Abstract

Electroreduction of carbon dioxide (CO2) into multicarbon products provides possibility of large-scale chemicals production and is therefore of significant research and commercial interest. However, the production efficiency for ethanol (EtOH), a significant chemical feedstock, is impractically low because of limited selectivity, especially under high current operation. Here we report a new silver–modified copper–oxide catalyst (dCu2O/Ag2.3%) that exhibits a significant Faradaic efficiency of 40.8% and energy efficiency of 22.3% for boosted EtOH production. Importantly, it achieves CO2–to–ethanol conversion under high current operation with partial current density of 326.4 mA cm−2 at −0.87 V vs reversible hydrogen electrode to rank highly significantly amongst reported Cu–based catalysts. Based on in situ spectra studies we show that significantly boosted production results from tailored introduction of Ag to optimize the coordinated number and oxide state of surface Cu sites, in which the *CO adsorption is steered as both atop and bridge configuration to trigger asymmetric C–C coupling for stablization of EtOH intermediates.

Similar content being viewed by others

Introduction

Electroreduction of carbon dioxide (CO2) to high-value chemicals and fuels is seen to be practically promising for the utilization of renewable electricity and mitigation of CO2 emissions, which has emerged as a frontier in energy conversion and carbon neutrality1,2,3. During the CO2 reduction reaction (CO2RR), the applied electrical energy is converted to stored chemical energy via reorganizing the molecular bonds in CO2 and water to generate products with one (C1), or two or more (C2+) carbon atoms, under the effect of catalysts4,5,6. Most metal catalysts such as gold (Au), silver (Ag), tin (Sn), and lead (Pb) generate a mix of C1 products7,8, whilst only Cu-based catalysts transform CO2 toward C2+ products via coupling the adsorbed *CO intermediates9,10,11. Amongst the various C2+ products formed on Cu catalysts, EtOH is important as the liquid fuel because of its wide application and high-energy-density and because it provides the possibility of long-term, large-scale and seasonal energy storage, and convenient transport3,12. The production of EtOH with high current density and Faradaic efficiency (FE) via Cu-based catalysts is significant to advancing CO2RR as a renewable chemical feedstock2,3,13. During CO2RR, EtOH and ethylene (C2H4) are both 12-electron reduced products, and share the initial intermediates *HCCOH. Given the more saturated structure of EtOH compared with that for C2H4, the next-intermediates for EtOH are more difficult to stabilize on a pure Cu surface compared with C2H4. The production of EtOH via C–O bond-reserving of *HCCOH will therefore have chemical difficulty in competing with C2H4 generation. This typically results in the EtOH production in the range of 2–3 times less than that for C2H4 on Cu-based catalyst3,11,12,13,14.

To boost EtOH production, research interest has concentrated on optimal re-design of Cu-based catalysts5,6,15,16,17,18,19,20,21,22. Strategies including, control of morphology and facet16,17, vacancy steering18, dopant and modification engineering19,20, and defects control21,22 have been reported. Among these, the modification of Cu with other CO2-–active metals to form Cu-based bimetallic is reported as practically attractive15,23,24,25,26,27,28. For example, Jaramillo et al. reported Cu–Au bimetallic catalysts with boosted selectivity for CO2RR to EtOH, and a synergistic catalytic pathway with CO–tandem mechanism was proposed that CO was first generated on Au, desorbed and migrated to near Cu active sites where C–C coupling to EtOH was conducted24. Zheng et al. reported a boosted EtOH selectivity in a Cu3Ag1 bimetallic catalyst with electron-deficient Cu sites via promoting adsorption of key intermediates25. Clark et al. hypothesized that the boosted EtOH selectivity results from Ag-induced strain effects of Cu surfaces that modulate EtOH production and suppresses the hydrogen evolution reaction (HER)26. Despite significant progress, the advances of reported bimetallic catalysts for FE of EtOH (FEEtOH) remain limited, especially the production and output efficiency for EtOH is far from the current target for practical application29,30,31,32,33,34,35,36,37,38 (i.e., partial current density > 300 mA cm−2 and half-cell cathodic energy efficiencies (EEHC) > 20%). In addition, the key impact of modified components on intrinsic kinetics of reported Cu-based bimetallic catalysts for CO2RR at high conversion rates is unclear, which significantly hinders understanding of the mechanism and catalyst design3,14. Taken together, there is a need therefore for more efficient catalysts and an improved understanding of the mechanism for CO2RR to practically boost EtOH under commercial current densities.

Here, through modifying Ag onto cubic Cu2O and activating under CO2RR, we investigated derived CuAg bimetallics (dCu2O/Ag) with controlled morphology, phase, and composition for CO2RR at high current operation. In contrast to the Cu2O and Au-modified Cu2O derivatives which favor the conversion of CO2 to C2H4 and CO, respectively, the optimal dCu2O/Ag2.3% exhibited an asymmetric C–C coupling to stabilize reaction intermediates for boosted EtOH production under high current density. The as-obtained dCu2O/Ag2.3% exhibits FE and EEHC for EtOH of, 40.8% and 22.4%, respectively. We show in a direct comparison with reported catalysts that it has the greatest reported partial EtOH current density with 326.4 mA cm−2. In situ studies confirm that the redispersion of Ag into Cu significantly optimizes the coordinated number and oxide state of Cu. In this way, the *CO binding strength is altered to form a blended adsorption configuration, that triggers asymmetric C–C coupling for stabilization of EtOH intermediates, and results in boosted EtOH production. This work constructs an efficient catalyst for CO2RR with high EtOH selectivity at commercially relevant current densities, and provides guidance for designing catalysts with tailored selectivity in multi-electron reactions.

