Abstract

A procedure for the preparation of optically pure α-keto-γ-hydroxy carboxylic acids through stereospecific aldol addition catalyzed by pyruvate aldolases from the Entner–Doudoroff and the DeLey–Doudoroff glycolytic pathways is described. This highly versatile fragment serves as a precursor for a variety of commonly encountered functionalities, including β-hydroxy aldehydes and carboxylic acids, α-amino-γ-hydroxy carboxylic acids and α,γ-dihydroxy carboxylic acids. The protocol described here uses recombinant His6-tagged KDPG aldolase for the synthesis of (S)-4-hydroxy-2-keto-4-(2′-pyridyl)butyrate. A protocol for evaluating enantiomeric excess through formation of the γ-lactone of the dithioacetal followed by chiral-phase gas–liquid chromatography is also described. Enzyme expression and enzymatic synthesis can be accomplished in approximately 1 week. The enzymatic aldol addition proceeds in nearly quantitative yields with enantiomeric excesses greater than 99.7%.

Similar content being viewed by others

Introduction

In addition to managing the flow of small molecules that create and support life, enzymes have found great utility in chemical synthesis1,2,3. With the exception of only a few categories, every mechanistic class of reactions known to the organic chemist has an enzymatic equivalent. Enzymes operate with enormous efficiency, providing rate enhancements up to 1012 over the uncatalyzed reaction, and proceed in aqueous solution, at or near room temperature and neutral pH. Of greatest advantage, enzymes are chiral catalysts, and in many instances carry out reactions stereospecifically. Roughly 60% of all pharmaceutical agents at market today are chiral, and the well-known problems associated with the use of racemic drugs has led to a growing regulatory pressure for the sale and use of enantiomerically pure formulations4,5,6,7,8. The chiral nature of enzymes facilitates both enantiomerically pure synthesis and the resolution of racemates: today, every major pharmaceutical producer has in place or makes use of a biocatalysis unit.

All synthesis ultimately rests on carbon–carbon bond formation. Although a number of carbon–carbon bond formation strategies are known in nature, the enzymatic aldol reaction has found the greatest use in organic synthesis9,10. Originally reported by Whitesides11,12,13,14 and Effenberger15,16,17, and later elaborated by Wong18,19,20,21, Fessner22,23,24 and others25,26,27, the dihydroxyacetone phosphate glycolytic aldolases provide access to virtually any 1,3,4-trihydroxy-2-butanone skeleton. Although the enzymes show a strict requirement for dihydroxyacetone phosphate as the nucleophilic component, the enzymes accept virtually any aldehyde as the electrophilic component, providing a powerful set of catalysts. Thus, for example, the use of azide-containing electrophilic substrates facilitated the synthesis of an enormous diversity of azasugar glycosidase inhibitors28. Still, difficulties associated with the preparation of dihydroxyacetone phosphate, mixed kinetic and thermodynamic diastereoselectivity and the production of a highly but not differentially functionalized carbon skeleton have limited the broader use of the DHAP aldolases in organic synthesis.

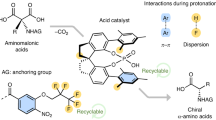

In contrast, aldolases of the Entner–Doudoroff and DeLey–Doudoroff glycolytic pathways catalyze aldol addition of pyruvate to an electrophilic aldehyde to produce a 2-keto-4-hydroxybutyrate skeleton (Fig. 1). This moiety is both highly and differentially functionalized, lending itself to ready synthetic elaboration to, for example, α-amino-γ-hydroxybutyrates, α,γ-diydroxybutyrates and α-hydroxy aldehydes and acids.

