Abstract

In this paper, we report our experimental study on directly coupling a micro/nano fiber (MNOF) ring with a side-polished fiber(SPF). As a result of the study, the behavior of an add-drop filter was observed. The demonstrated add-drop filter explored the wavelength dependence of light coupling between a MNOF ring and a SPF. The characteristics of the filter and its performance dependence on the MNOF ring diameter were investigated experimentally. The investigation resulted in an empirically obtained ring diameter that showed relatively good filter performance. Since light coupling between a (MNOF) and a conventional single mode fiber has remained a challenge in the photonic integration community, the present study may provide an alternative way to couple light between a MNOF device and a conventional single mode fiber based device or system. The hybridization approach that uses a SPF as a platform to integrate a MNOF device may enable the realization of other all-fiber optical hybrid devices.

Similar content being viewed by others

Introduction

Micro/nano optical fibers (MNOF) are the building blocks of new micro/nano optical fiber systems1. The development of a growing number of micro/nano photonic devices, including Mach-Zender interferometer2, micro-ring resonator3, twisted coupler4, polarizer5, micro-ring laser6, has played an important role in making MNOF transmission systems a potential reality. However, owing to the wide deployment of conventional optical fiber (COF) systems, when a MNOF system needs to be connected to a COF system, light coupling between the two systems becomes an issue. Tapered fiber has traditionally been used as light mode transition element for this coupling. However, since the length of a tapered fiber is generally several centimeters, in order to meet the adiabatic requirement7 to enable relatively high efficiency light coupling, this approach makes the miniaturization of such a coupling device no longer possible. Furthermore, for certain applications, wavelength dependent light coupling is desirable and the tapered-fiber light coupling technique cannot provide the desired function without additional filter between the tapered fiber and the COF system.

Because of their high Q value and tight confinement of light, micro-ring optical resonators have found extensive applications in various areas including quantum nondemolition detection8, optical polarization9 and frequency conversion10,11, biosensors12,13,14, particle transport15,16, all-optical devices17,18,19. Although good performance add-drop filter made from a MNOF-ring has been demonstrated20, its direct coupling with a COF requires that the MNOF-ring be fixed on specific substrate21 and this affects the transmission and coupling characteristics of the MNOF. Moreover, such a filter also faces the light coupling challenge when it needs to be combined with a COF system.

In this paper, we report a hybrid optical fiber add-drop filter based on wavelength dependent light coupling between a MNOF-ring and a side-polished fiber (SPF). The SPF has a side-polished section made from a standard single mode fiber. Therefore, the coupling scheme of the filter has several advantages. Firstly, the side polished section provides an evanescent field penetrating into the environment. Therefore, guided light mode field can interact with the optical medium on the polished area, making it possible to coupling light with a MNOF disposed there. Benefitting from this advantage, various optical fiber devices, including optically reconfigurable surface grating fiber22, optically controllable fiber-optic rotator23 and various optical fiber sensors24,25,26, have already been demonstrated. Secondly, the polished area provides a platform to mount and fix a MNOF with relative ease, thus enabling possible integration of a MNOF-based device with a standard optical fiber. Thirdly, a SPF can also provide a seamless connection with a COF system and in-line light coupling to a MNOF without the need for additional assistant coupling elements. Therefore, the approach reported here can perhaps provide an alternative solution for integrating a MNOF device with a standard optical fiber.

Results

Schematic diagram and experimental setup

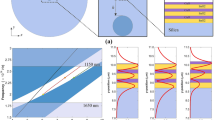

As schematically shown in Fig. 1, the studied add-drop filter has 4-ports and consists of a micro/nano fiber knot ring and a SPF. Since the knot ring is formed from a single micro/nano fiber pulled from and still linked to a conventional fiber through a fiber taper, light can therefore be efficiently coupled into the ring from a conventional fiber with minimum insertion loss (~1 dB). This offers an advantage over other types of resonators formed by positioning the freestanding end of one microfiber next to another3. Fig. 1 (b) shows the schematic diagram of the experimental setup used to characterize the performance of the filter. In our experiments, the Input port and Add port were connected to a tunable laser (ANDO-AQ4321DTSL) operating around a wavelength of 1.55 μm and the Drop port and Through port were connected to an optical spectrum analyzer (OSA). The experimental study comprised three main steps. Firstly, a micro/nano fiber was made from a standard single mode fiber (SMF) using the flame-heated taper-drawing technique. An alcohol burner was used to provide a high enough temperature for fiber stretching. Under a certain pulling force, the fiber was stretched and elongated gradually until a desired diameter of 6 μm was reached. The micro/nano fiber was then tied into a knot ring, with both ends fastened by two fiber holders fixed on two translation stages. Detailed fabrication process can be found in our previous report27. The transmission spectrum of one fabricated micro/nano fiber ring with a ring diameter of ~1 mm was measured and is shown in Fig. 2. The full width at half maximum (FWHM) and free spectrum range (FSR) was respectively 0.04 nm at a resonant wavelength of 1527.4 nm and 0.64 nm, resulting in a high Q value of 39310.

