Abstract

LiNi0.5Mn1.5O4 nanorods wrapped with graphene nanosheets have been prepared and investigated as high energy and high power cathode material for lithium-ion batteries. The structural characterization by X-ray diffraction, Raman spectroscopy and Fourier transform infrared spectroscopy indicates the LiNi0.5Mn1.5O4 nanorods prepared from β-MnO2 nanowires have ordered spinel structure with P4332 space group. The morphological characterization by scanning electron microscopy and transmission electron microscopy reveals that the LiNi0.5Mn1.5O4 nanorods of 100–200 nm in diameter are well dispersed and wrapped in the graphene nanosheets for the composite. Benefiting from the highly conductive matrix provided by graphene nanosheets and one-dimensional nanostructure of the ordered spinel, the composite electrode exhibits superior rate capability and cycling stability. As a result, the LiNi0.5Mn1.5O4-graphene composite electrode delivers reversible capacities of 127.6 and 80.8 mAh g−1 at 0.1 and 10 C, respectively and shows 94% capacity retention after 200 cycles at 1 C, greatly outperforming the bare LiNi0.5Mn1.5O4 nanorod cathode. The outstanding performance of the LiNi0.5Mn1.5O4-graphene composite makes it promising as cathode material for developing high energy and high power lithium-ion batteries.

Similar content being viewed by others

Introduction

Renewable and sustainable energy resources, such as solar, wind and tide, attract more and more attention because of the shortage of fossil fuels and their associated environmental problems. However, these renewable energy resources are only intermittently available and require energy storage systems to improve the power reliability and quality1,2. Lithium-ion batteries with high energy density, light weight, long cycle life and environmental friendliness have recently shown potential applications in the areas of electric vehicles and stationary energy storage for smart grids3. However, higher requirements are raised by these applications and further improvements in terms of energy and power densities, safety and lifetime are imperative for lithium-ion batteries4.

To further increase the energy density for lithium-ion batteries, various positive electrode materials have been widely investigated to obtain either high working voltage or large capacity. Among them, LiNi0.5Mn1.5O4 spinel is particularly attractive due to its high average discharge voltage of about 4.7 V (vs. Li/Li+) with a theoretical capacity of about 148 mAh g−15,6. LiNi0.5Mn1.5O4 can exist in two different crystallographic structures. The disordered LiNi0.5Mn1.5O4-δ has the normal face-centered spinel structure with Fd-3m symmetry, while Mn4+ and Ni2+ ions order in stoichiometric LiNi0.5Mn1.5O4 resulting in the P4332 symmetry7,8. The disordered spinel shows higher electronic conductivity due to the presence of Mn3+/Mn4+ redox couple and Ni/Mn disordering9. However, the nonstoichiometry in disordered spinel often induces impurities such as NiO and LixNiyO and the 4 V (vs. Li/Li+) Mn3+/Mn4+ redox couple, thus reducing the specific capacity and energy10. It is still a challenge to achieve both high energy and high power densities for the ordered spinel due to its poor electronic conductivity. Moreover, the high working voltage at about 4.7 V (vs. Li/Li+) induces side reactions at the electrode/electrolyte interface, resulting in continuous capacity fading during the cycling11.

To circumvent the drawbacks of the high voltage spinels, two strategies are often employed to improve the electrochemical performance. One approach is to construct nanostructures for the spinel, which can drastically shorten the transport distance for both electrons and lithium ions, resulting in greatly improved rate capability12,13,14,15. However, the increased surface area associated with nanostructuring will aggravate the side reactions at high voltage and deteriorate the capacity fading during cycling. Another approach people often used is to modify the spinel surface by coating a thin protective layer, which can greatly improve the interface stability with enhanced cycling performance16,17,18,19,20. However, the coating materials, most of which are metal oxides and metal fluorides, only function as protective layers for the spinel without improvement in electrical conductivity. Therefore, new strategies that can combine the advantages of the above mentioned two approaches need to be developed to further improve the electrochemical performance of the high voltage spinels.

Herein, we developed a facile method to prepare graphene nanosheets wrapped ordered LiNi0.5Mn1.5O4 nanorods as high energy and high power cathode material for lithium-ion batteries (Fig. 1). In the hybrid electrode design, the one-dimensional nanostructure of LiNi0.5Mn1.5O4 enables fast lithium ion transport while the graphene wrapping suppresses the side reactions at high voltage and further improves the electron transfer. It has been demonstrated that the graphene or grahene oxide nanosheets incorporation can greatly improve the rate capability and cycling stability for the disordered spinels21,22. Consequently, the ordered LiNi0.5Mn1.5O4 nanorods-graphene composite cathode exhibited greatly improved cycling performance and rate performance compared to the bare ordered LiNi0.5Mn1.5O4 nanorods. The promising results indicate the great potential of developing high energy and high power lithium-ion batteries by utilizing the graphene nanosheets wrapped ordered LiNi0.5Mn1.5O4 nanorods.

