Abstract

Single-mode ytterbium-doped phosphate all-solid photonic crystal fiber (AS-PCF) with 13.8 W output power and 32% slope efficiency was reported. By altering the diameter of the rods around the doped core and thus breaking the symmetry of the fiber, a polarization-maintaining AS-PCF with degree of polarization of >85% was also achieved, for the first time to knowledge, in a phosphate PCF.

Similar content being viewed by others

Rare-earth (RE) doped double-clad fibers have been investigated for many years1,2; one of the primary objectives is to enlarge their core diameter and shorten the length, which is especially important in single-frequency fiber laser3 and pulsed laser4,5,6. Many solutions have been suggested to break the limitation of the core diameter in a traditional silica step-index fiber, including chirally-coupled-core (CCC) fibers7, leaky channel fibers8, gain-guiding fibers9, photonic bandgap fiber10, multi-trench fiber11, distributed modal filtering rod fiber12, large pitch fiber13, photonic crystal fibers (PCF)14,15,16,17 and so forth. To date, a single-mode large mode area (LMA) PCF with a core diameter up to 100 µm14, a large pitch fiber (LPF), modified version of PCF, with core diameter of ~135 µm13 and a LPF with 100 W output power and a short length of 40 cm were demonstrated18. However, typical LMA-PCFs are made of silica and the photonic crystal cladding (PCC) contains hollows19,20,21,22 that limit the further improvement of PCF performance. On one hand, although PCF with heavily doped core contributes to increase the pump absorption efficiency and thus shorten the fiber, the rare-earth-solubility (RES) in silica is at a low level23,24,25,26,27. In addition, although using the Ge-doped background glass contributes to enhance the refractivity of the background and thereby increase the doping level in silica glass18, the enhanced RE increases the difficulty in handling the refractive indices of the core, which leads to index-mismatching between the core and the background glass, restricting the core diameter scalability of the PCF18. By contrast, the RES of a phosphate glass is almost ten times higher than silica28,29,30,31 and adjusting the indices of the glasses is remarkably convenient32,33,34,35,36,37. The high doping level contributes to remarkably increase the pump absorption of the fiber with length of several millimeters30,38, which is of importance in high power single frequency fiber with low noise and narrow laser linewidth and ultrafast fiber laser and amplifier with high stability, high repetition rate, low timing jitter and low nonlinear effects39,40,41,42. On the other hand, the hollows in the PCC in a traditional silica and phosphate PCF14,30,43 complicate the splice process of the PCF with the commercially pigtailed optical devices such as the fiber-coupled pump source, thereby weakening the application potential of this kind of fiber in industry7. Fortunately, the all-solid (AS)44 PCF was suggested to solve this issue and make the splice process convenient, as in step-index fiber. Consequently, a high absorption, short length and rigid LMA-PCF can be expected by adopting the soft glass and the AS structure. After the suggestion of the first Nd3+-doped phosphate multimode AS-PCF44, the Nd3+-doped silicate AS-PCF45 and Nd3+-doped phosphate single mode AS-PCF with core diameter up to 40 µm46 were obtained.

In this paper, we demonstrate an Yb3+-doped phosphate single mode all-solid photonic crystal fiber with output power of 13.8 W and core diameter of 17 µm. By breaking the symmetry of the fiber, a polarization-maintaining PCF with polarization extinction ratio of 11 dB was obtained for the first time in a phosphate PCF.

