Abstract

A porous phenolsulphonic acid—formaldehyde resin (PAFR) was developed. The heterogeneous catalyst PAFR was applied to the esterification of carboxylic acids and alcohols, affording the carboxylic acid esters in a yield of up to 95% where water was not removed from the reaction mixture. Surprisingly, the esterification in water as a solvent proceeded to afford the desired esters in high yield. PAFR provided the corresponding esters in higher yield than other homogeneous and heterogeneous catalysts. The transesterification of alcohols and esters was also investigated by using PAFR, giving the corresponding esters. PAFR was applied to the batch-wise and continuous-flow production of biodiesel fuel FAME. The PAFR-packed flow reactor that was developed for the synthesis of carboxylic acids and FAME worked for four days without loss of its catalytic activity.

Similar content being viewed by others

Introduction

Dehydrative esterification of carboxylic acids and alcohols, also known as Fischer esterification1, and transesterification of esters with alcohols2,3,4,5,6,7 are important fundamental reactions for obtaining organic esters. These are both equilibrium reactions: the esterification of carboxylic acids and alcohols gives the carboxylic acid esters and water; the transesterification of organic esters with alcohols affords the corresponding organic esters and released alcohols. Since these reactions are thermodynamically reversible, their completion requires removal of the resulting water and alcohols.

Nonequilibration of these equilibrium reactions should overcome the issue. For example, some enzymes mediate the dehydrative reaction in water for the synthesis of nucleic acids and proteins with the assistance of phase separation8. Some homogeneous/heterogeneous catalysts promoted in-water esterification by tuning their hydrophobicity or hydrophilicity as well as phase separation ability9,10,11,12,13,14,15,16,17,18,19,20,21. Some homogeneous/heterogeneous catalysts promoted it under neat or solvent conditions9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27. For example, Kobayashi et al. reported esterification under neat conditions by using a surfactant-type dodecylbenzene sulfonic acid catalyst (DBSA). Yamamoto and Ishihara et al. reported highly efficient and direct ester condensation in hydrocarbons by using hafnium(IV) salts such as an HfCl4·(THF)2 catalyst under azeotropic reflux conditions. Transesterification of various esters with alcohols using heterogeneous and homogeneous acidic catalysts has also been reported28,29,30,31,32,33,34,35,36,37,38.

We designed a phenolsulfonic acid – formaldehyde resin (PAFR) catalyst as a novel acidic insoluble catalyst for the esterification of carboxylic acids and alcohols. Although PAFRs have been utilized as electron-conductive compositions or cation exchangers39,40,41,42,43,44,45, they have not been used for heterogeneous catalysts. During our investigation of their preparation procedure, we found that macroporous and nonporous PAFR (1a and 1b, respectively (Fig. 1)) were prepared separately by changing the cooling time. To our surprise, 0.7 mol% of the macroporous PAFR 1a promoted the esterification of carboxylic acids and alcohols under neat conditions without removal of water more efficiently than the nonporous PAFR 1b and general homogeneous/heterogeneous acid catalysts, affording the corresponding esters with up to a quantitative yield. Here, we show the full details of the preparation of PAFR 1a and its application to the esterification of carboxylic acids and alcohols under neat conditions without removal of water46. At the time, we were pleased to find that the in-water esterification proceeded smoothly by using 1a to give the corresponding esters with high yield. Catalyst 1a was also applied to the transesterification of carboxylic esters with alcohols. Moreover, a column packed with PAFR was utilized for the continuous-flow esterification to give the corresponding esters including the biodiesel fuel FAME.

