Abstract

To enhance the carbon dioxide (CO2) uptake of metal-organic frameworks (MOFs), amine functionalization of their pore surfaces has been studied extensively. In general, amine-functionalized MOFs have been synthesized via post-synthetic modifications. Herein, we introduce a one-step construction of a MOF ([(NiLethylamine)(BPDC)] = MOFNH2; [NiLethylamine]2+ = [Ni(C12H32N8)]2+; BPDC2− = 4,4‘-biphenyldicarboxylate) possessing covalently tethered alkylamine groups without post-synthetic modification. Two-amine groups per metal centre were introduced by this method. MOFNH2 showed enhanced CO2 uptake at elevated temperatures, attributed to active chemical interactions between the amine groups and the CO2 molecules. Due to the narrow channels of MOFNH2, the accessibility to the channel of CO2 is the limiting factor in its sorption behaviour. In this context, only crystal size reduction of MOFNH2 led to much faster and greater CO2 uptake at low pressures.

Similar content being viewed by others

Introduction

Global warming by the accumulation of carbon dioxide (CO2) is a serious environmental problem, because it leads to severe natural disasters1. Therefore, the need for practical CO2 adsorbents is critical and various efforts have been made in this field2,3,4. Currently, alkylamine solutions are used as CO2 adsorbents in industry due to their ease of use and low cost5. However, ease of degradation, toxic by-products and a high regeneration energy are endemic problems of this technology6. Thus, tethering alkylamine groups on solid supports is considered as a useful strategy to stabilize the amine groups and reduce the energy required for regeneration4,7,8,9,10,11,12. Metal-organic frameworks (MOFs) provide appropriate solid supports due to the chemical tunability of their metal building blocks and organic ligands. To prepare amine-functionalized MOFs, open-metal sites (OMSs) on the internal pore surfaces are decorated with multi-amine molecules to capture CO2 molecules13,14,15. Physical impregnation of polyalkylamines like polyethyleneimine (PEI) into pore-activated MOFs is also the good approach to introduce active amine groups into the pore16. These synthetic methods allow the MOFs to show advanced CO2 uptake behaviour. However, several preparation steps and leaching of the impregnated amines during multiple regeneration cycles can be potential problems in their practical utilization. Thus, covalent grafting of amine groups on the organic building blocks is very efficient in achieving stable amine-functionalized solid adsorbents17,18,19. However, amino groups substituted to aromatic ligands do not interact strongly with CO2 due to the electron withdrawing effect of benzene rings16,20. Thus, herein we suggest a one-step self-assembly toward a MOF with a pore surface decorated with covalently tethered alkylamines, which can be stable during regeneration. To achieve this synthetic approach, we selected a Ni(II)-complexed macrocycle as a metal building block, which contains two pendant ethylamine groups ([NiLethylamine]2+ = [Ni(C12H32N8)]2+)21 (Fig. 1a). The amine-tethered MOF shows chemical interactions with CO2 leading to the formation of ammonium carbamate, which is elucidated by infrared (IR) spectroscopy. In addition, only reducing the crystal size leads at most sevenfold enhancement of CO2 adsorption by increasing the gas accessibility, which resolves the diffusion resistance caused by the high amine density in the pore. Adsorption-desorption cyclic performance is also tested to show the durability of the MOF.

Results and Discussion

X-ray Structure of MOFNH2-as

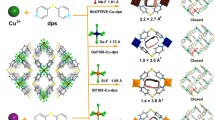

Self-assembly of [NiLethylamine]2+ and an organic ligand, BPDC2− yields rod-shaped purple crystals of {[(NiLethylamine)(BPDC)]·3H2O} (MOFNH2-as). Each NiII macrocycle has a square planar geometry and acts as a linear linker; its axial sites are coordinated by carboxylate anions from two different BPDC2− ligands in a monodentate fashion, resulting in octahedral centres (Fig. S1). Infinite coordination between BPDC2− and NiII macrocycles results in one dimensional (1D) chains, which are extended in three different directions. This was similar to a previously reported structure22, generating honeycomb-like 1D channels. The pendant ethylamine groups are exposed to the 1D channels, decorating the internal pore surface (Fig. 1b,c). Amine moieties from three pendant arms are adjacent to each other in the pore (the shortest distance between amine groups is 2.70 Å), generating a very narrow pore diameter of 1.59 Å. The void volume calculated by PLATON23 is 612.8 Å3 (9.1%).