Results

Catalyst preparation and characterization

Pristine Ag-modified Cu2O nanocubes (Cu2O/Ag NCs) were prepared by a one-pot seed-medium method in which Cu2O NCs were achieved via reduction of Cu(OH)2 at room temperature (RT, 25 °C) with ascorbic acid (AA) as a reducing agent, followed by the addition of AgNO3. Because of the appropriate lattice spacing match, the added AgNO3 rapidly nucleates and grows due to the effect of AA to deposit ‘small’ Ag nanoparticles (Ag NPs) on Cu2O NCs surface (Fig. 1a). Transmission electron microscopy (TEM) images reveal that the Cu2O/Ag NCs exhibit heterostructure that Ag NPs sporadically adorn the Cu2O surface (Fig. 1b and Supplementary Fig. 1a), in comparison to Cu2O NCs with cubic morphology and a side length of ~45 nm (Supplementary Fig. 2). X-ray photoelectron spectroscopy (XPS) and scanning electron microscopy energy-dispersive X-ray spectroscopy (SEM-EDS) confirm that the Ag NPs in Cu2O/Ag NCs are metallic, with the content controlled to 2.3% (Fig. 1c and Supplementary Fig. 1b). High-resolution TEM (HRTEM) image highlights the interplanar spacing of the lattice fringes for Cu2O NCs and Ag NPs regions to be 0.214 nm and 0.236 nm in Cu2O/Ag2.3% NCs. This finding is consistent with the Cu2O (200) plane and Ag (111) plane, respectively (Fig. 1d). Powder X-ray diffraction (XRD) was carried out to confirm the phase of Cu2O/Ag NCs. It was found that Cu2O/Ag NCs exhibit the same peak as for Cu2O NCs which is attributed to the low Ag NPs content (Fig. 1e). In addition, the EDX mapping images for Cu2O/Ag2.3% NCs also display an apparent element separation between Ag NPs and Cu2O NCs, (Fig. 1f). XPS assesses the surface properties of catalysts. The peaks at 951.8 and 931.8 eV for Cu2O NCs are ascribed to, Cu 2p1/2 and 2p3/2, respectively, confirming the presence of Cu(I) in Cu2O NCs (Fig. 1g)39. Following Ag modification, two shoulder peaks for Cu(II) were apparent in the XPS spectra, demonstrating that electrons transfer from Cu2O to Ag. This finding is validated via the Auger electron spectroscopy (AES) for Cu LMM in which the peaks for Cu2O/Ag2.3% NCs downshifts to a lower kinetic energy compared with those for Cu2O NCs (Supplementary Fig. 3). These findings indicate that an Ag/Cu2O heterostructure with altered electron structure for Cu2O was reached with Cu2O/Ag2.3% NCs.

a Schematic for preparation of Cu2O/Ag NCs. b TEM image, c Ag 3d XPS curve, d HRTEM images and f EDS elemental mapping images of Cu2O/Ag2.3% NCs. e XRD patterns and g Cu 2p XPS curves for Cu2O and Cu2O/Ag2.3% NCs. Scale bars, 10 nm in (b), 1 nm in (d), and 100 nm in (f). White-color, orange and azure spheres in the model represent O, Cu, and Ag atoms, respectively.

Catalyst evolution under CO2RR

Given the reported evolution of Cu-based catalysts under high current CO2RR36, activation and in situ characterization was therefore conducted for Cu2O/Ag2.3% NCs to determine the actual state of the catalyst during CO2RR. A flow cell with gas diffusion electrode (GDE) was especially designed as a reactor for a high current test (Supplementary Fig. 4). As a basis for a detailed comparison, Cu2O NCs and Au-modified Cu2O NCs (Cu2O/Au2.3% NCs) with similar morphology, composition, and structure to Cu2O/Ag2.3% NCs were synthesized and assessed (Supplementary Fig. 5). The catalysts were deposited onto the GDE via spray-coating of the configured ink (details in Supplementary Methods). Activation was controlled by electroreduction of the parent material under CO2RR at a current density of 200 mA cm−2 in 1 M KOH for 30 min. The derived Cu-based catalysts obtained following activation supported on the GDE, denoted as dCu2O, dCu2O/Ag, and dCu2O/Au, were subjected to additional characterization.

High-angle annular dark-field scanning TEM (HAADF STEM) and SEM images confirm that following activation the original cubic morphology and surface deposited NPs are visually less pronounced, and that instead, ragged surface and hollow structures formed in dCu2O/Ag2.3% and dCu2O/Au2.3% (Fig. 2a and Supplementary Figs. 6 and 7a). Concomitantly, the original surface phase separation between deposited metal and Cu is lost following activation as is confirmed in EDS mapping images (Fig. 2a, Supplementary Fig. 7b). The lattice space for dCu2O/Ag2.3% was altered to 0.210 nm following activation, a value near to the Cu (111) facet (Fig. 2b). Ex situ XRD patterns reveal that the diffraction peaks for Cu2O for all catalysts are decreased significantly whilst the diffraction peaks for Cu became dominant. This finding demonstrates that all catalysts are transformed to mainly metallic Cu following activation (Supplementary Fig. 8). Compared with dCu2O, the XRD peaks of Cu (111) for dCu2O/Ag2.3% and dCu2O/Au2.3% exhibit a meaningful, slight shift to a higher degree to underscore that the original Cu2O/metal heterostructures are evolved into the bimetallic alloy following activation (Fig. 2c).

a HAADF–STEM image with EDS elemental mappings and b high resolution STEM image of dCu2O/Ag2.3%. c Enlarged XRD patterns for dCu2O, dCu2O/Ag2.3% and dCu2O/Au2.3%. d In situ XANES spectra and e Wavelet transform images of EXAFS data with optimized Morlet parameter (i.e., κ = 5, σ = 1) at Cu K-edge for commercial Cu-foil, dCu2O, dCu2O/Ag2.3% and dCu2O/Au2.3%. Fourier transform curves of in situ EXAFS data and corresponding fitted results (first coordination shell) for f dCu2O, g dCu2O/Ag2.3% and h dCu2O/Au2.3%. Scale bars, 10 nm in (a) and 1 nm in (b).