Schematic of an add-drop filter and its experimental setup.

(a) Schematic diagram of an add-drop filter based on light coupling between a micro/nano fiber knot ring and a side polished fiber (bottom). The arrow indicates the direction of light propagation in the ring (b) Schematic diagram of the experimental setup.

Different ring diameters of 780 μm, 680 μm, 580 μm and 480 μm were obtained by controlling the two translation stages. Secondly, a SPF with a total polished length of 20 mm and a residual cladding thickness of 6 μm (the minimum distance between the fiber core and the polished surface) was fabricated from a SMF using the side wheel-polishing technique. Fig. 3(a) and 3(b) respectively show the longitudinal cross-section profile of the SPF in comparison with a SMF. From Fig. 3 (a), it can be seen that the SPF consists of three sections: a polished section and two transitional sections. The variation of the residual cladding thickness is about 0.7 μm/mm within the polished section. The SPF with its polished surface facing upward was placed horizontally on a XYZθZ four-dimensional translation/rotation stage and was held by two fiber holders. The SPF was arranged next to the micro/nano-fiber knot ring to form a coupling region and to act as a supporting substrate. It was noticed that the micro/nano fiber ring and the SPF strongly attracted each other because of Van Der Waals force and electrostatic force. Fig. 3 (c) shows the add-drop filter thus formed and Fig. 3 (d) shows the coupling region between the micro/nano fiber ring and the SPF. The diameter of the shown micro/nano fiber and the ring is about 6 μm and 800 μm, respectively. To illustrate that there is light coupling, a red beam of light was launched into the input port. As shown in Fig. 3 (c) and Fig. 3 (d), scattered red light could be observed along the closed loop path of the ring from the Input port to the Through port and also along the Drop port of the SPF.

Polished caldding thickness profile of a SPF and micrographs of the SPF side view and the add-drop filter.

(a) The residual thickness of a side polished fiber (SPF) as a function of different positions along the coupling region; (b) A photograph of the SPF in comparison with a SMF; (c) A photograph of a micro/nano fiber knot ring optically coupled with a SPF; (d) A zoomed-in photograph of the coupling region.

Add-drop functionality and its performance dependence on the MNOF ring diameter

To test drop functionality and evaluate optical spectral filtering characteristics, light from a tunable laser with an optical power of 2 mW and a tunable wavelength range from 1520 nm to 1620 nm was launched into the Input port and was coupled into the micro/nano fiber ring through the knot coupling region. Depending on the wavelength and other factors such as temperature, when a constructive interference condition is satisfied, the input light oscillates in the ring and the corresponding optical energy stored in the ring is the strongest. In the experiments, we kept the diameter of the micro/nano fiber at 6 μm according to our filter performance optimization calculation and we changed the diameter of the micro/nano fiber ring by varying the position of the two translation stages. Fig. 4 shows the experimental results of the transmission spectra of the filter with different ring diameters. All the measured spectra clearly show the expected resonance characteristics at the Drop port, the Through port and the Add port. As light travels to the coupling region between the micro/nano fiber ring and the SPF, some light is scattered and could propagate to the Add port. Thus, the resonant spectra could also be detected at the Add port. It can be seen from Fig. 4 that with the diameter of the micro/nano fiber ring (RD) at 780 μm, 680 μm, 580 μm and 480 μm, the measured average optical power at the Drop port was -55 dBm, -54.5 dBm, -52 dBm and -53.7 dBm, respectively; while the extinction ratio of the Drop port was 5.3 dB, 5.9 dB, 7.5 dB and 3.6 dB, respectively. The coupling efficiency from each of the 4 MNOF rings of different diameters to the SPF, defined as the ratio in dB of an average transmission power at the Drop port over that at the Through port, was estimated to be -33.5 dB, -33.5 dB, -29 dB and -30.7 dB. For the micro/nano fiber ring with a diameter of 580 μm, a maximum output power of -52 dBm, a maximum coupling efficiency of -29 dB and a maximum extinction ratio of 7.5 dB at the Drop port were achieved. In addition, the resonance period of the transmission spectra increased with the decrease of the ring diameter, as a result of the free spectral range (FSR) increase.