Stability of MOFNH2-as

Thermogravimetric analysis (TGA) of MOFNH2-as (Fig. S2) revealed weight loss up to a temperature of ~230 °C, which was concurrent to the total weight percent of guest water molecules (8.6 wt%) occupying the void spaces. The X-ray powder diffraction (XRPD) pattern of as-synthesized MOFNH2-as showed strong reflections in the region 5−30 °, which were commensurated with the simulated pattern from single crystal X-ray diffraction data (Fig. 2a,b). After heating up to 250 °C under pure N2 flow, the MOF retained the same structure, showing high thermal stability (Fig. 2c). Since real flue gas usually contains more than 10% (v/v) water and water molecules are very good ligands for metal centres, the water stabilities of MOFs as well as the amine moieties coordinated to the OMSs cannot be assured under humid condition. In the present study, upon suspending the activated MOF in water for 24 h, its structure and the crystallinity were maintained as evidenced by the XRPD pattern (Fig. 2d). Re-activation of the hydrated MOF also resulted in the intact structure as shown in Fig. 2e. Therefore, MOFNH2-as, in which the amine moieties were tethered by covalent bonds, is a potentially good sorbent due to its thermal and water stability.

Gas Sorption Properties of MOFNH2

After activation of the MOFNH2-as crystals at 90 °C under vacuum for 7 h (MOFNH2), MOFNH2 maintained the same structure to MOFNH2-as as evidenced by the XRPD patterns (Fig. S3). N2 isotherm of MOFNH2 at 77 K showed a type II shape, indicating that the narrow channels (1.59 Å) are not accessible to N2 molecules (3.64 Å) (Fig. S4). The CO2 adsorption isotherms for MOFNH2 at several temperatures are depicted in Fig. 3. At 0 °C and 1 bar, MOFNH2 adsorbed a small amount of CO2 (0.17 mmol g−1). However, as the temperature increased to 100 °C, the CO2 uptake increased to 1.32 mmol g−1 (Table S3). This behaviour is the opposite of what has been observed for previous amine-grafted MOFs, which show a decrease in CO2 uptake with increasing temperature14,15. In the previous reports, owing to their large pores, chemisorption was followed by physisorption, which might be weakened at the higher temperature. On the other hand, MOFNH2 does not have a large enough pore diameter to access multi-layer adsorption and thus the uptake by physisorption can be exclusively considered. Therefore, at high temperatures the chemisorption in MOFNH2 is much sufficiently occurred to form C-N bonds between amines and CO2. The desorption isotherms at 0–75 °C did not trace back to the adsorption curve with large hysteresis even in the low-pressure region and at 100 °C the adsorbed CO2 molecules were completely desorbed by evacuation (Figs S5 and S6). These different desorption behaviours upon temperatures were verified by the gravimetric uptake result under 100% CO2 gas flow (Fig. S7). It was found that adsorption and desorption are at the equilibrium around 100 °C and thus the chemisorbed CO2 molecules in MOFNH2, can be liberated at 100 °C upon pressure reduction.

As described previously, the pore size of MOFNH2 is only half of the kinetic diameter of CO2 (3.3 Å). Then, how the CO2 adsorption can occur in this MOF? The flexible movement of the pendant alkylamine groups may allow the uptake of CO2. At the low temperature, 100 K, at which X-ray single crystal data was collected, the alkylamine groups did not show significant thermal disorderness. However, as the temperature increases, thermal motion of the alkylamines, which have conformational flexibility, become active. Consequently, at certain moments the thermal disorderness makes the pores accessible to CO2 molecules. Therefore, higher temperatures afford not only stochastically more possibilities to generate a suitable pore size, but also thermal energy to produce chemical bonds between the amino groups and CO2.