2-Keto-3-deoxy-6-phosphogluconate aldolase (KDPG) is a type I pyruvate aldolase of the Entner–Doudoroff glycolytic pathway, which metabolizes glucose through sequential conversion to KDPG followed by retro-aldol cleavage to the key metabolites pyruvate and glyceraldehyde-3-phosphate (G3P)29. The equilibrium characterizing KDPG–pyruvate/G3P interconversion lies far toward synthesis30, and during aldol addition, KDPG aldolase catalyzes the addition of pyruvate to electrophilic aldehydes with si-facial selectivity (Fig. 1). In contrast to other pyruvate aldolases, KDPG aldolase displays complete kinetic stereoselectivity, further enhancing its utility as a synthetic catalyst31. The related enzyme 2-keto-3-deoxy-6-phosphogalactonate (KDPGal) aldolase catalyzes the analogous reaction, but with re-facial selectivity, providing access to both stereochemical sequences32. The enzyme shows reasonably broad substrate specificity with regard to the electrophilic moiety, accepting straight-chain, branched and cyclic aldehydes, provided they possess polar functionality at C2, C3 or C4. Like the DHAP aldolases, both KDPG and KDPGal aldolase show more restricted substrate specificity with regard to the nucleophilic component, accepting in addition to pyruvate, 2-oxobutyrate and fluoropyruvate.

In the course of developing an enzymatic synthesis of the unnatural amino acid (2S,4S) 2-amino-4-hydroxy-4-(2-pyridyl)butyrate, we developed an enzymatic strategy to prepare the key intermediate (S)-4-hydroxy-2-keto-4-(2′-pyridyl)butyrate33,34. The synthesis involves aldol addition between 2-pyridinecarboxaldehyde and pyruvate catalyzed by KDPG aldolase (Fig. 2), and is illustrative of the use of KDPG and KDPGal aldolases for stereocontrolled carbon–carbon bond formation. Formation of the dithioacetal accompanies formation of the corresponding γ-lactone: this species is sufficiently volatile to permit determination of enantiomeric excess by chiral-phase gas–liquid chromatography.

Experimental design

This protocol describes the expression and application of KDPG aldolase for stereocontrolled carbon–carbon bond formation. Although we describe the protocol for the specific case of 2-pyridinecarboxaldehyde as the electrophilic substrate, the protocol is applicable to other aldehydic substrates. Similarly, substitution of KDPGal aldolase furnishes the analogous series of products epimeric at C4. The protocol described here is directly applicable to substrates other than 2-pyridinecarboxaldehyde, although reaction times and enzyme concentrations must be scaled to reflect relative reactivities. The protocols are also applicable for related enzymes—for example, KDPGal aldolase—although substrate specificities must first be evaluated to determine the feasibility of each transformation.

Materials

Reagents

-

Kanamycin sulfate (Fluka, cat. no. 60615)

-

Terrific broth (EMD Chemicals Inc., cat. no. 1.01629.5007)

-

HEPES (Sigma, cat. no. H3375)

-

Luria broth (EMD Chemicals Inc., cat. no. 1.10285.5007)

-

Agar (Difco, cat. no. 214530)

-

Trizma hydrochloride (Sigma, cat. no. T5941)

-

Imidazole (Sigma-Aldrich, cat. no. I2399)

-

EDTA (Aldrich, cat. no. 431788)

-

Nickel(II) sulfate hexahydrate (Sigma-Aldrich, cat. no. 467901)

-

His•Bind Resin (Novagen, cat. no. 69670-5)

-

pET28b plasmid (Novagen, cat. no. 69865-3)

-

KDPG-pet (available from the authors on request36)

-

KDPG aldolase (available from the authors on request36)

-

BL21 CodonPlus (DE3)-RIL cells (Stratagene, cat. no. 230245)

-

SOC media

-

IPTG (Calbiochem, cat. no. 420322)

-

12% (w/v) Tris-HCl gel (Bio-Rad, cat. no. 161-1102)

-

Amberlyst 131 (Sigma, cat. no. A2461)

-

Sodium chloride (Sigma-Aldrich, cat. no. 204439)

-

Sodium hydroxide (Sigma-Aldrich, cat. no. 480878)

-

Sodium pyruvate (Sigma-Aldrich, cat. no. P8574)

-

2-pyridinecarboxaldehyde (Aldrich, cat. no. P62003)

-

Hydrochloric acid (Sigma-Aldrich, cat. no. 435570)

-

Oxalacetic acid (Aldrich, cat. no. 171255)

-

Magnesium sulfate (Aldrich, cat. no. 203726)

-

Methylene chloride (Aldrich, cat. no. 676853)

-

Ethanethiol (Aldrich, cat. no. E3708)

-

Lithium chloride (Sigma-Aldrich, cat. no. 310498)

-

Ethanol, 200 proof (Aldrich, cat. no. 459836)

