHx stretching regions30,31 from 0.2 to −0.6 VRHE (Fig. 1a, b and Supplementary Figs. 2–4), demonstrating the initiation of CO2RR. Thus, to reduce surface Cu2O to metallic Cu (Supplementary Figs. 2 and 5) and to avoid the reconstruction of Cu at very negative potentials during CO2RR18,32, a moderate reduction potential of −0.3 VRHE was chosen for further Raman study.

The reoxidation of OD-Cu surface was investigated via real-time Raman test, by applying a reduction potential at −0.3 VRHE for 30 s firstly, and then switching to OCP for 60 s. The spectra were acquired every 10 s. As shown in Fig. 1a, once switching the potential from −0.3 VRHE to OCP, the metallic Cu was rapidly oxidized to Cu2O species within 10 s, and its three characteristic bands at 146, ~520, and ~620 cm−1 re-appeared after 20 s28,30,31. This rapid reoxidation phenomenon indicates a strongly oxidative species existing in the KHCO3 electrolyte, in contrast to the non-reoxidation process of OD-Cu in the Ar-saturated 0.25 M K2SO4 electrolyte (Supplementary Fig. 6). Here K2SO4 was selected as a control electrolyte because of its moderate solubility relative to KClO4 (~0.12 M), suitable chemical stability, and relatively weaker interaction with Cu in contrast to such as KCl and KI.

To further confirm the reduction/reoxidation phenomenon, we implemented a loop test where alternate potentials between OCP for 20 s and −0.3 VRHE for 10 s were employed. As shown in Fig. 1b, during the five cycles, we observed that the Cu2O phase disappears at −0.3 VRHE and re-produces at OCP. We found that the surface Cu species go through the process: Cu2O → CuOx → metallic Cu, with the cathode potential decreasing from OCP to −0.3 VRHE (Supplementary Fig. 2). It is a reverse process when switching from −0.3 VRHE to OCP. Thus, we suggest that the chemical state of Cu and the phase of surface Cu species are the results of dynamic equilibrium between the cathodic reduction and the reoxidation caused by strongly oxidative species in KHCO3 electrolytes. This explanation may reconcile the debates on the stability of Cuδ+ species during CO2RR observed from different groups8,9,16,17,18,19,20,21,22,23.

To preclude the effect of trace undesired oxidative species, such as residual O2, in the electrolyte or at the electrode surface, we implemented a long-time reduction of electrodeposited Cu electrode in CO2-saturated KHCO3 solution at −0.3 VRHE for 20 min. Then we switched the potential to OCP while recording the time-dependent optical microscopic images of the electrode surface (Supplementary Fig. 7). Within 10 min, the bright Cu surface gradually converted into a light-black surface, indicating an explicit oxidation process of Cu in the bulk KHCO3 electrolyte.

OH• radicals in KHCO3 electrolytes

Inspired by the formation of various radicals in the KHCO3 system33,34,35,36,37, we speculate that there may be free radicals in the as-used KHCO3 electrolytes. Thus, EPR spectroscopy was applied to investigate the radical species in a 0.5 M KHCO3 aqueous solution. Considering the very short lifetimes of radicals (up to several ms), 5,5-dimethyl-1-pyrroline N-oxide (DMPO) as a spin trapping agent was added into KHCO3 electrolytes, thus the formed DMPO-radical adducts have the lifetimes as long as minute-scale38, facilitating the EPR tests.

To eliminate any pre-introduced oxidative species, a 20 min of long-time reduction on the Cu electrode at −0.3 VRHE was performed in CO2-saturated 0.5 M KHCO3 containing 100 mM DMPO. At −0.3 VRHE, the hydrogen evolution reaction (HER) occurs and the generated hydrogen radicals (H•) can be trapped as a DMPO-H adduct (hyperfine splitting constants, AN = 1.65 mT, AH = 2.25 mT)38. Once the potential was switched to OCP, immediately the radicals in the solution were tested through a real-time EPR. As shown in Fig. 2a, DMPO-H radical adduct generated during the HER did not disappear as soon as we stopped the bias, owing to the increased lifetime, thus they can be measured even if we switched the potential from −0.3 VRHE to OCP. Interestingly, after 10 min, the DMPO-OH (AN = 1.50 mT, AH = 1.48 mT)39 emerged and gradually became the dominant signal with increasing the time within 60 min. Based on this carefully designed test protocol, we claim that the newly generated OH• radicals were indeed activated in the HCO3− electrolyte. The continuously ascending OH• radical intensity was further confirmed when resting the KHCO3 solution at OCP for 24 h without pre-reduction at −0.3 VRHE (Supplementary Fig. 8).

