Abstract

Supported metal catalysts play a crucial role in the modern industry. Constructing strong metal-support interactions (SMSI) is an effective means of regulating the interfacial properties of noble metal-based supported catalysts. Here, we propose a new strategy of ultrafast laser-induced SMSI that can be constructed on a CeO2-supported Pt system by confining electric field in localized interface. The nanoconfined field essentially boosts the formation of surface defects and metastable CeOx migration. The SMSI is evidenced by covering Pt nanoparticles with the CeOx thin overlayer and suppression of CO adsorption. The overlayer is permeable to the reactant molecules. Owing to the SMSI, the resulting Pt/CeO2 catalyst exhibits enhanced activity and stability for CO oxidation. This strategy of constructing SMSI can be extended not only to other noble metal systems (such as Au/TiO2, Pd/TiO2, and Pt/TiO2) but also on non-reducible oxide supports (such as Pt/Al2O3, Au/MgO, and Pt/SiO2), providing a universal way to engineer and develop high-performance supported noble metal catalysts.

Similar content being viewed by others

Introduction

Supported noble metal catalysts, dispersed the noble metal nanoparticles (NPs) on an oxide support with high specific surface area, are one of the most important heterogeneous catalysts1,2. They have a wide range of applications in the fields of energy conversion, chemical production, and exhaust gas purification, and play a vital role in the global economy3. In the original catalytic studies, oxide support was considered chemically inert, serving only to anchor and disperse the active component. In the late 1970s, Tauster et al. found that the adsorption of small molecules (such as CO, H2) was significantly suppressed by the high temperature reduction of platinum group metals (PGMs) supported on TiO2, and that the cause of this phenomenon was not due to sintering or poisoning of the noble metals. Therefore, this unusual interaction between metal and reducible metal oxides was named “strong metal-support interaction” (SMSI)4,5. The formation of SMSI effect can profoundly affect the electronic structure and geometry of catalysts, thus altering their activity, selectivity, and stability, and has therefore been extensively investigated in recent decades6,7,8. It is generally accepted that the classical SMSI effect is associated with the encapsulation of the metal by the support species. The overcoating consists of several atomic layers, usually in an amorphous state, and has a dynamic structure in different gas atmospheres9,10. In general, SMSI effect tends to occur between reducible metal oxides with relatively low surface energy (such as TiO2, V2O3, Nb2O5, and Ta2O5) and Pt group metals, where the thermodynamic driving force is the minimization of surface energy7,11,12. The most classical method for constructing SMSI effects is high-temperature hydrogen treatment. The lattice oxygen on the oxide support surface is abstracted to form a suboxide and migrates to the metal surface to form a stable overlayer4,5,13,14. Although the study of constructing SMSI by hydrogen reduction has been developed for decades, the insufficiency of this approach is significant, focusing on the following aspects: (i) Catalyst systems are mostly limited to reducible metal oxide loaded Pt group metals. (ii) The formation of SMSI effects may be accompanied by sintering of the metal particles, as the temperature of thermal reduction is usually higher than 500 °C11. In order to break the bottleneck, classical SMSI was achieved between Au and non-reducible MgO through CO2-induced activation of the oxide surface15. Wang et al. reported a strong interaction between Au and TiO2 induced by melamine. The presence of a permeable TiOx overlayer ensured that the catalyst maintained high catalytic activity even after calcination at 800 °C16. Recently, Xiao and co-workers17 proposed a wet-chemistry methodology to construct SMSI on titania-supported Au NPs (Au/TiO2-wcSMSI), avoiding the necessity of high-temperature treatment17. Thermally induced reactions in specific gaseous atmospheres are generally required in traditional procedures. Moreover, constructing SMSI with the above methodology is usually not widely generalizable. Therefore, new methods that enable the universal construction of SMSI in various catalytic systems under ambient conditions are still essential to design high-performance catalysts and understand SMSI effects in more depth.

Laser ablation in liquid (LAL) is generally accepted as a universal, green, and one-step method for synthesizing metastable functional nanomaterials with novel properties through photo-induced localized physical/chemical processes18,19,20,21,22,23,24. Recently, LAL has been utilized to fabricate TiO2 NPs for solar energy conversion and environmental remediation25,26,27. Self-doped TiO2 nanocrystals were synthesized using a nanosecond laser, and Ti3+/oxygen vacancies were successfully induced in the TiO2 NPs, which resulted in high photocatalytic activity. However, the high temperature and high pressure caused by the nanosecond or longer pulse irradiation may induce unfavorable phase transformation of anatase to rutile TiO2 with inferior properties28. For aggregated CuO NPs, the photothermal effects involved in long-pulse laser irradiation may cause sintering with the sacrifice of active sites29. For non-aggregated TiO2 NPs, when using nanosecond laser irradiation, a gradual decrease of photocurrent may result from the formation of bulk defects due to thermally initiated isochoric melting. When using a small number of picosecond pulses, the performances improved by a factor of two30,31. The unique characteristics of ultrafast laser, ultrahigh intensity and ultrashort pulse duration, can induce nonlinear absorption, which may provide a solution to these challenges. When the high-energy laser interacts with the metal oxides dispersed in the solution, the surface structure is reconfigured. Oxygen vacancies formed on the surface of the metal oxides, leaving the surface species in a suboxide state, thus achieving activation of the metal oxides surface. The above phenomenon may provide the preliminary conditions for the successful construction of the SMSI effect.

In this study, we proposed a novel strategy to induce SMSI in CeO2-supported Pt NPs based on ultrafast laser excitation. We succeeded in creating porous overlayers of CeOx on Pt NPs, which exhibit superior catalytic activity and stability (Fig. 1). The mechanism underlying the SMSI formation was revealed, and depended on the localized energy deposition. To the best of our knowledge, this is the first report on the laser-induced SMSI, and our approach can be facilely extended to other material systems (such as Pt/TiO2, Pd/TiO2, Au/TiO2, Pt/Al2O3, Au/MgO, and Pt/SiO2).