Results

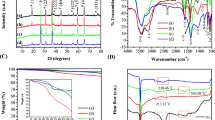

The hydrothermally prepared β-MnO2 nanowires were used as the template and the XRD pattern shows no trace of impurity (Fig. S1, Supporting Information). Figure 2 shows the XRD patterns of the pristine graphene nanosheets, the as-synthesized LiNi0.5Mn1.5O4 nanorods and the LiNi0.5Mn1.5O4-graphene composite. The XRD pattern of the graphene shows a small hump at about 26°, which can be attributed to the (002) reflection of graphite. The as-synthesized LiNi0.5Mn1.5O4 nanorods and the LiNi0.5Mn1.5O4-graphene composite show similar XRD patterns, which can be indexed to the cubic spinel structure with space group P4332 (JCPDS No. 80-2184). No impurity peaks from NiO or LixNiyO can be detected, indicating the existence of pure spinel phase. Rietveld refinement gives a lattice parameter of a = 8.169 Å, which agrees well with reported value for the ordered LiNi0.5Mn1.5O412,13. No diffraction peaks of graphene can be observed from the XRD pattern of the LiNi0.5Mn1.5O4-graphene composite, which is probably due to the strong diffraction peaks from the highly crystalline LiNi0.5Mn1.5O4 and the nanoscale size feature of low content graphene. However, the superstructure peaks, which are characteristics of Ni and Mn ordering, cannot be resolved from the XRD patterns of the spinels because of their low intensities23. Therefore, further structural investigation by Raman and FTIR are required to confirm the P4332 symmetry of the synthesized spinel in this work.

Raman spectra of the pristine graphene nanosheets, the bare LiNi0.5Mn1.5O4 nanorods and the LiNi0.5Mn1.5O4-graphene composite are shown in Fig. 3a. The Raman spectra of the bare LiNi0.5Mn1.5O4 nanorods and the LiNi0.5Mn1.5O4-graphene composite show similar features in the frequency range of 300–1000 cm−1, which are in good agreement with published works on ordered LiNi0.5Mn1.5O4 spinel23,24. The Raman spectrum of the LiNi0.5Mn1.5O4 nanorods in the frequency range between 300 to 700 cm−1 was enlarged and shown in Fig. 3b, revealing six Raman bands. The strong band around 638 cm−1 is assigned to the symmetric Mn-O stretching mode of MnO6 octahedral (A1g), while the two bands at 407 and 498 cm−1 are associated with the Ni2+-O stretching mode in the structure25. The peak near 580–620 cm−1 is considered as T2g(3) of the spinel compound and the split of T2g(3) is the strong evidence of the ordered spinel due to its low symmetry (P4332). In the frequency range between 1000 and 3700 cm−1, the Raman spectrum of the LiNi0.5Mn1.5O4-graphene composite show similar Raman features as the pristine graphene nanosheets, revealing the characteristic D band, G band and 2D band of graphene.

To further confirm the structural symmetry of the spinel in the present work, FTIR analysis was carried out on different spinel powder samples. For comparison, disordered LiNi0.5Mn1.5O4 powders were prepared by a solid state synthesis according to the literature26. Figure 4a,b show the FTIR spectra of the as-prepared LiNi0.5Mn1.5O4 nanorods and the LiNi0.5Mn1.5O4 powders prepared by solid state synthesis, respectively. There are eight distinctive bands for the as-prepared LiNi0.5Mn1.5O4 nanorods and the observed wavenumbers match well with those of ordered spinel in literature8,23. By contrast, some bands are not well resolved for the disordered LiNi0.5Mn1.5O4 because of lacking of Ni/Mn ordering. Another evidence to distinguish the two structures is the change of the intensity ratio of the two bands at 622 and 584 cm−1. In specific, the 584 cm−1 Ni-O band increases in intensity compared to the 622 cm−1 Mn-O band with increasing level of ordering8. Agreeing well with Raman analysis, the FTIR analysis confirms that the as-prepared LiNi0.5Mn1.5O4 nanorods have ordered spinel structure with P4332 symmetry.