a Time-dependent EPR spectra of the KHCO3 solution after switching potential from −0.3 VRHE (20 min reduction) to OCP for different periods. b EPR spectra of the KHCO3 solution with 10 mM VC. Inset shows the structure transition from VC and oxidized VC-OX caused by OH•. The simulated EPR spectra of DMPO-OH, DMPO-H, and VC-OX adducts were obtained according to their hyperfine splitting constants.

We assume that the generation of fresh H• radical will end once stopping the potential at −0.3 VRHE, thus it is reasonable that the DMPO-H signal decays owing to its limited lifetime (Fig. 2a). In contrast, the signal of DMPO-OH increased over 24 h (Supplementary Fig. 8), suggesting a continuous production of OH• radicals with a considerable amount excited by the electrolyte, considering its half-time of DMPO-OH adduct (minute-scale)40,41. Besides, the Raman vibration of Cu-OH mode at 710 cm−1, which could be caused by OH• radical, was observed during CO2RR from 0.2 to −0.3 VRHE (Supplementary Fig. 2)28,42. OH• radical is a strongly oxidative species, with a high electrode potential of 2.73 V versus normal hydrogen electrode43, which can lead to the rapid reoxidation of surface OD-Cu in KHCO3 electrolytes during CO2RR.

The control experiments showed that no relevant DMPO-OH signals were detected in both pure water and 0.25 M K2SO4 solutions containing 100 mM DMPO (Supplementary Fig. 9). Meanwhile, the reoxidation behavior of surface OD-Cu in 0.25 M K2SO4 electrolytes was not observed via the in situ Raman test (Supplementary Fig. 6). These results imply that pure water or K+ cations alone cannot produce OH• radicals at room temperature. Nevertheless, we found that HCO3− anions play a key role in the generation of OH• radicals, by tuning the HCO3−/SO42− mole ratio under the same K+ concentration (0.5 M), where the DMPO-OH signals decreased with decreasing the HCO3− concentrations (Supplementary Fig. 10).

To further verify the OH• radicals, we added 10 mM vitamin C (VC) as an OH• scavenger into the CO2-saturated 0.5 M KHCO3 solution containing 100 mM DMPO. As shown in Fig. 2b, the EPR signal of the DMPO-OH adduct disappeared and was replaced by a newly formed VC-OX radical (AH = 0.18 mT) that is from VC oxidation (VC-OX) by OH• radicals44. The inset in Fig. 2b displays the oxidation process. The oxidation phenomenon was further demonstrated via the color variation of VC KHCO3 solution from colorless to light yellow after 24 h aging (Supplementary Fig. 11). A control experiment excludes the VC-OX radicals from self-oxidation, where no EPR signals were observed in the 10 mM VC water solution containing 100 mM DMPO (Supplementary Fig. 12). Besides, the reoxidation of OD-Cu electrode at OCP was not observed after the reduction of surface Cu2O species to metallic Cu at −0.3 VRHE in the CO2-saturated KHCO3 solution containing VC, by using in situ Raman spectroscopy (Supplementary Fig. 13).

To consider whether the formation of OH• radicals could be a thermally activated process, the signal of the DMPO-OH adduct has been tracked via a temperature-dependent study. We hypothesize that the room temperature may activate HCO3− solutions to produce OH• radicals. To confirm it, we implemented the temperature-dependent EPR measurements from 5 to 40 °C in an Ar-saturated 0.5 M KHCO3 electrolyte containing 100 mM DMPO (Fig. 3). When the temperature is as low as 5 °C, no EPR signals were detected. An obvious EPR signal from DMPO-OH was observed around 20 °C and increased with the enhanced temperature. This result indicates that temperature is a key parameter for OH• radical generation in the KHCO3 solutions.