Results

Ultrafast laser induced strong metal-support interactions

Figure 2a shows the schematic illustration of the ultrafast laser irradiation of Pt/CeO2 NPs, and the nanoconfined electric field between Pt NPs and CeO2 were created. The calculated electric field distributions on multiple and single Pt/CeO2 excited at an 800-nm wavelength with parallel polarization are presented (Fig. 2b, c). Figure 2d shows the calculated electric field enhancement profiles along the longitudinal axis of Pt/CeO2 excited at parallel polarization with the wavelength of 800 nm. Note that the electric field intensity at the interface between Pt and CeO2 was significantly larger than that on other regions. It means that the laser energy was mainly deposited on the interface. Pt/CeO2 catalysts were prepared by the NaBH4 reduction method. According to the transmission electron microscopy (TEM) images of the Pt/CeO2 (Fig. 2e, f), the Pt NPs exhibited a spherical shape with a diameter of about 10 nm. As indicated by the high-resolution transmission electron microscopy (HRTEM) images (Fig. 2g), the interface contrast between the Pt and CeO2 NPs can clearly be observed, and no material was deposited on the surface of Pt NPs. The nanostructure was confirmed by energy-dispersive X-ray spectroscopy (EDS) elemental mapping (Fig. 2h). In the EDS profiles, there was no other element signal on the region where it exhibited an obvious Pt element signal. Upon ultrafast laser irradiation, Pt NPs were encapsulated by a thin overlayer (Fig. 2i–k). Moreover, Pt NPs with different sizes can be covered by thin overlayers (Supplementary Fig. 1). As shown in the EDS elemental mapping (Fig. 2l), cerium and oxygen were detected in the overlayers. It suggests that the surface of the Pt NPs was decorated with material coming from the support after ultrafast laser irradiation. In addition, a small number of NPs showed signs of growth after laser treatment, but the overall NP size distribution did not change significantly (Supplementary Fig. 2). The above results indicate that the ultrafast laser irradiation successfully induced the overlayer structure formation in CeO2-supported Pt NPs.

a Schematic of the setup for ultrafast laser irradiation of Pt/CeO2. b, c Calculated electric field distribution and (d) the enhancement profiles along the longitudinal axis of the Pt/CeO2 excited at an 800-nm wavelength with parallel polarization. Inset is the enlarged image of the enhanced electric field at the interface between Pt and CeO2 (width = 0, 1, 2 nm). e, f TEM image of as-prepared Pt/CeO2. Inset is the FFT. g The enlarged image of the areas marked in (f. h) EDS elemental mapping of as-prepared Pt/CeO2. i, j TEM image of laser-irradiated Pt/CeO2. Inset is the FFT. k The enlarged image of the areas marked in (j). l EDS elemental mapping of laser-irradiated Pt/CeO2.

The electron energy loss spectroscopy (EELS) was employed to further study the nature of the overlayer in laser-irradiated Pt/CeO2 (Fig. 3a, b). Both on the support (region 4) and Pt NP (regions 2 and 3) surface, two obvious peaks located at 882 and 901 eV in Ce spectra, which correspond to M5 and M4 edges, respectively. These two peaks come from electrons transitioning from the spin–orbit splitting energy levels 3d5/2 and 3d3/2 to the unoccupied 4f state. The previous study showed that the intensity ratios between M4 and M5 edges were 1.12 and 0.75 for Ce4+ and Ce3+, respectively32,33. The increase in Ce3+ concentration in Ce-containing oxides with fluorite or modified-fluorite structure is reflected in a decrease in the M4/M5 intensity ratio. On the support (CeO2), the M4/M5 value is about 1.1, while on the Pt NP the value is about 0.95. This result provides substantial evidence that the overlayer is CeOx (x < 2) species, which is well consistent with the previous studies. In addition, EELS spectra were performed on relatively small size Pt NP (about 4 nm) and corresponding interfacial perimeter (Supplementary Fig. 3), cerium species mainly exists in the trivalent state in these regions. It is worth mentioning that the EELS results also indirectly proved that the surface reconstruction of the support after laser irradiation resulted in the formation of metastable CeOx species. Figure 3c, d illustrates the XRD spectra of the samples. After laser irradiation, the intensity of the diffraction peaks has become significantly weaker. In general, the weakening of the intensity of the diffraction peaks is the result of poor crystallinity or smaller particle size. But the BET surface area of the fresh-Pt/CeO2 and laser-irradiated Pt/CeO2 was about 52.7 and 46.1 m2 g−1, respectively (Supplementary Fig. 4a). The corresponding Raman spectra shows a significant enhancement of the characteristic peaks corresponding to the symmetric breathing mode of Ce–O in fluorite CeO2 after laser irradiation, which also indicates that CeO2 NPs grown after laser treatment34,35 (Supplementary Fig. 4b). So the decrease of intensity of diffraction peaks can be attributed to the more inferior crystallinity of catalyst, and corresponding HRTEM images can confirm this (Supplementary Fig. 1). The diffraction peak center around 40° can be indexed to the (111) plane of face-centered cubic Pt, which shifted to a higher angle after laser irradiation. Previous reports suggested that this may be due to the incorporation of cerium into the platinum crystal structure to form an alloy, causing lattice contraction36,37. In our case, comparing the XPS spectra of Ce 3d before and after laser irradiation, there were no characteristic peaks related to metallic Ce, which indicates that no CePt alloy phase was formed (Supplementary Fig. 5). To demonstrate it more closely, several large size Pt NPs with thick CeOx overlays were selected for HRTEM analysis (Supplementary Fig. 6). No CePt alloy phase was observed at the interface between the Pt and CeOx layers, which was in agreement with the XPS results. It is worth noting that the surface of Pt NPs is enriched with lattice defects after laser irradiation. Therefore, the shift of the diffraction peak may be due to the distortion of the Pt NP lattice by laser irradiation. The particle size distribution results show the size of Pt NPs did not decrease after the laser treatment and there is no broadening of the diffraction peak. It is known that under ultrafast laser irradiation, abundant metastable structures could be formed in metal NPs because of the strong quenching effect22. The weakening of the diffraction peaks can be attributed to the surface-induced poor crystallinity34. The formation of a CeOx overlayer on the surface of Pt particles is responsible for the seemingly contradictory phenomenon that CeO2 particles grow after laser irradiation while Pt particles do not show excessive growth. X-ray photoelectron spectroscopy (XPS) was performed to analyze the valence and surface chemical information of the catalyst. The Pt 4f spectra showed that Pt existed mainly in the metallic state before and after laser irradiation with an asymmetric 4f7/2 peak centered at 71.05 eV. The peak located at the 72.05 eV is attributed to Ptδ+, and the intensity of this characteristic peak increases after laser irradiation. As mentioned, Pt/CeO2 is first dispersed in water and then laser irradiated, and the whole process is exposed to air. On the one hand, water has a certain solubility of oxygen (the solubility of oxygen at 20 °C is 9.17 mg L−1). On the other hand, laser irradiation is performed with continuous agitation, suggesting that the catalysts are all directly exposed to air. In the presence of oxygen, the local heat generated by laser irradiation may induce Pt NPs to bind to oxygen. Moreover, previous studies have shown that in the presence of oxygen involved in the construction of SMSI, Pt–O bonds are generated at the interface between Pt NPs and the overlayer38,39. Accordingly, the increase in the intensity of the Ptδ+ characteristic peak can either be attributed to the partial oxidation of Pt or the formation of Pt–O bonds at the interface between Pt NPs and CeOx overlayer. In particular, the signal of the Pt characteristic peak is obviously weakened after laser irradiation. It is known that XPS is a surface analysis technique. After laser treatment, the Pt content decreased from 1.3 to 0.94 atom%, while the Ce content changed from 17.12 to 17.94 atom%. It means that the Pt/Ce ratio on the surface decreases with a CeOx overlayer on the Pt surface, which was in good agreement with XRD results.