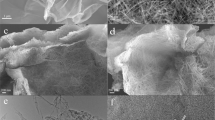

The typical morphologies of β-MnO2 nanowires, LiNi0.5Mn1.5O4 nanorods, graphene nanosheets and LiNi0.5Mn1.5O4-graphene composite are shown in Fig. 5. As shown in Fig. 5a, the β-MnO2 nanowires are about 50–100 nm in diameter and 2-3 μm in length. Figure 5b reveals that the as-synthesized LiNi0.5Mn1.5O4 nanorods well preserve the one-dimensional morphology of the β-MnO2 nanowires. However, the LiNi0.5Mn1.5O4 nanorods have larger diameters of about 100–200 nm and shorter lengths of about 0.5–1 μm, which are probably caused by the phase transition and breaking of β-MnO2 nanowires due to the strain associated with the volume expansion. As shown in Fig. 5c, the prepared graphene nanosheets are corrugated and transparent, well resembling the two-dimensional morphology. LiNi0.5Mn1.5O4-graphene composite shows a laminated morphology (Fig. 5d) with LiNi0.5Mn1.5O4 nanorods well dispersed on the graphene nanosheets without severe aggregation.

Figure 6a,b show the TEM images of the LiNi0.5Mn1.5O4 nanorods with low and high magnifications, respectively, revealing the single crystalline feature of the nanorods. The interplanar spacing determined by the HRTEM image in Fig. 6c is about 0.48 nm, which is consistent with the (111) planes of LiNi0.5Mn1.5O4 spinels. For the LiNi0.5Mn1.5O4-graphene composite, Fig. 6d,e clearly reveal that the LiNi0.5Mn1.5O4 nanorods are well distributed and wrapped in the transparent graphene nanosheets. The HRTEM image in Fig. 6f shows a clear interface between one LiNi0.5Mn1.5O4 nanorod and one graphene sheet, indicating good adhesion and close contact between the two components in the composite. The interplanar spacing of about 0.48 nm shown in Fig. 6f is also attributed to the (111) planes of the spinel. The uniform LiNi0.5Mn1.5O4-graphene heterostructure can be attributed to the facile chemical mixing method. Initially, the mortar grinding can effectively separate the LiNi0.5Mn1.5O4 nanorods from aggregation. Afterward, the ultrasonication and the continuous stirring facilitate the uniform nanorods distribution in the graphene matrix, resulting the graphene wrapped LiNi0.5Mn1.5O4 nanorods. The graphene content was determined to be about 4.7 wt% by TGA measurement (Fig. S2, Supporting Information).

To evaluate the electrochemical properties of the LiNi0.5Mn1.5O4-graphene composite, half cells were assembled using lithium foil as both counter and reference electrodes. Fig. 7 compares the typical CV curves of the bare LiNi0.5Mn1.5O4 nanorod electrode and the LiNi0.5Mn1.5O4-graphene composite electrode between 3.5 and 5 V (vs. Li/Li+) at a scan rate of 0.05 mV s−1. For both electrodes, a pair of strong redox peaks at about 4.7 V (vs. Li/Li+) can be clearly observed, which can be attributed to the Ni2+/Ni4+ redox reactions8,27. The 4 V redox peaks, corresponding to the Mn3+/Mn4+ redox couple, are almost negligible in the CV curves for the bare LiNi0.5Mn1.5O4 nanorod electrode and the LiNi0.5Mn1.5O4-graphene composite electrode, indicating their nearly perfect stoichiometry. By contrast, apart from the obvious 4 V (vs. Li/Li+) redox peaks, the disordered LiNi0.5Mn1.5O4 will show clear two pairs of redox peaks at about 4.7 V (vs. Li/Li+) in CV28. Previous studies indicate that the redox peak splitting at about 4.7 V (vs. Li/Li+) for the high voltage LixNi0.5Mn1.5O4 (0 < x < 1) is probably due to two separate redox couples of Ni2+/Ni3+ and Ni3+/Ni4+ and/or Li/vacancy ordering at x = 0.529. However, such peak splitting is not obvious for the ordered spinel as only one pair of redox peaks are observed in the typical CV curve. As discussed in our previous work on disordered LiNi0.5Mn1.5O4-δ thin films30, the ordering arrangement of Ni and Mn in the ordered spinel is probably not commensurate with the preferred Li/vacancy ordering at x = 0.5 so that the Ni/Mn ordering suppresses Li/vacancy ordering and redox peak splitting at about 4.7 V (vs. Li/Li+). In comparison with the bare LiNi0.5Mn1.5O4 nanorod electrode, the LiNi0.5Mn1.5O4-graphene composite electrode shows much smaller peak separation between the cationic peak and anodic peak in the CV curve, indicating the electrode polarization can be greatly reduced by incorporating the graphene nanosheets into LiNi0.5Mn1.5O4 nanorods.