Measured spectra of drop functionality of the filter with different ring diameters.

The measured transmission spectra from the Through port and the Drop port of the filter with different ring diameters of 780 μm (a), 680 μm (b), 580 μm (c) and 480 μm (d), when light from a wavelength tunable laser source was launched into the Input port.

To study the add functionality, light from the same laser source was launched into the Add port and the transmission spectra were measured at the Input port, the Through port and the Drop port under the same experimental condition as in the drop functionality experiments. Fig. 5 shows the transmission spectra of the filter with different diameters of the micro/nano fiber ring. Wavelength dependent resonance behaviors were observed at the Input port and the Through port. However, no resonance behavior was observed at the Drop port. This was caused by the relative low optical power in the ring in comparison with that in the SPF. The optical power inside the SPF is far greater than that coupled from the micro/nano fiber ring back into the SPF. The difference is up to 30 dB, thus, the resonance light energy that gets coupled back to the SPF has very little effect on the optical energy of the light inside the SPF. In other words, the energy variation is almost of the same order of magnitude as the noise energy inside the SPF. Therefore, it is very difficult to detect the resonance phenomenon at the Drop port in the add functionality experiments. The ~1 μm roughness of the polished surface of the fabricated SPF22 limited a full contact of the MNOF ring with the polished surface, thus leading to a low coupling efficiency of about -30 dB. This limitation can be overcome and the coupling efficiency can be improved by smoothening the SPF surface with smaller polishing particles. As shown in Fig. 6, with the diameter of the micro/nano fiber ring at 780 μm, 680 μm, 580 μm and 480 μm, the extinction ratio of the Through port is 4.1 dB, 4.1 dB, 4.8 dB and 3.7 dB, respectively. The resonance period of the transmission spectra also increased with the decrease of the ring diameter. The extinction ratio of the add-drop output port of the filter as a function of the ring diameter is shown in Fig. 6. It can be observed that the maximum extinction ratio of the Drop port and the Add port were 7.5 dB and 4.8 dB respectively when the ring diameter was 580 μm.

Measured transmission spectra of add functionality of the filter with different ring diameters.

The transmission spectra are measured from the Drop port and the Through port of the add-drop filter when light from a tunable laser source was launched into the add port. The ring diameters are respectively 780 μm(a),680 μm(b), 580 μm(c) and 480 μm(d).

Influence of light coupling on the Q value and fineness of a MNOF ring

In order to analyze the effect of light coupling between the micro/nano fiber ring and the SPF on the filter extinction ratio, we also studied the variation of the quality factor (Q factor) and the finesse of the micro/nano fiber ring before and after its light coupling with the SPF. The dependence of the Q factor and finesse on the diameter of micro/nano fiber ring is shown in Fig. 7 (a) and Fig. 7 (b), respectively. The influence on the Q factor of the micro/nano fiber ring can be described by the ratio of the Q factor with light coupling to the SPF over the Q factor without light coupling to the SPF. A similar ratio is also defined for the finesse. As shown in Fig. 7 (a) and Fig. 7 (b), when the diameter of micro/nano fiber ring was 780 μm, 680 μm, 580 μm and 480 μm, the Q value without light coupling to the SPF was 15723, 12091, 9826 and 6549 and the Q value with light coupling to the SPF was 10482、8733、8279 and 8276, respectively. The relative change ratio of the Q factor was 33%, 28%, 16% and 26%, respectively, as shown in Fig. 7 (c). Under the same conditions, the finesse without light coupling to the SPF was 6.6、5.7、5.5 and 4.4 and the finesse with light coupling to the SPF was 4.4、4.1、4.6 and 5.5, respectively. Degradation of the Q value and decrease of the FSR as a result of light coupling are expected, since light coupling from the ring to the SPF will increase light loss along the loop path of the ring. A SPF with a smoother polished surface will reduce the influence of coupling on the performance of the ring. The relative ratio of the fineness is expected to the same as that of the Q factor and was indeed found to be 33%, 28%, 16% and 25%, respectively, as show in Fig. 7 (d). The relative ratio of the Q factor and the fineness is the smallest when the diameter of micro/nano fiber ring is 580 μm, which indicates that in this case, light coupling to the SPF has least influence on the extinction ratio of the filter.

