Abstract

Monodisperse Cu2O of different microstructures, such as cubes, flower-like and microspheres, have been extensively synthesized by a simple polyol reduction method using different copper salts, i.e. (Cu(acac)2, Cu(OH)2 and Cu(Ac)2·H2O). The effects of copper salts on the morphology of Cu2O were investigated in details through various characterization methods, including X-ray diffraction, transmission electron microscopy, scanning electron microscopy and UV-Vis absorption spectra. The effects of morphology on the electrochemical properties were further studied. Among the different structures, Cu2O with the microspheric morphology shows the highest specific capacitance and the best cycling stability compared with those of the other two structures, thus bear larger volume charge during the electrochemical reaction due to the microspheres of small nanoparticles.

Similar content being viewed by others

Introduction

Supercapacitor is referred as electrochemical capacitors with the capacity of storing electrical energy in the electrolyte/electrode interface. According to their charge storage mechanisms, they could be divided into three categories, double-layer capacitors (EDLCs), pseudocapacitors and hybrid capacitors1,2,3,4,5. Among them, EDLCs show adsorption from the interface of an electrolyte/electrode double layer by electrostatic attraction with accumulation of charges, while pseudocapacitors and hybrid exhibit Faradic redox reactions1. Materials like activated carbon, graphite, nanotubes (CNTs), etc., exhibit the capacity as EDLC and metal oxides, conducting polymers exhibit as pseudocapacitance2. Because of their high power density, excellent reversibility and long cycle life, the development of pseudocapacitor materials is extremely useful for the large-scale applications in automotives and portable electronic systems3. Until now, various transition metal oxides, such as RuO2, Co3O4, MnO2, Fe2O3, NiO, V2O5, CuO, In2O3, NiO and Cu2O, have been investigated as electrode candidates for electrochemical pseudocapacitors6,7,8,9,10,11,12,13,14,15,16. Among them, Cu2O, as a typical p-type semiconductor with a direct band gap of 2.2 eV, has many potential applications in solar cells, electrode materials, sensors and catalysts17,18,19,20. Also, due to the variety and stability of its structure, electrodes made of Cu2O usually exhibit remarkable electrochemical performance as supercapacitor. Xue et al. recently synthesized hollow octahedra and core@shell structure Cu2O by a facile room temperature reaction and their capacitances are 58 F g−1 and 88 F g−1, respectively21. Furthermore, for the electrochemical redox reaction, it usually happens at the interfaces between electrode and electrolyte. So, researchers did a lot of work try to reduce the path of electrons and improve the performance of active materials, such as using the nanosized particles, improving the conductive network of the materials using carbonaceous matrix and build hollow or hierarchical structures which could accommodating large volume changes or the electrolyte could be quickly permeate into the inner of active materials22. Therefore, the morphology and size of Cu2O might significantly influence their electrochemistry properties. It is also better to known that the formation of single and hierarchic nanostructures has a wide range of applications, not limited to capacitor performance22,23,24.

Recently, Cu2O of cubes, nanowires, solid and hollow spheres, octahedrons, nanoboxes and multistage shape structures have been prepared through different methods25,26,27,28,29,30,31. Among them, the polyol method is most amazing one in which the polyol medium itself acts as both solvent and stabilizer in the process, which can limit the growth of particles and prohibit the agglomeration32. Also, in this method, a wide variety of chemical species, including polymers, anions, surfactants and biomolecules, could be used to control the morphology and size of Cu2O, by certain species preferentially adsorbing on the specific crystal surfaces and inhibiting the growth rate33,34,35. For example, Cu2O nanospheres with a size of 50–70 nm were synthesized by dissolving Cu(NO3)2 and PVP in ethylene glycol (EG) with continuous stirring. The main driving force of this reaction is the oxidizing power of NO3- and the reducing power of EG36. It was also reported that various nanocrystalline Cu2O structures were obtained by using organic solution phase method and systematic manipulation of the reaction conditions. In this method, EG was used as the solvent while SDS and Tween 80 were used as surfactants37. However, there are fewer reports on using diethylene glycol as both solvent and reducing agent to prepare Cu2O particles with various structures.

