Abstract

A protocol for preparative isopenicillin N (IPN) purification, a highly interesting and hitherto unavailable intermediate of the penicillin and cephalosporin biosynthetic pathway due to its high unstability, is described. Culture broths of Acremonium chrysogenum TD189, a strain blocked in cephalosporin biosynthesis that accumulates this metabolite, were treated with acetone and filtered though charcoal and a hydrophobic resin in a single step as tandem columns. The cleared broth was then lyophilized and passed though a Sephadex G-25 column. The last step was the purification to homogeneity of IPN in a semipreparative HPLC equipment and, optionally, a desalting step by Sephadex G-10 column. Once purified, a complete analysis of the stability of the compound and the conditions for its long-term storage was carried out. Our results suggest a first-order model for IPN decomposition for all the pH and temperature analyzed. IPN is more stable at neutral pH, and once lyophilized, can be stored under vacuum and −75 °C with a half-life of 770 days.

Similar content being viewed by others

Introduction

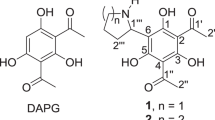

The β-lactam antibiotics, particularly penicillin and cephalosporin, represent over 40% of the total world market for antibiotics.1 The production of these compounds is mainly based on industrial fermentation, utilizing the filamentous fungi Penicillium chrysogenum and Acremonium chrysogenum. Although the biochemistry of penicillin and cephalosporin biosynthesis has been broadly studied, some specific steps are not yet clearly understood.2, 3 An important intermediate, common in penicillin and cephalosporin production, is isopenicillin N (IPN). IPN is the first bioactive compound found in β-lactam pathways and has a central role in the biosynthesis of these compounds in P. chrysogenum and A. chrysogenum.

Obtaining IPN by chemical synthesis or by purification from broths has been difficult. Synthetic methods are laborious and produce low yields and low levels of purity.4, 5, 6, 7 As an alternative, attempts have been made to isolate biosynthetically produced IPN. A protocol has been described by Neuss et al.8 for the micropurification of IPN from culture supernatants using a native strain of P. chrysogenum. The method is based on a previous procedure developed by Miller et al.9 for the purification of penicillin N from A. chrysogenum. Although IPN yields were not described by Neuss et al.8 they could be roughly similar to those described by Miller et al.,9 around 1–2 mg of IPN per purification round. These small quantities are just enough for some enzymatic microassays, but not for experiments such as in vivo transport assays or in vitro assays of enzymes using IPN as substrate, which require as much as 5–50 mg of IPN for each experiment.10

Here, we described a method for the preparative purification of IPN from culture filtrates from A. chrysogenum TD189, a strain that produces IPN as the only penicillin. This method yields high quantities of pure IPN. In addition, degradation kinetics and stability studies of IPN at different pH and temperatures were performed. These properties have not been described for this compound before.

Results and discussion

Development of a purification protocol of IPN

We selected a suitable microorganism for the purification of IPN among several genetically engineered fungal strains that accumulate this compound. Fermentations with A. chrysogenum TD189, P. chrysogenum ABC and P. chrysogenum npe6 pyrG− strains were performed and the results obtained showed that A. chrysogenum TD189 produces the highest level of IPN at 96 h (around 650 μg ml−1 of IPN) and was chosen for further IPN purification.

The purification protocol for IPN is summarized in Figure 2. Initially, we observed that our culture broths could not be lyophilized, because this procedure gives a treacle-like concentrate product of high concentration of sugars in the broth. To overcome this problem, we treated culture broth with acetone to remove excess sugars and eliminate proteins in the same step. We avoided deproteinization of culture broths by acidification, because IPN, similar to other β-lactams, is sensitive to strong pH.11, 12

IPN is adsorbed by active charcoal,13 but we found that this adsorption was so weak that a high volume of charcoal was required to avoid saturation. As charcoal does not produce a selective retention of significant amounts of IPN, we used charcoal to decolorize the broth (originally brown-orange colored), obtaining a clear and slightly yellow eluate. After this step, most hydrophobic compounds were eliminated by connecting an SM2 hydrophobic resin column in tandem to the charcoal column.

A Sephadex G-25 column was used to eliminate most of hydrophilic compounds distinct from IPN, obtaining fractions highly enriched in IPN. Finally, these fractions were injected in a semi-preparative HPLC, using ammonium formate as the mobile phase buffer, and the peak belonging to IPN was collected (Figure 1a), obtaining the compound with purity of over 95% (Figure 1b). The use of ammonium formate as the mobile phase had the advantages: (i) it produces an appropriate separation of IPN from other polar compounds in HPLC; (ii) it avoids the use of toxic compounds as pyridine or the occlusion of channels in HPLC by the use of phosphate/methanol mixes; (iii) ammonium formate is volatile and does not present problems for liquid chromatography–MS, allowing the complete spectroscopic characterization of IPN.

