Abstract

The widespread commercialization of dye-sensitized solar cells remains limited because of the poor long-term stability. We report on the influence of dye-molecules added in liquid electrolyte on long-term stability of dye-sensitized solar cells. Dye-desorption from the TiO2 surface during long-term cycling is one of the decisive factors that degrade photocurrent densities of devices which in turn determine the efficiencies of the devices. For the first time, desorption of dye from the TiO2 surface could be suppressed by controlling thermodynamic equilibrium; by addition of dye molecules in the electrolyte. The dye molecules in the electrolyte can suppress the driving forces for the adsorbed dye molecules to be desorbed from TiO2 nanoparticles. As a result, highly enhanced device stabilities were achieved due to the reduction of dye-desorption although there was a little decrease in the initial efficiencies.

Similar content being viewed by others

Introduction

Dye-sensitized solar cells (DSSCs) have attracted much attention as a promising next generation photovoltaic devices due to their potentials for low cost and high efficiency as reported by O'Regan and Gräzel1. Since then, the most DSSC researches have focused on improving the solar-to-electricity conversion efficiency. Recently, the efficiency of DSSCs has achieved 12.3% by the combination of co-sensitization of porphyrin dyes and a cobalt-complex redox mediator having more positive redox potential than iodine/iodide2. DSSCs consist of a dye-adsorbed TiO2 electrode, a Pt-coated counter electrode and an electrolyte filled between them. Under illumination, photoexcited dye injects electrons into the conduction band of TiO2. The injected electrons are then collected at the photoanode and transferred to the counter electrode. The oxidized dyes are regenerated by redox couple in the electrolyte.

Dyes are part of the key elements in DSSCs because they are directly involved in light harvesting, photoelectron generation and electron transfer3. For this reason, the bonding mechanism and electronic coupling between TiO2 and dye have been investigated and many dyes with suitable functional-groups were synthesized to increase the bonding strength between TiO2 and dyes3,4,5,6,7. Faster dye-adsorption has also been studied under high temperature8, high concentration9 and electric field10 in order to reduce the time for the dye-adsorption process, which resulted in improved productivity. In addition to the view point of kinetics for dye-adsorption, the viewpoint of thermodynamics was considered to control the binding mode of the dye with a co-adsorbent to obtain improved photoelectron generation11.

Meanwhile, long-term stability has emerged as a challenge to the commercialization of DSSCs. One of the reason for poor long-term stability of DSSCs is weakly bound dye molecules on TiO2 surface12. Recently, the long-term stability of DSSCs has been improved through molecular engineering of a sensitizer in conjunction with the use of a nonvolatile electrolyte13,14,15,16. However, the cell efficiencies of the DSSCs were lower than those of conventional DSSCs and the material is too expansive because of the use of ionic liquid. Moreover, it was reported that some modifications of molecular structure of dyes with long alkyl chains can diminish the negative effect on long-term stability resulting from the water content in TiO2 layers13,14,17,18. However, dye desorption from TiO2 and degradation by iodide ion or water in the electrolyte are fundamental problems which is harmful for the long-term stability of devices18,19,20. In this paper, we assured the effect of dye-desorption in contact with the electrolyte on device stability and achieved high stability by adding a controlled amount of dye molecules into the electrolyte. Surprisingly, these purposely added dye molecules in the electrolyte suppressed dye-desorption from the TiO2 surface by decreasing the driving force of desorption of the adsorbed dyes (Figure 1). Increasing the dye solution percentage in the model liquid electrolyte from 0 to 30 vol.% can retard the detachment of dye-molecules, thereby increasing the long-term stability of DSSCs.

Results

The reason for the reduction of dye-desorption

To confirm the reduction of dye-desorption, the freshly dye-sensitized TiO2 electrodes were immersed in electrolytes with different dye-molecule volume percentages for 24 h to check the number of remaining dye-molecules on the TiO2 electrode without desorption. After 24 h of electrolyte treatment, the electrodes were rinsed with acetonitrile and ethanol several times and the dyes on the TiO2 film were detached and collected using 0.1 M NaOH in water and ethanol solution in a 1:1 volume ratio. For comparison, a freshly dye-sensitized TiO2 electrode without electrolyte treatment was also immersed in 0.1 M NaOH solution. Following this, UV-Vis spectra intensities of the dye solution were observed and compared. As shown in Figure 2, the amount of dyes remained on the TiO2 photoanode was different from its initial amount of dyes on the TiO2 photoanode. However, the intensities of the absorbance of the desorbed dye solution after 24 h of treatment varied depending on the electrolyte composition, which confirmed the different behaviors of dye desorption in each electrolyte. The dotted line in Figure 2 represents the initial dye-loading quantity without electrolyte treatment. The absorbance after electrolyte treatment increased in proportion to the volume of dye solution in the electrolyte. The electrode immersed in the reference electrolyte showed the biggest difference from the initial dyes on the TiO2 electrode. These results confirmed that dye molecules in the electrolyte could suppress dye desorption from the TiO2 photoanode to find a new equilibrium state, resulting extremely improved stabilities.

