Abstract

Palladium (Pd)-catalyzed Suzuki coupling polymerization of macrocycle-bearing monomers, obtained through two-step nucleophilic aromatic substitution reactions with three types of diboric acid pinacol esters, produced aromatic poly(ether ketone)s that have optically active macrocycles composed of two 2,2′-dioxy-1,1′-binaphthyl-6,6′-diyl units and two aromatic ether ketone linkers. The macrocycle-bearing aromatic poly(ether ketone)s have excellent thermal and optical properties, that is, high glass-transition temperatures (Tg: 220–257 °C) and large molar rotations ([Φ]D25: +1906–1976 deg). In addition, polyketones have excellent solubility in typical solvents such as CHCl3 and N,N-dimethylformamide (DMF).

Similar content being viewed by others

Introduction

Aromatic poly(ether ketone)s, which consist of aromatic rings, ketone groups and ether units, have drawn much attention as physically and chemically stable organic materials.1, 2, 3 In particular, poly(ether ether ketone) is well known as one of the great engineering plastics. We synthesized aromatic poly(ether ketone)s4, 5, 6 and wholly aromatic polyketones7, 8 containing optically active 2,2′-dioxy-1,1′-binaphthyl-6,6′-diyl units. These polymers have high chemical stability and excellent solubility in organic solvents such as CHCl3 and DMF. Furthermore, we developed aromatic polyketones containing optically active macrocycles9, 10, 11, 12, 13 composed of 1,1′-binaphthyl-2,2′-dioxy units.14, 15 These macrocycle-bearing polymers have adequate thermal and optical properties and solubility for use in engineering applications.

In a previous paper, we reported on the synthesis of three types of optically active macrocycles consisting of 2,2′-dimethoxy-1,1′-binaphthyl-6,6′-diyl units and aromatic ether ketone linkers through a stepwise nucleophilic aromatic substitution reaction.16 The resulting macrocycles have high molar rotations.

In this paper, we report on the synthesis of poly(ether ketone)s containing optically active macrocycles composed of 1,1′-binaphthyl-6,6′-diyl units through palladium (Pd)(PPh3)4-catalyzed Suzuki coupling polymerization17 of macrocycle-bearing dibrominated monomer 10 with diboric acid esters 11a–c. Thermal and optical properties and solubility in organic solvents of the resulting poly(ether ketone)s (12) are also described.

Experimental procedure

Materials

(S)-1,1′-Bi-2-naphthol (BINOL, 1) was purchased from Kanto Chemical (Tokyo, Japan). 4-Bromodiphenyl ether (2), 4-fluorobenzoic acid and 4,4′-oxybiphenol (8) were purchased from Tokyo Kasei Kogyo (Tokyo, Japan). Aluminum chloride, potassium carbonate and pinacol were purchased from Wako Pure Chemical Industries (Osaka, Japan). Methanesulfonic acid (MsOH) was purchased from Aldrich. (St Louis, MO, USA) Pd(PPh3)4 was purchased from Nacalai Tesque (Kyoto, Japan). These reagents were used as received. DMF was purchased from Kanto Chemical and used after distillation under reduced pressure. 4-Fluorobenzoyl chloride (3) was provided by Ihara Nikkei Chemical Industry (Shizuoka, Japan). Diboric acid pinacol esters 11a–c were prepared through esterification of the corresponding diboric acids with pinacol. Diboric acids were prepared through lithiation of the corresponding diiodide or dibromide, followed by transmetallation by trimethoxyborane and acidic workup according to typical procedures.