Results and Discussion

Preparation of Phenolsulfonic Acid–Formaldehyde Resins (PAFRs) 1a and 1b

PAFRs 1a and 1b were prepared by polymerization of p-phenolsulfonic acid with formaldehyde in H2O to give brown precipitates. The suspension was cooled from 120 °C to 25 °C in 12 h, and dried under reduced pressure, affording brownish and insoluble PAFR 1a. High-resolution Scanning Electron Microscope (SEM) observation revealed that PAFR 1a was an aggregated macroporous solid with a pore size of 1–5 μm wide, in which sulfur moiety from the SO3H unit in 1a was readily detected (Energy Dispersive x-ray Spectroscopy, EDS) (Fig. 1(a–c)). Infrared spectra and elemental analysis (Figure S1, supporting information) of PAFR 1a showed the ratio of phenol sulfonic acid moiety/phenol moiety as 1/4. In contrast, when the reaction mixture was suddenly cooled down to 25 °C in 5 min, a hardly soluble brownish solid was also given. However, high- and low-resolution SEM did not show a macroporous structure in 1b although sulfur atoms (SO3H moiety) were uniformly dispersed on the polymeric matrix (Fig. 1(d–f)). The surface area of 1a and 1b was 11.5 m2/g and 3.1 m2/g, respectively (Kr-adsorption Brunauer–Emmett–Teller (BET) analysis; Fig. 1(g)). We have not clarified the reason for the formation of macropores in 1a. However, water could have been absorbed in 1a during gradual cooling, acting as a template for macropore formation. Evaporation of water under reduced pressure could have provided the macropores in 1a. In contrast, water might have been discharged from 1b during sudden cooling, giving the flat surface on 1b.

Direct Esterification and Transesterification without Removal of the Resulting Water/Alcohol

With PAFRs 1a and 1b in hand, the reaction of benzyl alcohol (2a) with acetic acid was carried out with less than 0.1 mol% of homogeneous and heterogeneous catalyst including 1a and 1b to survey the catalytic activity in the esterification (Fig. 2). In all the cases, the resulting water in the reaction was not removed from the reaction suspension/solution during the reaction. The reaction with PAFR 1a provided higher conversion to give benzyl acetate (3a) in 96% while that in PAFR 1b was slower to afford 3a in 76%. The esterification with homogeneous catalysts p-toluenesulfonic acid (p-TsOH) and p-phenolsulfonic acids under similar conditions yielded 3a in 82% and 79%, respectively. Heterogeneous catalyst (DOWEX, Amberlyst and MS3A) led to the formation of 3a in 51%, 31%, and 7%, respectively. Since PAFR 1a has hydrophilic pore structure in the catalyst, it could absorb hydrophilic alcohols and carboxylic acids and convert them to the less hydrophilic esters. The product might be discharged from the catalyst, and not attached to the catalyst. This is our working hypothesis of the efficient esterification with phase separation under nonequilibrium conditions to give the desired esters.

Since 1a was the best catalyst for direct esterification, the reaction of various alcohols with acetic acid was carried out at 50 °C for 12 h by using 1a (0.7 mol%) (Fig. 2). All the products in the following esterification were isolated to determine the isolated yield. The reaction of benzyl alcohol (2a) gave 3a in 94% isolated yield (Entry 1) that corresponded with GC yield (96%). The reaction of aliphatic primary alcohols 2b–g proceeded smoothly to give the corresponding esters 3b–g in 92–93% (Entries 2–7). The secondary alcohols 2 h–j was converted at 80 °C to the esters 3 h–j in up to 94% (Entries 8–10).

Figure 3 shows the esterification of carboxylic acids 4a–e with methyl alcohol and octanol. The reaction of a variety of carboxylic acid was carried out with methyl alcohol to afford the esters 5a–e in 93–95% (Entries 1–5). The reaction of 4a with octanol was performed to yield 6a in 95% (Entry 6).

Direct esterification in water is a kind of paradox reaction, and thus the development of heterogeneous acid catalysts is an important challenge in organic syntheses. Esterification of carboxylic acids and alcohols in water by homogeneous and heterogeneous catalysts has been reported although these catalytic system is still developing in terms of catalytic activity and loading9,10,11,12,13,14. Since catalyst 1a efficiently promoted esterification under neat conditions, we tested the reaction in water, as shown in Fig. 4, left. The reaction of octanol (2d) with acetic acid was performed with 3 mol% of 1a in water at 80 °C to give octylacetate (3d) with 80% yield (entry 1). The reaction of decanol (2e) and dodecanol (2 f) was also carried out under similar conditions to afford the corresponding acetates 3e and 3 f with 80% and 80% yield, respectively.

