Abstract

Single crystalline Co3O4 nanocrystals exposed with different crystal planes were synthesised, including cubic Co3O4 nanocrystals enclosed by {100} crystal planes, pseudo octahedral Co3O4 enclosed by {100} and {110} crystal planes, Co3O4 nanosheets exposed by {110} crystal planes, hexagonal Co3O4 nanoplatelets exposed with {111} crystal planes and Co3O4 nanolaminar exposed with {112} crystal planes. Well single crystalline features of these Co3O4 nanocrystals were confirmed by FESEM and HRTEM analyses. The electrochemical performance for Li-O2 batteries shows that Co3O4 nanocrystals can significantly reduce the discharge-charge over-potential via the effect on the oxygen evolution reaction (OER). From the comparison on their catalytic performances, we found that the essential factor to promote the oxygen evolution reactions is the surface crystal planes of Co3O4 nanocrystals, namely, crystal planes-dependent process. The correlation between different Co3O4 crystal planes and their effect on reducing charge-discharge over-potential was established: {100} < {110} < {112} < {111}.

Similar content being viewed by others

Introduction

The high energy density of Li-O2 battery (2–3 kWh kg−1), which is compatible with gasoline1,2, is making it to be the most advanced battery system as the power source for electric vehicles (EV). However, it is still far from the demand of realistic application as constrained by several serious issues, like large charge-discharge over-potential and poor cycling stability3,4. Previous reports showed non-aqueous rechargeable Li-O2 batteries only had limited cycles with extremely high charge-discharge voltage gap5. The large over-potential during charge-discharge processes is mainly caused by the sluggish oxygen reduction reaction (ORR) and oxygen evolution reaction (OER) of the air cathode. Recently, it was found that the proper non-aqueous electrolyte are the key factors to improve the cycle life of Li-O2 battery6,7,8,9,10,11 and the catalysts have comprehensive benefits on reducing the large charge-discharge voltage gap to increase the electrical energy efficiency for Li-O2 battery12,13,14. So far, tremendous efforts have been devoted to explore various cathode catalysts, such as metal oxides, metal nitrides and precious metals15,16,17,18. However, it is still not clear regarding to the theory of catalytic effect of the catalysts on Li-O2 battery. Therefore, more studies are needed on exploring the essence of catalysts' effect.

The exposed heterogeneous crystal planes of inorganic single crystals play a critical role in determining fascinating surface dependent properties. Essentially, it does not only impact the final shape of the particles themselves, but also generate different effect on their promising applications. Therefore, understanding the nanoscale topography of surface sites, such as terraces, steps, kinks, adatoms and vacancies and their effects on physicochemical properties is the key to designing nanoscale functional materials by nanotechnology. Follow this strategy, a breakthrough in the synthesis of TiO2 crystals with 46% high energy {001} facets has been achieved19, which demonstrated excellent photocatalytic activities. High-index {311} facets Cu2O microcrystals showing an enhanced specific catalytic rate toward CO oxidation was reported20. The crystal-phase and morphology controlled γ-Fe2O3 nanomaterials enclosed by the reactive {110} and {100} facets are highly active and distinctively stable for the selective catalytic reduction of NO with NH321.

As one of the commonly available and most studied metal oxides, Co3O4, has been widely used in heterogeneous catalysis22. The catalytic application is generally facilitated by its high adsorption capacity, high specific area and large part to their surface redox reactivity properties, accordingly, novel Co3O4 structures such as nanocubes23,24, nanorods25,26, nanowires27, nanoplatelets28, nanoboxes29 and nanodiscs30, have been synthesized successfully. Even hierarchically flower-like nanomaterials31, mircospheres32 and nanoclusters33, have also been fabricated. Most of the reported Co3O4 are enclosed by {001}34, {110}22, {111}35,36,37, or {112}30,38,39 facets. Because the surface energy increases with increasing density of dangling bonds, therefore it is not easy to achieve {hkl} on a face-centered cubic (fcc) metal oxide, where {hkl} represents high-index planes with at least one Miller index larger than 140. The different crystal planes of Co3O4 effect on catalytic property for methane combustion have been reported that follows {112} > {011} ≫ {001} order38. It also shows that Co3O4 predominantly expose {110} planes not only catalyse CO oxidation at low temperatures but also remain stable in a moist stream of normal feed gas22.