Crystal Size Effects on CO2 Uptake of MOFNH2

Based on this understanding, the access of CO2 into the MOF is of critical importance. Accordingly, we compared the CO2 sorption behaviours of MOFNH2 with the different crystal size, MOFNH2:crystal, which have been treated so far and well-ground MOFNH2 powder (MOFNH2:powder). MOFNH2:powder was prepared by pulverizing MOFNH2:crystal, using a sample grinder with stainless steel vial and ball. As shown in the scanning electron microscope (SEM) images (Fig. 4), MOFNH2:crystal are several tens of micrometres long (average 58.7 ± 27.8 μm measured from 71 crystals), whilst the size of MOFNH2:powder(average 15.4 ± 12.0 μm measured from 90 crystals) is mainly distributed in a few micrometre range. Interestingly, the only reduction in crystal size of MOFNH2 resulted in much faster and greater CO2 adsorption (Fig. 5a, S8 and Table S3). The uptake of MOFNH2:powder at 1 bar were greater by a factor of 1.3–7.5 than those of MOFNH2:crystal over all temperatures. This might be attributed to a decrease of the channel length in each grain of the adsorbent, which results in high accessibility under the same condition. In contrast with MOFNH2:crystal, MOFNH2:powder adsorbed the almost same CO2 uptake at 75 and 100 °C (~7.6 wt%). This suggests that under the guaranteed condition of the CO2 accessibility, the uptake of ~1.75 mmol g−1 might be the maximum value in this MOF. The relatively slow kinetics was observed at 100 °C because the adsorption and desorption are at the equilibrium around 100 °C as mentioned previously (Fig. 5a inset and S9). At 0.15 bar and 25 °C, comparable to the CO2 partial pressure of a typical post-combustion flue gas24, the CO2 uptake of MOFNH2:powderand MOFNH2:crystal are 1.19 and 0.12 mmol g−1, respectively (Fig. 5b). In other words, the sorption ability at 0.15 bar improved tenfold with a decrease in crystal size. Our result shows the good agreement with that of the amine-modified mesoporous silicas. Sayari group reported the effect of the pore length on CO2 adsorption in the porous silica with high loading of PEI25. SBA-15PLT silica with very short pore channels showed much enhanced adsorption and desorption kinetics as well as low temperature CO2 uptake. It is obvious that high amine loading is necessarily required for high CO2 uptake. However, it always comes with diffusion limitation and thus, the optimization of the loading amount ought to be accompanied. In this context, the reduction of the pore length can be the simple but effective way to enhance the sorption behaviour and our study is the first report of this trial using MOFs.

Evidence of Chemical Interaction between MOFNH2:powder and CO2

To verify the chemical interaction between CO2 molecules and the pendant amine groups, the IR spectra of MOFNH2:powder before and after CO2 adsorption were compared (Fig. 6). Upon CO2 adsorption at 75 °C, the stretching bands at 3368, 3293 cm−1 and bending band at 1660 cm−1, which correspond to the primary amine (N-H) tethered to the MOF mostly disappeared, remaining the small trace. Simultaneously, new peaks were observed at 3444 cm−1 and 1478 cm−1, assigned to N-H stretching of carbamate (NHCOO−) group and NH3+ deformation, respectively26,27. This result indicated that the chemical interactions between CO2 and MOFNH2:powder form ammonium carbamate, which results from a 2:1 amine:CO2 stoichiometric reaction (equation (1)).

The secondary amine (N-H) peak from the NiII macrocycle at 3135 cm−1 was maintained, showing that CO2 reacts with only the primary amine of the pendant in the MOF. A 600 MHz 13C NMR analysis also supports the formation of carbamate as a result of the chemical interaction between amine groups and CO2 molecules (Fig. S10). Unlike the spectra of MOFNH2 before adsorption and after regeneration, that of MOFNH2 adsorbing CO2 molecules show the distinct peak at 160.5 ppm. Because a carbamic acid C = O resonance is usually observed at 157–160 ppm and carbamate at 164–165 ppm28,29, the obseved peak might be the result of the equilibrium between carbamate and carbamic acid groups through proton transfer in the solution state. The formed carbamate groups can block the narrow pore to prevent the diffusion of the next CO2 molecules. However, from the maximum CO2 uptake amount, the pendants terminated by carbamate or ammonium groups might be expected to have the flexible motions to provide the accessible pathway to CO2 molecules including the conformational changes of alkyl chains. The isosteric heat of adsorption (Qst) by using CO2 adsorption data at 50 and 75 °C was calculated by applying a single site Langmuir-Freundlich model (Figs S11 and S12), because the chemisorption is major contribution to the total uptake at those temperatures. Qst is −59.5 kJ mol−1 at zero coverage, which is reasonable but relatively small value for the chemisorbed CO2 in MOF.

CO2 Cyclic Performance for MOFNH2:powder

Since durability of CO2 adsorbents is very important for practical applications, adsorption-desorption cyclic performance of MOFNH2:powder was tested by using TGA with a combined temperature swing and nitrogen purge approach (Fig. 7). The sample was activated at 150 °C under pure N2 flow for 7 h. Then, a simulated flue gas was introduced into the furnace for 2 h at 25 °C, followed by regeneration at 120 °C for 1 h under pure N2 gas. A CO2 uptake capacity of 4.80 wt% (1.09 mmol g−1) was recorded on an average over 12 cycles and there was no decrease in CO2 uptake, indicating that the CO2 adsorption ability of MOFNH2:powder is maintained over repeated cycling.