In-Water Esterification of Alcohols 2d–f and AcOHa, and In-Water Esterification of Carboxylic Acids and Alcoholsb. (a) Conditions: 2 (1.0 mmol), acetic acid (5.0 mmol), 1a (0.03 mmol), water (3.0 M substrate); (b) Conditions: 4 (1.0 mmol), alcohol (10 mmol), 1a (0.03 mmol), water (3.0 M substrate); (c) 90 °C.

In-water direct esterification of various carboxylic acids and alcohols was investigated (Fig. 4, right). When the reaction of octanoic acid (4a) was carried out with methyl alcohol in water at 80 °C, we were pleased to find that the reaction proceeded to give methyl octanoate (5a) with 85% yield (entry 1). C10, C12, C16 and C18 carboxylic acids were readily converted: the reaction of decanoic acid (4b), dodecanoic acid (4c), hexadecanoic acid (4d), and octadecanoic acid (4e) with methyl alcohol gave the corresponding esters 5b–5e with 92%, 91%, 85%, 82% yield, respectively (entries 2–5). Not only methyl alcohol but also ethyl alcohol, butyl alcohol and octanol were suitable reactants in this reaction: the reaction of decanoic acid (4b) and butyl alcohol in water gave butyl decanoate 6b with 80% yield (entry 6). In-water esterification of hydrocinnamic acid with methyl alcohol, butyl alcohol and octanol was carried out to afford the corresponding esters 6c–e with 80–93% yield (entries 7–9). As shown in the abovementioned results, the polymeric acid catalyst 1a efficiently promoted in-water esterification of many carboxylic acids and alcohols.

Catalytic transesterification of esters with alcohols is an important transformation to produce valuable ester materials by simple exchange of alcohol moieties, and thus PAFR 1a was applied to this transformation. The catalytic activity in transesterification was examined with less than 1 mol% of heterogeneous acid catalysts (Fig. 5, top). In all the cases, the resulting alcohol was not removed from the reaction vessel during the reaction. The reaction of octanol (2d) was performed with ethyl acetate and 0.7 mol% of 1a at 80 °C for 24 h, giving a fruity-scented octyl acetate (3d) with 93% GC yield. In contrast, catalyst 1b led to the formation of 3d with 71% GC yield under similar conditions. The general heterogeneous catalysts Dowex, Amberlyst and Zeolite (MS3A) showed lower activity than that of 1a to give 3d with 73%, 35% and 0% GC yield, respectively.

Since 1a had higher catalytic activity for not only direct esterification but also transesterification under neat conditions, the transesterification of various alcohols and ethyl acetate was investigated (Fig. 5, bottom). The products were isolated to determine the isolated yield. The reaction of octanol (2d) with ethyl acetate at 80 °C for 24 h gave 3d with 88% isolated yield (entry 1). More hydrophobic aliphatic alcohols, decanol (2e), dodecanol (2 f) and hexadecanol (2k) were readily converted to the corresponding esters 3e, 3 f and 3k with 87%, 88% and 86% yield, respectively (entries 2–4). Tetrahydrogeraniol (2 g) was reacted with ethyl acetate to give 3,7-dimethyloctyl acetate (3 g) with 80% yield (entry 5). Various benzylic alcohols were also suitable substrates for transesterification. The reaction of benzyl alcohol (2a) afforded benzyl acetate (3a) with 80% yield (entry 6). Benzylic alcohols bearing electron-donating and -withdrawing groups led to the formation of the corresponding esters with 78–83% yield (entries 6–12).

Transesterification of carboxylic acid ethyl esters with methyl alcohol also proceeded to give the corresponding methyl esters (Fig. 6). Ethyl heptanoate (7d) was reacted with methyl alcohol at 80 °C for 24 h in the presence of 1a to give methyl heptanoate (5 f) with 93% yield (entry 1). More hydrophobic carboxylic acid ethyl esters 7a, 7b, 7c and 7e were readily converted to the methyl esters 5a, 5b, 5c and 5e in 95%, 94%, 95% and 97% yield, respectively (entries 2–5).