a High-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) image of laser-irradiated Pt/CeO2. b EELS spectrum of laser-irradiated Pt/CeO2. c, d XRD spectra of Pt/CeO2 and laser-irradiated Pt/CeO2. e XPS spectra of fresh Pt/CeO2 and laser-irradiated Pt/CeO2. f In situ CO-DRIFT of fresh Pt/CeO2 and laser-irradiated Pt/CeO2.

The suppression of small molecules (such as CO, H2) adsorption is a typical feature of the classic SMSI. In situ diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS) of CO was employed to explore the adsorption characteristics and electronic structure of the Pt surface at room temperature, and corresponding results are shown in Fig. 3f. Three obvious bands centered at 2094, 2069, and 1836 cm−1 on fresh-Pt/CeO2, which ascribed to CO linearly adsorbed on ionic Pt (CO-Ptδ+), metallic Pt (CO-Pt0), and bridged CO adsorption on Pt species, respectively40,41,42. After laser irradiation for 1 h, the adsorption of CO molecules on Pt species was significantly weakened. It is already known from the Pt NP size distribution analysis that laser irradiation does not result in significant growth of Pt NPs. Therefore, the suppression of CO adsorption could be reasonably assigned to the coverage of Pt particles by the CeOx overlayer after laser irradiation, precisely as anticipated for classical SMSI. However, it is noteworthy that the adsorption of CO on Pt species is not completely inhibited, perhaps due to the fact that the CeOx overlayer is not completely dense but only partially encapsulated, as observed from TEM (Supplementary Fig. 7). Generally, classic SMSI is reversible upon reversal treatment. During the pulsed laser processing, the oxide could be reduced or oxidized, which depended on the initial oxidation state43. Under the experimental condition, the CeO2 support was reduced with the increase in Ce3+ concentration. The adsorption characteristics and microstructure evolution of laser-Pt/CeO2 under oxidizing atmosphere at 600 °C were investigated. The CO adsorption band was recovered for laser-Pt/CeO2-600 °C-O2 and the corresponding HRTEM showed that the CeOx overlayer was fade after high-temperature oxidation (Supplementary Fig. 8a, b). This result suggests that laser-induced construction of SMSI was well consistent with classic SMSI. Moreover, the SMSI effect was restored when the laser-Pt/CeO2−600 °C-O2 sample was irradiated with the laser again (Supplementary Fig. 8c–e).

Mechanisms of the ultrafast laser-induced SMSI

Several Pt/CeO2 NPs were characterized with increasing exposure time to quantify the ultrafast laser-induced structural reorganization, while the laser power was held constant. As we know, an ultrafast laser with ultrashort pulse duration (<50 fs) and ultrahigh intensity (>1013 W cm−2) can almost ionize any materials44. Figure 4a shows the laser-induced transformation of CeO2 to CeOx. When the ultrafast laser irradiated on the Pt/CeO2 NPs, the electric field would be confined in the localized Pt/CeO2 interface and enhanced, which arises from the localized plasmon resonance. The enhanced field can induce the nonlinear effects and ionize CeO2. Specifically, when a flux of photons (1.55 eV at 800 nm) was injected, the bounded electrons of CeO2 were excited to the conduction band by multiphoton absorption, leaving the holes in the valence band. On the surface of CeO2, O atoms donated the electrons to the Ce atoms. Therefore, Ce4+ accepted the electron to form the Ce3+, and the O atoms could be peeled off from the surface of the CeO2 to form the oxygen vacancies27. In the crystal structure, two of the cerium ions are replaced by trivalent ions, between which an oxygen vacancy appears45. On the other hand, ultrafast photoexcitation of H2O molecules can provide abundant electrons, which can potentially be injected into CeO2 to reduce Ce4+. Based on the above analysis, surface defects (Ce3+/oxygen vacancy) can be efficiently induced in the interface between the Pt NPs and the CeO2 support where the electric field intensity was larger, which was also demonstrated in the EPR and XPS spectral analysis (Supplementary Fig. 5). In the EPR spectra, compare to fresh Pt/CeO2, the signal of oxygen vacancy (g = 2.01) was increased in laser-irradiated Pt/CeO2. CeOx species may migrate randomly on the unstable surface to form reorganized structures at the perimeter interface46, and Pt NPs were partially encapsulated (Fig. 4b). The encapsulation that occurred during SMSI can be considered as a wetting process of the metal NPs by reduced metal oxide. According to the previous reports, the encapsulation process is mainly determined by the surface tension, and larger surface tension of the metal than that of metal oxide support is expected47. The case Pt (2.54 J m−2) being wetted by CeO2 (1–1.4 J m−2) is possible owing to the higher surface tension48. The minimization of surface free energy of Pt NPs is the major driven force. According to the XPS results (Supplementary Fig. 9), the Pt/Ce ratio on the surface of specimens were 0.076 (fresh-Pt/CeO2), 0.0459 (Pt/CeO2-laser-20 min), 0.0394 (Pt/CeO2-laser-40 min), 0.0344 (Pt/CeO2-laser-60 min), and 0.0557 (Pt/CeO2-H2), respectively. It means that Pt NPs were more prone to be encapsulated with the increased exposure time49, and the overlayers become thicker (Fig. 4c, d). Furthermore, several overlayers exhibited lattice fringes that can be identified as CeO2 structures that were epitaxial with the support (Supplementary Fig. 10). When increasing the laser power, the increased thickness of the overlayer was observed (Fig. 4e–g). It means that Pt NPs were more prone to be encapsulated with increasing the deposited energy. To further explain the mechanism of laser-induced SMSI, a reference experiment where CeO2 was irradiated without Pt NPs was performed. According to the XPS results (Supplementary Fig. 11), there were no more surface defects (Ce3+/oxygen vacancies) in the laser-treated CeO2. It means that the same laser fluence irradiation without the enhanced electric field could not induce surface defects, and the localized electric field plays a vital role in the formation of surface defects. After that, Pt NPs were loaded on the laser-treated CeO2 and subjected to heat treatment (under argon atmosphere at 500 °C for 2 h). According to the TEM images (Supplementary Fig. 12), no similar overlayers were observed, suggesting that only thermal excitation could not induce SMSI. During the pulsed laser irradiation, the nanoconfined field essentially boosts the formation of Ce3+/oxygen vacancies and metastable CeOx migration. On the other hand, thermal excitation could improve the metastable CeOx mobility.