Instruments

1H-nuclear magnetic resonance (NMR) spectra were obtained using Jeol JNM-AL-300 (Jeol, Tokyo, Japan; 300 MHz) and Jeol JNM-ECX-400 (400 MHz). Chemical shifts are expressed in p.p.m. relative to the internal standard of Me4Si (δ, 0.00). 13C-NMR spectra were obtained using Jeol JNM-AL-300 (75 MHz) and Jeol JNM-ECX-400 (100 MHz). Chemical shifts are expressed in p.p.m. relative to the internal standard of CDCl3 (δ, 77.0). Infrared (IR) measurements were obtained using Jeol FT/IR-4100. Recycling preparative high-performance liquid chromatography (HPLC) was performed using CHCl3 as an eluent using JAI LC-9201 (JAI, Tokyo, Japan) equipped with a ultraviolet detector (254 nm) and JAIGEL 2.5H and 3H gel-permeation chromatography columns. Molar rotations ([φ]D25) were determined in CHCl3 (5 × 10−5 mol l−1) using a Jasco DIP-1000 digital polarimeter (Jasco, Tokyo, Japan). Circular dichromism (CD) measurements were performed in CHCl3 (2 × 10−5 mol l−1, c: 1 cm) using Jasco J820. MALDI-TOF MS (matrix-assisted laser desorption/ionization-time of flight mass spectrometry) spectra were obtained using a Bruker Autoflex II TOF/TOF mass spectrometer (Bruker, Karlsruhe, Germany). The spectrometer was equipped with a nitrogen laser (λ=337 nm), a pulsed ion-extraction system and a reflector; the operation was performed at an accelerating potential of 20 kV in positive ion mode. A CHCl3 solution of macrocycle 10 (1 μmol ml−1, 3 μl) was mixed with a CHCl3 solution of 1,8-dihydroxy-9(10H)anthracenone (the matrix, dithranol, Aldrich) (10 mg ml−1, 8 μl). A 1-ml portion of the mixed solution was deposited onto a ground-steel sample target and allowed to dry in air at room temperature. Mass values were calibrated with peptide calibration standards purchased from Bruker Daltonics K.K. (Kanagawa, Japan) Gel-permeation chromatography measurements were performed at a flow rate of 1.0 ml min−1 at 40 °C using CHCl3 as an eluent in Jasco PU-2080 equipped with a ultraviolet detector (190–600 nm) and a Shodex K-804L column (Shodex, Tokyo, Japan). Glass transition temperatures (Tgs) were determined using differential scanning calorimetry (DSC) thermograms, which were obtained using a Rigaku DSC-8230 differential scanning calorimeter (Rigaku, Tokyo, Japan) with a heating rate of 10 K min−1. Thermal degradation temperatures (Td5) were determined using thermogravimetry analysis (TGA) thermograms, which were obtained using a Rigaku TG-8120 thermogravimeter with a heating rate of 10 K min−1.

P2O5-MsOH was prepared according to Eaton’s procedure.18 (S)-6,6′-Bis(4-fluorobenzoyl)-2,2′-dimethoxy-1,1′-binaphthyl (7) was prepared according to our previous paper.4

4-(4-Bromophenyloxy)-4′-fluorobenzophenone (4)

4-Bromodiphenyl ether (2, 2.49 g, 10 mmol), 4-fluorobenzoyl chloride (3, 1.59 g, 10 mmol) and 1,2-dichloroethane (40 ml) were added to a 100-ml one-necked flask. AlCl3 (2.67 g, 20 mmol) was then added at 0 °C. The reaction mixture was stirred at room temperature for 4 h. The mixture was poured into water in a beaker, and after the mixture was neutralized with 6 M aqueous sodium hydroxide, the separated aqueous layer was extracted three times using chloroform. The combined extracts were dried over anhydrous MgSO4. After removal of the drying agent, chloroform was removed under reduced pressure. The crude product was purified by recrystallization from EtOH to produce pure 4 as a yellow powder with 85% yield.

1H-NMR δ (300 MHz, CDCl3): 6.97(2H, d, J=8.4 Hz), 7.02(2H, d, J=8.7 Hz), 7.15(2H, t, J=8.7 Hz), 7.50(2H, d, J=8.4 Hz), 7.78(2H, d, J=8.7 Hz), 7.81(2H, dd, J=5.4, 8.7 Hz) p.p.m. 13C-NMR δ (75 MHz, CDCl3): 115.4(d, 2JCF=21.8 Hz), 117.2, 117.4, 121.7, 132.2, 132.4(d, 3JCF=9.3 Hz), 133.1, 133.9, 134.0, 154.7, 161.0, 165.2 (d, 1JCF=254 Hz), 193.9 p.p.m. IR ν (KBr): 1010, 1156, 1238, 1601, 1645 cm−1. Anal. calcd. for C19H12BrFO2: C, 61.48; H, 3.26. Found: C, 61.31; H, 3.44%.