To gain insight into the changed valence states and coordination environment of Cu following activation, operando X-ray absorption spectra (XAS) of Cu K-edge was recorded under activation conditions. The X-ray absorption near-edge structure (XANES) spectra show that the edge features for dCu2O, dCu2O/Ag2.3%, and dCu2O/Au2.3% are closed to those for the reference commercial Cu-foil. This finding confirms that the valence state for Cu for these catalysts decrease following activation to lie between 0 and +1, in following ordered sequence, dCu2O < dCu2O/Ag2.3% < dCu2O/Au2.3% (Fig. 2d). The wavelet transform analysis confirms that the Cu–Cu region in all activated catalysts are located at ~6.7 Å−1, suggesting that the alloyed CuAg and CuAu do not result in significant change in Cu–Cu bond length compared with the oxide-derived Cu (Fig. 2e). The corresponding Fourier transform curves (from extended X-ray absorption fine structure (EXAFS) spectra) and fitted results of the first coordination shell for these activated catalysts show that the Cu–Cu coordination located at ~2.23 Å is the dominant structure in each sample, whilst there remains another Cu–O coordination peak at 1.35 Å for dCu2O/Ag2.3% and dCu2O/Au2.3%. This finding confirms that a significantly small fraction of Cu(I) remained for dCu2O/Ag2.3% and dCu2O/Au2.3% following activation (Fig. 2f–g and Supplementary Table 1). The coordination number for Cu−Cu in these catalysts was determined to equal, respectively, 11.4, 10.5, and 10.2 for dCu2O, dCu2O/Ag2.3%, and dCu2O/Au2.3% (Supplementary Fig. 9). Except for variation in Cu, the XPS for Ag 3d for dCu2O/Ag2.3% shows that the binding energy for Ag 3d5/2 shifts to a high level following activation. This evidences that the activation of alloying Ag with Cu induces electron transfer (Supplementary Fig. 10). Based on the foregoing, it is concluded that under electroreduction with highly significant structural rearrangement, the pristine metal-modified Cu2O NCs evolves to Cu-based bimetallics in a regulated valence and coordination environment.

CO2RR performance

CO2RR performance for the activated catalysts was directly evaluated via electrolyzing at specified currents (Supplementary Fig. 11). Figure 3a shows the linear sweep voltammetry curves for dCu2O, dCu2O/Ag2.3% and dCu2O/Au2.3%. It is seen in the figure that the current density for CO2RR of dCu2O/Ag2.3% and dCu2O/Au2.3% are significantly increased, directly evidencing that modification boosted activity for CO2RR. The FEs were computed for liquid and gaseous product in the applied current range 200–800 mA in 1 M KOH by nuclear magnetic resonance (NMR, Supplementary Fig. 12) and gas chromatography (GC) (Supplementary Fig. 13) respectively. Figure 3b presents the FEs of C2+ products (FEsC2+) for these catalysts under different current. C2H4 and EtOH are the major C2+ products, plus minor acetate and n–propanol. With the applied current increased, all catalysts exhibited increased FEsC2+ and a decreased FEs of CO (FEsCO). Compared with the one–up FEC2+ for dCu2O from 200 to 400 mA, dCu2O/Ag2.3% exhibits greater FEC2+ at significant current > 600 mA. Importantly, the total FEC2+ for dCu2O/Ag2.3% is up to 82.1% at a current density 800 mA cm−2, to exhibit the greatest partial C2+ current density of 656.8 mA cm−2 and formation rate of 2042.2 μmol h−1 cm−2 at −2.11 V with reference to the reversible hydrogen electrode (VRHE, no iR correction, Fig. 3c and Supplementary Fig. 14a). In contrast, the FEC2+ for dCu2O/Au2.3% is significantly less than that for dCu2O/Ag2.3% at all currents, confirming that the Au modification resulted in directly boosting only targeted CO generation, but not C–C coupling.

a Linear sweep voltammetry curves toward CO2RR for dCu2O, dCu2O/Au2.3% and dCu2O/Ag2.3%. b FE value of C2+ products for dCu2O, dCu2O/Au2.3% and dCu2O/Ag2.3% under selected current density. c Partial C2+ current density and e C2+ formation vs potential referred to reversible hydrogen electrode (RHE) on dCu2O, dCu2O/Au2.3%, and dCu2O/Ag2.3%. d Ratio of FEEtOH to FEC2H4 on dCu2O, dCu2O/Au2.3%, and dCu2O/Ag2.3% under selected current density. f EtOH partial current density vs FEEtOH for reported Cu-based catalysts. Error bars correspond to the standard deviation of three independent measurements.

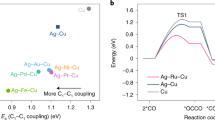

We analyzed the ratio of FEEtOH/FEC2H4 in C2+ products at high current density on these catalysts. It is interesting that dCu2O/Ag2.3% reaches the FEEtOH/FEC2H4 ratio 1.17 at an applied current 800 mA, which is significantly greater than that for dCu2O (0.51) and dCu2O/Au2.3% of 0.71. This finding confirms that the Ag modification significantly inhibits C–O bond-breaking and stabilizes intermediates for EtOH vs C2H4 (Fig. 3d). Relying on the boosted FEEtOH of 40.8 % at a high current density (800 mA cm−2), the dCu2O/Ag2.3% exhibits the greatest partial EtOH current density of 326.4 mA cm−2 at −2.11 VRHE (no iR correction, −0.89 VRHE with 85% iR correction, Supplementary Figs. 15 and 16). Importantly, this is 1.78 and 1.89 times greater than that for dCu2O and dCu2O/Au2.3%, respectively (Fig. 3e). The EtOH formation for dCu2O/Ag2.3% could reach 1014.9 μmol h−1 cm−2 with current densities of 800 mA cm−2 at −2.11 VRHE (without iR correction) (Supplementary Fig. 14b). Such highly significant performances for EtOH production on dCu2O/Ag2.3% were compared directly with reported catalysts (Fig. 3f, Supplementary Table 2). It is apparent that the dCu2O/Ag2.3% exhibits the greatest reported partial EtOH current density amongst these, and represents the ‘best’ production for electroreduction of CO2 to EtOH. In addition, the EEHC for EtOH on dCu2O/Ag2.3% reaches 22.4% following iR correction under similar conditions, a value greater than that for most catalysts (Supplementary Fig. 16d). In addition, the electrochemically active surface area (ECSA) for dCu2O/Ag2.3% was computed via different methods and compared, together with mass normalized current density for EtOH (JECSA(EtOH) and Jmass(EtOH)) with independently reported studies (Supplementary Figs. 17 and 18 and Supplementary Table 3). The dCu2O/Ag2.3% exhibited superior JECSA(EtOH) and Jmass(EtOH) compared with reported catalysts, confirming that the improved EtOH current density for dCu2O/Ag2.3% is because of the intrinsic Ag-modified oxide-derived Cu sites and not the changed ECSA and mass loading of the catalyst itself.