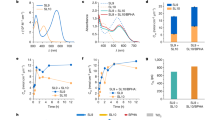

Characterization of cell performances

First, the initial DSSC performances containing different dye solution volume percentages were compared as shown in Figure 3 (A, B) and Table 1. Then, the cell aging stability was investigated by checking the efficiency decay as a function of storage time over 600 h (28 days). As the dye solution percentage increased in the electrolyte, the initial cell efficiency gradually decreased, which was mainly attributed to the reduced photocurrent density (JSC) (Table 1). The incident photon-to-current efficiency (IPCE) data (Fig. 3B) are determined by the efficiencies of light harvest (ηLH), charge injection (ηINJ) and charge collection (ηCOL)1. Obviously, the photon energy harvested by dye molecules in the electrolyte cannot contribute to photocurrent. The gradual decrease of JSC values as a function of dye concentration can support this hypothesis. Another possible reason for the decreased JSC values is the added ethanol from dye solution in the electrolyte. According to a previous research, the rate of electron injection from the dye to the TiO2 film was more rapid in acetonitrile than ethanol21. This was because the O atom in ethanol had a stronger attraction to the functional group of the dye than the N atom in acetonitrile22. Moreover, the different iodine/iodide salt concentrations of dye-containing electrolyte solutions was also regarded as an influential factor for our results. For further analysis, Nyquist plots for cells in initial state (Fig. 3C) and in a month (Fig. 3D) are compared after cell area normalization23,24,25. The equivalent circuit for the analysis is given in the Table 2, where Rs, Rct(TiO2), CPE(TiO2), Zw, Rct(CE) and CPE(CE) are series resistance, charge transfer resistance at an interface between TiO2 and electrolyte, capacitance of TiO2 and electrolyte interface, diffusion impedance in an electrolyte, charge transfer resistance at an interface between counter electrode and electrolyte and capacitance of an interface between electrolyte and counter electrode, respectively. Roughly, the impedance values of Zw and Rct(TiO2) for dye containing cells are greater than those for a reference cell, where Rct(CE) are quite comparable to each other. Since dye molecules are expected to impede a charge carrier flow in an electrolyte, a higher concentration of dye molecules in an electrolyte may increase Zw values. Rct(TiO2) values also shows dependency on dye concentration, which may mean that dye desorption from the TiO2 surface is suppressed from the very beginning. In addition, the impedance changes from an initial state to a state in a month have been summarized in Table 2. While Zw value changes are not noticeable (except samples for 30% volume percentage), Rct(TiO2) values are quite large in a month. Rct(TiO2) changes are expected since dyes in an electrolyte are playing roles at an interface between TiO2 and electrolyte. The Rct(TiO2) increase for a reference cell is based on replacing dyes with additives such as tertiary butyl pyridine. Normally, additive-replacing accompanies Voc increase as shown for a reference cell from 0.745 to 0.815 V at day 6 (Figure 4B). However, 10% dye solution percentage cell shows relatively smaller change from 0.76 to 0.80 V at day 6 compared to the reference cell. The suppression of dye-desorption from TiO2 surface during aging time may explain this Voc changes (Figure 4(B)). At the beginning, additives can affect the TiO2 surface, but high concentration of dyes are still active on the TiO2 surface and goes for an equilibrium in time.