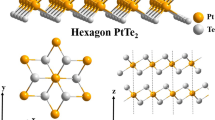

Figure 1 (a) shows the end-face of the fiber. The fiber is composed of three kinds of phosphate glasses. The 1-cell core is composed of Yb3+- doped phosphate glass (G0) with active dopant level of 6 wt.%. The inner cladding consists of glasses G1 (light grey area) and G2 (dark grey dots). The outer cladding was formed by G2. The compositions of G0, G1 and G2 are P2O5-Al2O3-K2O-BaO-Nb2O5-Sb2O3-La2O3-Yb2O3, P2O5-Al2O3-K2O-BaO-Nb2O5-Sb2O3-La2O3-Y2O3 and P2O5-Al2O3-Na2O-MgO-B2O3-La2O3-Y2O3, respectively. The refractive indices of G0, G1 and G2 are 1.5385, 1.5378 and 1.5143 at 1053 nm, respectively, measured by V prism method with accuracy of 5 × 10−5. The considerably large glass-forming region ensures a larger refractive index difference in the glasses, compared with silica, without the addition of any other dopants, such as germanium and fluorine37,38. The glasses were all provided by the Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences. Stack-and-draw method was used to prepare the fiber preform44. A G0 rod with diameter of 20 mm, a G1 tube with inner diameter of 12 mm and outer diameter of 20 mm and two G2 rods with 12 mm and 20 mm in diameter, respectively, are fabricated. All of the rods and tube are made of the bulk glasses and have length of ~20 cm. Then, after appropriate acid treatment, the G1 tube and the G2 rod with 12 mm diameter are drawn into rods with 1 mm in diameter by the rod-in-tube method. The G0 rod and the G2 rod with 20 mm-diameter are also drawn into 1 mm rods. After this, the rods were closed packed in a die and then the acquired fiber perform was fed into the fiber fabrication tower and drawn into fibers with desired outer diameters. The ratio of the rod diameter, d and the center-to-center distance between two nearest rods, Λ, is 0.6. A relatively large value of d/Λ and thereby a smaller core diameter of 17 µm was chose here because a larger core diameter, resulting from a small d/Λ value, necessitates a lower numerical aperture (NA) which induces a larger bend loss in our present 40-cm fiber. Further increasing the pump absorption, through raising the doping level and so forth, can contribute to shorten the fiber length and thus make the fiber with a larger core diameter immune to bend and other disturbance.

A fiber with 40 cm in length and an outer diameter of ~235 µm was used to build the laser. The NA and the normalized diameter of the inner cladding were 0.27 and ~115 µm, respectively. The doped core of the fiber was 17 µm in diameter, with a calculated effective NA of ~0.06 at around 1 µm. The core diameter is 1.7 times larger than that reported in Ref. 24, 25. Furthermore, the doped part has a loss of 2.3 dB/m at ~1330 nm and a pumping absorption coefficient (PAC) of ~27 dB/m at 970 nm. Both properties were measured using the cutback method. Please note that the PAC and the propagation loss of the fiber here are not optimal, which will weaken fiber performance, including the fiber length, slope efficiency and maximum output power. Nevertheless, by optimizing pump wavelength, using a heavily doped core (>12 wt.%), which can be easily realized for phosphate glass29,47 and improving the fiber fabrication technology to decrease the propagation loss, the performance of our AS-PCF will considerably improve. A fiber-coupled laser diode operating at 970 nm was used as the pumping source. The maximum output power and the diameter of the spot size of the pump source is 80 W and 100 µm, respectively. A collimating lens was utilized to align the pumping beam and a coupling lens with NA of 0.3 served as the laser input couple. Please note that the NA of the coupling lens is larger than that of inner cladding in the fiber, resulting in a relatively low pump coupling efficiency of ~65%. But the coupling efficiency can be easily improved by using a low NA coupling lens or by using a lower-index G3 glass to increase the NA of pump waveguide. The cavity was composed of a butt-coupled dichroic mirror with high reflectivity at around 1 µm and a cleaved fiber end with ~4.5% Fresnel reflectivity.

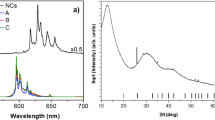

The laser performance is shown in Figure 2 and the spectrum is shown in Figure 3. A maximum output power of ~13.8 W was extracted with the slope efficiency of 32% from the fiber. No rollover was found at the highest output power, implying that the maximum power of the laser is only limited by the maximum available pump power. Please note that both the output power and slope efficiency were lower than the results reported in Ref. 24.To further figure out the performance of our fiber, an AS-PCF without doped core is used to measure the propagation loss of the pump power in the inner cladding to be as large as 10 dB/m, leading to an effective pump absorption of 17 dB/m for the doped core. Such high loss is ascribed to the impurity introduced when preparing the low-index rods in the PCC by rod-in-tube method and the fiber preform and is the main reason reducing the output power as well as the slope efficiency. However, by improving the fabrication technology, such as processing the glass rods and the tube more sophisticatedly, the loss of the inner cladding can be reduced and thus the laser performance can be improved. The laser spectrum has a full width at half maximum (FWHM) of ~3 nm with the central wavelength at 1047 nm. The beam quality factor (M2) of the laser is measured to be 1.07. The M2 factor and the far-field intensity profile of the laser are shown in Figure 4.