Based on these findings therefore of highly significant FEEtOH with high current density from dCu2O/Ag2.3% on CO2RR, a series of Cu2O/Ag NCs with different amounts of modified Ag were assessed for CO2RR performance (Supplementary Figs. 19 and 20). Characterizations underscore that all pristine Cu2O/Ag NCs with different compositions exhibit similar structures, whereas the density of deposited NPs and oxidation state on the surface of Cu2O NCs increased with the degree of modification (Supplementary Fig. 21). From the comparison of the potential for CO2RR of different catalysts at a high current density of 800 mA cm−2 (Fig. 4a), it can be seen that the demand potential decreases with increased Ag. This finding confirms the positive impact of Ag modification on CO2RR. The degree of introduced Ag-dependent FEs of products from these catalysts was assessed under the same current density. As is shown in Fig. 4b, c, increasing Ag in dCu2O/Ag leads to a volcano-shape for FEEtOH that corresponds with a reverse-volcano on FECO, and contrasts with the monotonously decreased FE for C2H4. This correlation between the amount of modified Ag and FEs for CO and EtOH was observed also with other applied currents (Supplementary Fig. 22). Common to Cu-based catalysts, the coverage of CO on Cu surface is conducive to C–C coupling to impact EtOH and C2H4 generation concurrently24. However, here for the dCu2O/Ag, only the FE for EtOH exhibits the dependent correlation with CO. These results indicate that the boosted EtOH is not only dependent on variable CO coverage on dCu2O/Ag, but also related to other unknown factors.

Comparison of a applied potentials, b FEs for C1 and H2 product, c FEs for C2H4 and EtOH and total C2+ product on dCu2O/Ag with modified Ag at current density 800 mA cm−2. d Total current density and e FEs for C2+ product for CO2RR on dCu2O/Ag2.3% at selected cell voltage under MEA measurement. f Stability test for dCu2O/Ag2.3% at the current density 800 mA cm−2 in MEA. Error bars correspond to the standard deviation of three independent measurements.

The stability of dCu2O/Ag2.3% was evaluated via long-term chronopotentiometry testing. It was found that there is no apparent decay of activity with 6 h continuous operation, in which the selectivity of EtOH decreased ~6% following CO2RR (Supplementary Fig. 23). TEM image and XRD pattern of spent dCu2O/Ag2.3% showed that morphology and structure are maintained following the stability test (Supplementary Fig. 24). Given the superior EtOH production on dCu2O/Ag2.3%, it was consequently assessed in a commercially relevant membrane electrode assembly (MEA) (Supplementary Fig. 25). It was found that there is a good, linear relationship between applied current and voltage in the MEA (Fig. 4e). The FEs for all products tested in flow cell electrolyzer were well-reproduced in MEA (Supplementary Fig. 26 and Fig. 4d), identifying that high current and high EtOH selectivity can be maintained under commercially relevant conditions (Fig. 4e). Importantly, the durability of CO2RR in the catholyte–free MEA significantly outperformed the flow cell electrolyzer, which exhibited a decrease of FEEtOH (~3%) in 12 h operation under a full–cell voltage of −4.72 V with a total current density 800 mA cm−2, evidencing the good stability of dCu2O/Ag2.3% for CO2RR (Fig. 4f).

Mechanistic studies

The CO reduction reaction (CORR) on dCu2O/Ag was assessed to identify whether boosted C–C coupling and EtOH generation followed a classic CO–tandem mechanism (Supplementary Fig. 27). To permit a direct comparison, the CORR behavior of dCu2O and dCu2O/Au2.3% were evaluated and the catalysts were activated by a similar process with CO2RR. It was expected that if the CO–tandem mechanism dominated, the CORR performance for the catalysts would be similar28. However, as is shown in Supplementary Fig. 28, the dCu2O/Ag2.3% exhibits significant suppression of H2 and promoted C–C coupling for C2+ products under CORR. This is in significant contrast to dCu2O/Au2.3% and dCu2O results. The partial current density of C2+ products for dCu2O/Ag2.3% reaches 696.0 mA cm−2 at –1.56 VRHE for CORR, and is significantly greater than those for dCu2O/Au2.3% (~154.0 mA cm−2) and dCu2O (~188.0 mA cm−2). Similarly, the ratio FEEtOH/FEC2H4 for dCu2O/Ag2.3% is also greater than that for dCu2O/Au2.3% and dCu2O under CORR. Significantly, these findings from dCu2O/Ag2.3% contrast with those for reported Cu–Ag catalyst with CO–tandem mechanism. This is interpreted that Ag modification results in intrinsic property changes in Cu active sites to: (1) suppress HER, (2) improve C–C coupling activity, and; (3) boost EtOH selectivity. In addition, the modification induced compressive strain, and morphology effects (crystal facets) for boosted EtOH production can be also excluded in our circumstances, because the exposed facets, surface structure and Cu–Cu bond length of both dCu2O/Au2.3% and dCu2O/Ag2.3% catalysts are similar. Therefore, other potential mechanisms on dCu2O/Ag2.3% need to be assessed for boosted CO2RR performance.

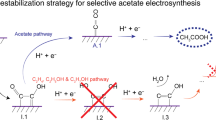

Reaction pathways for C2H4 and EtOH production are similar on Cu surfaces, as they initiate with two adsorbed–CO dimerization followed by several steps of protonation and dehydration to generate a shared intermediate, *HCCOH3,14. The selectivity between C2H4 and EtOH, is significantly dependent on the relative stabilities of the next-intermediates for EtOH and C2H4 pathways branched from *HCCOH on Cu sites3,14,40. Cu with a relatively low coordinated surface and optimal oxide state is favorable for EtOH generation over C2H4 because the reaction intermediates for EtOH are more saturated compared with those for C2H441, and the existing oxidation is feasible to binding of key oxygen-bound intermediates for EtOH generation33,42. Combined with this and previous experiment results, it is hypothesized that Ag-induced the moderate coordinated surface and optimal oxidation of Cu in dCu2O/Ag2.3% are responsible for boosted EtOH selectivity. Therefore, the CO2RR intermediates chemisorbed on dCu2O, dCu2O/Ag2.3%, and dCu2O/Au2.3% at different potentials were assessed via in situ attenuated total reflectance infrared absorption spectroscopy (ATR–IRAS) to determine the mechanism for boosted EtOH.