-

Distilled water

Equipment

-

50 ml tube top filter (Corning, cat. no. 430320)

-

50 ml centrifuge tube (Corning, cat. no. 430829)

-

250 ml filter system (Corning, cat. no. 430281)

-

250 ml Erlenmeyer flask (Corning, cat. no. 4980-250)

-

4 liter Erlenmeyer flask (Corning, cat. no. 4980-4L)

-

pH meter (Thermo Orion, cat. no. 0420A0)

-

Econo-Column column (Bio-Rad, cat. no. 737-2531)

-

Petri dish (BD Falcon, cat. no. 351009)

-

HP8453 UV–visible system (Hewlett Packard)

-

150 ml lyophilizer jar (Labcono, cat. no. 7540300)

-

600 ml lyophilizer jar (Labcono, cat. no. 7540800)

-

Lyophilizer (Labcono, cat. no. 7754500)

-

Incubator shaker (New Brunswick Scientific Inc.)

-

Incubator oven (Lab-line Instrument Inc.)

-

C18 reverse-phase column (Isco)

-

C18 reverse-phase thin-layer chromatography (TLC) plate (EMD Chemicals Inc., cat. no. 15683-3)

-

Varian CP-3800 Gas Chromotograph

-

Chromopack Chirasil-L-Val column (25 m × 0.25 mm)

-

CombiFlash column runner (Retrieve)

-

Mini-Protean 3 electrophoresis module (Bio-Rad, cat. no. 165-3302)

-

French pressure cell press (SLM Aminco Instrument Inc.)

-

Rotary evaporator (Buchi)

-

Sorvall RC 5C Plus centrifuge (DuPont Instruments)

Procedure

Protein expression of KDPG aldolase

-

1

A plasmid containing the gene KDPG-pet36, which encodes His6-tagged KDPG aldolase, is chemically transformed into a BL21 CodonPlus (DE3)-RIL cell according to published procedures35.

-

2

Plate 50 μl of the transformation mixture on an LB/Kan (50 μg ml−1) plate and incubate overnight at 37 °C.

Pause point

Plated cells are left in the incubator overnight at 37 °C.

-

3

Introduce a single isolated colony from the LB/Kan plate to 50 ml of TB/Kan (50 μg ml−1) and incubate the culture at 37 °C for 16 h.

Pause point

To be left in the shaker overnight at 37 °C.

-

4

Transfer 10 ml of inoculated culture to 1 liter of TB/Kan (50 μg ml−1) and shake at 37 °C until an OD600 of 0.8 is reached.

-

5

Induce protein expression by adding IPTG (230 mg liter−1, to 1 mM) to the cell culture to induce protein expression. IPTG binds to the Lac repressor, inducing protein production. The induced culture is shaken at 37 °C for an additional 4 h.

-

6

Collect the cell culture by centrifugation at 4,000g for 10 min at 4 °C, and freeze the pellet at −20 °C overnight.

Pause point

The cell pellet can be stored at −20 °C for up to 3 months with minimal loss in enzyme activity.

-

7

Thaw the pellet on ice and resuspended cells in 30 ml of 20 mM HEPES, pH 7.5.

-

8

Lyse the resuspended cells in a French press at 12,000 psi. Three consecutive passes through the French press ensures complete cell lysis. Alternately, sonication can be used to lyse the cell pellet. Optimal enzyme yields are achieved when lysis is conducted at 4 °C.

-

9

Remove cellular debris by centrifugation at 14,500g for 20 min at 4 °C.

-

10

Condition the Ni2+ affinity resin by washing with distilled water and charging with nickel(II) sulfate. Then, load the cellular supernatant onto the Ni2+ affinity column and elute His6-tagged enzyme according to published procedures35. The protein is eluted with 50 ml of elution buffer and collected in a 50 ml centrifuge tube.

-

11

Determine the purity of the expressed protein by analysis on 12% SDS-polyacrylamide gel electrophoresis.

-

12

Remove imidazole by dialysis of the eluted protein in a 10,000 MWCO cellulose membrane against three changes of 20 mM HEPES, pH 7.5 (2 liters each) at 4 °C for a total of 24 h.

Pause point

The protein can be stored at 4°C for up to 6 months without a significant loss in activity.