By changing the diameter of two rods around the doped core of the non-PM-AS-PCF (Figure 1 (a))48,49 to make the fiber asymmetrical50, the PM-AS-PCF was realized for the first time to knowledge in a phosphate PCF. The ratio of diameter of the larger rod d2 and Λ is 1, as shown in Figure 1 (b). Furthermore, based on Figure 1 (b) the presence of these two larger rods can be observed to make the core elliptical, which is also beneficial for improving the form birefringence51,52. The PM property was characterized through the setup shown in Figure 5. The output power is characterized by a Glan-Taylor Calcite Polarizer using the definition of the degree of polarization DOP = |P1 − P2|/(P1 + P2) where P1 is the maximum and P2 the minimum power obtained by rotation the polarizer. The DOP for this fiber of 40 cm in length was measured at different pump powers, as shown in Figure 6 in which the DOP of the non-PM-AS-PCF was also plotted. According to Figure 6, the PM-AS-PCF has a stable and high DOP (>85%, equivalent to a polarization extinction ratio of >11 dB) in every pump power. By contrast, the DOP of the Non-PM-AS-PCF is low (<20% in general) and unstable, confirming the satisfactory PM property of the PM-AS-PCF.

In conclusion, a phosphate single mode Yb-doped all-solid photonic crystal fiber with 13.8 W output power and core diameter of 17 µm is reported. The polarization-maintaining PCF with degree of polarization of >85% was also, for the first time to knowledge, fabricated and characterized in a phosphate PCF. By developing the PAC and the propagation loss of the fiber, a shortened fiber with higher slope efficiency and output power can be obtained.

References

Jauregui, C., Limpert, J. & Tünnermann, A. High-power fibre lasers. Nat. photonics 7, 861 (2013).

Lucianetti, A. et al. Design of a kJ-class HiLASE laser as a driver for inertial fusion energy. High Power Laser Sci Eng 2, e13 (2014).

Wang, X. et al. 51.5 W monolithic single frequency 1.97 μm Tm-doped fiber amplifier. High Power Laser Sci Eng 1, 123 (2013).

Tan, S. J., Harun, S. W., Arof, H. & Ahmad, H. Switchable Q-switched and mode-locked erbium-doped fiber laser operating in the L-band region. Chin. Opt. Lett 11, 73201 (2013).

Kasim, N. et al. Q-switched ytterbium doped fiber laser using multi-walled carbon nanotubes saturable absorber. Chin. Opt. Lett 12, 31403 (2014).

Su, R. et al. Kilowatt high average power narrow-linewidth nanosecond all-fiber laser. High Power Laser Sci Eng 2, e3 (2014).

Ma, X. et al. Single-mode chirally-coupled-core fibers with larger than 50 µm diameter cores. Opt Express 22, 9206 (2014).

Dasgupta, S., Hayes, J. R. & Richardson, D. J. Leakage channel fibers with microstuctured cladding elements: A unique LMA platform. Opt Express 22, 8574 (2014).

Sudesh, V. et al. Diode-pumped 200 μm diameter core, gain-guided, index-antiguided single mode fiber laser. Applied Physics B 90, 369 (2008).

Gu, G. et al. Ytterbium-doped large-mode-area all-solid photonic bandgap fiber lasers. Opt Express 22, 13962 (2014).

Jain, D., Jung, Y., Kim, J. & Sahu, J. K. Robust single-mode all-solid multi-trench fiber with large effective mode area. Opt Lett 39, 5200 (2014).