The purified compound was analyzed by NMR (1H and 13C) and MS measurements. The 1H-NMR (500 MHz, D2O) chemical shifts and J are in complete agreement with those previously published for IPN.4, 6, 7 The 13C-NMR (125 MHz, D2O) obtained was: 64.57 (C2), 26.64, 30.44 ((CH3)2-C2), 73.33 (C3), 67.58 (C5), 58.06 (C6), 34.58 (C10), 21.07 (C11), 30.00 (C12), 54.59 (C13), 174.44, 174.55, 174.99 and 175.93 (C=O). ESI–MS: m/z 360.2470 (M+H+), calcd 360.2229 for (C14H22N3O6S). To our knowledge, these are the first published data of 13C-NMR and MS for IPN.

IPN obtained after semi-preparative HPLC has sufficient purity for most applications, but ammonium formate salts may need to be eliminated for some specific applications. This desalting step was carried out using a Sephadex G-10 column.

The procedure described in Figure 2 yields 102.94±28.84 mg of pure IPN from 2 l of culture broth (around 10–15% yields in relation to the estimated IPN content in the culture broth), which is better than the expected yield for the previously published purification protocol, around 6–13 mg of pure IPN (around 2–5% yields in relation to the estimated IPN content in the culture broth) from the same volume of culture broth.8, 9 This improvement of IPN yield could be attributed to the purification process itself rather than the different strains used. Neuss et al.8 used a native strain of P. chrysogenum, whose fermentation for 96 h produces about 700 μg ml−1 of IPN in culture broth,14 similar to the amount produced by A. chrysogenum TD189 (around 650 μg ml−1 of IPN). Thus, we concluded that the purification method made the difference.

On the other hand, the strain seems to be important to obtain greater purity. In P. chrysogenum, IPN is the precursor for several natural hydrophilic penicillins, which are difficult to separate from IPN.13 IPN purified from P. chrysogenum would probably contain other hydrophilic penicillins as contaminants, reducing its purity. In contrast, A. chrysogenum TD189 does not produce other penicillins, which would improve the purity of the IPN obtained.

Stability at different pH and temperatures and determination of optimal storage conditions

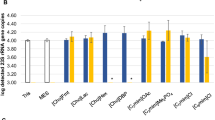

There is no published chemical analysis of IPN determining the temperature and pH conditions most suitable for the stability of this compound. To investigate its decomposition kinetics, IPN solutions were incubated at different pH and temperature and their residual concentrations were plotted at several time intervals (Supplementary information). The linear regression of plots suggests that IPN decomposition follows a first-order irreversible kinetics at all pH levels and temperatures analyzed. Using these linear regressions (Supplementary information), the rate constants of the decomposition (k) were estimated, and subsequently plotted versus pH at different temperatures (Figure 3). Figure 3 shows that IPN is stable at a pH range of 5.0–8.5, being optimal at pH 7.0. In general, the compound is more stable at acidic than basic pH values, and stability improves at lower temperatures.

Plot of log k versus pH at different temperatures for IPN. Temperatures were 37 °C (▪), 25 °C (Δ), 4 °C (□) and 0 °C (▴). The k (h−1) values were calculated from residual concentration of IPN versus time plots (Supplementary material) using the equation of the concentration profile of a first order decomposition reaction: ln (Co/Ct)=−kt, where Co is the initial concentration of IPN and Ct is its concentration after time t.

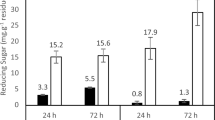

To investigate the long-term storage of IPN at −20 °C and −75 °C, aqueous solutions at different concentrations were used. In addition, samples of pure lyophilized compound at vacuum or room pressure were also used. Figure 4a shows differences in stability when IPN is stored at −20 °C. At this temperature, a more concentrated sample (10 mg ml−1) maintains itself better than a less concentrated one (100 μg ml−1 and 1 mg ml−1). Interestingly, a lyophilized sample at room pressure is less stable than the most concentrated solution, which suggests that an aerobic ambient is not appropriate for IPN storage. Consistently, the lyophilized sample stored under vacuum reaches it maximum stability. All samples were maintained better at −75 °C (Figure 4b) than at −20 °C, making the differences among storage conditions less evident. From the plot of the best kept sample (lyophilized IPN, stored under vacuum at −75 °C; Figure 4b), the k value obtained was used in equation (1) to predict the half-life of IPN under these conditions:

Effect of different long-term storage conditions on IPN stability: Samples of IPN were stored at −20 °C (a) or −75 °C (b) as liquid solutions at 100 μg ml−1 (♦), 1 mg ml−1 (▴) or 10 mg ml−1 (Δ), or lyophilized at room (□) or vacuum (▪). The residual concentration of each sample expressed as ln (Co/Ct) was plotted versus the number of days stored. Note the different scales at the y-axis between both plots. The k (h−1) value can be calculated from the plots as described in Figure 3.