Figure 8a,b show the charge/discharge curves of the bare LiNi0.5Mn1.5O4 nanorod and the LiNi0.5Mn1.5O4-graphene composite electrodes, respectively, at the 1st, 2nd, 50th, 100th and 200th cycles at a current rate of 0.1 C between 3.0 and 4.9 V (vs. Li/Li+). Agreeing well with the CV results, the charge/discharge curves of the two electrodes clearly show only one flat voltage plateau around 4.70 V (vs. Li/Li+) due to the Ni2+/Ni4+ redox couple, which is the characteristic electrochemical behavior of the ordered spinel8. In comparison, the charge/discharge curves of the LiNi0.5Mn1.5O4-graphene composite electrode show much smaller voltage difference between charge and discharge voltage plateaus, indicating smaller polarization and internal resistance of the spinel electrode with graphene incorporation. The first charge and discharge capacities of the LiNi0.5Mn1.5O4-graphene composite electrode are 127.6 and 122.4 mAh g−1, with a coulombic efficiency of about 96%. By contrast, the first charge and discharge capacities of the bare LiNi0.5Mn1.5O4 nanorod electrode are 127.3 and 119.7 mAh g−1, respectively, with a coulombic efficiency of about 94%. It is clear that the LiNi0.5Mn1.5O4-graphene composite electrode can deliver a larger reversible capacity and higher coulombic efficiency compared to the bare LiNi0.5Mn1.5O4 nanorod electrode. The larger reversible capacity of the LiNi0.5Mn1.5O4-graphene composite electrode can be attributed to the smaller polarization of the electrode, which favors fast charge transport and increases the utilization of the active material. The initial irreversible capacity loss is partially contributed by the solid electrolyte interface (SEI) layer formation due to the electrolyte decomposition at high voltage31. The wrapping with graphene could greatly suppress the SEI layer formation at high voltage, thus improving the initial coulombic efficiency of the composite electrode. Figure 8c compares the cycle performance of the two electrodes, revealing greatly improved cycling stability for the LiNi0.5Mn1.5O4-graphene composite electrode. After 200 cycles at 0.1 C rate, LiNi0.5Mn1.5O4-graphene composite electrode can still deliver a reversible capacity of about 115 mAh g−1, retaining 94% of its initial reversible capacity. In comparison, the bare LiNi0.5Mn1.5O4 nanorod electrode only retained 82% of its initial reversible capacity. The capacity fading of the high voltage spinel during cycling is mainly contributed by the structural deterioration induced by Mn3+ ion dissolution and internal resistance increase induced by the side reactions at the electrode surface at high voltage32,33. For the ordered spinel, Mn3+ ion dissolution may not be the major reason that causes the capacity fading since there are negligible Mn3+ ions in ordered spinel due to its nearly perfect stoichiometry. The side reactions, including SEI layer formation, could be more detrimental to the cycle performance because the increased polarization induced by the increasing resistance will lead to less reversible capacity. As shown in Fig. 8a, the voltage difference between charge and discharge keeps increasing with the cycling test, revealing a obvious cell polarization growth for the bare LiNi0.5Mn1.5O4 nanorod electrode. By contrast, the polarization growth for the LiNi0.5Mn1.5O4-graphene composite electrode is greatly mitigated, which can be attributed to the graphene protection, suppressing the side reactions at the electrode surface. Figure 8d compares the rate capability of the two electrodes by plotting the specific capacity as a function of cycle number at different current rates. The typical charge/discharge curves of bare LiNi0.5Mn1.5O4 nanorod electrode and the LiNi0.5Mn1.5O4-graphene composite electrode at different current rates are shown in Fig. S3 (Supporting Information). It is obvious that the LiNi0.5Mn1.5O4-graphene composite electrode possesses much better rate capability as it can retain more reversible capacity as the discharge rate increases. Even at 10 C rate, the LiNi0.5Mn1.5O4-graphene composite electrode can still deliver a reversible capacity of about 80.8 mAh g−1, which is much larger than that of the bare LiNi0.5Mn1.5O4 nanorod electrode (49.2 mAh g−1). When the current rate was set back to 0.1 C, the charge and discharge capacities of LiNi0.5Mn1.5O4-graphene composite electrode recover to the original values, indicating that large current density and rapid lithiation/delithiation did not cause any permanent damage to the crystal structure. However, after the bare LiNi0.5Mn1.5O4 nanorod electrode experienced the high current rate like 10 C, its reversible capacity didn't fully recover to the initial value when the current rate was changed back to 0.1 C. The superior rate performance of the LiNi0.5Mn1.5O4-graphene composite electrode can be attributed to the improved electron transport provided by the graphene conductive matrix. As confirmed by the EIS measurements, the LiNi0.5Mn1.5O4-graphene composite electrode shows much smaller charge transfer resistance compared to the bare LiNi0.5Mn1.5O4 nanorod electrode, indicating the graphene wrapping is beneficial to fast electrode kinetics (Fig. S4, Supporting Information).