Oxidizing corrosion of Cu plate in KHCO3 solution

Given the steady generation of OH• radicals in KHCO3 electrolytes, we supposed that it would result in a higher degree of oxidizing corrosion of Cu metal. A polished Cu plate (inset in Fig. 4a) was placed into a CO2-saturated KHCO3 solution. After 24 h resting, a visually light-black Cu surface was observed (inset in Fig. 4b). To preclude the CO2(aq) effect, the same operation was implemented in Ar-saturated KHCO3, and a darker Cu surface was observed associated with a stronger DMPO-OH signal (inset in Fig. 4c). Thus, the Cu oxidation by CO2(aq) was ruled out. To further ascertain Cu oxidation by electrolyte-induced OH•, the control experiments were carried out in KHCO3 solution containing VC, pure water, and K2SO4 solution, respectively. No obvious color changes were visually seen for the three cases (insets in Fig. 4d–f), compared to the pristine Cu plate (inset in Fig. 4a).

SEM images of Cu plates before a, and after 24 h oxidizing corrosions in b CO2-saturated KHCO3, c Ar-saturated KHCO3, d CO2-saturated KHCO3 containing VC, e Ar-saturated ultrapure water, and f Ar-saturated K2SO4 solutions. Correspondingly, the photographs are displayed in insets. g EPR spectra of the corresponding solutions containing 100 mM DMPO after 24 h resting. The concentrations of KHCO3, K2SO4, and VC are 0.5 M, 0.25 M, and 10 mM, respectively.

The surface morphology of polished Cu plates before and after oxidizing corrosions was characterized by using an optical microscope (Supplementary Fig. 14) and scanning electron microscopy (SEM, Fig. 4a–f). The oxidized surfaces were observed in CO2- and Ar-saturated KHCO3 solutions (Fig. 4b, c), relative to pristine Cu (Fig. 4a), KHCO3 solution with VC (Fig. 4d), pure water (Fig. 4e), and K2SO4 solution (Fig. 4f). Moreover, SEM images showed that the thicknesses of oxide layers at Cu plates reach ~596 and ~780 nm in CO2- and Ar-saturated KHCO3 solutions, respectively (Supplementary Fig. 15). The phase analyses by X-ray diffraction (Supplementary Fig. 16) and high-resolution transmission electron microscopy (HRTEM, Supplementary Fig. 17) illustrated that the corrosion products mainly consist of Cu2O. After corrosions, the atomic content of the O element determined by energy-dispersive spectroscopy (Supplementary Figs. 18–23) increased from pristine 0.65% to 14.72% and 19.82% in CO2- and Ar-saturated KHCO3 solutions respectively, while no obvious variations were discerned for the other three cases (Supplementary Fig. 24).

The oxidizing corrosion degrees are well related to the amount of OH• radicals. As shown in Fig. 4g, after 24 h resting, the CO2- and Ar-saturated KHCO3 solutions display obvious EPR signals of DMPO-OH and the latter has a higher intensity. By comparison, there was no signal for the other three solutions, except for the KHCO3 solution with VC that presents an EPR signal of VC-OX due to VC oxidation by OH• radicals. These results are further supported by analyzing the surface chemical states of Cu 2p of oxidized Cu plates using X-ray photoelectron spectroscopy (XPS), where a little Cu2+ species with deep oxidation was found for CO2- and Ar-saturated KHCO3 solutions, while only Cu1+/Cu0 species were identified for the other cases (Supplementary Fig. 25).