-

13

The protein concentration can be estimated by measuring A280 using the extinction coefficient of 16,516 M−1 cm−1. Typical yields for pure KDPG aldolase are about 120–150 mg liter−1. The specific activity of the protein is typically 300–600 U mg−1 (one unit of enzyme catalyzes the conversion of 1 mol of KDPG37 to pyruvate and glyceraldehyde-3-phosphate per minute at pH 7.0). If desired, the enzyme can be assayed in the retroaldol direction using a coupled lactate dehydrogenase assay29. In this assay, the disappearance of pyruvate is monitored by a decrease in absorbance at 340 nm as NADH is converted into NAD+. Typical kinetic parameters for conversion of KDPG by KDPG aldolase are Km of 0.1 mM, kcat of 80 s−1 and kcat/Km of 800 mM−1 s−1.

Synthesis of (S)-4-hydroxy-2-keto-4-(2′-pyridyl)butyrate

-

14

Dissolve 4 ml (36 mmol) of freshly distilled 2-pyridinecarboxaldehyde in 150 ml of 20 mM HEPES, pH 7.5.

Caution

2-pyridinecarboxaldehyde can cause irritation to skin, eye and/or throat.

-

15

Filter the solution through a 0.22 μm filter using a Corning filter system and set this solution aside.

-

16

Dissolve sodium pyruvate (3.8 g, 34 mmol) in 30 ml of 20 mM HEPES, pH 7.5, in a 50 ml centrifuge tube.

Caution

Sodium pyruvate can cause skin irritation.

-

17

Filter this solution through a 0.22 μm filter into a Corning 50 ml tube top filter.

-

18

Add 5 ml of the sodium pyruvate solution to the 2-pyridinecarboxaldehyde solution and set the rest of the sodium pyruvate solution aside.

-

19

Add 2–5 mg of KDPG aldolase to the Corning 250 ml reaction vessel and incubate the reaction mixture for 30 min at room temperature.

-

20

Add an additional 5 ml of sodium pyruvate solution to the reaction vessel and incubate for an additional 30 min.

-

21

Repeat Step 20 four more times until the pyruvate solution has been added.

-

22

Incubate the reaction for a further 24 h. During this incubation, the reaction mixture will develop a faint yellowish color.

Pause point

The reaction proceeds at room temperature overnight.

-

23

Transfer the reaction to a 600 ml lyophilizer bottle and freeze the material to liquid nitrogen temperature. Once frozen, lyophilize the reaction mixture.

Pause point

Lyophilization typically proceeds overnight.

-

24

Transfer the crude material to a 1 liter Erlenmeyer flask and add 250 ml of absolute ethanol to the crude reaction mixture. Stir the mixture at room temperature for 30 min.

-

25

Filter the insoluble precipitate through a Buchner funnel and into a 500 ml Erlenmeyer flask.

Critical Step

The insoluble materials are salts; the desired product remains soluble in the ethanol solution.

-

26

Concentrate the ethanol solution under reduced pressure using a rotary evaporator.

Critical Step

Heating the solution during concentration results in product decomposition, evidenced by the appearance of a dark brown color.

-

27

Redissolve the crude solid in distilled water (60 ml) containing LiCl (1.5 g, 0.035 mmol).

-

28

Transfer the solution to a 150 ml lyophilizer jar, freeze the sample to liquid nitrogen temperature and lyophilize overnight.

Pause point

The reaction remains on the lyophilizer overnight or until all the water has been removed.

-

29

Dissolve the crude material in 50 ml of absolute ethanol with stirring to break up any aggregates. The material is then placed at −20 °C for 4 h to facilitate precipitation.

-

30

The product as the insoluble lithium salt is then filtered and washed with cold absolute ethanol to recover the desired product.

-

31

The crude material can be further purified by reverse-phase chromatography. Load crude product on a C18 column (roughly 1 g crude mixture to 130 g support) and elute with distilled water at the rate of 70 ml min−1. Collect 10 ml fractions; product is eluted near fractions 15–30. (The C18 column is conditioned with distilled water for 15 min before the sample is loaded onto the column.)

-

32

Product-containing fractions are identified by spotting on C18 reverse-phase TLC plate and developed in 100% distilled water. The TLC plate is observed under a UV lamp at 254 or 365 nm and all UV-active fractions are collected.