Herein, the controllable synthesis of Co3O4 with different shape and crystal planes and their catalytic properties for Li-O2 batteries have been systematically studied in this work. Electrochemical performance testing shows Co3O4 nanocrystals can significantly reduce the discharge-charge over-potential via the effect on the oxygen evolution reaction (OER). Moreover, it was found that the essential factor to promote the OER is the surface crystal planes of Co3O4 nanocrystals, namely, crystal planes-dependent process. The correlation of different Co3O4 crystal planes and their effect on reducing charge-discharge over-potential were established: {100} < {110} < {112} < {111}. The study demonstrates that Co3O4 based nanomaterials could be applied as effective cathode catalysts for high performance Li-O2 batteries.

Results and discussion

Phase and crystal structure characterization

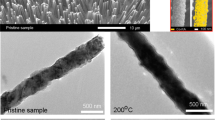

Figure 1a shows the FESEM image of CNT. They have approximately 100 nm diameter, as demonstrated by Figure 1b. The size less than 40 nm Co3O4 nanocubes were obtained in the solutions containing 10 mL of 0.1 M cobalt nitrate, 5 mL 0.01 M LiOH and H2BO3 via hydrothermal method at 180°C, as observed by FESEM image in Figure 1c and demonstrated by Figure 1d. With concentration of LiOH and H2BO3 solution increase, there is edge-truncation along a and b axes and the pseudo octahedral Co3O4 nanocrystals were achieved, as shown in Figures 1e and f. More FESEM images showing the uniform particle size distribution of Co3O4 nanocubes and Co3O4 pseudo octahedrons are given in Figures S1 and S2 (Supplementary Information, SI). By comparison, the {110} facets exposed Co3O4 nanosheets were synthesised by hydrothermal method also. From the FESEM image and geometric model (Figures 1g and h, Figure S3, SI), it can be seen that they are thin in thickness and have size less than 40 nm.

Morphology characterization of Co3O4 nanocrystals exposed with different crystal planes.

SEM images and models of CNT (a, b) and Co3O4 with different morphologies: nanocubes (c, d), pseudo octahedrons (e, f), nanosheets (g, h), hexagonal nanoplatelets (i, j) and nanolaminar (k, l). Different colours in the models represent different crystal planes: blue: {100}, yellow: {110}, green: {111} and light blue: {112}.

Two steps method was used to synthesize the {111} facets exposed Co3O4 nanoplatelets, following the crystal mismatch guided formation mechanisms. First we designed the precursor exposed with the facets which have the similar atoms arrangement as {111} crystal planes of Co3O4. Then, convert the precursor to the targeted product after recrystallization and oxidization at a moderate rate41. Therefore, {001} facets exposed Co(OH)2 was chosen as the precursor to obtain {111} facets exposed Co3O4 due to the 2% crystal mismatch (atoms arrangement) between them as illustrated by Scheme S1 (SI). Under poly(vinylpyrrolidone) (PVP) surfactant assists, the Co(OH)2 nanoplatelets with hexagonal shape were prepared (Figure S4a, XRD patterns, SI), which have size in the range of 200–300 nm and thickness less than 20 nm (Figure S4b, FESEM image, SI). After sintering, the targeted product, Co3O4, preserving the hexagonal platelet shape was obtained, as shown in Figures 1i and j, in which the mesoporous structure can be observed. Because of the gas emission during precursor's thermal decomposition process, it will result in mesoporosity in the final Co3O4 nanoplatelets (Figure S5, SI).