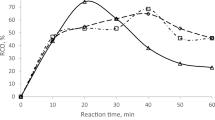

To clarify the high conversion rate of esterification and transesterification using PAFR 1a, time course experiments of the esterification of 4b with methyl alcohol, the hydrolysis of 5b, transesterification of 7b and 5b were investigated (Fig. 7). As shown in Eq. 1, direct esterification of 4b with methyl alcohol proceeded smoothly at 50 °C to give the methyl ester 5b with >90% conversion in 12 h. In contrast, the reverse reaction, the hydrolysis of 5b with water did not proceed (Eq. 2). These results suggest that the equilibrium is not an important factor when using PAFR 1a, and thus the high catalytic activity of 1a is important for full conversion. Since the transesterification of the ethyl ester 7b to the methyl ester 5b was faster than that of the methyl ester 5b to the ethyl ester 7b (Eqs. 3 and 4), more that 90% yield of the methyl esters 5 in Fig. 6 should be obtained.

Batch and Continuous-Flow Synthesis of Biodiesel Fuel (FAME) via Esterification and Flow Transesterification

Efficient production of biodiesel fuel (fatty acid methyl ester; FAME) is important for green sustainable chemistry and fossil chemistry47,48,49,50. Researchers have reported esterification with solid acid catalysts for the production of biodiesel fuel51,52,53,54,55. Since the heterogeneous catalyst PAFR 1a efficiently promoted direct esterification, it was applied to the synthesis of FAME 5 g (Fig. 8, top). The reaction of oleic acid (4 g) with methyl alcohol was carried out with 0.7 mol% SO3H of 1a to give 5 g in 93%. In contrast, the reaction was performed with homogeneous and heterogeneous catalysts, p-TsOH, poly(styrenesulfonic acid), p-phenolsulfonic acid and Amberlyst under similar conditions, affording 5 g in 74%, 77%, 73% and 38%, respectively. The results clearly show the superiority of PAFR 1a for the efficient production of FAME. Transesterification of the triglyceride 8 was also carried out with PAFR 1a to give FAME in 68%.

Moreover, the production of FAME 5 g was achieved by using a column-type PAFR 1a-promoted flow reactor under continuous-flow conditions. The flow reactor was composed of a PAFR 1a-packed column with a heater and HPLC pump in which a methanolic solution of oleic acid (4 g) was continuously injected from an inlet (Fig. 8, bottom). The flow catalytic reaction system promoted the esterification in 18 min to provide FAME 5 g in over 90% for continuous four days. Furthermore, the flow transesterification of 2d with EtOAc also proceeded in 20 min to afford 3d in 94% for continuous six days.

Conclusion

PAFR 1a was developed. The heterogeneous catalyst PAFR 1a with less than 1 mol% promoted the esterification of carboxylic acids and alcohols, where the resulting water was not removed from the reaction vessel during the reaction. Direct esterification in water also proceeded by using PAFR 1a to afford the corresponding esters. Transesterification was also performed with PAFR 1a, efficiently giving the desired esters. Moreover, PAFR 1a was applied to both batch and continuous-flow production of FAME, providing FAME 5 g in high yield. We found that porosity in the polymeric acid catalyst was particularly important for efficient catalytic esterification and transesterification.

Methods

Preparation of a porous PAFR 1a and 1b

A mixture of a 2.0 M aqueous solution of p-phenol sulfonic acid (14.5 mL; 29.0 mmol), an 37% aqueous solution of formaldehyde (14.3 mL; 145 mmol) was stirred in a 300 mL flask with a reflux condenser at 120 °C (oil bath temperature) for 6 h under refluxing conditions. The flask was gradually cooled down to 25 °C in 12 h (for 1a) or in 5 min (for 1b) on an oil bath (for 1a) or an ice-water bath (for 1b) to give a pale brownish gel. The obtained gel material was washed with methanol and acetone, and then was dried under reduced pressure. A hardly soluble polymer PAFR 1a was obtained in 72% yield (3.6 g) as a reddish brown solid. ATR-IR µ 3376, 1598, 1469, 1032, 773, 750, 708, 612 cm−1; Anal. Calcd. for (C35H30O8S·6 H2O)n: C, 58.49; H, 5.89; S, 4.46. Found: C, 57.78; H, 5.42; S, 4.08. 1b: Anal. Calcd. for (C35H30O8S·2 H2O)n: C, 65.00; H, 5.30; S, 4.96. Found: C, 64.82; H, 5.67; S, 2.99.