The result predicts that IPN stored under these conditions has a half-life of 770 days (about 2 years and 1 month).

Stability studies of natural β-lactams at different pH, temperature or storage conditions have been done only for benzylpenicillin.11, 12 IPN has a similar behavior to this compound, being stable at neutral pH. However, unlike benzylpenicillin, whose stability decreases at similar levels at acidic or basic pH levels,12 IPN is slightly more stable at acidic rather than basic pH levels. Finally, both compounds are stable at lower temperatures.

Methods

Microorganisms

A. chrysogenum TD189, a disrupted strain lacking isopenicillin epimerase activity,15 and P. chrysogenum strains ABC and npe6 pyrG, both lacking the penDE gene,10, 16, 17 were used. Micrococcus luteus ATCC 9341, an IPN sensitive bacterial strain,18, 19, 20 was used for bioassays in each step of purification. β-lactamase from Bacillus cereus UL1 was used to check the presence of penicillin compound in these assays.21

Materials and reagents

HPLC grade methanol was purchased from Merck (Darmstadt, Germany). Ammonium formate and formic acid (⩾99% purity) were purchased from Sigma-Aldrich Chemical (St Louis, MO, USA). For column chromatography, activated charcoal (Panreac Química, Barcelona, Spain) in a glass Econo-column (2.5 × 30 cm) from BioRad Laboratories (Richmond, CA, USA), hydrophobic resin SM2 (BioRad Laboratories) in a XK-50 column (GE Healthcare, Piscataway, NJ, USA), Sephadex G-25 (GE Healthcare) in a glass Econo-column (5 × 30 cm; BioRad Laboratories), and Sephadex G-10 (GE Healthcare) in a glass Econo-column (1.5 × 170 cm; BioRad Laboratories), were used. All the other chemicals reagents were of analytical grade.

HPLC instrumentation and procedures

The HPLC analytical system consisted of a Waters 2487 dual absorbance detector and a Waters 1525 binary HPLC pump equipped with a rheodyne injector and a 20 μl sample-loop. The analytical column employed was a LiChrospher 100 RP-C18, 5 μm, 250 × 4 mm, protected by a guard column, purchased from Merck. The HPLC analysis was carried out using 20 mM ammonium formate buffer (pH 3.5) as solvent A and methanol as solvent B, with an isocratic method (5% B) for 20 min. The flow used was 1 ml min−1. The detection was performed at 214 and 260 nm.

The semipreparative HPLC system consisted of a Waters 486 tunable absorbance detector and a Waters 600 pump equipped with a rheodyne injector and a 1 ml sample-loop. The column employed was a LiChrospher 100 RP-C18, 10 μm, 250 × 10 mm (Merck). The HPLC method was carried out using ammonium formate 20 mM (pH 5.5) as mobile phase, in the isocratic mode at 6.5 ml min−1 for 20 min. The detection was performed at 214 nm.

Culture conditions of fungal strains

A. chrysogenum TD189 was grown in LPE agar plates.22 Spores and mycelium fragments collected from six plates were suspended in 100 ml of seed medium,23 and agitated in an orbital shaker at 250 rpm and 25 °C for 48 h. Seed culture of 40 ml was used to inoculate 400 ml of MDFA23 medium. The cultures were incubated at 25 °C and 250 rpm for 96 h. All strains of P. chrysogenum were fermented as described.10

Treatment of culture broth and chromatographic pre-purification

Mycelia were discarded by centrifugation (8.000 rpm for 30 min) and filtration, thus obtaining 2 l of the culture supernatant. One volume of acetone was added to precipitate proteins and sugars. The mixture was stirred at 4 °C for 4 h, centrifuged and filtered. Acetone was eliminated by concentration under reduced pressure and the broth obtained was cooled at 4 °C and passed though a system of two columns connected in tandem: the first column (2.5 × 30 cm) contained active charcoal; the second one (5 × 15 cm) contained the hydrophobic resin SM2. The columns were washed with 2 l of Milli-Q water. The total eluted was lyophilized, obtaining 19.3±3.3 g l−1 of a crude yellow solid material.