Follow the same strategy, the {112} facets exposed Co3O4 nanolaminars were converted from  facets exposed (NH4)2Co8(CO3)6(OH)6·4H2O nanolaminars precursor (Scheme S2, SI). Figures S6 (SI) shows the phase and morphology of (NH4)2Co8(CO3)6(OH)6·4H2O nanolaminars precursor. After sintering, Co3O4 nanolaminars with mesoporous structure were obtained, as shown in Figure 1k and demonstrated by the geometric model (Figure 1l). It can be seen the mesopores distribute uniformly in the Co3O4 nanolaminar due to the thermal decomposition of the precursor to release carbonate, hydroxyl groups and ammonium anions. More FESEM images of Co3O4 nanolaminar are shown in Figure S7 (SI).

facets exposed (NH4)2Co8(CO3)6(OH)6·4H2O nanolaminars precursor (Scheme S2, SI). Figures S6 (SI) shows the phase and morphology of (NH4)2Co8(CO3)6(OH)6·4H2O nanolaminars precursor. After sintering, Co3O4 nanolaminars with mesoporous structure were obtained, as shown in Figure 1k and demonstrated by the geometric model (Figure 1l). It can be seen the mesopores distribute uniformly in the Co3O4 nanolaminar due to the thermal decomposition of the precursor to release carbonate, hydroxyl groups and ammonium anions. More FESEM images of Co3O4 nanolaminar are shown in Figure S7 (SI).

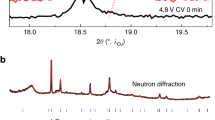

The crystal structures of different as-prepared Co3O4 nanocrystals were further confirmed by the X-ray diffraction (XRD) and high resolution transmission electron microscope (HRTEM). In the XRD patterns, as shown in Figure 2, all the diffraction peaks match well with the crystal structure of the spinel Co3O4 phase (space group Fd-3m (227)), exhibiting a well-crystalline phase (JCPDS Card No. 65-3103, a = 0.808 nm) without any impurity phase.

Figures 3 a1–a4 shows the HRTEM images of the cubic Co3O4 nanocrystals. In Figure 3 a1, the perfect sharp edges, corners and well-defined faces of the Co3O4 nanocube can be seen. Figures 3 a2 and a3 show lattice resolved HRTEM image, which is recorded from dotted rectangular area in Figure 3 a1 and corresponding fast-Fourier-transform (FFT) patterns, respectively. The characteristic of square spot array of the FFT pattern suggests that Co3O4 nanocubes show single crystal features. All the FFT spots can be indexed along [100] zone axis of spinal Co3O4 (Figure 3 a3), indicating Co3O4 nanocubes are enclosed by {100} facets. The (040) and (022) crystal planes with d-spacings of 0.2 and 0.28 nm, respectively and an interfacial angle of 45° can be directly observed in Figure 3 a2. It is consist with the crystal orientation relationship of spinel Co3O4 [100] projected direction. An atom resolved HRTEM image of (100) surface is shown in Figure 3 a4. The inset simulates 4 formula units (Co2+4Co3+8O16, 28 atoms in total, the Co2+, Co3+ and O marked as blue, green and red in colour, respectively) of spinel Co3O4 crystal structure along [100] projected direction, from which the Co2+ and Co3+ ion densities on the surface can be directly calculated. More TEM images of Co3O4 nanocubes are given in Figure S8 (SI).

Structure analysis of Co3O4 crystals.

HRTEM, fast-Fourier-transform (FFT), lattice and atom resolved HRTEM images of Co3O4 nanocrystals exposed with different crystal planes: nanocubes (a1–a4), pseudo octahedrons (b1, b2), nanoplatelets (c1, c2), hexagonal nanosheets (d1–d4) and nanolaminar (e1–e4). Insets in a1, b1, c1, d1 and e1 are corresponding geometric models. Left-top corner inset in b2 and inset in c2 are the corresponding FFT patterns. Insets in a4, d4 and e4 are the crystal structure of {100}, {111} and {112} crystal planes. Left-bottom inset in b2 is the lattice resolved HRTEM image and corresponding crystal structure of {110} crystal planes.