Sources of OH• radicals in KHCO3 solutions

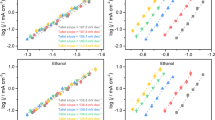

According to the above analysis, HCO3− anions play a vital role in determining the OH• generation. We thus studied the relationships between HCO3− concentration, the intensity of OH• radicals, and reoxidation dynamics on OD-Cu electrodes. Firstly, we investigated the influence of HCO3− concentrations on the amount of OH• radicals. As shown in Fig. 5a, at <0.1 M, the DMPO-OH signal increases with increasing the HCO3− concentrations, yet further increasing the concentrations cannot produce more OH• radicals. It is worth noting that further increasing the HCO3− concentration enhances the K+ concentration as well. Thus, at the same K+ concentration (0.5 M) with K+ compensation by K2SO4, the relationship between the HCO3− concentration and the intensity of DMPO-OH is more pronounced following the order 0.2 M < 0.4 M ≤ 0.5 M (Supplementary Fig. 10), and the intensity of DMPO-OH tends to saturate. The optimal HCO3− concentration without K+ compensation for the OH• radical formation is around 0.1 M (Fig. 5b).

a The acquired EPR spectra in different HCO3− concentrations. Each solution contains 100 mM DMPO. b Correspondingly, the normalized intensity of DMPO-OH versus HCO3− concentration. The intensity was normalized by that of 0.1 M HCO3−. The gray lines guide the trends of DMPO-OH intensity without the compensation of K+. The error bars represent the standard deviation. c–e Raman spectra of OD-Cu reoxidation in different KHCO3 concentrations at OCP after reduction at −0.3 VRHE.

Then, to correlate the OH• radicals with reoxidation of OD-Cu electrodes, we carried out in situ Raman in different concentrations of HCO3− solutions. As shown in Fig. 5c–e, with increasing the HCO3− concentration from 0.1 to 3.0 M, the Raman intensity of Cu2O species decreases, and the reappearance of Cu2O phase delays, during the reoxidation processes after reduction at −0.3 VRHE. Thus, it is indeed that the intensity of DMPO-OH is very related to the reoxidation ability. These results suggest that HCO3− contributes to the generation of OH• radicals that oxidize the Cu surfaces.

To clarify the sources of OH• radicals, we applied a Raman measurement with oxygen isotope labeling in Ar-saturated 0.5 M KHC16O3 H218O solution. The Raman vibrations of surface Cu2O species were recorded again by applying alternate potentials between −0.3 VRHE and OCP. As shown in Fig. 6a, during the three cycles, the characteristic bands of Cu2O species at ~502 and ~602 cm−1 locate between those of Cu216O (520, 620 cm−1) and Cu218O (495, 585 cm−1). This indicates that both HC16O3− anions and H218O are responsible for the OH• generation.

a Raman spectra of surface Cu2O species under the loop tests with reduction at −0.3 VRHE for 10 s and subsequently reoxidation at OCP for 20 s. The plots at the bottom show reference spectra for Cu216O and Cu218O. b 16O and 18O contents of the CuOx species at the Cu plates after 24 h oxidizing corrosion, measured by TOF-SIMS. c Raman spectra of carbonate species on the Cu electrode. Each spectrum was obtained after resting the solution for the indicated time. The bottom spectrum shows C16O32− vibration as a reference. d The proposed dynamic reduction/reoxidation process of surface OD-Cu during CO2RR.

To further reveal the respective contributions of HC16O3− and H218O to OH• radicals, we implemented time-of-flight secondary-ion mass spectrometry (TOF-SIMS) measurement to investigate the 16O and 18O contents of CuOx species formed after 24 h oxidizing corrosion of Cu plate in Ar-saturated 0.5 M KHC16O3 H218O solution. As illustrated in Fig. 6b, both 16O and 18O are detected in the whole sampling depth, and the latter has a little higher content. Concerning that pure water does not donate OH• radicals (Fig. 4g and Supplementary Fig. 9), and the isotope oxygen mole ratio (HC16O3− over H218O is around 1:100), we hypothesize that oxygen exchange between H218O and HC16O3− may exist.

To support this hypothesis, we tracked the adsorbed carbonate species on the OD-Cu electrode in Ar-saturated KHC16O3 H218O solution by using Raman spectroscopy. As displayed in Fig. 6c, within 30 min, both C16O32− vibration from pristine HC16O3− at 1073 cm−1 and C18O32− vibration from 18O-derived HC18O3− at 1050 cm−1 were detected45, indicating a fast oxygen exchange. After 45 min, dominant C18O32− vibration from 18O-exchanged HC18O3− was observed. Thus, we show that the OH• radicals have been generated at room temperature in HCO3− electrolytes while the dynamic oxygen exchange between HCO3− and H2O supplies oxygen sources for the formation of OH• radicals.