Dibromide 5

(S)-BINOL (1, 573 mg, 2 mmol), 4-(4-bromophenyloxy)-4′-fluorobenzophenone (4, 2.23 g, 6 mmol), potassium carbonate (831 mg, 6 mmol) and freshly distilled DMF (4 ml) were added to a 50-ml two-necked flask. After the reaction mixture was stirred at 150 °C for 4 h, it was poured into water, and the resulting solid was collected by suction filtration. After H2O and chloroform were added to the solid, the separated aqueous layer was extracted three times using chloroform. The combined extracts were dried over anhydrous MgSO4. After removal of the drying agent, chloroform was removed under reduced pressure. The residue was purified by column chromatography (CHCl3) to produce pure 5 as a yellow powder with 74% yield.

1H-NMR δ (300 MHz, CDCl3): 6.82(4H, d, J=8.7 Hz), 6.95(4H, d, J=8.4 Hz), 6.98(4H, d, J=8.4 Hz), 7.27–7.35(6H, m), 7.42–7.50(6H, m), 7.56(4H, d, J=8.7 Hz), 7.67(4H, d, J=8.4 Hz), 7.91(2H, d, J=8.1 Hz), 7.95(2H, d, J=9.0 Hz) p.p.m. 13C-NMR δ (75 MHz, CDCl3): 117.1, 117.4, 119.8, 121.6, 122.7, 125.3, 125.8, 126.9, 128.2, 130.2, 130.9, 131.8, 132.1, 132.6, 133.0, 134.0, 151.1, 154.9, 160.6, 161.1, 193.9 p.p.m. IR ν (KBr): 1011, 1244, 1602, 1650 cm−1. Anal. calcd. for C58H36Br2O6: C, 70.46; H, 3.67. Found: C, 70.68; H, 3.82%.

Dibromide 6

4-Fluorobenzoic acid (168 mg, 1.2 mmol) and P2O5-MsOH (1.5 ml) were added to a 30-ml two-necked flask. The mixture was stirred at 80 °C for 15 min. Dibromide 5 (198 mg, 0.2 mmol) was then added to the mixture. After the reaction mixture was stirred at 80 °C for 72 h, it was poured into water in a beaker. After the mixture was neutralized with 6 M aqueous sodium hydroxide, the separated aqueous layer was extracted three times using chloroform. The combined extracts were dried over anhydrous MgSO4. After removal of the drying agent, chloroform was removed under reduced pressure. The crude product was purified with preparative thin-layer chromatography (TLC, CHCl3) to produce pure 6 as a yellow powder with 57% yield.

1H-NMR δ (300 MHz, CDCl3): 6.88(4H, d, J=8.7 Hz), 6.96(4H, d, J=9.0 Hz), 6.99(4H, d, J=8.7 Hz), 7.22(4H, t, J=8.7 Hz), 7.39(2H, d, J=9.0 Hz), 7.41(2H, d, J=8.7 Hz), 7.49(4H, d, J=8.7 Hz), 7.63(4H, d, J=8.7 Hz), 7.70(4H, d, J=8.7 Hz), 7.79(2H, dd, J=1.5, 8.7 Hz), 7.91(4H, dd, J=5.1, 9.0 Hz), 8.07(2H, d, J=9.0 Hz), 8.33(2H, s) p.p.m. 13C-NMR δ (75 MHz, CDCl3): 115.5(d, 2JCF=21.8 Hz), 117.1, 117.3, 117.8, 120.4, 121.6, 122.0, 125.9, 127.0, 129.6, 131.8, 131.9, 132.1, 132.3, 132.6, 132.7, 133.0, 133.7, 133.8, 134.2, 136.0, 153.5, 154.7, 160.2, 160.8, 165.4(d, 1JCF=254 Hz), 193.7, 194.7 p.p.m. IR ν (KBr): 1011, 1159, 1240, 1600, 1654 cm−1. Anal. calcd. for C72H42Br2F2O8: C, 70.14; H, 3.43. Found: C, 70.26; H, 3.60%.

Diol 9

(S)-6,6′-Bis(4-fluorobenzoyl)-2,2′-dimethoxy-1,1′-binaphthyl (7, 279 mg, 0.5 mmol), 4,4′-oxybiphenol (8, 606 mg, 3.0 mmol), potassium carbonate (208 mg, 1.5 mmol) and freshly distilled DMF (13.5 ml) were added to a 50-ml one-necked flask. After the mixture was stirred at 150 °C for 18 h, it was poured into aqueous 0.1 M HCl in a beaker. The resulting precipitates were collected by suction filtration. After H2O and ethyl acetate were added to the solid, the separated aqueous layer was extracted three times using ethyl acetate. The combined extracts were dried over anhydrous MgSO4. After removal of the drying agent, ethyl acetate was removed under reduced pressure. The residue soluble in CHCl3 was purified by recycling HPLC (CHCl3) to afford pure 9 as an orange powder with 45% yield.