Figure 3 b1 and b2 show TEM images of pseudo octahedral Co3O4 nanocrystals. A typical free standing Co3O4 octahedron is shown in Figure 3 b1 and its outline and relative enclosed facets is illustrated by the geometric model from the suitable projected direction (inset of Figure 3 b1). In the lattice resolution HRTEM image (Figure 3 b2), two orthogonal crystal planes: ( ) and (002) and another crystal plane:

) and (002) and another crystal plane:  (with 0.46 nm d-spacing and 144.7 and 54.7° interfacial angles towards

(with 0.46 nm d-spacing and 144.7 and 54.7° interfacial angles towards  and (002) crystal planes, respectively), can be observed. Its corresponding FFT image (inset of Figure 3 b2) shows rhombic spot array, which can be indexed as [110] zone axis. Therefore, the main exposed facets of pseudo octahedral Co3O4 nanoparticle should be {110}. More TEM images of pseudo octahedral Co3O4 are given in Figure S9 (SI). Figures 3 c1 and c2 show the TEM images of Co3O4 nanosheets. From the lattice resolved HRTEM image (Figure 3 c2) and its corresponding FFT pattern image (inset of Figure 3 c2), it can be observed that the dominated facets on both top and down sides of the nanosheets are {110} crystal planes. More TEM images of Co3O4 nanosheets are shown in Figure S10 (SI).

and (002) crystal planes, respectively), can be observed. Its corresponding FFT image (inset of Figure 3 b2) shows rhombic spot array, which can be indexed as [110] zone axis. Therefore, the main exposed facets of pseudo octahedral Co3O4 nanoparticle should be {110}. More TEM images of pseudo octahedral Co3O4 are given in Figure S9 (SI). Figures 3 c1 and c2 show the TEM images of Co3O4 nanosheets. From the lattice resolved HRTEM image (Figure 3 c2) and its corresponding FFT pattern image (inset of Figure 3 c2), it can be observed that the dominated facets on both top and down sides of the nanosheets are {110} crystal planes. More TEM images of Co3O4 nanosheets are shown in Figure S10 (SI).

The HRTEM images of Co3O4 nanoplatelets (Figures 3 d1–d4) prove that they maintain the hexagonal platelet shape of Co(OH)2 precursors (Figure S11, SI) and have mesoporous architecture. It needs to be noticed that although the mesoporous structure is generated, the as-prepared Co3O4 nanoplatelets still have single crystalline feature which is consist with the mesocrystal feature42. It can be evidenced by the FFT spot patterns, taken from a whole free standing Co3O4 nanoplatelet, as shown in Figure 3 d3. All the spots can be well indexed as  ,

,  and

and  crystal planes along the [111] zone axis. The lattice resolved HRTEM image (Figure 3 d2) shows the

crystal planes along the [111] zone axis. The lattice resolved HRTEM image (Figure 3 d2) shows the  ,

,  and

and  crystal planes with 0.57 nm d-spacing and 60° interfacial angle, which confirm that the Co3O4 nanoplatelets are exposed with {111} facets. The rhombic atomic arrangement on the {111} surfaces is shown in the atom resolved HRTEM image (Figure 3 d4) and illustrated by the crystal structure along [111] projected direction (inset of Figure 3 d4).

crystal planes with 0.57 nm d-spacing and 60° interfacial angle, which confirm that the Co3O4 nanoplatelets are exposed with {111} facets. The rhombic atomic arrangement on the {111} surfaces is shown in the atom resolved HRTEM image (Figure 3 d4) and illustrated by the crystal structure along [111] projected direction (inset of Figure 3 d4).

Figures 3 e1–e4 present the TEM images of Co3O4 nanolaminars. In Figures 3 e2 and e3, we can observe  ,

,  and

and  crystal planes along the [112] zone axis, which have 0.46, 0.24 and 0.28 nm d-spacings, respective. They are less than 2% crystal mismatch with (200), (212) and (012) crystal planes of (NH4)2Co8(CO3)6(OH)6·4H2O precursor. Therefore, it is reasonable to convert the

crystal planes along the [112] zone axis, which have 0.46, 0.24 and 0.28 nm d-spacings, respective. They are less than 2% crystal mismatch with (200), (212) and (012) crystal planes of (NH4)2Co8(CO3)6(OH)6·4H2O precursor. Therefore, it is reasonable to convert the  facets exposed (NH4)2Co8(CO3)6(OH)6·4H2O nanolaminar precursor into {112} facets exposed Co3O4 nanolaminar, maintaining the single crystal feature as illustrated by Scheme S2 (SI). More TEM images of (NH4)2Co8(CO3)6(OH)6·4H2O precursor and Co3O4 nanolaminar are given in Figure S12 and Figure S13 (SI), respectively. The {112} crystal planes have more open surface structure than other crystal planes, which can be seen in Figure 3 e4 (the atom resolved HRTEM image and simulated crystal structure along [112] projected direction).