General procedure for the direct esterification under solvent-free conditions

To a 4 mL vial was added PAFR 1a (0.7 mol%, 5.6 mg), an alcohol 2 (1.0 mmol), and acetic acid (1.2 mol equiv). The mixture was shaken by a shaker (16 Hz, Petisyzer) for 12 h at 50–80 °C. After the reaction, PAFR 1a was filtered by filtration and washed with acetone. The filtrate was evaporated to give the corresponding acetate 3.

General procedure for the esterification in water

To a 4 mL vial was added PAFR 1a (3 mol%, 24 mg), an alcohol 2 (1.0 mmol), and acetic acid (5 mol equiv) in water (3.0 M). The mixture was shaken by a shaker (16 Hz, Petisyzer) for 48 h at 80 °C. After the reaction, FAPR 1a was filtered by filtration and washed with acetone. The filtrate was evaporated to give the corresponding acetate 3.

General procedure for the transesterification

To a 4 mL vial was added PAFR 1a (0.7 mol%, 5.6 mg), 2 (1.0 mmol), and ethyl acetate (10 mol equiv). The mixture was shaken by a shaker (16 Hz, Petisyzer) for 24 h at 80 °C without removal of ethanol. After the reaction, PAFR 1a was filtered by filtration and washed with acetone. The filtrate was evaporated to give the corresponding methyl esters 3.

Continuous flow reaction

PAFR 1a (900 mg, 1.1 mmol) was packed into a glass column (15 cm × 6.6 mm bed reactor) that was attached to a heat block. A solution of the mixture of oleic acid and methanol was installed with a flow pump through capillary tubing. The flow reaction of oleic acid and methanol (5 mol equiv) was carried at a flow rate of 10 μL/min through the PAFR-packed column at 80 °C (residence time: 18 min). The reaction mixture solution was collected from the outlet of column, and evaporated to give FAME 5 g in 92–96% conversion.

Additional Information

How to cite this article: Baek, H. et al. In-Water and Neat Batch and Continuous-Flow Direct Esterification and Transesterification by a Porous Polymeric Acid Catalyst. Sci. Rep. 6, 25925; doi: 10.1038/srep25925 (2016).

References

Fischer, E. & Speier, A. Darstellung der Ester. Chem. Ber. 28, 3252–3258 (1895).

Otera, J. Esterification. WILEY-VCH, Weinheim, Germany (2003).

Otera, J. Transesterification. Chem. Rev. 93, 1449–1470 (1993).

Otera, J. Toward Ideal (Trans)Esterification by Use of Fluorous Distannoxane Catalysts. Acc. Chem. Res. 37, 288–296 (2004).

Nahmany, M. & Melman, A. Chemoselectivity in Reactions of Esterification. Org. Biomol. Chem. 2, 1563–1572 (2004).

Hoydonckx, H. E., De Vos, D. E., Chavan, S. A. & Jacobs, P. A. Esterification and Transesterification of Renewable Chemicals. Top. in Catal. 27, 83–96 (2004).

Ishihara, K. Dehydrative Condensation Catalyses. Tetrahedron, 65, 1085–1109 (2009).

Alberts, B. et al. Molecular Biology of the Cell 5thEd., Garland Science (2008).

Sakakura, A., Koshikari, Y., Akakura, M. & Ishihara, K. Hydrophobic N,N-Diarylammonium Pyrosulfates as Dehydrative Condensation Catalysts under Aqueous Conditions. Org. Lett. 14, 30–33 (2012).