1H-NMR δ (300 MHz, CDCl3): 3.80(6H, s), 5.96(2H, brs), 6.81(4H, d, J=9.0 Hz), 6.83–7.03(16H, m), 7.16(2H, d, J=9.0 Hz), 7.51(2H, d, J=9.0 Hz), 7.65(2H, dd, J=1.8, 9.0 Hz), 7.84(4H, d, J=9.0 Hz), 8.07 (2H, d, J=9.0 Hz), 8.30 (2H, s) p.p.m. 13C-NMR δ (75 MHz, CDCl3): 56.6, 114.4, 116.4, 116.5, 118.7, 119.0, 120.7, 121.6, 125.3, 126.5, 127.8, 131.5, 131.9, 132.2, 132.5, 132.8, 135.9, 150.0, 150.1, 152.2, 155.3, 156.9, 162.2, 195.8 p.p.m. IR ν (KBr): 1248, 1593, 1646, 3434 cm−1. Anal. calcd. for C72H42Cl2F2O8: C, 78.08; H, 4.59. Found: C, 77.88; H, 4.68%.

Macrocycle-bearing monomer 10

Potassium carbonate (83 mg, 0.6 mmol), freshly distilled DMF (20 ml) and toluene (4 ml) were added to a 50-ml two-necked flask equipped with a Dean-Stark apparatus and a reflux condenser. The DMF solution (5 ml) of dibromide 6 (123 mg, 0.1 mmol) and diol 9 (184 mg, 0.2 mmol) was then dropped at 150 °C over 6 h. The reaction mixture was stirred at 150 °C for 72 h. The solvent was reduced to 5 ml under reduced pressure. The concentrated mixture was poured into water, and the resulting solid was collected by suction filtration. After H2O and chloroform were added to the solid, the separated aqueous layer was extracted three times using chloroform. The combined extracts were dried over anhydrous MgSO4. After removal of the drying agent, chloroform was removed under reduced pressure. The residue was purified with both recycling preparative HPLC and preparative TLC (CHCl3) to produce pure 10 as a yellow powder with 20% yield.

1H-NMR δ (400 MHz, CDCl3): 3.82(6H, s), 6.86 (4H, d, J=8.8 Hz), 6.93–7.13 (34H, m), 7.33–7.39(4H, m), 7.48(4H, d, J=8.8 Hz), 7.52(2H, d, J=8.8 Hz), 7.58(2H, d, J=8.8 Hz), 7.61(4H, d, J=8.8 Hz), 7.67–7.71 (6H, m), 7.83(4H, d, J=8.4 Hz), 7.85(4H, d, J=8.4 Hz), 8.05–8.10(4H, m), 8.36(2H, s), 8.38(2H, s) p.p.m. 13C-NMR δ (100 MHz, CDCl3): 56.5, 114.4, 116.7, 117.1, 117.3, 117.7, 118.7, 120.0, 120.1, 120.4, 121.6, 121.7, 121.8, 122.0, 124.9, 125.6, 126.6, 127.2, 127.9, 129.8, 131.4, 131.6, 131.9, 132.1, 132.3, 132.4, 132.5, 133.0, 134.7, 135.7, 150.7, 150.9, 153.2, 153.8, 154.0, 154.7, 156.8, 160.3, 160.7, 161.7, 162.1, 193.7, 194.9, 195.2 p.p.m. IR ν (KBr): 1010, 1241, 1594, 1654 cm−1. MALDI-TOF MASS: m/z 2113.3, calcd. for C132H82Br2O18 ([M+H]+) m/z 2113.3. Anal. calcd. for C132H82Br2O18: C, 74.93; H, 3.91. Found: C, 74.86; H, 3.94%.