Conclusions

In conclusion, an amine-functionalized MOF, MOFNH2, was successfully synthesized via a one-step construction method. The structure of MOFNH2 was determined by using single-crystal XRD, confirming that the covalently tethered alkylamine groups conserved the loading of amine groups as two per metal centre. MOFNH2 showed enhanced CO2 adsorption as temperature increases and the results of sorption experiments and IR spectroscopy revealed that chemisorption occurred through the interaction between CO2 molecules and amine groups. Since the narrow channel in the MOF restricts the easy access of CO2 molecules, reducing the crystal size led faster and greater CO2 adsorption under same sorption condition with diminished diffusion resistance and enhanced amine accessibility inside the pores. The chemical interaction between the primary amine groups tethered to the MOF and CO2 molecules formed ammonium carbamate, which was reversibly dissociated at mild temperature, 100 °C, to release CO2 molecules. MOFNH2 was found to be a renewable CO2 adsorbent with good stability over repeated cycling.

Methods

Materials and Methods

All chemicals and solvents used in the syntheses were of reagent grade and were used without further purification. [NiLethylamine](ClO4)2 was prepared by a reported method with minor modifications21. Infrared spectra were measured on a Thermo Fisher Scientific Nicolet 6700 FT-IR spectrometer. Thermogravimetric analyses (TGA) were performed under N2 at a scan rate of 5 °C/min and under pure CO2 at a scan rate of 1 °C/min using a Q50 from TA instruments. XRPD data were collected using both a Bruker D2 PHASER automated diffractometer at 30 kV and 10 mA for Cu Kα (λ = 1.54050 Å), with a step size of 0.02 ° in 2θ and an ADSC Quantum-210 detector at 2D SMC with a silicon (111) double crystal monochromator (DCM) at the Pohang Accelerator Laboratory, Korea. Scanning electron microscope (SEM) images were taken using a Quanta 200 microscope (FEI) operating at 18 kV. The gas sorption data were collected by using a BELsorp-MAX. UV/Vis diffuse reflectance spectra were recorded on a Cary 5000 UV/Vis spectrophotometer. Nuclear magnetic resonance (NMR) spectra were recorded on a Varian VNMRS 600 spectrometer. Elemental analyses were conducted by UNIST Central Research Facilities centre (UCRF) in Ulsan National Institute of Science and Technology (UNIST).

Synthesis of MOFNH2-as, {[(NiLethylamine)(BPDC)]·3H2O}

[NiLethylamine](ClO4)2 (0.04 g, 0.07 mmol) and Na2BPDC (0.02 g, 0.07 mmol) were dissolved in N,N-diethylformamide (4 mL) and in a mixed solution of acetonitrile (MeCN) and H2O (MeCN:H2O = 2 mL:1 mL), respectively. The solution of Na2BPDC was diffused onto the former solution and powder was formed at the boundary of the layered solution prior to the formation of crystals. The mixed solution allowed to stand at room temperature for 1 day until the pale purple crystals were formed along with some powder. Only crystals were used for analyses. Yield: 22.7%. FT-IR (KBr): 3368 and 3293 cm−1 (NH), 3062 cm−1 (CH), 1587 cm−1 and 1379 cm−1 (COO−); UV-Vis (diffuse reflectance spectrum): λmax 517 nm (NiII d-d transition); Elemental analysis calcd., found for Ni1C26H46N8O7: C (48.69, 49.36), H (7.23, 7.10), N (17.47, 17.52).

Preparation of MOFNH2:crystal and MOFNH2:powder

The as-synthesized compounds, MOFNH2-as, were heated at 90 °C under vacuum for 7 h and then cooled to an ambient temperature and refilled with Ar (MOFNH2:crystal). To prepare the powder samples (MOFNH2:powder), MOFNH2-as was pulverized for 10 s using a sample grinder with a stainless steel vial and ball (ShakIR sample grinder, PIKE), which is usually used for preparation of infrared spectroscopy samples. The resultant powder was also activated at 90 °C for 7 h, yielding MOFNH2:powder.