Herein, monodisperse Cu2O with cubic, flower-like and hierarchical microspheric structures were prepared in the modified polyol method using different copper sources, including Cu(acac)2, Cu(OH)2 and Cu(Ac)2·H2O. The growth mechanisms of different morphology were discussed in details. Furthermore, the influences of morphology on the electrochemical performances of Cu2O supercapacitor anodes were comprehensively studied. Among these three structures, the microspheres show higher specific capacitance and better cycling stability than those of the other two structures.

Results and Discussion

Structure and morphological analysis

The XRD patterns of the samples synthesized using different copper sources are shown in Figure 1. The XRD data of the three as-synthesized samples are all in good agreement with those of Cu2O (JCPDS NO. 65–3288), the six typical peaks located at 29.60°, 36.52°, 42.44°, 61.53°, 73.68° and 77.74°, which were attributed to the (110), (111), (200), (220), (311) and (222) planes of cuprous oxide, respectively. No characteristic peaks arising from Cu or CuO could be observed in the XRD patterns, indicating that the products obtained via our synthetic routes consist of only Cu2O phase. From the XRD results, it reveals that pure Cu2O could be successfully obtained using these three kinds of copper sources.

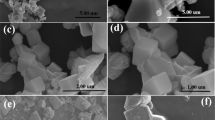

SEM was employed to investigate the size and morphology of Cu2O synthesized using different copper salts and the results are shown in Figure 2. As shown in Figure 2a, the Cu2O synthesized using Cu(acac)2 has a cubic shape with a narrow size distribution, the average width of the cubes is about 120 nm. From the magnified SEM image (Figure 2b), it can be clearly observed that the surfaces of these Cu2O cubes are very smooth with clear distinction of the edges and corners. When using Cu(OH)2 as the precursor, it is clear that the sample presents hierarchical flower-like structure which was composed of many nanowires with a diameter of ~25 nm and a length of ~800 nm (Figure 2c and 2d). Figure 2e is the panorama image of the Cu2O prepared by choosing Cu(Ac)2·H2O as the copper source. It shows that it comprises nearly monodisperse particles with a spherical morphology, averaging 1 μm in diameter. From the high-resolution image of Figure 2f, it can be seen that the microspheres are made up of closely packed prismatic bulge-like structures. The above results indicated that the morphology of the final Cu2O samples could be regulated by simply changing the copper sources while keeping the other experiment parameters same. Figure 3 shows the TEM and HRTEM images of the as-synthesized Cu2O with cubic, flower-like and hierarchical microspheric structures. Figure 3a and 3b show clearly that the surface of cubic-like Cu2O particles are rather smooth which is consistent with the SEM results. The interplane distances of 0.2123 nm and 0.2514 nm calculated from HRTEM of the nanocubes (Figure 3c) are well consistent with the interplane distance values of (200) and (111) faces in the cubic Cu2O20. As for Cu2O made from Cu(OH)2, the whole flower-like structure is too big, here only presents the TEM images of its secondary structure-nanowires. It is interesting to note that the sub-nanowire composed of small nanoparticles in the range of 5–10 nm are in intensive arrangement (Figure 3d and 3e). Fringes with spacing of ca. 0.2532 nm taken from the small nanoparticles are corresponding to the (111) plane of Cu2O (Figure 3f). Figure 3g and 3h display the TEM images of an individual Cu2O microsphere which has rather rough surface corresponding to the bulges shown in the SEM images. Also, the pure black microsphere indicates the particle is solid and not the inner hollow or core-shell structure. The observed width, 0.2493 nm, of the adjacent lattice fringes corresponds to the (111) plane of Cu2O. The surface area of the Cu2O with different morphology were characterized by the nitrogen adsorption-desorption isotherm measurements and their corresponding BET surface area is 4.1 m2 g−1, 27.5 m2 g−1 and 4.3 m2 g−1 for the cubes, flower-like and microspheres, respectively.