Based on the above results, we proposed a mechanism for the dynamic reduction/reoxidation behavior at the OD-Cu surface during CO2RR in Fig. 6d. The reduction of Cuδ+ species to metallic Cu0 driven via cathodic reduction competes with the reoxidation of Cu0 to Cuδ+ state caused by the highly oxidative OH• radicals. Thereby, there is a “seesaw-effect” between the reduction and reoxidation, determining the chemical state of Cu and the content of CuOx species at the surfaces of Cu electrodes in CO2RR.

We discovered that strongly oxidative OH• radicals can be easily generated in HCO3− aqueous solutions at room temperature, and the fast oxygen exchange between HCO3− and H2O provides dynamic oxygen sources for the OH• radical formation. The generated OH• radicals enable rapid reoxidation of OD-Cu electrodes in KHCO3 electrolytes during CO2RR. Besides, the continuous generation of OH• radicals can make higher degrees of oxidizing corrosion of Cu electrodes in KHCO3 solutions to form substantial surface CuOx species relative to those electrolytes without OH• radicals. We further suggest that the dynamic chemical states of Cu and the content of surface CuOx species are determined by a “seesaw-effect” between the cathodic reduction potentials and the OH• radical-involving oxidation. This work provides insights into the reoxidation mechanism of OD-Cu and a general guide for understanding the crucial role of electrolyte composition for the CO2RR.

Methods

Electrodeposited Cu electrodes

All the electrochemical operations were performed using a Bio-logic SP200 potentiostat. A modified electrodeposition method was used to deposit micro-nano Cu particles at the Cu mesh substrate29. The copper mesh was ultrasonically cleaned in acetone, ethanol, and deionized water in sequence. After drying by flowing N2, the electrodeposition was carried out by applying a reduction current of −40 mA cm−2 for 20 min to the Cu mesh electrode in an Ar-saturated solution consisting of 0.1 M CuSO4·5H2O (>99.99%, Aladdin) and 1.5 M H2SO4 (>98%, Chron Chemicals). The as-prepared electrode was rinsed with water and ethanol sequentially and then dried under a stream of N2.

Polished Cu plates

Cu plate with a thickness of ~0.2 mm was first polished by using 3000 mesh sandpaper and then cleaned in acetone, ethanol, and deionized water in sequence. Further, it was electropolished in 85% phosphoric acid (Chron Chemicals) solution at 3.0 V versus counter-electrode of another Cu plate for 5 min. After that, the polished Cu plate was ultrasonically cleaned in Ar-saturated ultrapure water (Milli-Q, 18.2 MΩ) to remove the surface residual particles.

Oxidizing corrosion of polished Cu plates

The polished Cu plates were placed into CO2-, Ar-saturated 0.5 M KHCO3, CO2-saturated 0.5 M KHCO3 containing 10 mM VC, Ar-saturated ultrapure water, Ar-saturated 0.25 M K2SO4, and Ar-saturated 0.5 M KHCO3 H218O solutions, respectively. After resting for 24 h, the corrosive Cu plates were rinsed with water and then dried under a stream of N2.

Materials characterization

Crystal phase structures were characterized by an XRD diffractometer (Equinox 1000, Thermo Fisher Scientific) with Cu Kα radiation (λ = 1.54 Å). Morphology was observed by field-emission SEM (FEI Inspect F50). Elemental analysis was implemented by using EDS. TEM and HRTEM images were acquired by using an FEI Titan G2 60-300 electron microscope. The surface chemistry of the Cu electrode/plate was investigated using XPS (Thermo ESCALAB 250XI) with Al Kα X-rays (1486.6 eV). The depth 16O and 18O contents of CuOx species formed at the surface of the Cu plate were analyzed by applying TOF-SIMS (ION TOF-SIMS 5) with 30 keV-Bi3+ as an analysis gun and 2 keV-Cs+ as the sputtering source.