Jørgensen, M. M. et al. Optimizing single mode robustness of the distributed modal filtering rod fiber amplifier. Opt Express 20, 7263 (2012).

Limpert, J. et al. Yb-doped large-pitch fibres: effective single-mode operation based on higher-order mode delocalisation. Light-Sci Appl 1, e8 (2012).

Brooks, C. D. & Di Teodoro, F. Multimegawatt peak-power, single-transverse-mode operation of a 100 μm core diameter, Yb-doped rodlike photonic crystal fiber amplifier. Appl Phys Lett 89, 111119 (2006).

Han, L. et al. Dispersion compensation properties of dual-concentric core photonic crystal fibers. Chin. Opt. Lett 12, 10603 (2014).

Qureshi, K. K. Switchable dual-wavelength fiber ring laser featuring twin-core photonic crystal fiber-based filter. Chin. Opt. Lett 12, 20605 (2014).

Liang, W., Liu, N., Li, Z. & Lu, P. Octagonal dual-concentric-core photonic crystal fiber for C-band dispersion compensation with low confinement loss. Chin. Opt. Lett 11, S20604 (2013).

Gaida, C. et al. Triple-clad large-pitch fibers for compact high-power pulsed fiber laser systems. Opt. Lett 39, 209 (2014).

Wang, Y. et al. Hollow-core photonic crystal fibre for high power laser beam delivery. High Power Laser Sci Eng 1, 17 (2013).

Zhao, J. et al. Large mode area and nearly zero flattened dispersion photonic crystal fiber by diminishing the pitch of the innermost air-holes-ring. Chin. Opt. Lett 12, S10607 (2014).

Huang, C. et al. Transmission characteristics of photonic crystal fiber gas cell used in frequency stabilized laser. Chin. Opt. Lett 12, 80602 (2014).

Xu, Q. Simulation on Dispersion and Birefringence Properties of Photonic Crystal Fiber. Chin. Opt. Lett 12, S11302 (2014).

Burshtein, Z. et al. Impurity local phonon nonradiative quenching of Yb3+ fluorescence in ytterbium-doped silicate glasses. IEEE J. Quantum Electron 36, 1000 (2000).

Li, W. et al. Watt-level Yb-doped silica glass fiber laser with a core made by sol-gel method. Chin. Opt. Lett 11, 91601 (2013).

Wang, C. et al. Spectral evolution of NIR luminescence in a Yb3+-doped photonic crystal fiber prepared bynon-chemical vapor deposition. Chin. Opt. Lett 11, 61601 (2013).

Sulaiman, A., Harun, S. W. & Ahmad, H. Ring microfiber coupler erbium-doped fiber laser analysis. Chin. Opt. Lett 12, 21403 (2014).

Yang, X., Chen, Y., Zhao, C. & Zhang, H. Pulse dynamics controlled by saturable absorber in a dispersion-managed normal dispersion Tm-doped mode-locked fiber laser. Chin. Opt. Lett 12, 31405 (2014).

Li, L. et al. Ultracompact cladding-pumped 35-mm-short fiber laser with 4.7-W single-mode output power. Appl Phys Lett 88, 101106 (2006).

Lee, Y. W. et al. High-Power Yb3+-Doped Phosphate Fiber Amplifier. IEEE J Sel Top Quant 15, 93 (2009).

Franczyk, M. et al. Phosphate Yb3+ photonic crystal fiber single-mode laser with enormous high pump absorption. Laser Phys. Lett 11, 085104 (2014).

Stepien, R. et al. Ytterbium-Phosphate Glass for Microstructured Fiber Laser. Materials 7, 4723 (2014).

Li, X. et al. Emission enhancement in Er3+/Pr3+-codoped germanate glasses and their use as a 2.7-µm laser material. Chin. Opt. Lett 11, 121601 (2013).

Huang, F. et al. Energy transfer mechanism in Er3+ doped fluoride glass sensitized by Tm3+ or Ho3+ for 2.7-µm emission. Chin. Opt. Lett 12, 51601 (2014).