Formation mechanism

As discussed above, Cu2O with cubic, flower-like and hierarchical microspheric structures were obtained only by simply changing the copper salts in the normal polyol method. And it is well-known that the copper salts could be reduced by diethylene glycol (DEG) to form Cu2O, which are widely used in the synthesis of Cu2O with different morphologies17,18,27. The chemical reactions are as follows:

At the beginning of the reaction, Cu2+ is reduced by the decomposition product of DEG at high temperature (Equation (1) and (2)) and instantly formed the spherical Cu2O nanocrystalline. The surface of the new generated Cu2O nanocrystalline contains high index crystallography planes, through which the particles tend to aggregate with each other to decrease the surface energy of the planes1. As the reaction proceeding, the polyhedral particles would grow along different directions with different growth rates due to their different surface energies. According to the previous reports38, the growth rate ratio R of the {100} and {111} directions usually determines the geometry of the Cu2O crystals. That is, when R = 0.58, cubic like Cu2O will be prepared. Therefore, the formation of our cubic Cu2O might be caused by the different adsorption of acac- and PVP on the surface of (111) and (100), which leading to the different growth rates of these two crystal faces. In the present system, we got the Cu2O hyper polyhedral microspheres composed of prismatic structures through changing the copper source to Cu(Ac)2·H2O. Thus, we inferred that the adding of Ac- can lead to stronger interaction with the (111) facet than acac-. This may result in the increasing of R, the value of which can be speculated higher than 1.73 due to the hyper polyhedron structure of our product1. While flower-like Cu2O composed of nanowires were obtained by changing copper source to Cu(OH)2. It is known that Cu(OH)2 could be thermal decomposed into tiny CuO particles at high temperature (~80°C). Therefore the formation of nanowires might be interpreted that the CuO particles once generated is rapidly reduced to Cu2O nanoparticles, at the same time, organics, such as excessive polyols and PVP, coated on the Cu2O nanoparticles to form the nanowires. Namely, the synergistic effect between the pyrolysis of Cu(OH)2, the instant reduction of CuO and the coating of organics, together create the flower-like Cu2O assembling by sub-nanowires. In conclusion, the diverse copper sources possessing different anions used in this reaction process play a critical role on the morphology of the resulting Cu2O. Also, the effect of DEG acted as both solvent and reducing agent is indispensable. These factors synergistically lead to the formation of Cu2O with disparate morphologies. The simple sketch of these three reaction processes are depicted in Figure 4.

A series of color variations have been observed during the reactions which could be used to monitor the reaction process. In addition, as shown in Figure 5a, the colors of the mixture containing the final Cu2O particles are entirely distinct. They present orange, green and red brown in turn when using Cu(acac)2, Cu(OH)2 and Cu(Ac)2·H2O as the copper source respectively. The colors of the final reaction mixtures might have relationship with the size and morphology of the Cu2O. To confirm this, the UV-Vis absorption spectra were taken with the Cu2O particles dispersed in ethanol (Figure 5b). In general, the optical absorption peak of bulk Cu2O is at 570 nm (band gap ~2.17 eV)39,40. The Cu2O cubes exhibit absorption peak located at 470 nm, the blue shift compared with the bulk Cu2O might be due to the size effect. For flower-like Cu2O synthesized using Cu(OH)2, the broad absorption peak is from 380 nm to 500 nm, resulting from the inhomogeneous size of wires and the flower-like structure. As Luo has reported41, Cu2O with the similar flower-like structure has a centered peak at 370 nm, giving absorption edge energies corresponding to Eg = 2.23 eV and the increase in the band gap of the Cu2O nanoflowers possibly be the resulting of the quantum confinement effects arising from the tiny petals and secondary small nanoparticles. Then, the plasma absorption peak of Cu2O with the hierarchical microspheric structure is shown at 518 nm probably resulting from the larger size and rough surface.