a Explanation of ultrafast laser-induced formation of CeOx overlayer. TEM images of Pt/CeO2 after ultrafast laser irradiation with various exposure time of (b) 20 min, c 40 min, d 60 min (laser power: 250 mW), and laser power of (e) 80 mW, f 160 mW, g 250 mW (exposure time: 60 min). Insets are schematics of laser-fabricated Pt/CeO2 NPs.

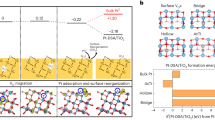

Pt/CeO2 NPs were dispersed in the liquid, and the angles between laser polarization and the longitudinal axis of Pt/CeO2 NPs were various. In order to analyze the effect of polarization angles on the deposited energy, the electric field distributions of Pt/CeO2 NPs irradiated with different polarization angles at 800-nm wavelength were calculated using finite-difference time-domain (FDTD) simulation. Figure 5a–c shows the electric field distributions excited at polarization angles of 10°, 30°, and 50°, respectively. When the polarization angle was less than 50°, the electric field intensity at the interface between Pt and CeO2 NPs was significantly larger than that on other regions. The dependence of the enhanced electric field at the interface on the polarization angles is given in Fig. 5d. When the polarization angle increased to 90°, no enhanced electric field was observed at the interface. It means that not all polarization angles irradiation can produce enhanced field at the interface. Under the experimental condition with rapid stirring, almost all the NPs can absorb the same amount of energy, which was demonstrated by the previous report50. The range of the polarization angles that can result in the enhanced field at the interface was larger, suggesting that ultrafast laser irradiation can efficiently induce structural reorganization. Figure 5e–g shows the electric field distributions excited with laser intensities of 2, 3, and 4 V m−1, respectively. The electric field at the interface between Pt and CeO2 increased with the increase of the laser intensity (Fig. 5h), which was consistent with the experimental results. The effect of laser wavelength on the deposited energy was also investigated. Supplementary Figure 13 shows the electric field distributions excited at 400-nm wavelength. Different from 800-nm wavelength excitation, the enhanced field at the interface was observed even when the polarization angle increased to 60°. It should be noted that the enhanced localized fields were dependent on the laser polarization and wavelength, suggesting that the SMSI can be successfully induced in Pt/CeO2 NPs using the proper processing strategy. In order to investigate the effect of the shape of the support, the Pt/CeO2 nanorods (NRs) were synthesized (Supplementary Fig. 14), and the electric field distributions of Pt/CeO2 NRs irradiated with a laser pulse were calculated (Supplementary Fig. 15). The electric field intensity at the interface between Pt and CeO2 NRs was significantly larger than that on other regions. After pulsed laser irradiation, SMSI was successfully fabricated in Pt/CeO2 NRs (Supplementary Fig. 16). In addition, the laser-induced SMSI was also obtained in Pt/TiO2, Pd/TiO2, Au/TiO2, Pt/Al2O3, Pt/SiO2, and Au/MgO NPs, suggesting that this strategy can be extended to other metal/metal oxide materials (Supplementary Figs. 17–22 and Supplementary Table 1).

Polarization angles of (a) 10°, b 30°, and (c) 50°. d Simulated dependence of the enhanced electric field at the interface between Pt and CeO2 on the polarization angles. Calculated electric field distribution of Pt/CeO2 irradiated with laser intensities of (e) 2 V m−1, f 3 V m−1, g 4 V m−1. h The electric field along the longitudinal axis of the Pt/CeO2 excited at 800-nm wavelength. Inset is the enlarged image of the electric field at the interface between Pt and CeO2.