-

33

Pool product-containing fractions and lyophilize to yield product as a white powder.

Synthesis of 2,2-dithioethyl-4-(2′-pyridyl)-4-butyro-γ-lactone

-

34

Dissolve 400 mg of (S)-4-hydroxy-2-keto-4-(2′-pyridyl)butyrate in 6 ml of ethanethiol and 2 ml of concentrated HCl. Stir the mixture for 24 h at room temperature.

Caution

Ethanethiol has a strong stench and is a skin irritant. Concentrated hydrochloric acid will cause skin burns.

Pause point

Reaction can be left stirring overnight.

-

35

Remove excess ethanethiol by distillation.

-

36

Extract the resulting solid three times with 10 ml of methylene chloride. Combine the organic extracts, wash with water and dry the organic phase over MgSO4. The organic extracts are then concentrated, leaving a yellow oil.

-

37

The product is analyzed by chiral gas chromatography using a chiral Chromopack Chirasil-L-Val column (25 × 0.25 m) at a temperature of 160 °C and a pressure of 15 psi to determine the enantioselectivity. A racemic product was synthesized as a calibration standard (Box 1).

Troubleshooting

Troubleshooting advice can be found in Table 1.

Timing

Protein expression

-

Step 1: 2 h

-

Step 2: 16 h

-

Step 3: 16 h

-

Steps 4–6: 8 h

-

Step 7–9: 1 h

-

Steps 10 and 11: 5 h

-

Step 12: 24 h

-

Step 13: 20 min

(S)-4-hydroxy-2-keto-4-(2′-pyridyl)butyrate synthesis

-

Steps 14–21: 8 h

-

Step 22: 24 h

-

Step 23: 24 h

-

Steps 24–27: 4 h

-

Step 28: 24 h

-

Steps 29 and 30: 5 h

-

Steps 31 and 32: 3 h

-

Step 33: 24 h

2,2-dithioethyl-4-(2′-pyridyl)-4-butyro-γ-lactone synthesis

-

Step 34: 24 h

-

Steps 35 and 36: 2 h

-

Step 37: 2 h

Anticipated results

Typical yields

Typical protein expression yields of KDPG aldolase should be between 180 and 200 mg per liter of growth. Typical isolated yield of (S)-4-hydroxy-2-keto-4-(2′-pyridyl)butyrate is 80–90% after reverse-phase C18 purification.

Analytical data

(S )-4-hydroxy-2-keto-4-(2′-pyridyl)butyrate

1H NMR (400 MHz, D2O) δ 2.93 (dd, 1H, J = 5.5, 15.6 Hz), 3.14 (dd, 1H, J = 8.0, 15.0 Hz), 5.21 (dd, 1H, J = 6.0, 8.0 Hz), 7.41 (t, 1H, J = 6.5 Hz), 7.56 (d, 1H, J = 8.0 Hz), 7.93 (t, 1H, J = 7.7), 8.40 (d, 1H, J = 5.5 Hz). 13NMR (400 MHz, D2O) δ 41.8, 63.5, 120.0, 123.1, 138.0, 140.9, 155.1, 167.3, 168.0 ppm. IR (KBr) ν 1,725, 1,715, 1,640 cm−1.

2,2-dithioethyl-4-(2′-pyridyl)-4-butyro-γ-lactone

1H NMR (300 MHz, CDCl3) δ 1.21 (q, 6H, J =7.7 Hz), 2.56–2.94 (m, 6H), 5.64 (dd, 1H, J = 6.3, 9.3 Hz), 7.21 (dd, 1H, J = 4.1, 7.0 Hz), 7.50 (d, 1H, J = 8.0 Hz), 7.76 (dt, 1H, J = 1.9, 7.8 Hz), 8.59 (d, 1H, J 4.9 Hz). 13C NMR (300 Hz, CDCl3) δ 13.8, 13.9, 24.3, 24.8, 46.0, 58.3, 78.1, 120.6, 123.5, 137.5, 148.8, 155.9, 168.3 ppm.

References

Gijsen, H.J.M. & Wong, C.H. Sequential 3-substrate and 4-substrate aldol reactions catalyzed by aldolases. J. Am. Chem. Soc. 117, 7585–7591 (1995).