Electrochemical performance

The electrochemical measurements of the three Cu2O particles with different morphology were performed with a three-electrode system in 2 M KOH solution. Figure 6a displays the CV curves of the as-synthesized cubic, flower-like and microspheric morphology in the potential range of 0 to 0.8 V (vs. Hg/HgO) at a potential scan rate of 5 mV s−1. For each curve, a typical pair of anodic and cathodic signals and a broad redox background is clearly visible, indicating that the electrochemical mechanism is governed by pseudocapacitive behavior. This behavior differs remarkably from the electric double-layer capacitance, which would produce a CV curve of nearly ideal rectangular shape. The pseudeocapacitance of the Cu oxide electrode is the result of transitions between oxidation states Cu(I) oxide-Cu(II) oxide and vice versa. The redox reaction for the Cu oxide electrode is presented as follows:42

(a) CV curves of cubes, flower-like and microsphere structures in 2 M KOH aqueous solution at scan rates of 5 mV s−1. (b) CV curves of microspheres at different scan rates of 5, 10, 20, 30 and 50 mV s−1 in 2 M KOH solution. (c) Specific capacitance of the three structures recorded at various potential scan rates.

It is very clear that the areas surrounded by the CV curves of the microsphere electrode are larger than those of the cubes and flower-like electrodes at the same scan rate, indicating a higher specific capacitance of the microsphere electrode. The reasons why Cu2O microspheres has the best specific capacitance were analysed. For the electrochemical peaks are consistent with the discharge-charge plateaus in Figure 6a, in the cycle of microsphere structure, the two cathodic peaks are observed at 0.36 and 0.54 V, corresponding to the multistep electrochemical Cu+ reaction process or additional sites for Cu+ intercalation. Meanwhile, in the cycle of cubic and flower-like structures, the decrease of the individual peak intensity and integral area resulting in reversible losses, is observed with shifts to 0.33 and 0.58 V of the peak potentials in the cathodic direction. So it indicates that the rough surface of microspheres could endure large volume charge during the electrochemical reactions and show the highest specific capacitance.

The specific capacitance calculated from the CV curves can be derived from the Equation (4):

Where Cs is the specific capacitance from evaluated samples; V1 and V2 are the starting and ending points of potential window, respectively; i(V) is the instantaneous current as the function of potential; m is the mass of two symmetric devices; and v is the scan rate in mV s−1. The calculated values of specific capacitance at 5 mV s−1 scan rate are 157.5 F g−1, 92.3 F g−1 and 173.2 F g−1 for cubes, flower-like and microsphere of Cu2O electrode, respectively. It is seen that, microspheres exhibit the maximum specific capacitance as stated above.

Figure 6b shows the CV curves of the microsphere structures recorded at various potential scan rates. Pairs of well-defined cathodic and anodic signals are clearly observed over the entire range of scan rates from 5 to 50 mV s−1. The enhancement in current with the scan rate suggests the effective utilization of electrode material by the electrolyte, owing to better ionic diffusion, mostly as a result of well-spaced nanostructured, indicating an ideally capacitive behaviour43,44. The shape of current responses is essentially the same over the entire range of scan rates, indicting rapid faradaic reactions at large scan rates. As shown in Figure 6c, the optimum specific capacitance of the microsphere evaluated at 50 mV s−1 is 122.6 F g−1; as much as 70% of the capacitance can be maintained relative to that measured at 5 mV s−1 (173.2 F g−1). In contrast, the cubic structures retained only 57% of the initial capacitance when the potential scan rate was increased by the same amount. This rapid charge-discharge is an attractive feature for high-power supercapacitor applications, which are essential for rapid applications of energy such as in automotives.

The galvanostatic charge/discharge curves of the cubes, flower-like and microsphere structures at current density of 0.1 A g−1 are depicted in Figure 7a and their cycle stabilities at the same current density are presented in Figure 7b, respectively. As we can see from Figure 7a, the charge/discharge curves are nearly symmetric with slight curvature. These charge/discharge curves can be employed to estimate the average specific capacitances (Cs) of the as-obtained cubic, flower-like and microspheric morphology from the following equation (5):