(a) Charge/discharge curves of the bare LiNi0.5Mn1.5O4 nanorod electrode at various cycle numbers at 0.1 C rate. (b) Charge/discharge curves of the LiNi0.5Mn1.5O4-graphene composite electrode at various cycle numbers at 0.1 C rate. (c) Comparison of cycle performance between the bare LiNi0.5Mn1.5O4 nanorod electrode and the LiNi0.5Mn1.5O4-graphene composite electrode. (d) Comparison of rate capability between the bare LiNi0.5Mn1.5O4 nanorod electrode and the LiNi0.5Mn1.5O4-graphene composite electrode.

Discussion

Although the conductivity of the ordered LiNi0.5Mn1.5O4 is relatively low, the ordered LiNi0.5Mn1.5O4 nanorod-graphene composite developed in this work exhibited excellent rate capacity as well as good cycling stability. The rate performance of the present ordered LiNi0.5Mn1.5O4-graphene composite is even better than those of the previously reported disordered LiNi0.5Mn1.5O4-grahene composite and disordered LiNi0.5Mn1.5O4-grahene oxide composite21,22, which can be attributed to its unique hybrid electrode design. First, the one-dimensional nanostructure of ordered LiNi0.5Mn1.5O4 provides short solid diffusion length for lithium ions. This, along with fast electron transport supplied by the highly conductive graphene matrix, endows the hybrid electrode with fast lithiation and delithiation capability. Second, the ordered LiNi0.5Mn1.5O4 nanorods with P4332 symmetry contain negligible Mn3+ ions, which minimizes Mn disproportionative dissolution and Jahn-Teller structural distortion, resulting in good structural stability during cycling. Last, the graphene wrapping effectively modify the surface of LiNi0.5Mn1.5O4, which suppresses the side reactions at the electrode/electrolyte interface, resulting in a slow cell polarization growth and excellent cycling stability. Unlike disordered LiNi0.5Mn1.5O4, the ordered LiNi0.5Mn1.5O4 do not have the 4 V voltage plateau, thus making the LiNi0.5Mn1.5O4-grpahene composite more promising for application in high energy and high power lithium-ion batteries.

In summary, a smart hybrid cathode material featuring graphene nanosheets wrapped one-dimensional ordered LiNi0.5Mn1.5O4 nanorods has been developed by a facile method combining oxide template synthesis and chemical mixing. The structural characterization confirmed the as-prepared LiNi0.5Mn1.5O4 nanorods possess a ordered spinel structure with P4332 symmetry. The LiNi0.5Mn1.5O4-graphene composite electrode exhibited excellent rate capability, delivering reversible capacities of 122.4 and 81.2 mAh g−1 at 0.1 and 10 C, respectively. In addition to the fast charge and discharge capability, the LiNi0.5Mn1.5O4-graphene composite electrode also revealed promising cycling stability, with 94% capacity retained after 200 cycles. In comparison with the bare LiNi0.5Mn1.5O4 nanorod electrode, the composite electrode showed greatly improved electrochemical performance, which can be ascribed to the smart hybrid electrode design, enabling both fast charge transport and good interface stability. The superior electrochemical performance and the facile synthesis procedure make the present LiNi0.5Mn1.5O4-graphene composite promising as cathode for high energy lithium-ion batteries.

Methods

Preparation β-MnO2 nanowires and ordered LiNi0.5Mn1.5O4 nanorods

β-MnO2 nanowires were prepared by a modified hydrothermal method according to the literature34. In a typical synthesis, 10 g KNO3 were added into a solution containing 20 ml 50 wt% MnNO3 and 20 ml deionized water to get a supersaturated system. Then the well mixed solution was transferred into a 50 mL Teflon-lined stainless steel autoclave and heated at 140 °C for 14 h. After cooling down to room temperature, the precipitated product was filtered and washed sequentially with deionized water and ethanol for three times. The obtained β-MnO2 nanowires were then dried at 80 °C for 6 h in air for further usage. The ordered spinel LiNi0.5Mn1.5O4 nanorods were then synthesized by using the β-MnO2 nanowires as the template. Briefly, stoichiometric amounts of Ni(CH3COO)2, LiOH·H2O and β-MnO2 nanowires were homogeneously dispersed in high purity ethanol and stirred for 24 h. The obtained precursor was dried at 60 °C for 3 h and ground in a mortar for 1 h. After that, the mixture was first preheated at 300 °C for 5 h and then calcined at 700 °C for 10 h in air to obtain the ordered LiNi0.5Mn1.5O4 nanorods.