Single-Crystal X-ray crystallography

Single-crystals of MOFNH2-as were coated with paratone-N oil because they lost their crystallinity upon exposure to the air. The diffraction data of MOFNH2-as were measured at 100 K using synchrotron employing a PLSII-2D SMC an ADSC Quantum-210 detector with a silicon (111) double crstal monochromator (DCM) at Pohang Accelerator Laboratory, Korea. The ADSC Q210 ADX program30 was used for both data collection and HKL3000sm (Ver. 703r)31 was used for cell refinement, reduction and absorption correction. The structures of MOFNH2-as were solved using direct methods with SHELX-XS (Ver. 2008) and refined by full-matricx least-squares calculation with SHELX-XL (Ver. 2008) program package32. An half of ligands, an half of Ni ions and one unligated water molecule were observed as an asymmetric unit. For the structure MOFNH2-as, the alkyl amine pendant group was restrained using ISOR during the least-squares refinement. All non-hydrogen atoms in whole structures were refined anisotropically and hydrogen atoms were assigned geometrically using a riding model. Refinement of the structure MOFNH2-as converged at a final R1 = 0.0709, wR2 = 0.2208 for 18729 reflections with I > 2σ (I); R1 = 0.0776, wR2 = 0.2294 for all reflections. The largest difference peak and hole were 0.959 and −0.543 e·Å−3, respectively. A summary of the crystals and some crystallographic data are given in Table S1 and S2. CCDC 1044896 contains the supplementary crystallographic data. The data can be obtained free of charge at www.ccdc.cam.ac.uk/conts/retrieving.html or from the Cambridge Crystallographic Data Centre, 12, Union Road, Cambridge CB2 EX, UK.

Additional Information

How to cite this article: Kim, Y. K. et al. Crystal-Size Effects on Carbon Dioxide Capture of a Covalently Alkylamine-Tethered Metal-Organic Framework Constructed by a One-Step Self-Assembly. Sci. Rep. 6, 19337; doi: 10.1038/srep19337 (2016).

References

Quadrelli, R. & Peterson, S. The energy–climate challenge: Recent trends in CO2 emissions from fuel combustion. Energy policy 35, 5938–5952 (2007).

Haszeldine, R. S. Carbon capture and storage: how green can black be? Science 325, 1647–1652 (2009).

Sumida, K. et al. Carbon dioxide capture in metal-organic frameworks. Chem. Rev. 112, 724–781 (2012).

Wang, J. et al. Recent advances in solid sorbents for CO2 capture and new development trends. Energy Environ. Sci. 7, 3478–3518 (2014).

Rochelle, G. T. Amine scrubbing for CO2 capture. Science 325, 1652–1654 (2009).

Notz, R., Tonnies, I., McCann, N., Scheffknecht, G. & Hasse, H. CO2 capture for fossil fuel-fired power plants. Chem. Eng. Technol. 34, 163–172 (2011).

Goeppert, A. et al. Carbon dioxide capture from the air using a polyamine based regenerable solid adsorbent. J. Am. Chem. Soc. 133, 20164–20167 (2011).

Chaikittisilp, W., Kim, H. J. & Jones, C. W. Mesoporous alumina-supported amines as potential steam-stable adsorbents for capturing CO2 from simulated flue gas and ambient air. Energy Fuels. 25, 5528–5537 (2011).

Gebald, C., Wurzbacher, J. A., Tingaut, P., Zimmermann, T. & Steinfeld, A. Amine-based nanofibrillated cellulose as adsorbent for CO2 capture from air. Environ. Sci. Technol. 45, 9101–9108 (2011).

Leal, O., Bolivar, C., Ovalles, C., Garcia, J. J. & Espidel, Y. R. Reversible adsorption carbon dioxide on amine surface-bonded silica gel. Inorg. Chim. Acta. 240, 183–189 (1995).

Harlick, P. J. E. & Sayari, A. Applications of pore-expanded mesoporous silica. 3. Triamine silane grafting for enhanced CO2 adsorption. Ind. Eng. Chem. Res. 45, 3248–3255 (2006).

Du, Y. et al. Carbon dioxide adsorbent based on rich amines loaded nano-silica. J. Colloid Interface Sci. 409, 123–128 (2013).

Hu, Y., Verdegaal, W. M., Yu, S. H. & Jiang, H. L. Alkylamine-tethered stable metal–organic framework for CO2 capture from flue gas. ChemSusChem 7, 734–737 (2014).

Lee, W. R. et al. Diamine-functionalized metal–organic framework:exceptionally high CO2 capacities from ambient air and flue gas, ultrafast CO2 uptake rate and adsorption mechanism. Energy Environ. Sci. 7, 744–751 (2014).

McDonald, T. M. et al. Capture of carbon dioxide from air and flue gas in the alkylamine-appended metal−organic framework mmen-Mg2(dobpdc). J. Am. Chem. Soc. 134, 7056–7065 (2012).