Where I is the constant discharge current, t is the discharge time, m is the mass of the active material on the electrode and ΔV is the potential window. The specific capacitance value of the microsphere Cu2O is calculated to be about 144 F g−1 at discharge current density of 0.1 A g−1 and the cubic Cu2O has the nearly specific capacitance value of about 132 F g−1 at the same discharge current density. However, the specific capacitance value of Cu2O flower-like structure at the discharge current density of 0.1 A g−1 catches the lowest value of about 45 F g−1. As shown in Figure 7b, the columbic efficiency of these three structures show the similar efficiency of about 99% in the 100 cycles and the specific capacitances of flower-like structure, cube and microsphere decrease from 45 F g−1 to 30 F g−1, 132 F g−1 to 126 F g−1 and 144 F g−1 to 143 F g−1 at the discharge current density of 0.1 A g−1 after 100 cycles, respectively. The results further prove that the Cu2O microspheres have much predominance as electrochemical energy storage materials and better cycling stability than that of Cu2O cubes and flower-like structures. The reason for the highest capacitance and cycling performance of microsphere morphology might be caused by the uniform structure with rough surface which could endure large volume charge during electrochemical reactions. What's more, the microspheres composed of many small particles increase the electrical properties. On the contrary, small crystallites embedded in an amorphous matrix form nanowires, which self-assembled to flower-like structure seriously hinder the interaction between the Cu2O particles gain the lowest specific capacitance value of about 45 F g−1. The smooth surface of uniform cubic Cu2O obtains the specific capacitance just under 12 F g−1 of microspheric Cu2O.

Conclusions

In summary, we successfully synthesized series of monodisperse Cu2O with various structures through different copper sources by a facile polyol method. The obtained Cu2O with different morphology is resulting from the disparate copper salts possessing different anions, acac-, OH- and Ac-, which could selectively adsorbed on the various crystal face of Cu2O and leading to the diverse growth rates of each crystal direction. Furthermore, the effects of shape and size on the electrochemical properties of Cu2O were investigated. It shows that the Cu2O with hierarchical microspheres has much predominance as supercapacitor materials than that of Cu2O with cubic and flower-like structures. The specific capacitance value of the Cu2O microspheres is calculated to be about 144 F g−1 at discharge current density of 0.1 A g−1. The microspheres also present higher specific capacitance and better cycling stability than that of the other structures, because that the rough surface of uniform microspheres composed of small particles can endure large volume charge during electrochemical reactions. It also provides a simple method to prepare Cu2O with cubic or flower-like nanostructures, which might find applications in other fields, such as gas sensors, CO oxidation catalysts and various heterogeneous catalysts.

Experimental Section

Material synthesis

Copper hydroxide (Cu(OH)2) and copper acetylacetonate (Cu(acac)2) were purchased from Aladdin Reagent Co. Ltd. Diethylene glycol (DEG), polyvinyl pyrrolidone (PVP, K-30) and copper acetate monohydrate (Cu(Ac)2·H2O) were purchased from Sinopharm Chemical Co. Ltd.

In a typical synthesis, 0.01 mol of Cu(acac)2 and 2 g PVP were mixed into 100 mL DEG inside a round-bottom flask and keep vigorously stirring from room temperature (RT) to 170°C, then the mixture was stirred at 170°C for 30 min till the formation of Cu2O we needed. The resulting dark yellow precipitate was collected by centrifugation, washed with pure ethanol and finally dried under vacuum at RT for 12 h. For comparison, Cu2O with other morphology were prepared under the same experiment procedure except changing the copper source from Cu(acac)2 to Cu(OH)2 or Cu(Ac)2·H2O, only shorten the reaction time to 20 min as using Cu(OH)2 or prolong the reaction time to 1 h when choosing Cu(Ac)2·H2O.

Characterization

X-ray diffraction (XRD) patterns of the samples were recorded on an X-ray diffractometer (Rigaku D/Max 2500, Japan) using the Kα radiation of Cu (λ = 1.54187 Å) from 20° to 80° at a scanning rate of 8°·min−1. The nanoscopic feature of the samples was observed by field-emission scanning electron microscopic (FE-SEM, FEI Nova Nano SEM 450) and transmission electron microscopy (TEM, FEI Tecnai G2F20S-TWIN). The UV-Vis absorption spectra of the samples were recorded on an UV-Vis-NIR spectrometer (Shimadzu UV-3600, Japan) with a wavelength range of 300–800 nm. Nitrogen adsorption–desorption isotherms for surface area were measured using a Micromeritics ASAP 2020 BET apparatus.