Manabe, K., Sun, S.-M. & Kobayashi, S. Dehydration Reactions in Water. Surfactant-Type Brønsted Acid-Catalyzed Direct Esterification of Carboxylic Acids with Alcohols in an Emulsion System. J. Am. Chem. Soc. 123, 10101–10102 (2001).

Inagaki, T. et al. Dehydrative Esterification of Carboxylic Acids with Alcohols Catalyzed by Diarylammonium p-Dodecylbenzenesulfonates in Water. Applied Catalysis, B: Environmental 119, 304–307 (2012).

Kobayashi, S., Iimura, S. & Manabe, K. Dehydration Reactions in Water. Surfactant-type Brønsted Acid-catalyzed Dehydrative Etherification, Thioetherification, and Dithioacetalization in Water. Chem. Lett. 31, 10–11 (2002).

Manabe, K., Iimura, S., Sun, X.-M. & Kobayashi, S. Dehydration Reactions in Water. Brønsted Acid−Surfactant-Combined Catalyst for Ester, Ether, Thioether, and Dithioacetal Formation in Water. J. Am. Chem. Soc. 124, 11971–11978 (2002).

Manabe, K. & Kobayashi, S. Dehydrative Esterification of Carboxylic Acids with Alcohols Catalyzed by Polymer-Supported Sulfonic Acids in Water. Adv. Synth. Catal. 344, 270–273 (2002).

Sakakura, A., Koshikari, Y. & Ishihara, K. Open-Air and Solvent-Free Ester Condensation Catalyzed by Sulfonic acids. Tetrahedron Lett. 49, 5017–5020 (2008).

Chakraborti, A. K., Singh, B., Chankeshwara, S. V. & Patel, A. R. Protic Acid Immobilized on Solid Support as an Extremely Efficient Recyclable Catalyst System for a Direct and Atom Economical Esterification of Carboxylic Acids with Alcohols. J. Org. Chem. 74, 5967–5974 (2009).

Thombal, R. S., Jadhava, A. R. & Jadhav, V. H. Biomass Derived β-Cyclodextrin-SO3H as a Solid Acid Catalyst for Esterification of Carboxylic Acids with Alcohols. RSC Adv. 5, 12981–12986 (2015).

Cai, L. et al. SO3H and NH2+ Functional Carbon-Based Solid Acid Catalyzed Transesterification and Biodiesel Production. RSC Adv. 5, 72146–72149 (2015).

Ishihara, K., Ohara, S. & Yamamoto, H. Direct Condensation of Carboxylic Acids with Alcohols Catalyzed by Hafnium(IV) Salts. Science 290, 1140–1142 (2000).

Ishihara, K., Nakagawa, S. & Sakakura, A. Bulky Diarylammonium Arenesulfonates as Selective Esterification Catalysts. J. Am. Chem. Soc. 127, 4168–4169 (2005).

Karimi, B. & Vafaeezadeh, M. SBA-15-Functionalized Sulfonic Acid Confined Acidic Ionic Liquid: a Powerful and Water-Tolerant Catalyst for Solvent-free Esterifications. Chem. Commun. 48, 3327–3329 (2012).

Barrett, A. G. M. & Braddock, D. C. Scandium(III) or lanthanide(III) Triflates as Recyclable Catalysts for the Direct Acetylation of Alcohols with Acetic Acid. Chem. Commun. 351–352 (1997).

Chen, C. & Munot, Y. S. Direct Atom-Efficient Esterification between Carboxylic Acids and Alcohols Catalyzed by Amphoteric, Water-Tolerant TiO(acac)2 . J. Org. Chem. 70, 8625–8627 (2005).

Nakayama, M., Sato, A., Ishihara, K. & Yamamoto, H. Water-Tolerant and Reusable Catalysts for Direct Ester Condensation between Equimolar Amounts of Carboxylic Acids and Alcohols. Adv. Synth. Catal. 346, 1275–1279 (2004).

Funatomi, T., Wakasugi, K., Misaki, T. & Tanabe, Y. Pentafluorophenylammonium Triflate (PFPAT): an Efficient, Practical, and Cost-Effective Catalyst for Esterification, Thioesterification, Transesterification, and Macrolactone Formation. Green. Chem. 8, 1022–1027 (2006).