Broadrup, R.L., Sundar, H.M. & Swindell, C.S. Total synthesis of 12,13-desoxyepothilone B (epothilone D). Bioorg. Chem. 33, 116–133 (2005).

O'Sullivan, P.T. A concise synthesis of the octalactins. J. Am. Chem. Soc. 126, 2194–2207 (2004).

Patel, R.N. Biocatalysis: synthesis of chiral intermediates for drugs. Curr. Opin. Drug Discov. Dev. 9, 741–764 (2006).

Patel, R.N. Microbial/enzymatic synthesis of chiral intermediates for pharmaceuticals. Enzyme Microb. Tech. 31, 804–826 (2002).

Patel, R.N. Enzymatic preparation of chiral pharmaceutical intermediates by lipases. J. Lipos. Res. 11, 355–393 (2001).

Patel, R.N. Biocatalytic synthesis of intermediates for the synthesis of chiral drug substances. Curr. Opin. Biotechnol. 12, 587–604 (2001).

Patel, R.N. Enzymatic synthesis of chiral intermediates for drug development. Adv. Synth. Catal. 343, 527–546 (2001).

Henderson, D.P. & Toone, E.J. in Comprehensive Natural Product Chemistry Vol. 3 (ed. Pinto, B.M.) 367–440 (Elsevier Science, Amsterdam, 1999).

Modern Aldol Reactions, Vol. 1. Enolates, Organocatalysis, Biocatalysis, and Natural Product Synthesis (Mahrwald, R., Ed.; Wiley-VCH Verg GmbH & Co. KGaA, Weinheim, Germany, 2004).

Lees, W.J. & Whitesides, G.M. Diastereoselectivity (enantioselectivity) of aldol condensations catalyzed by rabbit muscle aldolase at C-2 of Rchohcho if R has an appropriately placed negatively charged group. J. Org. Chem. 58, 1887–1894 (1993).

Schmid, W. & Whitesides, G.M. A new approach to cyclitols based on rabbit muscle aldolase (Rama). J. Am. Chem. Soc. 112, 9670–9671 (1990).

Borysenko, C.W., Spaltenstein, A., Straub, J.A. & Whitesides, G.M. Synthesis of aldose sugars from half-protected dialdehydes using rabbit muscle aldolase. J. Am. Chem. Soc. 111, 9275–9276 (1989).

Wong, C.H. & Whitesides, G.M. Synthesis of sugars by aldolase-catalyzed condensation-reactions. J. Org. Chem. 48, 3199–3205 (1983).

Straub, A., Effenberger, F. & Fischer, P. Enzyme-catalyzed reactions. 4. Aldolase-catalyzed C–C bond formation for stereoselective synthesis of nitrogen-containing carbohydrates. J. Org. Chem. 55, 3926–3932 (1990).

Ziegler, T., Straub, A. & Effenberger, F. Enzyme-catalyzed reactions. 3. Enzyme-catalyzed synthesis of 1-deoxymannojirimycin, 1-deoxynojirimycin, and 1,4-dideoxy-1,4-imino-D-arabinitol. Angew. Chem. Int. Ed. 27, 716–717 (1988).

Effenberger, F. & Straub, A. A novel convenient preparation of dihydroxyacetone phosphate and its use in enzymatic aldol reactions. Tetrahedron Lett. 28, 1641–1644 (1987).

Alajarin, R., Garciajunceda, E. & Wong, C.H. A short enzymatic-synthesis of L-glucose from dihydroxyacetone phosphate and L-glyceraldehyde. J. Org. Chem. 60, 4294–4295 (1995).

Liu, K.K.C. Use of dihydroxyacetone phosphate dependent aldolases in the synthesis of deoxyazasugars. J. Org. Chem. 56, 6280–6289 (1991).

Pederson, R.L. & Wong, C.H. Enzymatic aldol condensation as a route to heterocycles—synthesis of 1,4-dideoxy-1,4-imino-D-arabinitol, fagomine, 1-deoxynojirimycin and 1-deoxymannojirimycin. Heterocycles 28, 477–480 (1989).

Pederson, R.L., Kim, M.J. & Wong, C.H. A combined chemical and enzymatic procedure for the synthesis of 1-deoxynojirimycin and 1-deoxymannojirimycin. Tetrahedron Lett. 29, 4645–4648 (1988).