Nitrogen adsorption–desorption isotherms for surface area were measured using a Micromeritics ASAP 2020 BET apparatus with liquid nitrogen at 77 K.

Electrochemical measurements

The electrochemical measurements were conducted using a three-electrode mode in a 2 M KOH aqueous solution. The working electrode was prepared by mixing Cu2O, acetylene black and polytetrafluoroethylene (PTFE) in a weight ratio of 70:20:10. Briefly, the resulting paste was pressed on a sheet of nickel foam at 10 MPa and the surface area of the electrode equal to the area of nickel foam, which is 1.766 cm2. The amount of active materials was totally about 10.00 mg, by the same coating method. The mercuric oxide electrode was used as the reference electrode and the Pt wire as a counter electrode. The cyclic voltammetry (CV) was carried out on a Zahner Zennium electrochemical workstation. Charge-discharge cycling tests were carried out between 0 and 0.8 V on a Land CT2001 battery test system at room temperature.

References

Wang, G., Zhang, L. & Zhang, J. J. A review of electrode materials for electrochemical supercapacitors. Chem. Soc. Rev. 41, 797–828 (2012).

Zhang, X. T., Zhang, J. & Liu, Z. F. Conducting polymer/carbon nanotube composite films made by in situ electropolymerization using an ionic surfactant as the supporting electrolyte. Carbon 43, 2186–2191 (2005).

Sharma, R. K., Oh, H. S., Shul, Y. G. & Kim, H. Carbon-supported, nano-structured, manganese oxide composite electrode for electrochemical supercapacitor. J. Power Sources 173, 1024–1028 (2007).

Salunkhe, R. R., Hsu, S. H., Wu, K. C.-W. & Yamauchi, Y. Large-scale synthesis of reduced graphene oxides with uniformly coated polyaniline for supercapacitor applications. ChemSusChem. 7, 1551–1556 (2014).

Bastakoti, B. P., Huang, H. S., Chen, L. C., Wu, K. C.-W. & Yamauchi, Y. Block copolymer assisted of porous α-Ni(OH)2 microflowers with high surface areas as electrochemical pseudocapacitor materials. Chem. Commun. 48, 9150–9152 (2012).

Wei, J. J. et al. A mild solution strategy for the synthesis of mesoporous CeO2 nanoflowers derived from Ce(HCOO)3 . CrystEngComm 13, 4950–4955 (2011).

Cao, C. Y. et al. Microwave-assisted gas/liquid interfacial synthesis of flowerlike NiO hollow nanosphere precursors and their application as supercapacitor electrodes. J. Mater. Chem. 21, 3204–3209 (2011).

Endut, Z., Hamdi, M. & Basirun, W. J. Pseudocapacitive performance of vertical copper oxide nanoflakes. Thin Solid Films 528, 213–216 (2013).

Kowalczyk, B. et al. Charged nanoparticles as supramolecular surfactants for controlling the growth and stability of microcrystals. Nat. Mater. 11, 227–232 (2012).

Zhong, J. H. et al. Co3O4/Ni(OH)2 composite mesoporous nanosheet networks as a promising electrode for supercapacitor applications. J. Mater. Chem. 22, 5656–5665 (2012).

Xia, X. et al. Self-supported hydrothermal synthesized hollow Co3O4 nanowire arrays with high supercapacitor capacitance. J. Mater. Chem. 21, 9319–9325 (2011).

Li, R. Z. et al. Synthesis of Fe3O4@SnO2 core–shell nanorod film and its application as a thin-film supercapacitor electrode. Chem. Commun. 48, 5010–5012 (2012).

Khan, Z., Bhattu, S., Haramb, S. & Khushalani, D. SWCNT/BiVO4 composites as anode materials for supercapacitor application. RSC. Adv. 4, 17378–17381 (2014).

Bastakoti, B. P. et al. Mesoporous carbon incorporated with In2O3 nanoparticles as high-performance supercapacitors. Eur. J. Inorg. Chem. 7, 1109–1112 (2013).