Coupling impact on the performance of micro/nano fiber with different diameters.

(a) The Q factor as a function of the diameter of the micro/nano fiber ring; (b) The finesse as a function of the diameter of the micro/nano fiber ring; (c) The relative ratio of Q Value as a function of the diameter of the micro-nano fiber ring; and (d) The relative ratio of the finesse as a function of the diameter of the micro-nano fiber ring.

Methods

Micro/nano fiber ring formation

Firstly, a standard single-mode fiber (with a core diameter of 9 μm and a cladding diameter of 125 μm from Corning Inc.) was heated with a flame and was elongated at a drawing speed of ~0.1 mm/s until the diameter of fiber was reduced to 6 μm. Secondly, the elongated portion of the fiber with a length of about ~5 cm i that has good optical connection to two unheated sections of a single mode fiber, was tied into a big knot ring with a diameter of about 20 cm. Afterwards, the two unheated sections of the single mode fiber were fixed on two precision translational stages and the two stages were moved in opposite directions to pull the two unheated sections and to reduce the diameter of the knot ring. The pulling action was stopped when a desired diameter of the knot ring was reached. During the pulling, a stainless needle with a diameter of about 100 μm diameter was used to very carefully adjust the elongated portion of the fiber until a desired knot ring was formedusing.

Preparation of side-polished fiber

A 4 cm long polymer jacket section of a standard single-mode fiber was stripped off using a fiber stripper. The two ends of the fiber was tied to a home-built polishing machine and the stripped section was lightly pressed against a polishing wheel coated with 3 μm-size polishing particles. During fiber cladding polishing, the rotational speed of the polishing wheel was set to 60 rpm and the removal of the cladding material was monitored with an optical power meter. When a desired optical power loss of 2 dB was reached, the polishing wheel was stopped.

Description of experimental setup

The experimental setup is shown in Fig. 1b. A personal computer interfaced stereo-microscope equipped with a charge-coupled device (CCD) camera was used for real-time video monitoring and image capturing. A 650 nm wavelength CW laser from a laser diode with a fiber output power of 2 mW was launched into the micro/nano fiber ring (See the ring in Fig. 3c). Using a high precision XYZθZ four-dimensional translation/rotation stage (0.1 μm resolution from Zolix Inc.), the side-polished fiber wass adjusted until its polished side faced upward and parallel to the ring before making contact the ring. During the adjustment, a 100 μm diameter stainless needle was used to position the ring and to prevent it from being blown away by air current. The needle was removed after the polished surface of the SPF touched and anchored the ring.

References

Tong, L. et al. Subwavelength-diameter silica wires for low-loss optical wave guiding. Nature 426, 816–819 (2003).

Li, Y. & Tong, L. Mach-Zehnder interferometer assembled with optical microfiber or nanofiber. Opt. Lett. 33, 303–305 (2008).

Jiang, X., Tong, L., Vienne, G. & Guo, X. Demonstration of optical microfier knot resonators. Appl. Phys. Lett. 88, 223501 (2006).

Xing, X., Heng, Z., Wang, Y. & Li, B. Ultracompact photonic coupling splitters twisted by PPT nanowires. Nano Lett. 8, 2839–2843 (2008).

Yu, J. et al. High performance micro-fiber coupler-based polarizer and band-rejection filter. Opt. Express 20, 17258–17270 (2012).

Jiao, X. et al. Demonstration of microfiber knot laser. Appl. Phys. Lett. 89, 143513 (2006).

Snyder, A. W. & Love, J. D. Theory of Optical Waveguide, London: Chapman and Hall, 1983, 542–544.

Bachor, H.-A., Levenson, M. D., Walls, D. F., Perlmutter, S. H. & Shelby, R. M. Quantum nondemolition measurements in an optical-fiber ring resonator. Phys. Rev. A 7 38, 180–190 (1988).

Melloni, A., Morichetti, F. & Martinelli, M. Polarization conversion in ring resonator phase shifters. Opt. Lett. 29, 2785–2787 (2004).