Macrocycle-bearing poly(ether ketone)s 12a–c

Macrocycle-bearing monomer 10 (106 mg, 0.05 mmol), diboric acid pinacol diester (11, 0.05 mmol), potassium carbonate (43 mg, 0.3 mmol) and Pd(PPh3)4 (11.5 mg, 0.01 mmol) were placed in a 30-ml two-necked flask. After DMF (0.5 ml) was added, the reaction mixture was stirred at 100 °C for 48 h. The reaction mixture was poured into a mixed solution of methanol/aqueous 2 M HCl (v/v=9/1) in a beaker. The resulting precipitates were collected by suction filtration and washed first with water and then with acetone. After the resulting solid was dissolved in CHCl3, the residual solid was removed using Celite filtration. Chloroform was removed under reduced pressure to yield a pale yellow solid. The crude solid was purified with recycling preparative HPLC to produce macrocycle-bearing poly(ether ketone) 12 as brown films with moderate yields.

Poly(ether ketone) 12a: Yield 68%. 1H-NMR δ (400 MHz, CDCl3): 3.81(6H, s), 6.86 (4H, d, J=8.4 Hz), 6.99–7.12 (38H, m), 7.34(2H, d, J=9.6 Hz), 7.37(2H, d, J=9.6 Hz), 7.50–7.58(12H, m), 7.61–7.63(4H, m), 7.66–7.70(6H, m), 7.82(4H, d, J=7.2 Hz), 7.84(4H, d, J=7.6 Hz), 8.06(2H, d, J=9.2 Hz), 8.08(2H, d, J=9.6 Hz), 8.35(2H, s), 8.37(2H, s) p.p.m. 13C-NMR δ (100 MHz, CDCl3): 56.6, 114.4, 116.6, 117.2, 117.7, 118.7, 119.2, 120.1, 120.2, 120.3, 121.7, 122.0, 125.0, 125.6, 125.8, 126.6, 127.2, 127.9, 128.3, 128.4, 129.8, 131.1, 131.4, 131.7, 131.9, 132.1, 132.4, 132.5, 132.9, 134.7, 135.4, 135.7, 136.8, 150.7, 151.0, 153.3, 153.8, 154.1, 154.8, 156.6, 156.8, 160.2, 161.3, 161.7, 162.1, 193.9, 194.9, 195.2 p.p.m. IR ν (KBr): 1235, 1593, 1654 cm−1. Anal. calcd. for (C144H90O19)n: C, 81.42; H, 4.27. Found: C, 80.48; H, 4.55%.

Poly (ether ketone) 12b: Yield 72%. 1H-NMR δ (400 MHz, CDCl3): 3.81(6H, s), 6.77–6.90(4H, m), 6.92–7.16(42H, m), 7.30–7.40(4H, m), 7.43–7.74(22H, m), 7.76–7.90(8H, m), 7.98–8.12(4H, m), 8.36(2H, s), 8.38(2H, s) p.p.m. 13C-NMR δ (100 MHz, CDCl3): 56.5, 114.4, 116.6, 117.2, 117.7, 118.5, 118.7, 120.0, 120.1, 120.3, 120.5, 121.7, 121.9, 124.9, 125.6, 126.6, 126.8, 127.2, 127.9, 128.2, 128.3, 128.7, 129.8, 131.4, 131.6, 131.9, 132.1, 132.4, 132.5, 132.8, 134.7, 135.1, 135.7, 136.8, 150.7, 150.9, 152.5, 153.3, 153.8, 154.0, 154.7, 156.8, 157.2, 160.2, 161.2, 161.7, 162.0, 193.8, 194.9, 195.1 p.p.m. IR ν (KBr): 1239, 1593, 1653 cm−1. Anal. calcd. for (C150H94O20)n: C, 81.29; H, 4.27. Found: C, 78.92; H, 4.51%.

Poly(ether ketone) 12c: Yield 74%. 1H-NMR δ (400 MHz, CDCl3): 3.81(6H, s), 6.71–6.77 (3H, m), 6.86 (4H, d, J=8.8 Hz), 6.99–7.12(34H, m), 7.24–7.28(2H, m), 7.33–7.37(7H, m), 7.51–7.69(22H, m), 7.81–7.83(8H, m), 8.04–8.09(4H, m), 8.35(2H, s), 8.37(2H, s) p.p.m. 13C-NMR δ (100 MHz, CDCl3): 56.6, 109.4, 113.3, 114.4, 116.6, 117.0, 117.3, 117.7, 118.7, 119.1, 120.0, 120.1, 120.2, 121.3, 121.7, 122.0, 122.2, 124.9, 125.6, 126.6, 126.9, 127.2, 127.9, 128.6, 129.8, 130.1, 130.5, 131.4, 131.7, 131.9, 132.1, 132.4, 132.5, 132.9, 134.7, 135.7, 136.6, 142.1, 150.7, 150.9, 153.3, 153.8, 154.0, 155.3, 156.8, 157.1, 158.5, 160.2, 161.1, 161.7, 162.1, 193.8, 194.9, 195.2 p.p.m. IR ν (KBr): 1239, 1594, 1654 cm−1. Anal. calcd. for (C150H94O20)n: C, 81.29; H, 4.27. Found: C, 79.57; H, 4.20%.