As is shown in Fig. 5a, b and Supplementary Fig. 29, with the cathode potential at −0.3 VRHE, the ATR–IRAS spectra for these catalysts exhibit several new peaks. These are assigned to corresponding intermediates based on independently reported studies (Supplementary Table 4). In particular, there appear two peaks at 2044 and 1923 cm−1 for dCu2O/Ag2.3%, which are associated with the atop–adsorbed *CO (*COatop) and bridge–adsorbed *CO (*CObridge) on Cu surface, respectively43,44,45. In comparison, dCu2O and dCu2O/Au2.3% mainly show the *COatop peak with little evidence of *CObridge binding in the same potential region. The different *CO binding configurations on these catalysts can also be observed from CO temperature-programmed desorption (CO–TPD) (Supplementary Fig. 30b). Mathematical integration and statistical analyses confirm the ratio *CObridge/*COatop for dCu2O/Ag2.3% is significantly greater than that for dCu2O or dCu2O/Au2.3% over the potential range (Supplementary Fig. 31 and Fig. 5c). These findings evidence that compared with dCu2O and dCu2O/Au2.3%, the moderate coordination numbers and optimal oxidation for Cu surface in dCu2O/Ag2.3% result in tailored *CO configuration. Given the different electron back-donating and proton-combining ability of adsorbed *CO on atop and bridge Cu sites, the energy barrier for following *CO protonation is altered. Previous studies demonstrate that *CObridge protonation is more energetically favorable than that of *COatop on Cu surface46. Therefore, the C–C coupling on dCu2O/Ag2.3% could be triggered under asymmetry between *CO and *CHO (or *COH) following the *CObridge protonation step. Notably, adsorbed *CHO intermediate was observed on dCu2O/Ag2.3% from ATR-FTIR spectra, and increased with the applied potential (Fig. 5b), strongly evidencing this process. This asymmetric C−C coupling has a lower energy barrier than that for *CO dimerization as evidenced by the reported theory studies19, which contributes to increased C2+ production.

In situ ATR–IRAS obtained during chronopotentiometry in a potential window 0.2 to −1.2 VRHE for a dCu2O, and b dCu2O/Ag2.3% under CO2RR. (A reference spectrum obtained at 0.3 VRHE in 1 M KOH is subtracted). Potential dependence of ratio of c *CObridge/*COatop and d *OC2H5/*OCCOH obtained for dCu2O, dCu2O/Ag2.3% and dCu2O/Au2.3%. e Schematic for boosted EtOH generation over dCu2O/Ag2.3%. Yellow-color, gray, white, orange, red, and azure spheres in the model represent H, C, O, Cu1+, Cu0, and Ag atoms, respectively.

Additional peaks from ATR–IRAS spectra at ~1567 and ~1182 cm−1 and ~1336 and ~1117 cm−1 were analyzed. These peaks, indexed to the absorbed *OCCOH and *OC2H5 on these catalysts, exhibit a ratio value for *OC2H5/*OCCOH on dCu2O/Ag2.3% that is significantly greater compared with that for dCu2O and dCu2O/Au2.3%. This finding evidences that the key *OC2H5 intermediates for EtOH production are more stable on dCu2O/Ag2.3% (Fig. 5d)42,43. This is attributed to the asymmetric C−C coupling induced unbalanced coordination environment, which disrupts the coordination sites for C2H4 intermediates, and thereby, stabilizes the EtOH intermediates. This is in agreement with report that diversity of *CO binding site enhances C2+ liquid product formation27. Therefore we hypothesize that triggered asymmetric C−C coupling on dCu2O/Ag2.3% boosts C2+ production and favors EtOH pathway via stabilizing pivotal intermediates.

In addition, the peak for the absorbed bicarbonate at 1547 cm−1 on dCu2O/Ag2.3% is missing compared with dCu2O and dCu2O/Au2.3%, confirming that the value of the local pH on the electrode of dCu2O/Ag2.3% is greater than that for dCu2O and dCu2O/Au2.3% during CO2RR47. The high pH at the surface of electrode is thought to favor C–C coupling by lowering the energy barrier of CO2 activation and suppressing H2 evolution, and contributes to the boosted activity for CO2RR. Moreover, the CO–TPD and CO2–TPD for dCu2O/Ag2.3% also exhibit a higher temperature for CO2 and CO desorption than those for dCu2O and dCu2O/Au2.3, indicating dCu2O/Ag2.3% has stronger bonding strength of CO2 and CO for efficient CO2RR at large current (Supplementary Fig. 30).

Accordingly, based on the ATR–IRAS spectra analysis, the mechanism for boosted EtOH on dCu2O/Ag2.3% can be soundly proposed (Fig. 5e). At first, the coordinated pure-Cu surface is replaced with neighboring Ag atoms with modification by Ag in Cu2O and reduces these to CuAg alloy under CO2RR. Then, the Ag-induced moderate coordination numbers and optimal oxidation of Cu surface regulate binding strength of *CO, to configure mixed *CObridge and *COatop adsorption that triggers asymmetric C–C coupling after *CObridge protonation. Because of the relatively low oxygen affinity and unsaturated nature of the C2H4 intermediates compared with EtOH, the asymmetric C–C coupling provides an unbalanced coordination environment that is beneficial for EtOH intermediate formation and stabilization in lower energy than that for C2H4, and thereby promotes the pathway for EtOH.

Discussion

In summary, an assessment of a newly synthesized, silver-modified copper-oxide catalyst has confirmed that the CO2RR to EtOH pathway is accelerated via triggering the asymmetric C–C coupling. An optimized dCu2O/Ag2.3% exhibits a FE of 40.8% and EEHF of 22.3% for EtOH production in flow cell, together with boosted EtOH partial current density of 326.4 mA cm−2 at −0.89 VRHE (with an 85 % iR correction). In situ ATR–IRAS spectroscopy confirmed that boosted EtOH selectivity results from moderate coordinated surface and optimal oxidation state of the Cu sites that gives mixed *CObridge and *COatop configurations for asymmetric C–C coupling to stabilize the EtOH intermediates. This demonstrated understanding of the mechanism for electroreduction of CO2–to– EtOH contrasts with reported, classic CO–tandem catalysis. It can be practically used to significantly boost EtOH production.