Komura, K., Ozaki, A., Ieda, N. & Sugi, Y. FeCl3·6 H2O as a Versatile Catalyst for the Esterification of Steroid Alcohols with Fatty Acids. Synthesis 3407–3410 (2008).

Srinivas, K. V. N. S., Mahender, I. & Das, B. Silica Chloride: A Versatile Heterogeneous Catalyst for Esterification and Transesterification. Synthesis 2479–2482 (2003).

Pereira, W., Close, V., Patton, W. & Halpern, B. Transesterification with an Anion-Exchange Resin. J. Org. Chem. 34, 2032–2034 (1969).

Seebach, D., Hungerbühler, E., Schnurrenberger, P., Weidmann, B. & Züger, M. Titanate-Mediated Transesterifications with Functionalized Substrates. Synthesis 138–141 (1982).

Waldmann, H. & Kunz, H. 1,3-Dithian-2-ylmethyl Esters as Two-Step Carboxy-Protecting Groups in the Synthesis of N-Glycopeptides. J. Org. Chem. 53, 4172–4175 (1988).

Ranu, B. C., Dutta, P. & Sarkar, A. A Simple and Efficient Procedure for Transesterification Catalyzed by Indium Triiodide. J. Org. Chem. 63, 6027–6028 (1998).

Masaki, Y., Tanaka, N. & Miura, T. Mild Esterification and Transesterification of Carboxylic Acids Catalyzed by Tetracyanoethylene and Dicyanoketene Dimethyl Acetal. Chem. Lett. 26, 55–56 (1997).

Xiang, J., Toyoshima, S., Orita, A. & Otera, J. A Practical and Green Chemical Process: Fluoroalkyldistannoxane-Catalyzed Biphasic Transesterification. Angew. Chem. Int. Ed. 40, 3670–3672 (2001).

Baumhof, P., Mazitschek, R. & Giannis, A. A Mild and Effective Method for the Transesterification of Carboxylic Acid Esters. Angew. Chem. Int. Ed. 40, 3672–3674 (2001).

Chen, C.-T., Kuo, J.-H., Ku, C.-H., Weng, S.-S. & Li, C.-Y. Nucleophilic Acyl Substitutions of Esters with Protic Nucleophiles Mediated by Amphoteric, Oxotitanium, and Vanadyl Species. J. Org. Chem. 70, 1328–1339 (2005).

Iwasaki, T., Maegawa, Y., Hayashi, Y., Ohshima, T. & Mashima, M. Transesterification of Various Methyl Esters Under Mild Conditions Catalyzed by Tetranuclear Zinc Cluster. J. Org. Chem. 73, 5147–5150 (2008).

Singh, A. S., Bhanage, B. M. & Nagarkar, J. M. Formylation and Acetylation of Alcohols Using Amberlyst-15 as a Recyclable Heterogeneous Catalyst. Green Chem. Lett. Rev. 5, 27–32 (2012).

Tanemura, K. & Suzuki, T. Sulfonated Polypyrene (S-PPR) as Efficient Catalyst for Esterification of Carboxylic Acids with Equimolar Amounts of Alcohols without Removing Water. Tetrahedron Lett. 54, 1972–1975 (2013).

Klausener, P. & Woermann, D. Structure and Transport Properties of Cation Exchange Gel Membranes: Facilitated Transport of Ethene with Silver Ions as Carriers. J. Membrane Sci. 168, 17–27 (2000).

Mayer, K. & Woermann, D. Diffusion- and Convection-Induced Transport of Nonelectrolytes in Aqueous Solution across a Cation-Exchange Membrane. J. Membrane Sci., 127, 35–45 (1997).

van Keulen, H., Hollander, J. G. & Smit, J. A. M. Measurement and Theoretical Description of Ion Sorption and Diffusion of Water and Counterions in a Cation Exchange Resin Bearing Sulfonic Acid Groups. J. Colloid Interface Sci. 185, 119–130 (1997).