Catalytic application

CO oxidation reaction employed as a model reaction to assess the catalytic activity of the catalyst because of its importance in basic research, especially its size-dependent behavior. The T50 (temperature at which 50% conversion of CO is achieved) value is used as an appraisal standard to evaluate the catalytic activity of the catalyst. Figure 6a shows the CO conversion curve of the samples and the catalytic activity of the catalysts decreases in the following sequence: laser-irradiated Pt/CeO2 (T50 = 145 °C), fresh-Pt/CeO2 (T50 = 175 °C), CeO2 (T50 = 250 °C). Obviously, the catalytic activity of laser-irradiated Pt/CeO2 is significantly superior to that of fresh-Pt/CeO2, with complete CO conversion at 155 °C for laser-irradiated Pt/CeO2 and 185 °C for the corresponding fresh-Pt/CeO2. The apparent activation energy of the reaction obtained by the Arrhenius equation is shown in Supplementary Fig. 23. The apparent activation energy of the catalyst did not change significantly before and after laser irradiation, which were 59.34 and 58.99 kJ mol−1, respectively. The similarity of the apparent activation energy suggests that the catalysts before and after laser treatment follow similar reaction pathways. Therefore, the difference in activity probably mainly derived from the different number of effective active sites rather than the exposed sites, which is in good agreement with previous studies51,52,53,54. It is generally accepted that CeO2-loaded Pt NPs in CO catalytic oxidation follow Mars-Van-Krevelen mechanism and that the catalytic activity is size-dependent, where the perimeter of interface between the Pt NPs and CeO2 is the active site of the reaction55,56,57. This mechanism also worked in our case, in which the improved catalytic activity of the laser-treated sample can be attributed to the increase in the number of Pt-CeO2 interfacial sites. According to the above, the size of Pt particles did not decrease after laser irradiation. Thus, the increase in the number of metal-support interface sites was clearly not assigned to a decrease in the size of Pt NPs. Therefore, it is reasonable to infer that the increase in catalytic activity is due to the formation of the SMSI effect. It is already known from the substantial analysis above that the modification of CeOx overlayer on the surface of Pt NPs will undoubtedly increase the interface between metal Pt and CeOx. However, in general, the catalytic activity of the catalyst tends to degrade after the occurrence of the SMSI effect, due to the presence of overlayer on the metal surface. An important factor resulting in this catalyst passivation is that the overlayer is often dense and thus almost completely obscures the active sites of the catalyst58. But in our case, it has been known from the HRTEM representation that laser-induced formation of CeOx overlayer is more distinctly different from the classical hydrogen reduction method. Due to the high-energy nature of the femtosecond laser, the overlayer induced with the laser is frequently discontinuous, and even a small number of Pt NPs are only partially encapsulated (Supplementary Fig. 7). The in situ CO-DRIFT and H2-TPD spectra demonstrate the porous nature of the CeOx overlayer (Supplementary Fig. 24). When the femtosecond laser successfully constructs the SMSI effect between Pt and CeO2, on the one hand, the discontinuous overlayer obscures the sites on the Pt surface, and on the other hand, it provides more active sites at the metal-support interface that are in direct contact with the reactants. This may be the main reason why the catalytic activity of Pt/CeO2 increases rather than decays after the laser-induced SMSI effect.

a CO oxidation curves of laser-irradiated Pt/CeO2 catalyst and the reference fresh Pt/CeO2 catalyst. b Conversion of CO from 90 to 200 °C with 1st–10th cycles on laser-Pt/CeO2 catalyst. c On-stream reaction of laser-irradiated Pt/CeO2 and Pt/CeO2 at 150 °C (space velocity: laser-irradiated Pt/CeO2 60,000 mL g−1 h−1, Pt/CeO2 20,000 mL g−1 h−1). d HRTEM image of laser-irradiated Pt/CeO2 after CO emission control reaction at 150 °C for 50 h.

To further demonstrate the structural specificity of the laser-induced SMSI effect, the classical method of hydrogen reduction was also adopted to construct SMSI on Pt/CeO2. According to a previous report, fresh-Pt/CeO2 was calcined at 700 °C under hydrogen atmosphere for 2 h59. The HRTEM images revealed that an amorphous and dense CeOx overlayer was formed on the surface of Pt NPs after H2 reduction, which is more significantly different from the non-dense overlayer formed by laser-induced SMSI, but is consistent with previous reports (Supplementary Fig. 25)60. The in situ CO-DRIFT shown that the adsorption of CO is suppressed after high temperature reduction of Pt/CeO2 by hydrogen (Supplementary Fig. 26). The above results all demonstrate the formation of SMSI between Pt and CeO2 after high temperature reduction. CO oxidation was also used as a probe reaction to study the changes in its activity before and after the formation of SMSI. It was found that the catalytic activity of Pt/CeO2 showed a significant decay after the formation of SMSI under hydrogen reduction, and its complete conversion temperature increased from 170 to 230 °C for fresh samples. However, the catalytic activity was restored after reoxidation of the H2-Pt/CeO2 sample under air atmosphere at 600 °C, and its complete conversion of CO was achieved at 160 °C (Supplementary Fig. 27). The above experimental phenomena are in good agreement with the uniform classical SMSI, but differ significantly from the laser-induced SMSI effect. The root cause of this difference is perhaps the difference in the structure of the CeOx overlayer, as mentioned above. Although the H2 reduction construct SMSI effect is also able to increase the interface between the Pt and CeOx, but the dense CeOx overlayer formed on the surface of Pt NPs makes it difficult for the reactants to directly contact the interfacial sites, which instead reduces the activity of the catalyst. The laser-irradiated Pt/CeO2 exhibits excellent cycling stability due to the SMSI effect, with no decay in activity after ten cycles (Fig. 6b). It is generally accepted that the low on-stream stability of supported noble metal catalysts has been a major challenge preventing their practical applications. Whereas the previous studies have shown that constructing SMSI effects can significantly improve the stability of supported noble metal catalysts61,62. Therefore, we investigated the stability of laser-irradiated Pt/CeO2 for CO catalytic oxidation. As expected, laser-irradiated Pt/CeO2 showed no significant decay in activity after 50 h of reaction at 150 °C, while the corresponding fresh-Pt/CeO2 decreased gradually (Fig. 6c). HRTEM was performed to analyze the microstructure of laser-irradiated Pt/CeO2 after reaction (Fig. 6d). The overlayer still kept intact with no apparent fade even after prolonged oxidation, which demonstrates the high reliability.