Methods

Preparation of Cu2O, Cu2O/Ag, and Cu2O/Au NCs

In a typical preparation for Cu2O/Ag2.3% NCs, 0.5 mL NaOH solution (1 M) and 0.5 mL Cu(NO3)2 solution (0.1 M) were added to a 30 mL vial with 9 mL water under vigorous stirring for 5 min at RT to give a blue-color Cu(OH)2 suspension. 27 mg AA was added to the vial under vigorous stirring. The suspension changed from blue color to yellow, confirming the formation of Cu2O NCs. Following stirring for 30 min, 0.1 mL AgNO3 solution (0.01 M) was added to the vial, and stirring continued for 30 min. Cu2O/Ag2.3% NCs were obtained and resulting products were collected by centrifugation and washed with EtOH. Preparation of Cu2O and Cu2O/Au NCs was similarly conducted, but without the addition of AgNO3 and with the replacement of AgNO3 with HAuCl4•4H2O. Cu2O/Ag and Cu2O/Au NCs with different compositions were prepared by adding selected volumes of AgNO3 and HAuCl4•4H2O solution (Supplementary Table 5).

Characterizations

TEM and HAADF–STEM were conducted on a FEI Tecnai F20 transmission electron microscope with an acceleration voltage 200 kV. Samples were prepared by dropping EtOH dispersions of the samples onto carbon-coated, Cu TEM grids using a pipette, and dried under ambient RT conditions. SEM images were taken with a HITACHI S–3700 cold–field emission scanning electron microscope operated at 15 kV. XRD patterns were collected on X’Pert–Pro MPD diffractometer (Netherlands PANalytical) with a Cu Kα X-ray source (λ = 1.540598 Å). XPS was determined with an SSI S–Probe XPS Spectrometer. The carbon peak at 284.6 eV was used as a reference to correct for charging effects. XAS data were collected at the TPS–44 A beamline of the National Synchrotron Radiation Research Center (NSRRC, Hsinchu, Taiwan) using a Si (111) quick-scanning monochromator, and processed according to standard procedures using the Demeter program package (Version 0.9.24).

CO2RR test in flow cell

Electroreduction of CO2 was tested in a microfluidics flow cell that consisted of two electrolyte chambers (20 × 5 × 3, mm) and one gas chamber (20 × 5 × 5, mm)48. An anion exchange membrane (Fumasep FAB–PK–130) was placed between two electrolyte chambers for products separation and ionic conduction. Catalyst-deposited GDE, micro Ag/AgCl electrode (4.0 M KCl), and Ni-foam (0.5 mm thickness), respectively, served as working electrode, reference electrode, and anode. To fabricate the working electrode, a certain amount of catalysts (3 mg) were dispersed in 1 mL EtOH with 20 µL 5 wt% Nafion solution and then sprayed onto a gas diffusion layer (CeTech, NIS1007) via airbrush. The loading amount of catalysts on GDE was controlled to ~0.44 mg cm−2. The working electrode was placed between gas and catholyte chambers to ensure gaseous CO2 diffusion and reaction at the catholyte/catalysts interface. The reference electrodes were inserted in catholyte chamber and maintained at a specified distance with the working electrode. An electrochemical workstation (CHI660, Chenhua, Shanghai) with a current amplifier was used to perform the CO2RR test. 1 M KOH (20 mL) was circulated through the electrolyte chambers under constant flow (15 mL min−1) via peristaltic pump. CO2 was supplied into gas chambers by a mass-flow controller at a constant flow rate of 30 mL min−1. Reactions were tested via chronopotentiometry at differing currents for 1 h without iR correction. Gas and liquid products were analyzed, respectively, via GC (Agilent 8890) and 1H NMR (Agilent 600 MHz DirectDrive2 spectrometers).

Potentials were referenced to RHE and iR correction performed based on the following, namely:

where i is the current at each applied potential and R the equivalent series resistance measured via electrochemical impedance spectroscopy in the frequency.

FE for the formation of CO2RR product was computed from:

in which e is the number of transferred electrons for each product, F the Faraday constant, Q charge, I applied current, t reaction time, and n total product (in mole).

EEHC was computed on the basis of the cathodic CO2RR coupled with the anodic oxygen evolution reaction (O2 + 4H+ + 4e− ↔ 2H2O; 1.23 V vs RHE) from:

where Eoeo and Eredo are, respectively, the thermodynamic potential for oxygen evolution and CO2RR to EtOH (0.08 V vs RHE), Eoe and Ered applied potentials at, respectively, anode and cathode. For the computation of the half-cell EE, the anodic reaction was assumed to occur with an overpotential of 0 V, that is, Eoe = 1.23 V.

CO2RR test in MEA

Electroreduction of CO2 in MEA consisted of two titanium backplates (TA2 grade) with a 4.0 cm2 serpentine flow field, and MEA. Catalyst-deposited GDE (~0.44 mg cm−2 for Cu2O/Ag2.3% NCs) and Ni-foam (0.5 mm thickness) were used, respectively, as cathode and anode. The cathode and anode were pressed onto sides of the anion exchange membrane (Sustainion 37–50, Dioxide Materials). The gap between the electrodes was minimized to reduce ohmic loss. Gaseous CO2 (30 mL min−1) was passed behind the GDL to contact the catalyst, and 0.1 M solution was used as the anolyte which was circulated via pump at 20 mL min−1. CO2RR performance for MEA was evaluated by applying different currents with a current amplifier in the two-electrode system at the CHI660 (Chenhua, Shanghai) electrochemical workstation. Cathodic gas products were vented through a simplified cold–trap to collect permeable liquid prior to gas chromatograph testing. FE values for the liquid products were computed based on the total mass of product collected on anode and cathode.

ECSA measurement

ECSA was measured by double-layer capacitance (DLC) and Pb underpotential deposition (Pb UPD) methods. All experiments are conducted in the flow cell and the used catalysts are obtained following activation under CO2RR. For DLC method, Cyclic Voltammetry (CV) scans were conducted at the potential range from 0.15 to 0.20 V vs RHE with increasing scan rates of 10, 20, 40, 60, 80, and 100 mV s−1. The capacitance currents at 0.17 V vs RHE were plotted against the scan rates, and the double-layer capacitance (Cdl, mF cm−2) was derived from the slope according to the following:

where I is the capacitance current (half of the difference between the anodic current density and cathodic current density, (Ja−Jc)/2), and v is the scan rate.