Milli-Q water of 5 ml was added to 6 g of the lyophilized residue, mixed vigorously and centrifuged. The precipitate (mainly salts) was discarded. The supernatant was applied to a column (5 × 30 cm) of Sephadex G-25 (medium) in 70:30 2-propanol:water mixture according to Usher et al.5 Elution was carried out at 4 °C with the same mixture and a flow rate of 0.8 ml min−1. After substances absorbing at 260 nm were eluted and discarded, the eluate was pooled into 100 ml fractions that were concentrated to 10 ml. The fractions containing the greatest amount of IPN, according to the bioassays, were diluted twice, filtered though 0.45 μm filters (Millipore, Bedford, MA, USA) and purified by semi-preparative HPLC.

Purification to homogeneity of IPN by semi-preparative HPLC and further desalting

IPN was purified from a peak with a retention time of 6.5 min at 214 nm (Figure 1a). Collected peaks were pooled and lyophilized, obtaining IPN as a white solid (25.0±2.09 mg/G-25 column, 95% purity estimated by HPLC, Figure 1b). After this stage, IPN was pure but contained formate salts. IPN was desalted in a Sephadex G-10 column. Amounts of 23–30 mg of product were put in the column and elution was performed with distilled water at 4 °C. The eluate was pooled into 10 ml fractions. Samples of these fractions were analyzed by bioassay and the fractions with bioactivity were pooled and lyophilized. The yield of pure IPN (99% purity) was 14.6±3.5 mg per G-10 column.

Stability assays of IPN

Decomposition studies of IPN at different pH and temperatures

Desalted and lyophilized IPN was resuspended in Milli-Q water at 10 mg ml−1. Accurate volumes from this solution were diluted to 100 μg ml−1 at suitable pH using the following buffer solutions: 25 mM KCl-HCl (pH 2.5), 25 mM sodium acetate (pH 4), 25 mM sodium citrate (pH 5), 25 mM potassium phosphate (pH 7 and 8.5) and 25 mM glycine-NaOH (pH 10). The buffered IPN solutions were incubated at 0, 4, 25 and 37 °C. Aliquots were drawn at different time intervals and analyzed by HPLC (Supplementary information). Each experiment was done in triplicate.

Stability of IPN under different storage conditions

Samples of desalted and lyophilized IPN were stored at room or vacuum pressure, at −20 °C and −75 °C. In addition, aqueous solutions of IPN at different concentrations were kept at the same temperatures. All these stored samples were analyzed by HPLC in triplicate for each storage condition in five periods: 1 week, 2 months, 4 months, 9 months and 1 year after storage.

Microbiological assay

The hole-plate diffusion method was used for the antibacterial bioassay. Briefly, 50 μl of samples were placed on Trypticase Soy Agar containing M. luteus ATCC 9341. The agar plates were then incubated for 15–18 h at 30 °C until growth-inhibition zones were visible.

References

Kresse, H., Belsey, M. J. & Rovini, H. The antibacterial drugs market. Nat. Rev. Drug Discov. 6, 19–20 (2007).

Teijeira, F. et al. The transporter CefM involved in translocation of biosynthetic intermediates is essential for cephalosporin production. Biochem. J. 418, 113–124 (2009).

Jami, M. S., Barreiro, C., García-Estrada, C. & Martín, J. F. Proteome analysis of the penicillin producer Penicillium chrysogenum: characterization of protein changes during the industrial strain improvement. Mol. Cell Proteomics. 9, 1182–1198 (2010).

Vanderhaeghe, H., Vlietinck, A., Claesen, M. & Parmentier, G. Preparation of penicillin N and isopenicillin N. J. Antibiot. 27, 169–177 (1974).

Usher, J. J., Loder, B. & Abraham, E. P. Synthesis of tritium-labelled isopenicillin N, penicillin N and 6-aminopenicillanic acid. Biochem. J. 151, 729–739 (1975).

Huffman, G. H. Improved preparation of penicillin N and isopenicillin N. Org. Prep. Proced. Int. 20, 497–503 (1988).

Madeira-Lau, R. et al. Synthesis of penicillin N and isopenicillin N. Tetrahedron. 56, 7601–7606 (2000).

Neuss, N. et al. High performance liquid chromatography (HPLC) of natural products V. The use of HPLC in the cell-free biosynthetic conversion of alpha-aminoadipyl-cysteinyl-valine (LLD) into isopenicillin N. J. Antibiot. 35, 580–584 (1982).