Lin, Y., Yan, Q., Kong, C. & Chen, L. Polyethyleneimine incorporated metal-organic frameworks adsorbent for highly selective CO2 capture. Sci. Rep. 3, 1859–1865 (2013).

Ko, N. et al. A significant enhancement of water vapour uptake at low pressure by amine-functionalization of UiO-67. Dalton Trans. 44, 2047–2051 (2015).

Couck, S. et al. An amine-functionalized MIL-53 metal-organic framework with large separation power for CO2 and CH4 . J. Am. Chem. Soc. 131, 6326–6327 (2009).

Lu, W. et al. Polyamine-tethered porous polymer networks for carbon dioxide capture from flue gas. Angew. Chem. Int. Ed. 51, 7480–7484 (2012).

Brune, S. N. & Bobbitt, D. R. Role of electron-donating/withdrawing character, pH and stoichiometry on the chemiluminescent reaction of Tris (2,2′-bipyridyl) ruthenium (III) with Amino Acids. Anal. Chem. 64, 166–170 (1992).

Kang, S. G., Ryu, K., Jung, S. K. & Kim, J. Template synthesis, crystal structure and solution behavior of a hexaaza macrocyclic nickel (II) complex containing two N-aminoethyl pendant arms. Inorganica Chimica Acta. 293, 140–146 (1999).

Moon, H. R., Kim, J. H. & Suh, M. P. Redox-active porous metal-organic framework producing silver nanoparticles from AgI ions at room temperature. Angew. Chem. Int. Ed. 44, 1261–1265 (2005).

Sluis, P. V. D. & Spek, A. L. BYPASS: an effective method for the refinement of crystal structures containing disordered solvent regions. Acta Cryst. A46, 194–201 (1990).

Granite, E. J. & Pennline, H. W. Photochemical removal of mercury from flue gas. Ind. Eng. Chem. Res. 41, 5470–5476 (2012).

Heydari-Gorji, A., Yang, Y. & Sayari, A. Effect of the pore length on CO2 adsorption over amine-modified mesoporous silicas. Energy Fuels 25, 4206–4210 (2011).

Bacsik, Z. et al. Mechanisms and kinetics for sorption of CO2 on bicontinuous mesoporous silica modified with n-propylamine. Langmuir 27, 11118–11128 (2011).

Danon, A. Stair, P. C. & Weitz, E. FTIR Study of CO2 Adsorption on amine-grafted SBA-15: elucidation of adsorbed species. J. Phys. Chem. C 115, 11540–11549 (2011).

Ballard, M., Bown, M., James, S. & Yang, Q. NMR studies of mixed amines. Energy Procedia 4, 291–298 (2011).

Kortunov, P. V., Siskin, M., Baugh, L. S. & Calabro, D. C. In situ nuclear magnetic resonance mechanistic studies of carbon dioxide reactions with liquid amines in non-aqueous systems: evidence for the formation of carbamic acids and zwitterionic species. Energy Fuels 29, 5940–5966 (2015).

Arvai, A. J. & Nielsen, C. ADSC Quantum-210 ADX Program ; Area Detector System Corporation: Poway, CA, USA (1983).

Z. Otwinowski, W. Minor and C. W. Carter Jr, Sweet (Eds.), R. M. Methods in Enzymology 276 Part A; Academic Press: New York, 307 (1997).

Sheldrick, G. M. SHELXTL-PLUS: Crystal Structure Analysis Package ; Bruker Analytical X-Ray: Madison, WI, USA (1997).

Acknowledgements

We acknowledge financial support from the Korea CCS R&D Centre (KCRC) grant funded by the Korea government (Ministry of Science, ICT & Future Planning) (NRF-2014M1A8A1049255) and Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology (NRF-2013R1A1A3010846).

Author information

Authors and Affiliations

Contributions

Y.K.K., S.-m.H. and H.R.M. designed the experiments. Y.K.K., S.-m.H. and T.K.K. conducted experiments and analyzed data. J.H.L. performed the NMR analysis. D.M. supported the synchrotron experiments. H.R.M. wrote the manuscript. All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Kim, Y., Hyun, Sm., Lee, J. et al. Crystal-Size Effects on Carbon Dioxide Capture of a Covalently Alkylamine-Tethered Metal-Organic Framework Constructed by a One-Step Self-Assembly. Sci Rep 6, 19337 (2016). https://doi.org/10.1038/srep19337

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep19337

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.