Characterization of long-term stability

In spite of the little disadvantage of the added dye molecules in the electrolyte on the initial performances, the device stability was remarkably improved. The performance of devices was monitored for over 600h (28 days) to investigate the effects of dye-molecules in the electrolyte on the suppression of dye desorption from TiO2. All the devices were kept in room temperature (~25°C) in the dark. The humidity was kept around 40%. We chose that the moderate condition to exclude other elements that can induce other problems regarding to the device stability such as leakage or volatilization of electrolyte under high temperature. The efficiency of reference cell gradually decreased over more than 600 h (28 days) while the others nearly retained the initial performances. As it can be seen in Figure 4, the efficiency decay was mainly correlated with the decrease of JSC. On the other hand, a slight increase of VOC and FF can retard the efficiency decay, but with insignificant contribution compared to the negative effect of JSC. As mentioned previously, JSC was affected by the combination of light harvesting, charge injection and charge collection efficiencies. One of the possible explanations for the improved cell stability after adding dye molecules into the electrolyte is the light harvesting step. The binding of dyes onto the TiO2 particle and the detachment of dyes from TiO2 particles might be reversible phenomena. Because dye adsorption energy is dependent on solvents, the equilibrium state of dye molecules on the TiO2 surface might be different in each solvent environment26. Upon the dye-adsorption process, the amount of adsorbed dyes on the TiO2 photoanodes reaches its maximum point at the equilibrium state under dye-rich solution27. However, the equilibrium state of dye-coated TiO2 photoanodes should be changed after being in contact with the pure electrolyte. In other words, the dyes bound on the TiO2 photoanodes should find another steady-state because of the change in their confronted environment and this may cause detachment of dyes from the surface of TiO2, which may in turn induce efficiency decay. Because the detached dye molecules cannot participate in the light harvesting, a prominent degradation of JSC is expected for the reference cell in Figure 4(A). The devices that employed dye-added electrolytes showed less reduced JSC than the reference cell. This indicates that the dye molecules in the electrolyte induced suppression of dye-desorption from TiO2 layers by deriving a new equilibrium with the electrolyte toward a less desorption state. The normalized efficiencies and JSC data versus their initial values as shown in Fig. 4 (E,F) manifested the advantage of dye added electrolytes for improved long-term stability with more clarity. As the concentration of dye solution increased, the values were close to 1. The efficiency and JSC of the reference cell were reduced by 21.5% and 30.4%, respectively, while those of the 30% dye-solution-containing cell were decreased by 1.7% and 3%.

To investigate the usefulness of our approach in another high efficiency DSSC, a dye-solution-containing electrolyte was incorporated into another DSSC with more optimized photoanode to have ~9.5% cell efficiency as described in Method section. As shown in Fig. 5(A) and 5(B), the devices that employed dye-added electrolytes also showed less reduced JSC than the reference cell. In addition, recently, several new ionic liquid based electrolytes have been investigated as alternative stable electrolyte solvents for DSSCs28,29. We also applied our concept to a ionic liquid based electrolyte. Figure 5(C) and 5(D) show the normalized efficiencies and JSC data versus their initial values. Because of high stability nature of the ionic liquid electrolyte, the advantage of dye added electrolytes for improved long-term stability was not obvious within 16 days compared to high volatile electrolytes. However, DSSC with a dye-solution-containing electrolyte shows more improved stability compared to the reference DSSC.

Cell parameter decays of a high efficiency DSSC (~9.5%) for 16 days: Jsc (A) and Efficiency (B).All experiment conditions were same with Figure 3 and Figure 4, but initial cell efficiencies were much higher than the devices of Figure 3 and Figure 4. Normalized cell parameter decays of DSSC with a ionic liquid electrolyte for 16 days: Jsc (C) and Efficiency (D): reference electrolyte (black), 20 vol% dye solution added reference electrolyte (red).

Discussion

It was found that dye-desorption was vital to the stability of DSSCs. Desorption of dye molecules from the TiO2 surface can be strongly correlated with the decay of light harvesting efficiency, resulting in poor long-term stability. The stability of the device was extremely improved by simply adding dye molecules into the electrolyte even though it showed a slightly diminished initial performance. The dye molecules in the electrolyte suppressed the extent of dye-desorption from the TiO2 film. The tendency of different dye-detachment behaviors of dye sensitized TiO2 electrodes was confirmed by measuring the UV-Vis absorbance of remaining dyes on the TiO2 electrode after treatment in different electrolytes. We believe this simple but valuable observation can speed up the commercialization of DSSCs.

Methods

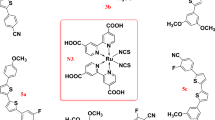

Fabrication of dye-sensitized solar cells (DSSCs)