Results and Discussion

Synthesis of macrocyclic precursors 6 and 9

The AlCl3-mediated Friedel–Crafts acylation reaction of 4-bromodiphenyl ether (2) with 4-fluorobenzoyl chloride (3) in 1,2-dichloroethane proceeded at the 4′-position of ether 2 regioselectively to produce fluoride 4 with 85% yield. The nucleophilic aromatic substitution reaction of (S)-BINOL (1) with fluoride 4 in DMF produced the corresponding disubstituted binaphthyl (5) with 74% yield. The direct condensation of the binaphthyl (5) with 4-fluorobenzoic acid mediated by P2O5-MsOH proceeded at 6,6′-positions regioselectively to produce macrocyclic precursor 6 with 57% yield. The decrease in the yield is probably due to the lower reactivity of the binaphthyl units containing benzophenone structures, which require a higher temperature and a longer reaction time.

The other macrocyclic precursor (9) was prepared through nucleophilic aromatic substitution reaction of (S)-6,6′-bis(4-fluorobenzoyl)-2,2′-dimethoxy-1,1′-binaphthyl (7)4 with 6 equimolar amounts of 4,4′-oxybiphenol (8) under high dilution conditions. Pure macrocyclic precursor 9 was obtained with 45% yield after using recycling preparative HPLC purification (Scheme 1).

Cyclization

Cyclization between macrocyclic precursors 6 and 9 under high dilution conditions proceeded to produce macrocycle 10 with 20% yield after recycling preparative HPLC and preparative PLC purification. Figure 1 shows 1H-NMR spectra of precursors 6/9 and macrocycle 10. A triplet signal that is assigned to the proton Hc of precursor 6 disappears completely in the spectrum of macrocycle 10. In addition, a doublet signal that is assigned to the proton Hd of precursor 9 also disappears completely in the spectrum of 10. The peak positions of the singlet signals observed under the lowest magnetic field in the spectra of precursors 6 and 9, that is, Ha and Hb, shift to lower magnetic fields in the spectrum of macrocycle 10, that is, H′a and H′b. Furthermore, the MALDI TOF-MASS measurement of the resulting product (measured m/z=2113.3) proved that the product is macrocycle 10.

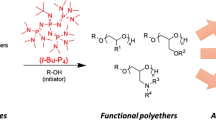

Suzuki coupling polymerization

Macrocycle-bearing monomer 10 was allowed to react with diboric acid pinacol diester 11a in the presence of 20 mol% of Pd(PPh3)4 against monomer 10 and K2CO3 in DMF for 24 h, producing the corresponding macrocycle-bearing poly(ether ketone) (12a) with 64% yield (Table 1, run 1). When the reaction time was lengthened to 48 h, the yield increased slightly (run 2). Even when a 10 mol% catalyst was used, high-molecular-weight poly(ether ketone) 12a was obtained with a moderate yield (run 4).

Polymerization of macrocycle-bearing monomer 10 with diboric diester 11b/c yielded the corresponding macrocycle-bearing poly(ether ketone)s 12b/c. When diboric acid esters 11b and 11c were used, high-molecular-weight polyketones 12b/c were obtained (runs 5 and 6). In addition, molecular weights of poly(ether ketone)s 12a–c in this study are much higher than those of wholly aromatic polyketones (Mn: 5000–6400) synthesized through nickel complex-mediated aromatic homo-coupling polymerization, previously reported.15 The difference between these polymerization behaviors probably depends on the length of the linkers that connect the macrocycles. The macrocycles are so large and bulky that homo-coupling polymerization with nearby neighboring macrocycles would be disadvantageous for producing the polymer. Instead, with cross-coupling polymerization the neighboring macrocycles are further apart, which leads to smooth polymerization (Scheme 2).