Vijayakumar, S., Nagamuthu, S. & Muralidharan, G. Supercapacitor studies on NiO nanoflakes synthesized through a microwave route. ACS Appl. Mater. Inter. Appl. Mater. Interfaces. 5, 2188–2196 (2013).

Huang, H. S. et al. Evaporation-induced coating of hydrous ruthenium oxide on mesoporous silica nanoparticles to develop high-performace supercapacitors. Small 9, 2520–2526 (2013).

Li, B. J., Cao, H. Q., Lu, Y. X. & Yin, J. F. Cu2O@reduced graphene oxide composite for removal of contaminants from water and supercapacitors. J. Am. Chem. Soc. 21, 10645–10648 (2011).

Park, J. C., Kim, J., Kwon, H. & Song, H. Gram-scale synthesis of Cu2O nanocubes and subsequent oxidation to CuO hollow nanostructures for lithium-ion battery anode materials. Adv. Mater. 21, 803–807 (2009).

Wang, W. C., Lyu, L. M. & Huang, M. H. Synthesis of Cu2O nanocrystals from cubes to rhombic dodecahedral structures and their comparative photocatalytic activity. J. Am. Chem. Soc. 134, 1261–1267 (2012).

White, B., Yin, M., Hall, A. & Le, D. Complete CO oxidation over Cu2O nanoparticles supported on silica gel. Nano Lett. 6, 2095–2098 (2006).

Chen, K. F., Song, S. Y. & Xue, D. F. Chemical reaction controlled synthesis of Cu2O hollow octahedra and core–shell structures. CrystEngComm 15, 10028–10033 (2013).

Ariga, K. et al. Layer-by-layer Nanoarchitectonic: Invention, Innovation and Evolution. Chem. Lett. 43, 36–68 (2014).

Gai, S. L., Li, C. X., Yang, P. P. & Lin, J. Recent progress in rare earth micro/nanocrystals: soft chemical syntehsis, luminescent properties and biomedical applications. Chem. Rev. 114, 2343–2389 (2014).

Auxilia, F. M. et al. Low-temperature remediation of NO catalyzed by interleaved CuO nanoplates. Adv. Mater. 26, 4481–4485 (2014).

Chen, K. F. & Xue, D. F. Chemoaffinity-mediated crystallization of Cu2O: a reaction effect on crystal growth and anode property. CrystEngComm 15, 1739–1746 (2013).

Shang, Y., Zhang, D. F. & Guo, L. CuCl-intermediated construction of short-range-ordered Cu2O mesoporous spheres with excellent adsorption performance. J. Mater. Chem. 22, 856–861 (2012).

Liang, X. D., Gao, L., Yang, S. W. & Sun, J. Facile synthesis and shape evolution of single-crystal cuprous oxide. Adv. Mater. 21, 2068–2071 (2009).

Zhao, X., Bao, Z. Y., Sun, C. T. & Xue, D. F. Polymorphology formation of Cu2O: A microscopic understanding of single crystal growth from both thermodynamic and kinetic models. J. Cryst. Growth 311, 711–715 (2009).

Zhang, Z. et al. Shape-controlled synthesis of Cu2O microparticles and their catalytic performances in the Rochow reaction. Catal. Sci. Technol. 2, 1207–1212 (2012).

Tan, Y. W., Peng, Q. & Li, Y. Controllable fabrication and electrical performance of single crystalline Cu2O nanowires with high aspect ratios. Nano Lett. 7, 3723–3728 (2007).

Huang, L., Peng, F., Yu, H. & Wang, H. Synthesis of Cu2O nanoboxes, nanocubes and nanospheres by polyol process and their adsorption characteristic. Mater. Res. Bull. 43, 3047–3053 (2008).

Zhu, P. L., Zhang, J. W., Wu, Z. S. & Zhang, Z. J. Microwave-assisted synthesis of various ZnO hierarchical nanostructures: effects of heating parameters of microwave oven. Cryst. Growth Des. 9, 3148–3153 (2008).

Liu, J., Xia, H., Xue, D. F. & Lu, L. Double-shelled nanocapsules of V2O5-based composites as high-performance anode and cathode materials for Li ion batteries. J. Am. Chem. Soc. 131, 12086–12087 (2009).