Fluorine-doped tin oxide (FTO) glasses were cleaned with the solution containing 1:1 volume percent of ethanol and acetone in an ultrasonic bath. FTO was then treated with 40 mM titanium tetrachloride (TiCl4) at 80°C for 30 min to form a thin compact layer and was rinsed with ethanol. 12 μm-thick TiO2 paste (TiO2 paste-20 nm EnB Korea) was deposited by the doctor blade method and was subsequently annealed at 550°C for 30 min. In case of high efficiency DSSCs around ~9.5%, a light-scattering film composed of ~400 nm sized (CCIC, Japan) was over-coated on the 20 nm TiO2 film. The sintered film was immersed into the dye solution of 0.3 mM N719 in ethanol for 18 h at 25°C. The counter electrode was prepared by spreading the 10 mM H2PtCl6·6H2O in 2-propanol solution on the predrilled FTO and annealing at 450°C for 30 min. The two electrodes were assembled using a 60 μm Surlyn sheet as sealant with light pressure applied at 140°C to seal the cell. The space between the electrodes was filled with an electrolyte through the hole on the counter electrode. The reference electrolyte consisted of 0.5 M 4-tert-butylpyridin, 0.6 M 1-butyl-3-methylimidazolium iodide (BMII), 0.03 M Iodine and 0.1 M Guanidine thiocyanate in acetonitrile and valeronitrile solution with a volume percent ratio of 85:15. Dye-molecules (N719) containing electrolyte solutions were prepared by adding the 0.3 mM dye solution (N719 in ethanol) to the reference electrolyte at 10, 20 and 30 volume percent. The molar concentration of each electrolyte was summarized in Table S1. As second electrolyte, dye-containing ionic liquid based electrolyte solutions were prepared by adding the 0.3 mM dye solution to the ionic liquid electrolyte (Mosalyte ADE-250, SOLARONIX) with 20 vol.%. The active cell area was approximately 0.12 cm2, which was measured by an image analysis program equipped with a digital microscope camera (Moticam 1000).

Characterization

The photovoltaic properties of the solar cells were measured using a Keithley model 2400 source measuring unit under 100 mWcm−2 illumination using a 1,000 W Xenon lamp (Spectra-Physics) as the light source. The IPCE was measured as a function of the wavelength ranging from 300 to 800 nm using a specially designed IPCE system for dye-sensitized solar cells (PV Measurement, Inc.). The electrochemical impedance spectra were measured under 100 mWcm−2 illumination at open circuit voltage by a potentiostat (IM6, ZAHNER).

References

O'Regan, B. & Gräzel, M. A low-cost, high-efficiency solar cell based on dye-sensitized colloidal TiO2 films. Nature 353, 737–740 (1991).

Yella, A. et al. Porphyrin-Sensitized Solar Cells with Cobalt (II/III)–Based Redox Electrolyte Exceed 12 Percent Efficiency. Science 334, 629–634 (2011).

Lee, K. E. et al. Further understanding of the adsorption mechanism of N719 sensitizer on anatase TiO2 films for DSSC applications using vibrational spectroscopy and confocal Raman imaging. Langmuir 26, 9575–9583 (2010).

Fillinger, A. & Parkinson, B. A. The adsorption behavior of a Ruthenium-based sensitizing dye to nanocrystalline TiO2: coverage effects on the external and internal sensitization quantum yields. J. Electrochem. Soc. 146, 4559–4564 (1999).

Stergiopoulos, T. et al. Resonance micro-Raman spectrophotoelectrochemistry on nanocrystalline TiO2 thin film electrodes sensitized by Ru(II) complexes. Coord. Chem. Rev. 248, 1407–1420 (2004).

Hirose, F. et al. In situ observation of N719 on TiO2 in dye-sensitized solar cells by IR absorption spectroscopy. Electrochem. Solid-State Lett. 12, B167–B170 (2009).

Mishra, A. Metal-free organic dyes for dye-sensitized solar cells: from structure: property relationships to design rules. Angew. Chem. Int. Ed. 48, 2474–2499 (2009).

Jo, Y. et al. A novel dye coating method for N719 dye-sensitized solar cells. Electrochim. Acta 66, 121–125 (2012).

Lee, C. R. et al. Pseudo first-order adsorption kinetics of N719 dye on TiO2 surface. ACS Appl. Mater. Inter. 3, 1953–1957 (2011).

Seo, H. et al. Faster dye-adsorption of dye-sensitized solar cells by applying an electric field. Electrochim. Acta 55, 4120–4123 (2010).

Lim, J. et al. Thermodynamic control over the competitive anchoring of N719 dye on nanocrystalline TiO2 for improving photoinduced electron generation. Langmuir 27, 14647–14653 (2011).

Lim, J. et al. Effect of coadsorbent properties on the photovoltaic performance of dye-sensitized solar cells. Chem. Commun. 47, 4147–4149 (2011)

Wang, P. et al. Molecular-scale interface engineering of TiO2 nanocrystals: improving the efficiency and stability of dye-sensitized solar cells. Adv. Mater. 15, 2101–2104 (2003).