In situ Raman spectroscopy

Raman spectra were recorded with an XploRA PLUS Raman spectrometer (Horiba Jobin Yvon) equipped with a ×50 objective and a 638 nm He-Ne laser. The filter was set at 50%. The measurements were conducted using a custom-made three-electrode electrochemical cell with a quartz window, in which the as-prepared Cu electrode, Ag/AgCl (3.0 M KCl), and membrane-separated Pt wire were used as the working, reference, and counter electrodes. Before each test, the as-used electrolyte was pumped into the cell at a rate of 2 ml min−1. The equipped optical microscope was applied to acquire the real-time microscopic images of as-used Cu electrodes during the Raman tests.

EPR spectroscopy

EPR measurements were carried out using a continuous-wave Bruker EMX micro spectrometer operating in X-band mode with a frequency of 9.848 GHz at room temperature. Each spectrum was recorded using the following parameters: a microwave power of 20 mW, modulation amplitude of 1.0 G, and a single scan with a sweep time of 5 min. DMPO (Dojindo) was selected as the spin trapping agent, and its concentration in all solutions was 100 mM. For EPR measurements taken during electrocatalysis in the presence of a Cu electrode, the electrolyte was immediately measured after electrolysis at a given potential in a specific electrolyte containing 100 mM DMPO. EPR simulations were performed according to the hyperfine splitting constants of radicals, via using the Xenon software provided by the EPR manufacturer.

Data availability

All the data that support the findings of this study are available within the paper and its Supplementary Information files, or from the corresponding author on reasonable request.

References

Nitopi, S. et al. Progress and perspectives of electrochemical CO2 reduction on copper in aqueous electrolyte. Chem. Rev. 119, 7610–7672 (2019).

Fan, L. et al. Strategies in catalysts and electrolyzer design for electrochemical CO2 reduction toward C2+ products. Sci. Adv. 6, eaay3111 (2020).

Nguyen, T. N. & Dinh, C. T. Gas diffusion electrode design for electrochemical carbon dioxide reduction. Chem. Soc. Rev. 49, 7488–7504 (2020).

Li, C. W. & Kanan, M. W. CO2 reduction at low overpotential on Cu electrodes resulting from the reduction of thick Cu2O films. J. Am. Chem. Soc. 134, 7231–7234 (2012).

Popovic, S. et al. Stability and degradation mechanisms of copper-based catalysts for electrochemical CO2 reduction. Angew. Chem. Int. Ed. 59, 14736–14746 (2020).

Raciti, D. & Wang, C. Recent advances in CO2 reduction electrocatalysis on copper. ACS Energy Lett. 3, 1545–1556 (2018).

Lee, S. Y. et al. Mixed copper states in anodized Cu electrocatalyst for stable and selective ethylene production from CO2 reduction. J. Am. Chem. Soc. 140, 8681–8689 (2018).

Yang, P. P. et al. Protecting copper oxidation state via intermediate confinement for selective CO2 electroreduction to C2+ fuels. J. Am. Chem. Soc. 142, 6400–6408 (2020).

Arán-Ais, R. M., Scholten, F., Kunze, S., Rizo, R. & Roldan Cuenya, B. The role of in situ generated morphological motifs and Cu(I) species in C2+ product selectivity during CO2 pulsed electroreduction. Nat. Energy 5, 317–325 (2020).

Favaro, M. et al. Subsurface oxide plays a critical role in CO2 activation by Cu(111) surfaces to form chemisorbed CO2, the first step in reduction of CO2. Proc. Natl Acad. Sci. USA 114, 6706–6711 (2017).

Xiao, H., Goddard, W. A. 3rd, Cheng, T. & Liu, Y. Cu metal embedded in oxidized matrix catalyst to promote CO2 activation and CO dimerization for electrochemical reduction of CO2. Proc. Natl Acad. Sci. USA 114, 6685–6688 (2017).

Shang, L., Lv, X., Shen, H., Shao, Z. & Zheng, G. Selective carbon dioxide electroreduction to ethylene and ethanol by core-shell copper/cuprous oxide. J. Colloid Interface Sci. 552, 426–431 (2019).

Zhi, X., Vasileff, A., Zheng, Y., Jiao, Y. & Qiao, S.-Z. Role of oxygen-bound reaction intermediates in selective electrochemical CO2 reduction. Energy Environ. Sci. 14, 3912–3930 (2021).

