Growing up in Ghana, I wanted to be a doctor just like my father. In the early 1980s, there was a big problem from a disease called river blindness, caused by a parasitic worm and transmitted by blackfly (Simulium spp.) bites. As a regional medical officer for what was then the Upper Region of Ghana, my father worked with the World Health Organization to distribute a drug called ivermectin, which is derived from naturally occurring substances called avermectins, to people in Ghana for free.

Once I heard about this natural-product derivative — which could cure hundreds of thousands of people, many more than any individual doctor could — I was sold. I thought that becoming a chemist and developing medicines derived from natural products was a way to make an impact.

Humans have co-opted many other natural substances to use as medicines. Penicillin and paclitaxel are two good examples. Often, we can get only small amounts of these products from nature — no more than ten grams of paclitaxel can be extracted from a kilogram of bark from the slow-growing Pacific yew (Taxus brevifolia) — so chemists have worked out ways to make it using starting materials produced from petrochemicals.

In my laboratory at the University of California, Berkeley, my team and I are interested in finding more efficient ways to make medicines that originally came from nature. We’re also trying to find greener ways to make them, such as by using agricultural by-products as starting materials.

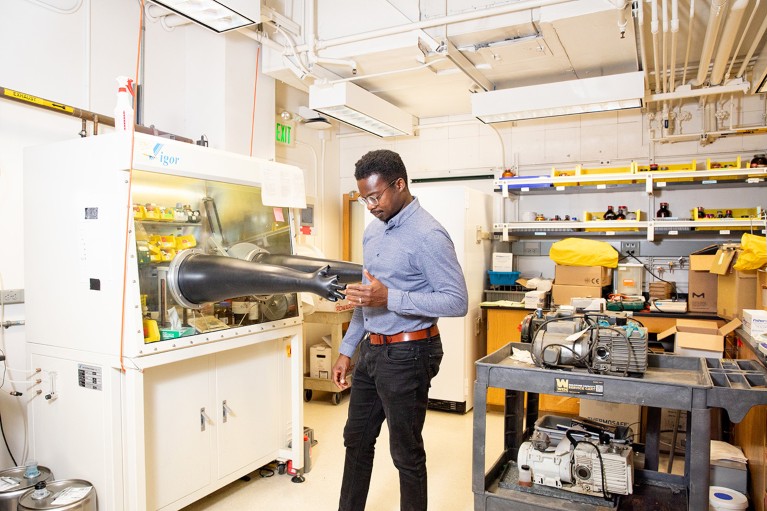

Some of the catalysts that we use are not stable in oxygen or water, so we keep them in a nitrogen glove box. We use them by pushing our hands into the gloves.

The glove box looks like it is ready to give you a hug. In this photograph, I was reaching out to shake its hand for serving our lab, of around 30 people, so admirably.

I love the glove box, but not everyone has access to one. We want to adapt our reactions to work in open air, so that anyone can carry them out.

‘Almost magical’: chemists can now move single atoms in and out of a molecule’s core

‘Almost magical’: chemists can now move single atoms in and out of a molecule’s core

I sample Antarctica’s seaweed to improve human health

I sample Antarctica’s seaweed to improve human health

A Jamaican medicinal-plant scientist explores his African roots

A Jamaican medicinal-plant scientist explores his African roots