Wang, P. et al. A high molar extinction coefficient sensitizer for stable dye-sensitized solar cells. J. Am. Chem. Soc. 127, 808–809 (2005).

Wang, P. et al. A stable quasi-solid-state dye-sensitized solar cell with an amphiphilic ruthenium sensitizer and polymer gel electrolyte. Nat. Mater. 2, 402–407 (2003).

Stergiopoulos, T. et al. Enhanced Open-Circuit Photopotential in Quasi-Solid-State Dye-Sensitized Solar Cells Based on Polymer Redox Electrolytes Filled with Anodic Titania Nanotubes. Adv. Energy Mater. 1, 569–572 (2011).

Wang, Z. S. et al. A high-light-harvesting-efficiency coumarin dye for stable dye-sensitized solar cells. Adv. Mater. 19, 1138–1141 (2007).

Hinsch, A. et al. Long-term stability of dye-sensitized solar cells. Prog. Photovolt: Res. Appl. 9, 425–438 (2001).

Grünwald, R. & Tributsch, H. Mechanisms of instability in Ru-based dye sensitization solar cells. J. Phys. Chem. B 101, 2564–2575 (1997).

Xue, G. et al. Degradation mechanisms investigation for long-term thermal stability of dye-sensitized solar cells. Int. J. Electrochem. Sci. 7, 1496–1511 (2012).

Pollard, J. A. et al. Solvent effects on interfacial electron transfer from Ru(4,4′-dicarboxylic acid-2,2′-bipyridine)2(NCS)2 to nanoparticulate TiO2: spectroscopy and solar photoconversion. J. Phys. Chem. A 109, 11443–11452 (2005).

Thavasi, V. et al. Controlled electron injection and transport at materials interfaces in dye sensitized solar cells. Mater. Sci. Eng. R 63, 81–99 (2009).

Han, L. et al. Modeling of an equivalent circuit for dye-sensitized solar cells. Appl. Phys. Lett. 84, 2433–2435 (2004).

Velten, J. et al. Carbon nanotube/graphene nanocomposite as efficient counter electrodes in dye-sensitized solar cells. Nanotechnology 23, 085201–085207 (2012).

Roy-Mayhew, J. D. et al. Functionalized graphene as a catalytic counter electrode in dye-sensitized solar cells. ACS Nano 4, 6203–6211 (2010).

Mosconi, E. et al. Solvent effects on the adsorption geometry and electronic structure of dye-sensitized TiO2: a first-principles investigation. J. Phys. Chem. C 116, 5932–5940 (2012).

Kim, J. K. et al. The analysis of the change in the performance and impedance of dye-sensitized solar cell according to the dye-adsorption time. Curr. Appl. Phys. 10, S418–S421 (2010).

Ahmad, S. et al. A new generation of platinum and iodine free efficient dye-sensitized solar cells. Phys. Chem. Chem. Phys. 14, 10631–10639 (2012).

Yum, J. H. et al. A cobalt complex redox shuttle for dye-sensitized solar cells with high open-circuit potentials. Nat. Commun. 3, 631 (2012).

Acknowledgements

This research was supported by NRF grant funded by the Korea government (MEST) (2011-0030254, 20110023215, NCRC program (2011-0006268), Future-based Technology Development Program (2010-0029321).

Author information

Authors and Affiliations

Contributions

J.H.P. contributed to the conception and design of the experiments, analysis of the data and writing the paper. N.H. carried out all experiments and wrote the paper. Y.J. analyzed impedance data.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Table S1

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Heo, N., Jun, Y. & Park, J. Dye molecules in electrolytes: new approach for suppression of dye-desorption in dye-sensitized solar cells. Sci Rep 3, 1712 (2013). https://doi.org/10.1038/srep01712

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep01712

This article is cited by

-

Optimization of reactive black 5 decolorization by the newly isolated Saccharomyces cerevisiae X19G2 using response-surface methodology

3 Biotech (2022)

-

Investigating the Effect of Shading Mask Aperture Area on I–V Curve Characterization of Nanostructured Photoanode of Dye-Sensitized Solar Cells

Journal of Electronic Materials (2021)

-

Ecofriendly biodegradation of Reactive Black 5 by newly isolated Sterigmatomyces halophilus SSA1575, valued for textile azo dye wastewater processing and detoxification

Scientific Reports (2020)

-

Selective photoelectrochemical oxidation of glycerol to high value-added dihydroxyacetone

Nature Communications (2019)

-

Imine-linked receptors decorated ZnO-based dye-sensitized solar cells

Bulletin of Materials Science (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.