Property

The glass transition temperatures (Tgs) of the resulting poly(ether ketone)s (12a–c) are 256, 257 and 220 °C, respectively (Table 2). The Tg of poly(ether ketone) 12c is relatively lower than those of poly(ether ketone)s 12a and 12b. Presumably, this variation in Tg is due to the introduction of m-phenylenedioxy units with bent structures, which would decrease the rigidity of polymer main chains. Poly(ether ketone)s (12a–c) have much higher Tgs than poly(ether ether ketone) 143 °C) and the other aromatic polyketones included in our studies. The incorporation of rigid macrocycles may suppress the free rotation of the polymer main chains. In addition, the Tgs of poly(ether ketone)s (12a–c) are much higher than those of macrocycle-bearing wholly aromatic polyketones (176–178 °C) synthesized through homo-coupling polymerization, previously reported.15 The reasons for this variation in Tg are the increase in molecular weight and the difference of the connecting positions of binaphthylene units, that is, 2,2′-positions or 6,6′-positions. Polymers bearing binaphthyl-2,2′-ene groups will be more rigid than those bearing binaphthyl-6,6′-ene groups according to the difference in steric hindrance. The temperature range at which 5% weight losses occur (Td5) for poly(ether ketone)s 12a–c is 427–435 °C (Table 2). Although poly(ether ketone)s (12a–c) have very high Tgs, they are soluble in typical organic solvents, such as chloroform and DMF (Table 3). By incorporating macrocycles that include twisted binaphthyl-2,2′-ene units, packing effects between polymer chains will be minimized.

In addition, poly(ether ketone)s 12a–c have sufficient molar rotations ([Φ]D25 in CHCl3, Table 2). Figures 2 and 3 show CD spectra of precursors 6/9, macrocycle 10 and macrocycle-bearing poly(ether ketone)s 12a–c. Although no clear peaks were observed in the CD spectrum of precursor 6, clear peaks were observed at ∼280 nm in those of precursor 9, macrocycle 10 and macrocycle-bearing poly(ether ketone)s 12a–c. These results suggest that macrocycle 10 and macrocycle-bearing poly(ether ketone)s 12a–c have optically active cyclic structures. Poly(ether ketone)s 12a–c may be useful for fine molecular recognition of optically active molecules using optically active cavities.

Conclusions

Macrocycle-bearing monomer 10 was synthesized through nucleophilic aromatic substitution cyclization of precursors 6 and 9 using high dilution conditions. Pd-catalyzed Suzuki coupling polymerization of macrocycle-bearing monomer 10 with diboric acid pinacol esters 11a–c produced aromatic poly(ether ketone)s with optically active macrocycles (12a–c). Poly(ether ketone)s 12a–c have high glass-transition temperatures (Tg: 220–257 °C), large molar rotations ([Φ]D25: +1906–1976 deg) and excellent solubility in typical solvents, such as CHCl3 and DMF. The improvement in thermal stability and maintenance of solubility in organic solvents by the incorporation of rigid macrocycles to polymer side chains will be a useful tool in the molecular designs used in the development of polymer materials with excellent thermal stability and excellent solubility in organic solvents.

Preparation of macrocyclic precursors 6 and 9.

Cyclization and Suzuki coupling polymerization.

References

Staniland, P. A., Eastmond, G. C., Ledwith, A., Russo, S. & Sigwalt, P. (ed.) Comprehensive Polymer Science Vol. 5, 483 (Pergamon Press, Oxford, UK, 1989.

Maeyama, K. Synthesis of wholly aromatic polyketones based on fine molecular designing. J. Synth. Org. Chem. 69, 616–626 (2005).

Maeyama, K. Aromatic poly(ether ketone)s functional materials. Expect Mater Future 8, 42–47 (2008).

Maeyama, K., Hikiji, I., Ogura, K., Okamoto, A., Ogino, K., Saito, H. & Yonezawa, N. Synthesis of optically active aromatic poly(ether ketone)s via nucleophilic aromatic substitution polymerization. Polym. J. 37, 707–710 (2005).

Maeyama, K., Maeda, S., Ogino, K., Saito, H. & Yonezawa, N. Synthesis of optically active aromatic poly(ether ketone)s containing 2,2′-bis(4-benzoylphenoxy)-1,1′-binaphthyl-6,6′-ene backbones. React. Funct. Polym. 65, 229–237 (2005).