Wu, Z.-Z., Gao, F.-Y. & Gao, M.-R. Regulating the oxidation state of nanomaterials for electrocatalytic CO2 reduction. Energy Environ. Sci. 14, 1121–1139 (2021).

Beverskog, B. & Puigdomenech, I. Revised Pourbaix diagrams for copper at 25 to 300°C. J. Electrochem. Soc. 144, 3476–3483 (1997).

Permyakova, A. A. et al. On the oxidation state of Cu2O upon electrochemical CO2 reduction: an XPS study. Chemphyschem 20, 3120–3127 (2019).

Moller, T. et al. Electrocatalytic CO2 reduction on CuOx nanocubes: tracking the evolution of chemical state, geometric structure, and catalytic selectivity using operando spectroscopy. Angew. Chem. Int. Ed. 59, 17974–17983 (2020).

Lee, S. H. et al. Oxidation state and surface reconstruction of Cu under CO2 reduction conditions from in situ X-ray characterization. J. Am. Chem. Soc. 143, 588–592 (2021).

Lei, Q. et al. Investigating the origin of enhanced C2+ selectivity in oxide-/hydroxide-derived copper electrodes during CO2 electroreduction. J. Am. Chem. Soc. 142, 4213–4222 (2020).

Farmand, M. et al. Electrochemical flow cell enabling operando probing of electrocatalyst surfaces by X-ray spectroscopy and diffraction. Phys. Chem. Chem. Phys. 21, 5402–5408 (2019).

De Luna, P. et al. Catalyst electro-redeposition controls morphology and oxidation state for selective carbon dioxide reduction. Nat. Catal. 1, 103–110 (2018).

Kim, D. et al. Insights into an autonomously formed oxygen-evacuated Cu2O electrode for the selective production of C2H4 from CO2. Phys. Chem. Chem. Phys. 17, 824–830 (2015).

Cavalca, F. et al. Nature and distribution of stable subsurface oxygen in copper electrodes during electrochemical CO2 reduction. J. Phys. Chem. C. 121, 25003–25009 (2017).

Mistry, H. et al. Highly selective plasma-activated copper catalysts for carbon dioxide reduction to ethylene. Nat. Commun. 7, 12123 (2016).

Chang, C. J. et al. Dynamic reoxidation/reduction-driven atomic interdiffusion for highly selective CO2 reduction toward methane. J. Am. Chem. Soc. 142, 12119–12132 (2020).

Chang, C. J. et al. Quantitatively unraveling the redox shuttle of spontaneous oxidation/electroreduction of CuOx on silver nanowires using in situ X-ray absorption spectroscopy. ACS Cent. Sci. 5, 1998–2009 (2019).

Wang, J., Tan, H. Y., Zhu, Y., Chu, H. & Chen, H. M. Linking the dynamic chemical state of catalysts with the product profile of electrocatalytic CO2 reduction. Angew. Chem. Int. Ed. 60, 17254–17267 (2021).

Zhao, Y. et al. Speciation of Cu surfaces during the electrochemical CO reduction reaction. J. Am. Chem. Soc. 142, 9735–9743 (2020).

Wakerley, D. et al. Bio-inspired hydrophobicity promotes CO2 reduction on a Cu surface. Nat. Mater. 18, 1222–1227 (2019).

Chen, X. et al. Controlling speciation during CO2 reduction on Cu-alloy electrodes. ACS Catal. 10, 672–682 (2019).

Jiang, S., Klingan, K., Pasquini, C. & Dau, H. New aspects of operando Raman spectroscopy applied to electrochemical CO2 reduction on Cu foams. J. Chem. Phys. 150, 041718 (2019).

Vavra, J., Shen, T. H., Stoian, D., Tileli, V. & Buonsanti, R. Real-time Monitoring Reveals dissolution/redeposition mechanism in copper nanocatalysts during the initial stages of the CO2 reduction reaction. Angew. Chem. Int. Ed. 60, 1347–1354 (2021).