Discussion

In summary, we proposed a novel approach to induce SMSI in CeO2-supported Pt NPs based on ultrafast laser excitation. It is found that the electric field intensity at the interface between Pt and CeO2 was significantly larger than that on other regions. The surface defects and metastable CeOx migration were formed under the local field excitation, indicating that the nanoconfined electric field played a key role in the formation process of SMSI. The ultrafast laser-induced SMSI with porous overlayers possessed more effective active sites and exhibited superior catalytic activity and stability. We also used this strategy to induce SMSI in Pt/TiO2, Pd/TiO2, Pt/Al2O3, Pt/SiO2, Au/TiO2, and Au/MgO NPs, showing its possibility of extending to other metal/metal oxide materials. We suggest that this study provides new insights for the formation of SMSI, and opens a general pathway to create novel nanomaterials, which have promising applications.

Methods

Raw materials

All the chemical reagent was analytically pure and without further refinement before use. CeO2 NPs were purchased from Beijing DK nano S&T Ltd, with the purity of 99.99% and the specific surface area of 30–50 m2 g−1. Chloroplatinic acid (H2PtCl4, AR, 99.99%) was purchased from Sigma Aldrich. NaHB4 (AR, 99.9%) was purchased from Sinopharm Chemical Reagent Beijing Co., Ltd.

Preparation of fresh-Pt/CeO2

In all, 0.2 g CeO2 NPs were dispersed in 180 mL deionized water under ultra-sonication to obtain a homogenous slurry. Then 4 mL H2PtCl4 (5 mmol L−1) solution was added into the slurry under stirring at room temperature for 30 min. Afterward, 4 mL newly prepared NaBH4 solution (0.01 mol L−1) was dropped into the slurry under rapid stirring (800 r min−1) for 1 h. The sample was washed with an amount of deionized water, until no obvious precipitation can be seen in wash water tested with AgNO3. After separation and drying, the resulting Pt/CeO2 catalyst was calcined in a glass tube furnace under argon atmosphere at 500 °C for 2 h to obtain fresh-Pt/CeO2.

Preparation of laser-irradiated Pt/CeO2

Femtosecond laser pulses (35 fs) emitted by an amplified Ti-Sapphire system (central wavelength: 800 nm, repetition rate: 1 kHz) was used as an excitation source to induce nanoconfined electric field. A frequency doubling crystal was employed to generate laser pulses centered at 400 nm. The temporal profile of the pulses was diagnosed by second harmonic autocorrelation, whereas laser fluence (80–250 mW) control was performed by a half-wave plate and a linear polarized beam splitter. The exposure time (20–60 min) was controlled using a shutter connected to a computer. A six-freedom translation platform was used to ensure a proper excitation of the entire solution. Generally, 50 mg Pt/CeO2 powders were dispersed in 2 mL deionized water, followed by ultrasonic stirring for 30 min. The laser pulses were focused below the air–liquid interface using a lens, and the incident spot size was fixed at about 5 mm. After homogeneous processing, laser-induced SMSI were produced. Then, 2 mL deionized water was added, and the nanostructures were dried at 50 °C for further characterization and surface activity tests.

Structural characterizations

The morphology, microstructure, and EDS-Mapping of the samples were characterized by a JEOL JEM-1010/2010 transmission electron microscope operating at 200 kV. X-ray diffraction (XRD) patterns were performed on a Bruker D8-Advance diffractometer using Ni-filtered Kα radiation. EELS spectra and corresponding HAADF-STEM images were conducted on Titan cubed Themis G2300 double aberration-corrected TEM equipped with a Quantum ER965 type EELS accessory. BET-specific surface area measurements were measured on an Autosorb-iQ2-MP automated gas sorption system. X-ray photoelectron spectra (ESCALAB 250Xi) were employed to analyze the valence states of the sample. EPR spectra were obtained at 77 K with a Bruker A300-10/12. H2-TPD spectra was obtained with a chemisorption apparatus (Autochemll2920). In situ DRIFTS spectra were obtained with a Bruker v70 spectrometer equipped with a mercury telluride detector with a resolution of 4 cm−1. Twenty millgrams sample was placed in a stainless steel crucible and then loaded into a ZnSe window that could be operated at high temperatures. Before the adsorption of CO, the samples were pre-treated in situ for 1 h in a He gas stream (33.3 mL min−1) at 120 °C and then cooled to room temperature. The gas stream was switched to pure He to collect background spectra. Subsequently, a mixture of 3 vol% CO/He (33.3 mL min−1) was introduced into the reaction cell, after the CO adsorption saturation, the gaseous CO was flashed off by evacuation and then the spectra were collected. For reoxidation samples, in situ heating at 10 vol% O2/He (33.3 mL min−1) at 600 °C for 1 h was also required before the background spectra were collected. For H2-Pt/CeO2, fresh-Pt/CeO2 was calcined in H2 atmosphere at 700 °C for 2 h and then the spectra were collected by the above method.

CO oxidation

The catalytic activity and stability of the sample were evaluated by a fixed-bed flow microreactor equipped with Shimadzu GC-2014 gas chromatograph under atmospheric pressure. Typically 50 mg catalyst mixed with 150 mg quartz sands to prevent reaction runaway. Then, the mixture was transferred into a quartz tube and secure with a quartz face. The composition of the reaction gas was CO/O2/N2 (1:20:79), and the reaction gas hourly space velocity was 60,000 mL g−1 h−1.

Data availability

The data that support the findings of this study are available within the paper and its Supplementary Information, and all data are available from the authors on reasonable request.

References

van Deelen, T. W., Mejía, C. H. & de Jong, K. P. Control of metal-support interactions in heterogeneous catalysts to enhance activity and selectivity. Nat. Catal. 2, 955–970 (2019).

Li, Z. et al. Well-defined materials for heterogeneous catalysis: from nanoparticles to isolated single-atom sites. Chem. Rev. 120, 623–682 (2019).

Mitchell, S., Qin, R., Zheng, N. & Pérez-Ramírez, J. Nanoscale engineering of catalytic materials for sustainable technologies. Nat. Nanotechnol., 16, 1–11 (2020).

Tauster, S., Fung, S. & Garten, R. L. Strong metal-support interactions. Group 8 noble metals supported on titanium dioxide. J. Am. Chem. Soc. 100, 170–175 (1978).