Turner, A. C., Foster, M. A., Gaeta, A. L. & Lipson, M. Ultra-low power parametric frequency conversion in a silicon microring resonator. Opt. Express 16, 4881–4887 (2008).

Preble, S. F., Xu, Q. & Lipson, M. Changing the colour of light in a silicon resonator. Nature Photonics 1, 293–296 (2007).

Zhu, H., White, I. M., Suter, J. D., Zourob, M. & Fan, X. Opto-fluidic mirco-ring resonator for sensitive label-free viral detection. Analyst 133, 356–360 (2008).

Ramachandran, A. et al. A universal biosensing platform based on optical micro-ring resonators. Biosenors and Bioelectronics 23, 939–944 (2008).

Ksendzov, A. & Lin, Y. Integrated optics ring-resonator sensors for protein detection. Opt. Lett. 30, 3344–3346 (2005).

Yang, A. H. J. & Erickson, D. Optofluidic ring resonator switch for optical particle transport. Lab Chip 10, 769–774 (2010).

Lin, S., Schonbrun, E. & Crozier, K. Optical Manipulation with Planar Silicon Microring Resonators. Nano. Lett. 10, 2408–2411 (2010).

Almeida, V. R., Barrios, C. A., Panepucci, R. R. & Lipson, M. All-optical control of light on a silicon chip. Nature 431, 1081–10084 (2004).

Xia, F., Sekaric, L. & Vlasov, Y. Ultracompact optical buffers on a silicon chip. Nature photonics 1, 65–71 (2007).

Xu, Q. & Lipson, M. All-optical logic based on silicon micro-ring resonators. Opt. Express 15, 924–929 (2007).

Jiang, X., Chen, Y., Vienne, G. & Tong, L. All-fiber add-drop filters based on microfiber knot resonators. Opt. Lett. 32, 1710–1712 (2007).

Xu, F. & Brambilla, G. Embedding optical microfiber coil resonators in Teflon. Opt. Lett. 32, 2164–2166 (2007).

Yu, J. et al. All-optically reconfigurable and tunable fiber surface grating for in-fiber devices:a wideband tunable filter. Opt. Express 22, 5950–5961 (2014).

Hsiao, V. K. S. et al. Optically switchable all-fiber optic polarization rotator. Opt. Comm. 285, 1155–1158 (2012).

Yu, J. et al. A fiber-optic violet sensor by using the surface grating formed by a photosensitive hybrid liquid crystal film on side-polished fiber. Meas. Sci. Technol. 24, 094019 (2013).

Zhang, J. et al. All-fiber-optic temprature sensor based on reduced graphene oxide. Laser Phys. Lett. 11, 035901 (2014).

Han, Y. et al. Side-polished fiber as sensor for the determination of nematic liquid crystal orientation. Sens.and Actuat. B: Chemical 196, 663–669 (2014).

Chen, Z., Hsiao, V. K. S., Li, X., Li, Z., Yu, J. & Zhang, J. Optically tunable microfiber-knot resonator. Opt. Express 19, 14217–14222 (2011).

Acknowledgements

This work is supported by the National Natural Science Foundation of China (No. 61177075; No. 61275046; No. 11004086; No. 61008057; No. 61475066; No. 61405075), the Core Technology Project of Strategic Emerging Industries of Guangdong Province (2012A032300016; 2012A080302004; 2011A081302002; 2012A080301002), Special Funds for Discipline Construction of Guangdong Province (2013CXZDA005) and the Fundamental Research Funds for the Central Universities of China (No. 21612437; No. 21613325; No. 21613405).

Author information

Authors and Affiliations

Contributions

Z.C. supervised the project; S.J. and J.Y. performed the experiment and prepared all figures; Q.W., J.T., J.Z. and Y.L. fabricated the side-polished fiber. Z.C., J.Y., S.J., Z.Z., H.L. and X.H. discussed the results and wrote the main manuscript text.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-sa/4.0/

About this article

Cite this article

Yu, J., Jin, S., Wei, Q. et al. Hybrid optical fiber add-drop filter based on wavelength dependent light coupling between micro/nano fiber ring and side-polished fiber. Sci Rep 5, 7710 (2015). https://doi.org/10.1038/srep07710

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep07710

This article is cited by

-

LiFi cross-connection node model using whispering gallery mode of light in a microring resonator

Microsystem Technologies (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.