Preparation of LiNi0.5Mn1.5O4-graphene composite

The grapnehe nanosheets were prepared from graphite powder in a two-step process, involving the oxidation and/or exfoliation of graphite to graphite oxide by Hummer's method and chemical reduction of graphite oxide to graphene according to literature35. To prepare the graphene wrapped LiNi0.5Mn1.5O4 nanorods, 0.05 g graphene and 1 g LiNi0.5Mn1.5O4 nanorods were first mixed in a mortar for 0.5 h by grinding and then dispersed in 30 ml ethanol by ultrasonication. After that, the dispersion was vigorously stirred at 50 °C for 8 h to achieve a uniform dispersion of LiNi0.5Mn1.5O4 nanorods in the graphene matrix. Finally, the obtained mixture was dried in an oven at 80 °C overnight to obtain LiNi0.5Mn1.5O4-graphene composite.

Materials Characterization

Structural features of the as-prepared LiNi0.5Mn1.5O4 nanorods and the LiNi0.5Mn1.5O4-graphene composite were characterized with X-ray diffraction (XRD), Raman spectroscopy and Fourier transform infrared (FTIR) spectroscopy. The XRD patterns were taken by a Shimadzu XRD-6000 X-ray diffractormeter with Cu Kα radiation between 10 and 80°. Raman spectra of different samples were acquired using a Renishaw in Via Reflex Raman microprobe with a 532 nm wavelength incident laser. FTIR spectra of the samples were collected from 800 to 400 cm−1 using a Nicolet-670 FTIR spectrometer. To determine the graphene content in the composite, thermogravimetric analysis (TGA) was carried out in the air at a heating rate of 10 °C min−1 from 30 to 700 °C using a DTG-60H Shimadzu thermal analyzer. The morphology features of the as-prepared samples were characterized with field-emission scanning electron microscopy (FESEM, JSM-6700F 15 kV), transmission electron microscopy (TEM) and high-resolution transmission electron microscopy (HRTEM, JEOL 2010 200 kV).

Electrochemical Measurements

To investigate the electrochemical properties, half cells using lithium foil as both counter and reference electrodes were assembled with Lab-made Swagelok cells in an Ar-filled glove box. To prepare the working electrodes, active cathode materials (LiNi0.5Mn1.5O4 nanorods and LiNi0.5Mn1.5O4-graphene composite), acetylene black (Super-P) and polyvinylidene fluoride (PVDF) with a weight ratio of 8:1:1 were mixed with N-methyl-2-pyrrolidinone (NMP) to form a slurry. The obtained slurry was coated onto the Al foils and dried at 120 °C for 2 h to remove the solvent. The electrodes were then pressed and cut into small disks (10 mm in diameter). The small disks were further dried at 80 °C in a vacuum oven for 12 h before battery tests. 1 M LiPF6 in ethylene carbonate and diethyl carbonate (EC/DEC, v/v = 1:1) solution was used as the electrolyte and Celgard 2400 membrane was used as the separator. The galvanostatic charge/discharge measurements were carried out on a LAND CT2001A electrochemical workstation with a voltage window between 3.0 and 4.9 V (vs. Li+/Li) at different current densities (1 C is 148 mAh g−1 for LiNi0.5Mn1.5O4) at room temperature. Cyclic voltammogram (CV) and electrochemical impedance spectroscopy (EIS) measurements were performed using a CHI660D electrochemical workstation. CVs were measured between 3.5 and 5.0 V (vs. Li/Li+) at a scan rate of 0.05 mV s−1. EIS measurements were carried out in the frequency range between 100 kHz to 0.01 Hz with an AC amplitude of 5 mV at an open circuit potential.

Additional Information

How to cite this article: Tang, X. et al. Graphene wrapped ordered LiNi0.5Mn1.5O4 nanorods as promising cathode material for lithium-ion batteries. Sci. Rep. 5, 11958; doi: 10.1038/srep11958 (2015).

References

Reddy, M. V., Subba Rao, G. V. & Chowdari, B. V. R. Metal Oxides and Oxysalts as anode materials for Li ion batteries. Chem. Rev. 113, 5364–5457 (2013).

Cheng, F. Y., Liang, J., Tao, Z. L. & Chen, J. Functional materials for rechargeable batteries. Adv. Mater. 23, 1695–1715 (2011).

Xu, B., Qian, D., Wang, Z. Y. & Meng, Y. S. Recent progress in cathode materials research for advanced lithium ion batteries. Mater. Sci. Eng. R 73, 51–65 (2012).

Kim, H. et al. Aqueous rechargeable Li and Na batteries. Chem. Rev. 114, 11788–11827 (2014).

Wang, G. et al. Submicron lithium nickel manganese oxide spinel with long cycling stability and high rate performance prepared by a facile route. J. Power Sources 265, 118–124 (2014).