Tauster, S., Fung, S., Baker, R. & Horsley, J. Strong interactions in supported-metal catalysts. Science 211, 1121–1125 (1981).

Li, Z. et al. Reactive metal–support interactions at moderate temperature in two-dimensional niobium-carbide-supported platinum catalysts. Nat. Catal. 1, 349–355 (2018).

Belzunegui, J. P., Sanz, J. & Rojo, J. M. Contribution of physical blocking and electronic effect to establishment of strong metal-support interaction in rhodium/titanium dioxide catalysts. J. Am. Chem. Soc. 114, 6749–6754 (1992).

Ko, C. & Gorte, R. A comparison of titania overlayers on Pt, Pd and Rh. Surf. Sci. 161, 597–607 (1985).

Zhang, S. et al. Dynamical observation and detailed description of catalysts under strong metal–support interaction. Nano Lett. 16, 4528–4534 (2016).

Tang, H. et al. Classical strong metal–support interactions between gold nanoparticles and titanium dioxide. Sci. Adv. 3, 1700231 (2017).

Wang, L., Wang, L., Meng, X. & Xiao, F. S. New strategies for the preparation of sinter‐resistant metal‐nanoparticle‐based catalysts. Adv. Mater. 31, 1901905 (2019).

Qin, Z.-H., Lewandowski, M., Sun, Y.-N., Shaikhutdinov, S. & Freund, H.-J. Encapsulation of Pt nanoparticles as a result of strong metal−support interaction with Fe3O4 (111). J. Phys. Chem. C 112, 10209–10213 (2008).

Du, X. et al. Size-dependent strong metal-support interaction in TiO2 supported Au nanocatalysts. Nat. Commun. 11, 1–8 (2020).

Liu, J. et al. Deep understanding of strong metal interface confinement: a journey of Pd/FeOx catalysts. ACS Catal. 10, 8950–8959 (2020).

Wang, H. et al. Strong metal–support interactions on gold nanoparticle catalysts achieved through Le Chatelier’s principle. Nat. Catal. 4, 418–424 (2021).

Liu, S. et al. Ultrastable Au nanoparticles on titania through an encapsulation strategy under oxidative atmosphere. Nat. Commun. 10, 1–9 (2019).

Zhang, J. et al. Wet-chemistry strong metal–support interactions in titania-supported Au catalysts. J. Am. Chem. Soc. 141, 2975–2983 (2019).

Zhu, D., Yan, J., Xie, J., Liang, Z. & Bai, H. Ultrafast laser-induced atomic structure transformation of Au nanoparticles with improved surface activity. ACS Nano 15, 13140–13147 (2021).

Zhang, D., Gökce, B. & Barcikowski, S. Laser synthesis and processing of colloids: fundamentals and applications. Chem. Rev. 117, 3990–4103 (2017).

Zhu, D., Yan, J., Liang, Z., Xie, J. & Bai, H. Laser stripping of Ag shell from Au@Ag nanoparticles. Rare Met. 40, 3454–3459 (2021).

Li, Z. et al. A silver catalyst activated by stacking faults for the hydrogen evolution reaction. Nat. Catal. 2, 1107–1114 (2019).

Yan, J., Zhu, D., Xie, J., Shao, Y. & Xiao, W. Light tailoring of internal atomic structure of gold nanorods. Small 16, 2001101 (2020).

Chen, C. H. et al. Ruthenium‐based single‐atom alloy with high electrocatalytic activity for hydrogen evolution. Adv. Energy Mater. 9, 1803913 (2019).

Zhu, D., Yan, J. & Xie, J. Reshaping enhancement of gold nanorods by femtosecond double-pulse laser. Opt. Lett. 45, 1758 (2020).

Körstgens, V. et al. Laser-ablated titania nanoparticles for aqueous processed hybrid solar cells. Nanoscale 7, 2900–2904 (2015).

Li, L., Yu, L., Lin, Z. & Yang, G. Reduced TiO2-graphene oxide heterostructure as broad spectrum-driven efficient water-splitting photocatalysts. ACS Appl. Mater. Interfaces 8, 8536–8545 (2016).

Chen, X. et al. Laser-modified black titanium oxide nanospheres and their photocatalytic activities under visible light. ACS Appl Mater. Interfaces 7, 16070–16077 (2015).

Tian, F. et al. Preparation and photocatalytic properties of mixed-phase titania nanospheres by laser ablation. Mater. Lett. 63, 2384–2386 (2009).

Pyatenko, A., Wang, H. & Koshizaki, N. Growth mechanism of monodisperse spherical particles under nanosecond pulsed laser irradiation. J. Phys. Chem. C 118, 4495–4500 (2014).

Lau, M., Reichenberger, S., Haxhiaj, I., Barcikowski, S. & Müller, A. M. Mechanism of laser-induced bulk and surface defect generation in ZnO and TiO2 nanoparticles: effect on photoelectrochemical performance. ACS Appl. Energy Mater. 1, 5366–5385 (2018).

Amendola, V. et al. Room-temperature laser synthesis in liquid of oxide, metal-oxide core-shells, and doped oxide nanoparticles. Chemistry 26, 9206–9242 (2020).

Zhu, L. et al. Visualizing anisotropic oxygen diffusion in Ceria under activated conditions. Phys. Rev. Lett. 124, 056002 (2020).

Douillard, L. et al. Local electronic structure of Ce-doped Y2O3: an XPS and XAS study. Phys. Rev. B 49, 16171 (1994).

Spanier, J. E., Robinson, R. D., Zhang, F., Chan, S.-W. & Herman, I. P. Size-dependent properties of CeO2- y nanoparticles as studied by Raman scattering. Phys. Rev. B 64, 245407 (2001).

Hattori, T., Kobayashi, K. & Ozawa, M. Size effect of Raman scattering on CeO2 nanocrystal by hydrothermal method. Jpn J. Appl. Phys. 56, 01AE06 (2016).

Beck, A. et al. The dynamics of overlayer formation on catalyst nanoparticles and strong metal-support interaction. Nat. Commun. 11, 1–8 (2020).