Miller, R. D. et al. High performance liquid chromatography (HPLC) of natural products. IV. The use of HPLC in biosynthetic studies of cephalosporin C in the cell-free system. J. Antibiot. 34, 984–993 (1981).

García-Estrada, C., Vaca, I., Lamas-Maceiras, M. & Martín, J. F. In vivo transport of the intermediates of the penicillin biosynthetic pathway in tailored strains of Penicillium chrysogenum. Appl. Microbiol. Biotechnol. 76, 169–182 (2007).

Kheirolomoom, A., Kazemi-Vaysari, A., Ardjmand, M. & Baradar-Khoshfetrat, A. The combined effects of pH and temperature on penicillin G decomposition and its stability modeling. Process Biochem. 35, 205–211 (1999).

Lu, X., Xing, H., Su, B. & Ren, Q. Effect of buffer solution and temperature on the stability of penicillin G. J. Chem. Eng. Data. 53, 543–547 (2008).

Mukherjee, B. B. & Lee, B. K. in Antibiotics, isolation, separation and purification (eds Weinstein, M.J., Wagman, G.H.) Journal of Chromatography Library 387–414. Vol. 15. (Elsevier Scientific Publishing Company, Amsterdam, 1978).

Ullán, R. V. et al. RNA-silencing in Penicillium chrysogenum and Acremonium chrysogenum: validation studies using β-lactam genes expression. J. Microbiol. Meth. 75, 209–218 (2008).

Ullán, R. V. et al. A novel epimerization system in fungal secondary metabolism involved in the conversion of isopenicillin N into penicillin N in Acremonium chrysogenum. J. Biol. Chem. 277, 46216–46225 (2002).

Cantoral, J. M. et al. Biochemical characterization and molecular genetics of nine mutants of Penicillium chrysogenum impaired in penicillin biosynthesis. J. Biol. Chem. 268, 737–744 (1993).

Fernández, F. J. et al. Molecular characterization of three loss-of-function mutations in the isopenicillin N-acyltransferase gene (penDE) of Penicillium chrysogenum. J. Bacteriol. 176, 4941–4948 (1994).

Jensen, S. E., Westlake, D. W. & Wolfe, S. Cyclization of delta-(L-alpha-aminoadipyl)-L-cysteinyl-D-valine to penicillins by cell-free extracts of Streptomyces clavuligerus. J. Antibiot. 35, 483–490 (1982).

López-Nieto, M. J., Ramos, F. R., Luengo, J. M. & Martín, J. F. Characterization of the biosynthesis in vivo of alpha-aminoadipyl-cysteinyl-valine in Penicillium chrysogenum. Appl. Microbiol. Biotechnol. 22, 343–351 (1985).

Luengo, J. M. et al. Direct enzymatic synthesis of penicillin G using cyclases of P. chrysogenum and A. chrysogenum. Bio/Technol. 4, 44–47 (1986).

Zanca, D. N. & Martn, J. F. Carbon catabolite regulation of the conversion of penicillin N into cephalosporin C. J. Antibiot. 36, 700–708 (1983).

Le Page, G. A. & Campbell, E. Preparation of streptomycin. J. Biol. Chem. 162, 163–171 (1946).

Shen, Y. Q., Heim, J., Solomon, N. A., Wolfe, S. & Demain, A. L. Repression of β-lactam production in Cephalosporium acremonium by nitrogen sources. J. Antibiot. 37, 503–511 (1984).

Acknowledgements

This work was supported by a grant from the European Union (Eurofungbase, LSSGCT2005018964) to JFM. I Vaca thanks for a fellowship of the Diputación de León (Spain) and the support of PBCT program of CONICYT (Chile), project PDA13. R Chávez thanks to DICYT-USACH for support. We thank C García-Estrada for scientific support and B Martín and J Merino for excellent technical assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supplementary Information accompanies the paper on The Journal of Antibiotics website

Supplementary information

Rights and permissions

About this article

Cite this article

Vaca, I., Casqueiro, J., Ullán, R. et al. A preparative method for the purification of isopenicillin N from genetically blocked Acremonium chrysogenum strain TD189: studies on the degradation kinetics and storage conditions. J Antibiot 64, 447–451 (2011). https://doi.org/10.1038/ja.2011.30

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/ja.2011.30

Keywords

This article is cited by

-

Precursor-directed combinatorial biosynthesis of cephalosporin analogue by endolithic actinobacterium Streptomyces sp. AL51 by utilizing thiophene derivative

3 Biotech (2018)

-

Structure elucidation and in silico docking studies of a novel furopyrimidine antibiotics synthesized by endolithic bacterium Actinomadura sp. AL2

World Journal of Microbiology and Biotechnology (2017)