Wang, H. L., Tan, T. A., Yang, P., Lai, M. O. & Lu, L. High-rate performances of the Ru-doped spinel LiNi0.5Mn1.5O4: effects of doping and particle size. J. Phys. Chem. C 115, 6102–6110 (2011).

Ariyoshi, K., Iwakoshi, Y., Nakayama, N. & Ohzuku, T. Topotactic two-phase reaction of Li[Ni1/2Mn3/2]O4 (P4332) in nonaqueous lithium cells. J. Electrochem. Soc. 151, A296–A303 (2004).

Kunduraci, M. & Amatucci, G. G. Synthesis and characterization of nanostructured 4.7 V LixMn1.5Ni0.5O4 spinels for high-power lithium-ion batteries. J. Electrochem. Soc. 153, A1345–A1352 (2006).

Lee, H. W., Muralidharan, P., Mari, C. M., Ruffo, R. & Kim, D. K. Facile synthesis and electrochemical performance of ordered LiNi0.5Mn1.5O4 nanorods as a high power positive electrode for rechargeable Li-ion batteries. J. Power Sources 196, 10712–10716 (2011).

Xia, H., Tang, S. B., Lu, L., Meng, Y. S. & Ceder, G. The influence of preparation conditions on electrochemical properties of LiNi0.5Mn1.5O4 thin film electrodes by PLD. Electrochim. Acta 52, 2822–2828 (2007).

Song, J. et al. Role of oxygen vacancies on the performance of Li[Ni0.5-xMn1.5+x]O4 (x = 0, 0.05 and 0.08) spinel cathodes for lithium-ion batteries. Chem. Mater. 24, 3101–3109 (2012).

Yang, J., Zhang, X., Zhu, Z., Cheng, F. & Chen, J. Ordered spinel LiNi0.5Mn1.5O4 nanorods for high-rate lithium-ion batteries. J. Electroanaly. Chem. 688, 113–117 (2013).

Zhang, X., Cheng, F., Yang, J. & Chen, J. LiNi0.5Mn1.5O4 porous nanorods as high-rate and long-life cathodes for Li-ion batteries. Nano Lett. 13, 2822–2825 (2013).

Chen, Z. et al. Surface-oriented and nanoflake-stacked LiNi0.5Mn1.5O4 spinel for high-rate and long-cycle-life lithum ion batteries. J. Mater. Chem. 22, 17768–17772 (2012).

Ding, Y. L., Goh, B. M., Zhang, H., Loh, K. P. & Lu, L. Single-crystalline nanotubes of spinel lithium nickel manganese oxide with lithium titanate anode for high-rate lithium ion batteries. J. Power Sources 236, 1–9 (2013).

Zhou, L., Zhao, D. Y. & Lou, X. W. LiNi0.5Mn1.5O4 hollow structures as high-performance cathodes for lithium-ion batteries. Angew. Chem. Inter. Ed. 51, 239–241 (2012).

Gao, X. W. et al. Improving the electrochemical performance of the LiNi0.5Mn1.5O4 sinel by polypyrrole coating as a cathode material for the lithium-ion battery. J. Mater. Chem. A 3, 404–411 (2015).

Konishi, H. et al. Effect of surface Li3PO4 coating on LiNi0.5Mn1.5O4 epitaxial thin film electrodes synthesized by pulsed laser deposition. J. Power Sources 269, 293–298 (2014).

Kim, K., Kim, Y., Oh, E. S. & Shin, H. C. The role of fluoride in protecting LiNi0.5Mn1.5O4 electrodes against high temperature degradation. Electrochim. Acta 114, 387–393 (2013).

Deng, H. F. et al. Highly enhanced lithium storage capability of LiNi0.5Mn1.5O4 by coating with Li2TiO3 for Li-ion batteries. J. Mater. Chem. A 2, 18256–18262 (2014).

Richard Prabakar, S. J., Hwang, Y. H., Lee, B., Sohn, K. S. & Pyo, M. Graphene-sandwiched LiNi0.5Mn1.5O4 cathode composites for enhanced high voltage performance in Li ion batteries. J. Electrochem. Soc. 160, A832–A837 (2013).

Fang, X., Ge, M., Rong, J. & Zhou, C. Graphene-oxide-coated LiNi0.5Mn1.5O4 as high voltage cathode for lithium ion batteries with high energy density and long cycle life, J. Mater. Chem. A 1, 4083–4088 (2013).

Wang, L., Li, H., Huang, X. & Baudrin, E. A comparative study of Fd-3m and P4332 "LiNi0.5Mn1.5O4". Solid State Ionics 193, 32–38 (2011).

Oh, S. H. et al. Structural and electrochemical investigations on the LiNi0.5-xMn1.5-yMx+yO4 (M = Cr, Al, Zr) compound for 5 V cathode material. J. Alloys Comp. 469, 244–250 (2009).