Zannetti, M.T., Walter, C., Knorst, M. & Fessner, W.D. Fructose 1,6-bisphosphate aldolase from Staphylococcus carnosus: overexpression, structure prediction, stereoselectivity, and application in the synthesis of bicyclic sugars. Chem. Eur. J. 5, 1882–1890 (1999).

Eyrisch, O. & Fessner, W.D. Disaccharide mimetics by enzymatic tandem aldol additions. Angew. Chem. Int. Ed. 34, 1639–1641 (1995).

Fessner, W.D. & Walter, C. Enzymatic C–C Bond Formation in Asymmetric Synthesis 97–194, 33rd edn., Vol. 184 (Springer-Verlag, Berlin, 1997).

Takayama, S., McGarvey, G.J. & Wong, C.H. Microbial aldolases and transketolases: new biocatalytic approaches to simple and complex sugars. Annu. Rev. Microbiol. 51, 285–310 (1997).

Wymer, N. & Toone, E.J. Enzyme-catalyzed synthesis of carbohydrates. Curr. Opin. Chem. Biol. 4, 110–119 (2000).

Fessner, W.D. & Helaine, V. Biocatalytic synthesis of hydroxylated natural products using aldolases and related enzymes. Curr. Opin. Biotechnol. 12, 574–586 (2001).

Kajimoto, T. Enzyme-catalyzed aldol condensation for asymmetric-synthesis of azasugars—synthesis, evaluation, and modeling of glycosidase inhibitors. J. Am. Chem. Soc. 113, 6187–6196 (1991).

Griffiths, J.S. Cloning, isolation and characterization of the Thermotoga maritima KDPG aldolase. Bioorg. Med. Chem. 10, 545–550 (2002).

Meloche, H.P. & O'Connell, E.L. 2-Keto-3-deoxy-galactonate-6-phosphate aldolase from Pseudomonas-saccharophila. Methods Enzymol. 90, 263–269 (1982).

Allen, S.T., Heintzelman, G.R. & Toone, E.J. Pyruvate aldolases as reagents for stereospecific aldol condensation. J. Org. Chem. 57, 426–427 (1992).

Cotterill, I.C., Henderson, D.P., Shelton, M.C. & Toone, E.J. The synthetic utility of KDPGal aldolase. J. Mol. Catal. B-Enzym. 5, 103–111 (1998).

Henderson, D.P., Shelton, M.C., Cotterill, I.C. & Toone, E.J. Stereospecific preparation of the N-terminal amino acid moiety of nikkomycins K–X and K–Z via a multiple enzyme synthesis. J. Org. Chem. 62, 7910–7911 (1997).

Henderson, D.P. et al. The synthetic utility of pyruvate aldolases: preparation of nikkomycin amino acids. Abst. Pap. Am. Chem. Soc. 216, U226–U226 (1998).

Sambrook, J. & Russell, D.W. Molecular Cloning: A Laboratory Manual, 3rd edn. (Cold Spring Laboratory Press, Cold Spring Harbor, NY, 2001).

Fullerton, S.W.B. et al. Mechanism of the class I KDPG aldolase. Bioorgan. Med. Chem. 14, 3002–3010 (2006).

O'Connell, E.L. & Meloche, H.P. Enzymic-synthesis of 2-keto-3-deoxygluconate 6-phosphate using 6-phosphogluconate dehydratase. Methods Enzymol. 89, 98–101 (1982).

Cornforth, J.W., Firth, M.E. & Gottshack, A. The synthesis of N-acetylneuraminic acid. Biochem. J. 68, 57–61 (1958).

Acknowledgements

This work was supported by the National Institutes of Health.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

About this article

Cite this article

Walters, M., Toone, E. Pyruvate aldolases in chiral carbon–carbon bond formation. Nat Protoc 2, 1825–1830 (2007). https://doi.org/10.1038/nprot.2007.260

Published:

Issue Date:

DOI: https://doi.org/10.1038/nprot.2007.260

This article is cited by

-

Extended substrate range of thiamine diphosphate-dependent MenD enzyme by coupling of two C–C-bonding reactions

Applied Microbiology and Biotechnology (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.