Hardacre, C., Rayment, T. & Lambert, R. M. Platinum/ceria CO oxidation catalysts derived from Pt/Ce crystalline alloy precursors. J. Catal. 158, 102–108 (1996).

Wu, Z., Li, Y. & Huang, W. Size-dependent Pt-TiO2 strong metal–support interaction. J. Phys. Chem. Lett. 11, 4603–4607 (2020).

Macino, M. et al. Tuning of catalytic sites in Pt/TiO2 catalysts for the chemoselective hydrogenation of 3-nitrostyrene. Nat. Catal. 2, 873–881 (2019).

Ding, K. et al. Identification of active sites in CO oxidation and water-gas shift over supported Pt catalysts. Science 350, 189–192 (2015).

Nie, L. et al. Activation of surface lattice oxygen in single-atom Pt/CeO2 for low-temperature CO oxidation. Science 358, 1419–1423 (2017).

Jones, J. et al. Thermally stable single-atom platinum-on-ceria catalysts via atom trapping. Science 353, 150–154 (2016).

Yu, M. et al. Laser fragmentation-induced defect-rich cobalt oxide nanoparticles for electrochemical oxygen evolution reaction. ChemSusChem 13, 520–528 (2020).

Shugaev, M. V. et al. Fundamentals of ultrafast laser–material interaction. MRS Bull. 41, 960–968 (2016).

Melchionna, M. & Fornasiero, P. The role of ceria-based nanostructured materials in energy applications. Mater. Today 17, 349–357 (2014).

Kuwauchi, Y., Yoshida, H., Akita, T., Haruta, M. & Takeda, S. Intrinsic catalytic structure of gold nanoparticles supported on TiO2. Angew. Chem. Int. Ed. Engl. 51, 7729–7733 (2012).

Du, X. et al. Size-dependent strong metal-support interaction in TiO2 supported Au nanocatalysts. Nat. Commun. 11, 5811 (2020).

Hayun, S., Ushakov, S. V., Navrotsky, A. & Klimm, D. Direct measurement of surface energy of CeO2 by differential scanning calorimetry. J. Am. Ceram. Soc. 94, 3679–3682 (2011).

Lau, M., Ziefuss, A., Komossa, T. & Barcikowski, S. Inclusion of supported gold nanoparticles into their semiconductor support. Phys. Chem. Chem. Phys. 17, 29311–29318 (2015).

González-Rubio, G., Díaz-Núez, Pablo & Rivera, Antonio Femtosecond laser reshaping yields gold nanorods with ultranarrow. Science 358, 640–644 (2017).

Grisel, R. & Nieuwenhuys, B. Selective oxidation of CO, over supported Au catalysts. J. Catal. 199, 48–59 (2001).

Ke, J. et al. Strong local coordination structure effects on subnanometer PtOx clusters over CeO2 nanowires probed by low-temperature CO oxidation. ACS Catal. 5, 5164–5173 (2015).

Pacchioni, G. & Freund, H.-J. Controlling the charge state of supported nanoparticles in catalysis: lessons from model systems. Chem. Soc. Rev. 47, 8474–8502 (2018).

Farmer, J. A. & Campbell, C. T. Ceria maintains smaller metal catalyst particles by strong metal-support bonding. Science 329, 933–936 (2010).

Zhang, B. & Qin, Y. Interface tailoring of heterogeneous catalysts by atomic layer deposition. ACS Catal. 8, 10064–10081 (2018).

Farnesi Camellone, M., Negreiros Ribeiro, F., Szabová, L., Tateyama, Y. & Fabris, S. Catalytic proton dynamics at the water/solid interface of ceria-supported Pt clusters. J. Am. Chem. Soc. 138, 11560–11567 (2016).

Conner, W. C. Jr & Falconer, J. L. Spillover in heterogeneous catalysis. Chem. Rev. 95, 759–788 (1995).

Liu, X. et al. Strong metal–support interactions between gold nanoparticles and ZnO nanorods in CO oxidation. J. Am. Chem. Soc. 134, 10251–10258 (2012).

Bernal, S. et al. Nanostructural evolution of a Pt/CeO2 catalyst reduced at increasing temperatures (473–1223 K): a HREM Study. J. Catal. 169, 510–515 (1997).

Bernal, S. et al. Electron microscopy (HREM, EELS) study of the reoxidation conditions for recovery of NM/CeO2 (NM: Rh, Pt) catalysts from decoration or alloying phenomena. Catal. Lett. 76, 131–137 (2001).

Zhang, Y. et al. Boosting the catalysis of gold by O2 activation at Au-SiO2 interface. Nat. Commun. 11, 1–10 (2020).

Ta, N. et al. Stabilized gold nanoparticles on ceria nanorods by strong interfacial anchoring. J. Am. Chem. Soc. 134, 20585–20588 (2012).

Acknowledgements

This research was supported by the National Natural Science Foundation of China (52173257, 51872159, 51775303, 52075289).

Author information

Authors and Affiliations

Contributions

J.Z. and D.Z. performed the experimental studies and carried out the analysis. All the authors discussed the result and commented on the manuscript. J.Y. and C.-A.W. jointly designed the study and supervised the project.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Communications thanks Stephan Barcikowski and the other, anonymous, reviewer for their contribution to the peer review of this work. Peer reviewer reports are available.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, J., Zhu, D., Yan, J. et al. Strong metal-support interactions induced by an ultrafast laser. Nat Commun 12, 6665 (2021). https://doi.org/10.1038/s41467-021-27000-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-021-27000-5

This article is cited by

-

Laser-assisted synthesis of PtPd alloy for efficient ethanol oxidation

Nano Research (2024)

-

Ultrafast laser processing of camouflaged metals by topography inherited multistep removal for information encryption

Nano Research (2024)

-

Enhanced catalytic activity and thermal stability by highly dispersed Pd-based nanocatalysts embedded in ZrO2 hollow spheres

Frontiers of Materials Science (2023)

-

Enhanced activity of bimetallic Fe-Cu catalysts supported on ceria toward water gas shift reaction: synergistic effect

Frontiers of Chemical Science and Engineering (2023)

-

New routes for the construction of strong metal—support interactions

Science China Chemistry (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.