Maeyama, K., Tsukamoto, T., Suzuki, M., Higashibayashi, S. & Sakurai, H. Synthesis of aromatic polyketones bearing 1,1′-Binaphthyl-2,2′-dioxy units through Suzuki-Miyaura coupling polymerization. Chem. Lett. 40, 1445–1446.

Maeyama, K., Ogura, K., Okamoto, A., Ogino, K., Saito, H. & Yonezawa, N. Nickel complex-mediated synthesis of optically active wholly aromatic polyketones bearing 2,2′-Dimethoxy-1,1′-binaphthylene units. Polym. J. 37, 736–741 (2005).

Okamoto, A., Mitsui, R., Maeyama, K., Saito, H., Oike, H., Murakami, Y. & Yonezawa, N. Electrophilic aromatic aroylation polycondensation synthesis of wholly aromatic polyketones composed of 2,2′-dimethoxy-1,1′-binaphthylene moiety. React. Funct. Polym. 67, 1243–1251 (2007).

Cao, H., Liu, X., Ben, T., Chen, C., Gao, Z. & Zhang, W. Synthesis and characterization of rigid cyclic oligomer containing thioether moiety. Polym. Prep. 43, 1112–1113 (2002).

Dang, G., Yang, W., Zhao, X., Chen, C., Li, F., Zhang, W. & Wu, Z. Molecular design and synthesis of a novel aromatic macrocycle with a [1,1′]binaphthalenyl moiety and a p-chlorophenyl substituent. Polym. Prep. 44, 911 (2003).

Wang, X., Liu, N., Cao, H., Liu, W., Chen, C., Zhang, W. & Wei, Y. Chiral crystal structure of racemic binaphthyl poly(ether ketone) macrocycles. Macromol. Rapid Commun. 26, 554–557 (2005).

Liu, N., Wang, X., Jin, E., Chen, C., Zhang, W. & Wei, Y. Synthesis and self-assembly of comb oligomers having rigid racemic or chiral binaphthyl macrocyclic pendant groups. Polymer 47, 3021–3027 (2006).

Ema, T., Tanida, D., Sugita, K., Sakai, T., Miyazawa, K. & Ohnishi, A. Chiral selector with multiple hydrogen-bonding sites in a macrocyclic cavity. Org. Lett. 10, 2365–2368 (2008).

Maeda, S., Maeyama, K. & Yonezawa, N. Synthesis of optically active Bis(binaphthyl) macrocycles. Synth. Commun. 37, 2663–2770 (2007).

Maeyama, K., Maeda, S., Saito, H. & Yonezawa, N. Synthesis of wholly aromatic polyketones containing optically active macrocycles. Polym. J. 39, 342–346 (2007).

Maeyama, K., Yamashita, K., Maeda, S., Yonezawa, N., Aikawa, S. & Yoshida, Y. Synthesis of optically active aromatic ether ketone macrocycles containing 2,2′-dimethoxy-1,1′-binaphthyl-6,6′-diyl moieties. Synth. Commun. 39, 4158–4170 (2009).

Miyaura, N. & Suzuki, A. Palladium-catalyzed cross-coupling reactions of organoboron compounds. Chem. Rev. 95, 2457–2483 (1995).

Eaton, P. E., Carlson, G. R. & Lee, G. T. Phosphorus pentoxide-methanesulfonic acid: Convenient alternative to polyphosphoric acid. J. Org. Chem., 38, 4071–4073 (1973).

Acknowledgements

This study is supported by a Grant-in-Aid for Young Scientists (B) (no. 20750173) from the Ministry of Education, Culture, Sports, Science and Technology of Japan. We are grateful to Professor Toshikazu Takata at the Tokyo Institute of Technology for measurement of the CD spectra.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Maeyama, K., Yamashita, K., Saito, H. et al. Synthesis of aromatic poly(ether ketone)s bearing optically active macrocycles through Suzuki coupling polymerization. Polym J 44, 315–320 (2012). https://doi.org/10.1038/pj.2011.134

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2011.134

Keywords

This article is cited by

-

Synthesis of organosoluble and fluorescent aromatic polyketones bearing 1,1′-binaphthyl units through Suzuki–Miyaura coupling polymerization

Polymer Bulletin (2015)

-

Nanosized palladium-catalyzed Suzuki–Miyaura coupling polymerization: synthesis of soluble aromatic poly(ether ketone)s

Polymer Journal (2013)