Hahn, O. & Woermann, D. Osmotic Properties of a Phenolsulfonic Acid Formaldehyde Cation Exchange Membrane in Contact with Mixed Aqueous Electrolyte Solutions. J. Membrane Sci. 117, 197–206 (1996).

Roettger, H. & Woermann, D. Osmotic Properties of Polyelectrolyte Membranes: Positive and Negative Osmosis. Langmuir 9, 1370–1377 (1993).

Weisshaar, D. E., Lamp, B., Merrick, P. & Lichty, S. Fabrication of Solid Polymer Electrolyte-based Electrodes for Voltammetry in the Absence of Supporting Electrolyte. Anal. Chem. 63, 2380–2383 (1991).

When, R. & Woermann, D. Static Viscoelastic Properties of Swollen Polyelectrolyte Gels in Equilibrium with Water and Aqueous Electrolyte Ssolutions. Polymer 28, 1729–1737 (1987).

Minakawa, M., Baek, H., Yamada, Y. M. A., Han, J. W. & Uozumi, Y. Direct Dehydrative Esterification of Alcohols and Carboxylic Acids with a Macroporous Polymeric Acid Catalyst. Org. Lett. 15, 5798–5801 (2013).

Bender, M. Economic Feasibility Review for Community-Scale Farmer Cooperatives for Biodiesel. Bioresource Technol. 70, 81–89 (1999).

Diasakou, M., Louloudi, A. & Papayannakos, N. Kinetics of the Non-Catalytic Transesterification of Soybean Oil. Fuel 77, 1297–1302 (1998).

Ogoshi, T. & Miyawaki, Y. Soap and Related Products: Palm and Lauric oil. J. Am. Oil Chem. Soc. 62, 331–335 (1985).

Kildran, G., Yucel, S. O. & Turkay, S. In-situ Alcoholysis of Soybean Oil. J. Am. Oil Chem. Soc. 73, 225–228 (1996).

Bossaert, W. D. et al. Mesoporous Sulfonic Acids as Selective Heterogeneous Catalysts for the Synthesis of Monoglycerides. J. Catal. 182, 156–164 (1999).

Mbaraka, I. K., Radu, D. R., Lin, V. S.-Y. & Shanks, B. H. Organosulfonic Acid-Functionalized Mesoporous Silicas for the Esterification of Fatty Acid. J. Catal. 219, 329–336 (2003).

Gang, L., Xinzong, L. & Eli, W. Solvent-Free Esterification Catalyzed by Surfactant-Combined Catalysts at Room Temperature. New J. Chem. 31, 348–351 (2007).

Bhunia, S., Banerjee, B. & Bhaumik, A. A New Hypercrosslinked Supermicroporous Polymer, with Scope for Sulfonation, and Its Catalytic Potential for the Efficient Synthesis of Biodiesel at Room Temperature. Chem. Commun. 51, 5020–5023 (2015).

Kim, Y.-H. et al. Production of Valuable Esters from Oleic Acid with a Porous Polymeric Acid Catalyst without Water Removal. Synlett 27, 29–32 (2016).

Acknowledgements

We thank Dr. T. Sato and Ms. A. Ohno in our project team for ATR-IR analysis and SEM observation, respectively. We gratefully acknowledge the financial support from JST ACT-C, JST ACCEL, JSPS (#24550126, #20655035, and #15K05510), the Takeda Science Foundation, the Naito Foundation, and the RIKEN-HYU Collaboration Foundation.

Author information

Authors and Affiliations

Contributions

Y.M.A.Y., Y.U. and J.W.H. conceived the experiments, and H.B. and M.M. conducted the experiments. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Baek, H., Minakawa, M., Yamada, Y. et al. In-Water and Neat Batch and Continuous-Flow Direct Esterification and Transesterification by a Porous Polymeric Acid Catalyst. Sci Rep 6, 25925 (2016). https://doi.org/10.1038/srep25925

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep25925

This article is cited by

-

Metal-free selective acylation reaction of aliphatic alcohols in neutral condition

Journal of the Iranian Chemical Society (2023)

-

Challenges and outlook for catalytic direct amidation reactions

Nature Catalysis (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.