Fang, J. et al. Doping transition metal ions as a method for enhancement of ablation rate in femtosecond laser irradiation of silicate glass. Chin. Opt. Lett 12, 121402 (2014).

Wan, R. et al. Influence of alkali metal ions on thermal stability of Bi-activated NIR-emitting alkali-aluminoborosilicate glasses. Chin. Opt. Lett 12, 111601 (2014).

Hu, J. et al. Effect of temperature on refractive index match of laser glass edge cladding. Chin. Opt. Lett 12, 101401 (2014).

Xu, Y. et al. Nanocrystal-enhanced near-IR emission in the bismuth-doped chalcogenide glasses. Chin. Opt. Lett 11, 41601 (2013).

Schulzgen, A. et al. Single-frequency fiber oscillator with watt-level output power using photonic crystal phosphate glass fiber. Opt Express 14, 7087 (2006).

Wang, Q., Geng, J., Luo, T. & Jiang, S. Mode-locked 2 μm laser with highly thulium-doped silicate fiber. Opt Lett 34, 3616 (2009).

Ortaç, B. et al. High-energy soliton pulse generation with a passively mode-locked Er/Yb-doped multifilament-core fiber laser. Applied Physics B 98, 27 (2010).

Thapa, R., Nguyen, D., Zong, J. & Chavez-Pirson, A. All-fiber fundamentally mode-locked 12 GHz laser oscillator based on an Er/Yb-doped phosphate glass fiber. Opt Lett 39, 1418 (2014).

Akbulut, M. et al. High energy, high average and peak power Phosphate-Glass fiber amplifiers for 1micron band. Fiber Lasers XI: Technology, Systems and Applications 8961, 89611X (2014).

Li, L. et al. Short cladding-pumped Er/Yb phosphate fiber laser with 1.5 W output power. Appl Phys Lett 85, 2721 (2004).

Zhang, G. et al. Neodymium-doped phosphate fiber lasers with an all-solid microstructured inner cladding. Opt Lett 37, 2259 (2012).

Wang, L. F. et al. All-Solid Silicate Photonic Crystal Fiber Laser With 13.1 W Output Power and 64.5% Slope Efficiency. J. Lightwave Technol. 32, 1116 (2014).

Wang, L. F. et al. Phosphate single mode large mode area all-solid photonic crystal fiber with multi-watt output power. Appl Phys Lett 104, 131111 (2014).

Lee, Y. W. et al. 20 W single-mode Yb3+-doped phosphate fiber laser. Opt. Lett. 31, 3255 (2006).

Kubota, H. et al. Absolutely Single Polarization Photonic Crystal Fiber. IEEE Photonic Tech L 16, 182 (2004).

Hu, D. J. J. et al. Holey fiber design for single-polarization single-mode guidance. Appl. Opt. 48, 4038 (2009).

Tiu, Z. C., Tan, S. J., Ahmad, H. & Harun, S. W. Dark pulse emission in nonlinear polarization rotation-based multiwavelength mode-locked erbium-doped fiber laser. Chin. Opt. Lett 12, 113202 (2014).

Hansen, T. P. et al. Highly birefringent index-guiding photonic crystal fibers. IEEE Photonic Tech L 24, 588 (2001).

Ulrich, R. & Simon, A. Polarization optics of twisted single-mode fibers. Appl. Opt 18, 2241 (1979).

Acknowledgements

This research was supported by the Chinese National Natural Science Foundation (No. 51272262).

Author information

Authors and Affiliations

Contributions

L.W. wrote the main manuscript text, co-authors D.C., J.Q. and L.H. checked the paper and D.H., S.F. and C.Y. are responsible for the experiment. All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 4.0 International License. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/4.0/

About this article

Cite this article

Wang, L., He, D., Feng, S. et al. Phosphate ytterbium-doped single-mode all-solid photonic crystal fiber with output power of 13.8 W. Sci Rep 5, 8490 (2015). https://doi.org/10.1038/srep08490

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep08490

This article is cited by

-

Yb–Er doped composite fiber with silicate clad and phosphate core prepared by stack-and-draw method

Optical and Quantum Electronics (2017)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.