Ho, J. Y. & Huang, M. H. Synthesis of submicrometer-sized Cu2O crystals with morphological evolution from cubes to hexapod structures and their comparative photocatalytic activity. J. Phys. Chem. C 113, 14159–14164 (2009).

Kowalczyk, B. et al. Charged nanoparticles as supramolecular surfactants for controlling the growth and stability of microcrystals. Nat. Mater. 11, 227–32 (2012).

Hong, X. et al. Synthesis of sub-10 nm Cu2O nanowires by poly (vinyl pyrrolidone)-assisted electrodeposition. J. Phys. Chem. C 113, 14172–14175 (2009).

Ahmed, A., Gajbhiye, N. S. & Joshi, A. G. Shape controlled synthesis and characterization of Cu2O nanostructures assisted by composite surfactants system. Mater. Chem. Phys. 129, 740–745 (2011).

Sui, Y. M. et al. Photoluminescence and X-ray diffraction studies on Cu2O. Cryst. Growth Des. 10, 99–108 (2010).

Lu, B. C. et al. One-Pot synthesis of octahedral Cu2O nanocages via a catalytic solution route. Adv. Mater. 17, 2562–2567 (2005).

Ma, L. L. et al. Self-assembled Cu2O flowerlike architecture: Polyol synthesis, photocatalytic activity and stability under simulated solar light. Mater. Res. Bull. 45, 961–968 (2010).

Luo, Y. S. et al. Facile synthesis of flowerlike Cu2O nanoarchitectures by a solution phase route. Cryst. Growth Des. 1, 87–92 (2007).

Deng, M. J. et al. Three-dimensionally ordered macroporous Cu2O/Ni inverse opal electrodes for electrochemical supercapacitors. Phys. Chem. Chem. Phys. 15, 7479–7483 (2013).

Debart, A. et al. A transmission electron microscopy study of the reactivity mechanism of tailor-made CuO particles toward lithium. J. Electrochem. Soc. 148, 1266–1274 (2001).

Gillot, F. et al. The LixMPn4 phases (M/Pn = Ti/P, V/As): new negative electrode materials for lithium ion rechargeable batteries. Electrochim. Acta 49, 2325–2332 (2004).

Acknowledgements

This work was financially supported by the National Basic Research Program of China (973 Program) (2012CB933700-G), Guangdong Innovative Research Team Program (No. 2011D052 and KYPT20121228160843692), Shenzhen Electronic Packaging Materials Engineering Laboratory (2012-372), Shenzhen basic research plan (JC201005270372A and GJHS20120615161915279).

Author information

Authors and Affiliations

Contributions

L.C. performed the experiment, Y.Z. and P.Z. assisted the experiments. F.Z. did the TEM and SEM, P.Z. designed the research. W.Z. modifed the english and also help do the BET test. D.L., R.S. and C.W. conceived the study. L.C. wrote the manuscript. All authors discussed the results on the manuscript and reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Chen, L., Zhang, Y., Zhu, P. et al. Copper Salts Mediated Morphological Transformation of Cu2O from Cubes to Hierarchical Flower-like or Microspheres and Their Supercapacitors Performances. Sci Rep 5, 9672 (2015). https://doi.org/10.1038/srep09672

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep09672

This article is cited by

-

Comparison of Adsorption Performance of Biochar Derived from Urban Biowaste Materials for Removal of Heavy Metals

Environmental Management (2024)

-

Orange peel-derived Cu2O/RGO nanocomposite: Mesoporous binary system for degradation of doxycycline in water

Environment, Development and Sustainability (2023)

-

The physical and optical investigations of the tannic acid functionalised Cu-based oxide nanostructures

Scientific Reports (2022)

-

Bio synthesis of Zinc oxide nanoparticles using Clerodendrum phlomidis extract for antibacterial, anticancer, antioxidant and photocatalytic studies

Journal of Materials Science: Materials in Electronics (2022)

-

Optical, structural, and catalytic properties of synthesized Cu2O nanocubes

Indian Journal of Physics (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.