For Pb UPD method, the CV scans were conducted in Ar-saturated 0.01 M HClO4 and 1 mM PbCl2 at the potential range from 0.15 to 0.20 V vs RHE with scan rates of 10 mV s−1. The ECSA of catalysts was determined according to the following:

where APb UPD is the peak area of monolayer Pb stripping, v the scan rate and the constant 320 μC cm−2 is the charge density factor for the UPD of Pb on copper33.

In situ ATR–IRAS measurement

In situ ATR–IRAS was performed on a Nicolet iS20 spectrometer equipped with an HgCdTe (MCT) detector and a VeeMax III (PIKE Technologies) accessory. The measurement was conducted in a homemade electrochemical single-cell furnished with Pt–wire and Ag/AgCl as counter and reference electrodes. A fixed-angle Ge prism (60°) coated with catalysts embed into the bottom of the cell served as the working electrode. Before testing, the detector was cooled with liquid nitrogen for at least 30 min to maintain a stable signal. Chronoamperometry was used for CO2RR test and was accompanied by the spectrum collection (32 scans, 4 cm−1 resolution). All spectra were subtracted with the background.

Data availability

Data that support findings from this study are available from the corresponding author on reasonable request.

References

Arakawa, H. et al. Catalysis research of relevance to carbon management: progress, challenges, and opportunities. Chem. Rev. 101, 953–996 (2001).

Jouny, M., Luc, W. & Jiao, F. General techno–economic analysis of CO2 electrolysis systems. Ind. Eng. Chem. Res. 57, 2165–2177 (2018).

Birdja, Y. Y. et al. Advances and challenges in understanding the electrocatalytic conversion of carbon dioxide to fuels. Nat. Energy 4, 732–745 (2019).

Qiao, J., Liu, Y., Hong, F. & Zhang, J. A review of catalysts for the electroreduction of carbon dioxide to produce low–carbon fuels. Chem. Soc. Rev. 43, 631–675 (2014).

Ross, M. B. et al. Designing materials for electrochemical carbon dioxide recycling. Nat. Catal. 2, 648–658 (2019).

Gao, D., Arán–Ais, R. M., Jeon, H. S. & Roldan Cuenya, B. Rational catalyst and electrolyte design for CO2 electroreduction towards multicarbon products. Nat. Catal. 2, 198–210 (2019).

Kuhl, K. P. et al. Electrocatalytic conversion of carbon dioxide to methane and methanol on transition metal surfaces. J. Am. Chem. Soc. 136, 14107–14113 (2014).

Verma, S. et al. Insights into the low overpotential electroreduction of CO2 to CO on a supported gold catalyst in an alkaline flow electrolyzer. ACS Energy Lett. 3, 193–198 (2018).

Nitopi, S. et al. Progress and perspectives of electrochemical CO2 reduction on copper in aqueous electrolyte. Chem. Rev. 119, 7610–7672 (2019).

Kuhl, K. P., Cave, E. R., Abram, D. N. & Jaramillo, T. F. New insights into the electrochemical reduction of carbon dioxide on metallic copper surfaces. Energy Environ. Sci. 5, 7050–7059 (2012).

Dinh, C.–T. et al. CO2 electroreduction to ethylene via hydroxide–mediated copper catalysis at an abrupt interface. Science 360, 783–787 (2018).

Nguyen, T. N. et al. Electrochemical CO2 reduction to ethanol: from mechanistic understanding to catalyst design. J. Mater. Chem. A 9, 12474–12494 (2021).

Bushuyev, O. S. et al. What should we make with CO2 and How can we make it? Joule 2, 825–832 (2018).

Zheng, Y. et al. Understanding the roadmap for electrochemical reduction of CO2 to multi–carbon oxygenates and hydrocarbons on copper–based catalysts. J. Am. Chem. Soc. 141, 7646–7659 (2019).

Vasileff, A., Xu, C., Jiao, Y., Zheng, Y. & Qiao, S. –Z. Surface and interface engineering in copper–based bimetallic materials for selective CO2 electroreduction. Chem 4, 1809–1831 (2018).

Wang, P. et al. Phase and structure engineering of copper tin heterostructures for efficient electrochemical carbon dioxide reduction. Nat. Commun. 9, 4933 (2018).

Huang, J., Mensi, M., Oveisi, E., Mantella, V. & Buonsanti, R. Structural sensitivities in bimetallic catalysts for electrochemical CO2 reduction revealed by Ag–Cu nanodimers. J. Am. Chem. Soc. 141, 2490–2499 (2019).

Zhuang, T.–T. et al. Steering post–C–C coupling selectivity enables high efficiency electroreduction of carbon dioxide to multi–carbon alcohols. Nat. Catal. 1, 421–428 (2018).

Ma, W. et al. Electrocatalytic reduction of CO2 to ethylene and ethanol through hydrogen–assisted C–C coupling over fluorine–modified copper. Nat. Catal. 3, 478–487 (2020).

Zhou, Y. et al. Dopant–induced electron localization drives CO2 reduction to C2 hydrocarbons. Nat. Chem. 10, 974–980 (2018).

Hoang, T. T. H., Ma, S., Gold, J. I., Kenis, P. J. A. & Gewirth, A. A. Nanoporous copper films by additive–controlled electrodeposition: CO2 reduction catalysis. ACS Catal. 7, 3313–3321 (2017).

Lee, S., Park, G. & Lee, J. Importance of Ag–Cu biphasic boundaries for selective electrochemical reduction of CO2 to ethanol. ACS Catal. 7, 8594–8604 (2017).

She, X. et al. Tandem electrodes for carbon dioxide reduction into C2+ products at simultaneously high production efficiency and rate. Cell Rep. Phys. Sci. 1, 100051 (2020).

Morales–Guio, C. G. et al. Improved CO2 reduction activity towards C2+ alcohols on a tandem gold on copper electrocatalyst. Nat. Catal. 1, 764–771 (2018).

Lv, X. et al. Electron–deficient Cu sites on Cu3Ag1 catalyst promoting CO2 electroreduction to alcohols. Adv. Energy Mater. 10, 2001987 (2020).

Clark, E. L., Hahn, C., Jaramillo, T. F. & Bell, A. T. Electrochemical CO2 reduction over compressively strained CuAg surface alloys with enhanced multi–carbon oxygenate selectivity. J. Am. Chem. Soc. 139, 15848–15857 (2017).

Li, Y. C. et al. Binding site diversity promotes CO2 electroreduction to ethanol. J. Am. Chem. Soc. 141, 8584–8591 (2019).