Draganić, Z. D. et al. Radiolysis of aqueous solutions of ammonium bicarbonate over a large dose range. Int. J. Radiat. Appl. lnstrum. Part C. Radiat. Phys. Chem. 38, 317–321 (1991).

Walton, J. C. Radical-enhanced acidity: why bicarbonate, carboxyl, hydroperoxyl, and related radicals are so acidic. J. Phys. Chem. A 121, 7761–7767 (2017).

Pan, H. et al. Recent advances in bicarbonate-activated hydrogen peroxide system for water treatment. Chem. Eng. J. 408, 127332 (2021).

Gennaro, A. et al. Mechanism of the electrochemical reduction of carbon dioxide at inert electrodes in media of low proton availability. J. Chem. Soc., Faraday Trans. 92, 3963–3968 (1996).

Gupta, N., Gattrell, M. & MacDougall, B. Calculation for the cathode surface concentrations in the electrochemical reduction of CO2 in KHCO3 solutions. J. Appl. Electrochem. 36, 161–172 (2005).

Buettner, G. R. Spin trapping: ESR parameters of spin adducts. Free Radic. Biol. Med. 3, 259–303 (1987).

Chen, J. et al. OH radicals determined photocatalytic degradation mechanisms of gaseous styrene in TiO2 system under 254 nm versus 185 nm irradiation: combined experimental and theoretical studies. Appl. Catal. B-Environ. 257, 117912 (2019).

Tsai, P., Pou, S., Straus, R. & G. M. Rosen evaluation of various spin traps for the in vivo in situ detection of hydroxyl radical. J. Chem. Soc. Perkin Trans. 2, 1759–1764 (1999).

Nakamura, K. et al. Reevaluation of quantitative ESR spin trapping analysis of hydroxyl radical by applying sonolysis of water as a model system. Bull. Chem. Soc. Jpn. 83, 1037–1046 (2010).

Bodappa, N. et al. Early stages of electrochemical oxidation of Cu(111) and polycrystalline Cu surfaces revealed by in situ raman spectroscopy. J. Am. Chem. Soc. 141, 12192–12196 (2019).

Armstrong, D. A. et al. Standard electrode potentials involving radicals in aqueous solution: inorganic radicals (IUPAC Technical Report). Pure Appl. Chem. 87, 1139–1150 (2015).

Dodd, N. J. F. Some EPR signals in tumour tissue. Br. J. Cancer 28, 257–262 (1973).

Zhang, Z. et al. pH matters when reducing CO2 in an electrochemical flow cell. ACS Energy Lett. 5, 3101–3107 (2020).

Acknowledgements

C.C. acknowledges funding support from the Natural Science Foundation of China (22072013). S.M. thanks funding support from the China Postdoctoral Science Foundation (No. 2020M673169).

Author information

Authors and Affiliations

Contributions

C.C. supervised the project. S.M. carried out the experiments. H.L. and Q.W. contributed to the EPR measurements and analysis. L.L. and R.Z. contributed to partial Raman measurements. S.M., C.L. and C.C. wrote and revised the manuscript. All authors commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Joel Ager III and the other anonymous reviewer(s) for their contribution to the peer review of this work. Peer review reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mu, S., Lu, H., Wu, Q. et al. Hydroxyl radicals dominate reoxidation of oxide-derived Cu in electrochemical CO2 reduction. Nat Commun 13, 3694 (2022). https://doi.org/10.1038/s41467-022-31498-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-022-31498-8

This article is cited by

-

In situ reconstruction induced oxygen-deficient multiphase Cu based species hybridized with Ni single atoms as tandem platform for CO2 electroreduction

Nano Research (2024)

-

Nanocavity enriched CuPd alloy with high selectivity for CO2 electroreduction toward C2H4

Rare Metals (2024)

-

Promoting water dissociation for efficient solar driven CO2 electroreduction via improving hydroxyl adsorption

Nature Communications (2023)

-

Toward highly active electrochemical CO2 reduction to C2H4 by copper hydroxyphosphate

Journal of Solid State Electrochemistry (2023)

-

Active site identification and engineering during the dynamic evolution of copper-based catalysts for electrocatalytic CO2 reduction

Science China Chemistry (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.