Amdouni, N., Zaghib, K., Gendron, F., Mauger, A. & Julien, C. M. Structure and insertion properties of disordered and ordered LiNi0.5Mn1.5O4 spinels prepared by wet chemistry. Ionics 12, 117–126 (2006).

Wang, H., Xia, H., Lai, M. O. & Lu, L. Enhancements of rate capability and cyclic performance of spinel LiNi0.5Mn1.5O4 by trace Ru-doping. Electrochem. Commun. 11, 1539–1542 (2009).

Kunduraci, M. & Amatucci, G. G. Effect of oxygen non-stoichiometry and temperature on cation ordering in LiMn2-xNixO4 (0.50 > x > 0.36) spinels. J. Power Sources 165, 359–367 (2007).

Xia, H., Tang, S. B., Lu, L., Meng, Y. S. & Ceder, G. The influence of preparation conditions on electrochemical properties of LiNi0.5Mn1.5O4 thin film electrodes by PLD. Electrochim. Acta 52, 2822–2828 (2007).

Van der Ven, A., Marianetti, C., Morgan, D. & Ceder, G. Phase transformations and volume changes in spinel LixMn2O4 . Solid State Ionics 135, 21–32 (2000).

Xia, H., Meng, Y. S., Lu, L. & Ceder, G. Electrochemical properties of nonstoichiometric LiNi0.5Mn1.5O4-δ thin-film electrodes prepared by pulsed laser deposition. J. Electrochem. Soc. 154, A737–A743 (2007).

Arun, N. et al. Exceptional performance of a high voltage spinel LiNi0.5Mn1.5O4 cathode in all one dimensional architectures with an anatase TiO2 anode by electrospinning. Nanoscale 6, 8926–8934 (2014).

Xiao, J. et al. High-performance LiNi0.5Mn1.5O4 spinel controlled by Mn3+ concentration and site disorder. Adv. Mater. 24, 2109–2116 (2012).

Wang, G., Xie, J., Zhu, T., Zhao, X. & Zhang, S. Self-templating synthesis of single crystalline LiNi0.5Mn1.5O4 nanotubes with improved electrochemical performance. Funct. Mater. Lett. 7, 1450009 (2014).

Qian, Y., Fu, Y., Wang, X. & Xia, H. LiNi0.5Mn1.5O4 nanorod clusters as cathode material for high energy and high power lithium-ion batteries. J. Nanosci. Nanotech. 14, 7038–7044 (2014).

Jan, S. S., Nurgul, S., Shi, X. Q., Xia, H. & Pang, H. Improvement of electrochemical performance of LiNi0.8Co0.1Mn0.1O2 cathode material by graphene nanosheets modification, Electrochim. Acta 149, 86–93 (2014).

Acknowledgements

This work was supported by Natural Science Foundation of Jiangsu Province (No. BK20131349), National Natural Science Foundation of China (No. U1407106 and 51302181), A Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD), QingLan Project of Jiangsu Province, China Postdoctoral Science Foundation (No. 2013M530258, 2014M551647), Jiangsu Planned Projects for Postdoctoral Research Funds (No. 1202001B) and the Russian Scientific Fund (Project No. 14-43-00072).

Author information

Authors and Affiliations

Contributions

H.X., X.T. and S.S. designed project, carried out data analyses and co-wrote the manuscript. Y.Q. and J.N. performed the materials characterization. S.S. and S.A. also contributed equally to the discussion presented in this paper.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Tang, X., Jan, S., Qian, Y. et al. Graphene wrapped ordered LiNi0.5Mn1.5O4 nanorods as promising cathode material for lithium-ion batteries. Sci Rep 5, 11958 (2015). https://doi.org/10.1038/srep11958

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep11958

This article is cited by

-

Doping and Surface Modification Enhance the Applicability of Nanostructured Fullerene–MWCNT Hybrid Draped LiNi0.1Mg0.1Co0.8O2 as High Efficient Cathode Material for Lithium-Ion Batteries

Journal of Inorganic and Organometallic Polymers and Materials (2021)

-

Synthesis of Conductive Carbon Aerogels Decorated with β-Tricalcium Phosphate Nanocrystallites

Scientific Reports (2020)

-

Structural evolutions of LiNi0.5Mn1.5O4 nanorods synthesized by different lithium sources and effects on electrochemical performances

Ionics (2020)

-

Degradation mechanism and performance enhancement strategies of LiNixCoyAl1−x−yO2 (x ≥ 0.8) cathodes for rechargeable lithium-ion batteries: a review

Ionics (2020)

-

Hierarchical LiNi0.5Mn1.5O4 micro-rods with enhanced rate performance for lithium-ion batteries

Journal of Materials Science (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.