Chen, C. et al. Cu–Ag tandem catalysts for high–rate CO2 electrolysis toward multicarbons. Joule 4, 1688–1699 (2020).

Li, F. et al. Cooperative CO2–to–ethanol conversion via enriched intermediates at molecule–metal catalyst interfaces. Nat. Catal. 3, 75–82 (2020).

Ren, D., Ang, B. S. H. & Yeo, B. S. Tuning the selectivity of carbon dioxide electroreduction toward ethanol on oxide–derived CuxZn catalysts. ACS Catal. 6, 8239–8247 (2016).

Lv, J.–J. et al. A highly porous copper electrocatalyst for carbon dioxide reduction. Adv. Mater. 30, 1803111 (2018).

Ma, S. et al. One–step electrosynthesis of ethylene and ethanol from CO2 in an alkaline electrolyzer. J. Power Sources 301, 219–228 (2016).

Wang, X. et al. Efficient electrically powered CO2–to–ethanol via suppression of deoxygenation. Nat. Energy 5, 478–486 (2020).

Luo, M. et al. Hydroxide promotes carbon dioxide electroreduction to ethanol on copper via tuning of adsorbed hydrogen. Nat. Commun. 10, 5814 (2019).

Hoang, T. T. H. et al. Nanoporous copper–silver alloys by additive–controlled electrodeposition for the selective electroreduction of CO2 to ethylene and ethanol. J. Am. Chem. Soc. 140, 5791–5797 (2018).

Su, X. et al. Hierarchically porous Cu/Zn bimetallic catalysts for highly selective CO2 electroreduction to liquid C2 products. Appl. Catal. B 269, 118800 (2020).

Kim, C. et al. Cu/Cu2O interconnected porous aerogel catalyst for highly productive electrosynthesis of ethanol from CO2. Adv. Funct. Mater. 31, 2102142 (2021).

Kim, J. Y. et al. Synergistic effect of Cu2O mesh pattern on high‐facet Cu surface for selective CO2 electroreduction to ethanol. Adv. Mater. 34, 2106028 (2021).

Jung, H. et al. Electrochemical fragmentation of Cu2O nanoparticles enhancing selective C–C coupling from CO2 reduction reaction. J. Am. Chem. Soc. 141, 4624–4633 (2019).

Lum, Y., Cheng, T., Goddard, W. A. & Ager, J. W. Electrochemical CO reduction builds solvent water into oxygenate products. J. Am. Chem. Soc. 140, 9337–9340 (2018).

Wang, L. et al. Electrochemical carbon monoxide reduction on polycrystalline copper: effects of potential, pressure, and pH on selectivity toward multicarbon and oxygenated products. ACS Catal. 8, 7445–7454 (2018).

Zhang, W. et al. Atypical oxygen–bearing copper boosts ethylene selectivity toward electrocatalytic CO2 reduction. J. Am. Chem. Soc. 142, 11417–11427 (2020).

Zhu, S., Li, T., Cai, W.–B. & Shao, M. CO2 Electrochemical reduction as probed through infrared spectroscopy. ACS Energy Lett. 4, 682–689 (2019).

Katayama, Y. et al. An in situ surface–enhanced infrared absorption spectroscopy study of electrochemical CO2 reduction: selectivity dependence on surface C–bound and O/bound reaction intermediates. J. Phys. Chem. C 123, 5951–5963 (2019).

Chou, T.–C. et al. Controlling the oxidation state of the Cu electrode and reaction intermediates for electrochemical CO2 reduction to ethylene. J. Am. Chem. Soc. 142, 2857–2867 (2020).

Shen, H. et al. Asymmetrical C–C coupling for electroreduction of CO on bimetallic Cu–Pd catalysts. ACS Catal. 12, 5275–5283 (2022).

Chen, X. et al. Electrochemical CO2–to–ethylene conversion on polyamine–incorporated Cu electrodes. Nat. Catal. 4, 20–27 (2021).

Wang, P. et al. Synergized Cu/Pb core/shell electrocatalyst for high-efficiency CO2 reduction to C2+ liquids. ACS Nano 15, 1039–1047 (2021).

Acknowledgements

This work was financially supported by the Australian Research Council (ARC) through Discovery Project [FL170100154, DP220102596 (S.Z.Q.)], the National Key R&D Program of China [2020YFB1505802 (X.H.)], Ministry of Science and Technology [2017YFA0208200, 2016YFA0204100 (X.H.)], National Natural Science Foundation of China [21903058, 22173066, 22103054 (T.C.) and 22025108, 2212100020 (X.H)], Natural Science Foundation of Jiangsu Higher Education Institutions [BK20190810 (T.C.)] and Start-up support from Xiamen University (X.H.). T.C. gratefully acknowledges support from the Collaborative Innovation Center of Suzhou Nano Science & Technology, the 111 Project, Joint International Research Laboratory of Carbon-Based Functional Materials and Devices.

Author information

Authors and Affiliations

Contributions

S.Z.Q. and X.H. conceived and supervised the research. X.H. and P.W. designed and conducted the experiments. P.W., H.Y., X.H., and S.Z.Q. performed data analyses. C.T., Y.W., T.C., and Y.Z. participated in experiments and characterizations. P.W., K.D., X.H., and S.Z.Q. wrote and corrected the paper. All authors discussed results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Hee-Tae Jung and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, P., Yang, H., Tang, C. et al. Boosting electrocatalytic CO2–to–ethanol production via asymmetric C–C coupling. Nat Commun 13, 3754 (2022). https://doi.org/10.1038/s41467-022-31427-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-022-31427-9

This article is cited by

-

Dynamics of bulk and surface oxide evolution in copper foams for electrochemical CO2 reduction

Communications Chemistry (2024)

-

Self-supporting BiCu/carbon hybrid nanofiber membrane promotes efficient CO2 electroreduction to formate

Science China Materials (2024)

-

Acidic electroreduction CO2 to formic acid via interfacial modification of Bi nanoparticles at industrial-level current

Nano Research (2024)

-

Cu-Based Materials for Enhanced C2+ Product Selectivity in Photo-/Electro-Catalytic CO2 Reduction: Challenges and Prospects

Nano-Micro Letters (2024)

-

A tin-based tandem electrocatalyst for CO2 reduction to ethanol with 80% selectivity

Nature Energy (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.