facets exposed (NH4)2Co8(CO3)6(OH)6·4H2O nanolaminar precursor into {112} facets exposed Co3O4 nanolaminar, maintaining the single crystal feature as illustrated by Scheme S2 (SI). More TEM images of (NH4)2Co8(CO3)6(OH)6·4H2O precursor and Co3O4 nanolaminar are given in Figure S12 and Figure S13 (SI), respectively. The {112} crystal planes have more open surface structure than other crystal planes, which can be seen in Figure 3 e4 (the atom resolved HRTEM image and simulated crystal structure along [112] projected direction).

The surface-to-volume ratio and size effects associated with nanoparticles and surface area information were collected by nitrogen adsorption isotherms at 77 K, as shown in Figure 4. It can be seen the Co3O4 nanocubes, pseudo octahedrons and {110} facets exposed nanosheets show the typical type-II isotherm, which suggests no porous structure in these particles and they have around 20 m2 g−1 specific BET surface area. While {111} facets exposed hexagonal nanoplatelets and {112} facets exposed nanolaminars show a typical type-IV isotherm, revealing their mesoporous architecture feature (the average pore size is 6.0 and 2.2 nm respectively (calculated by the Barrett-Joyner-Halenda (BJH) method)). They also have much larger specific BET surface area. To avoid the inconformity affect, the surface area of different Co3O4 samples has been normalized. Figure S14 (SI) shows the adsorption pore area distribution versus the pore size of Co3O4 nanoplatelets and Co3O4 nanolaminars. They have 32.95 and 78.71 m2 g−1 integrated BJH adsorption pore areas, respectively, which were subtracted from the surface areas for the comparison.

Surface analysis of Co3O4 nanocrystals.

N2 absorption isotherms of (a) Co3O4 nanocubes, (b) pseudo octahedral Co3O4, (c) {110} facets exposed nanosheets, (d) {111} facets exposed hexagonal nanoplatelets and (e) {112} facets exposed nanolaminars. (f–j) are their corresponding pore size distribution, derived from absorption hysteresis of Brunauer-Emmett-Teller (BET) surface area measurement. The surface areas are listed in each subfigure from (f) to (j). The average pore sizes of hexagonal Co3O4 nanoplatelets and Co3O4 nanolaminars are given in (i) and (j).

Electrochemical performance of single crystalline Co3O4 nanocrystals exposed with different crystal planes for Li-O2 batteries

The electrochemical performance of single crystalline Co3O4 nanocrystals exposed with different crystal planes for Li-O2 batteries was tested through galvanostatical charge and discharge. Figure 5 shows the voltage-capacity profiles of bare CNT and various Co3O4 nanocrystal catalysts loaded CNT cathodes with curtailing the capacity to 500 mA h g−1. For the bare CNT electrode, the discharge plateau is at about 2.76 V and the charge plateau is at about 4.2 V during the first and second cycles (Figure 5a). Figures 5b–f demonstrate the charge-discharge profiles of various Co3O4 nanocrystal catalysts loaded CNT cathodes. Obviously, they all have lower charge potential by comparison with the bare CNT cathodes. Co3O4 nanocubes can achieve the 3.98 V charge potential in the initial cycle, although it was increased to 4.17 V during the second cycle. Pseudo octahedral Co3O4 presented the 3.76 V charge plateau on both first and second cycles. {110} facets exposed Co3O4 nanoplatelets further got decreased charge potential in the first cycle, which is 3.69 V. {112} facets exposed Co3O4 nanolaminars demonstrated about 3.68 V charging potential. {111} facets exposed hexagonal Co3O4 nanoplatelets achieved the lowest charge voltage (3.56 V). These observations indicate that Co3O4 nanocrystals exposed with different crystal planes have different effect on the catalytic properties for the oxygen evolution reaction (OER), which is lithium peroxides decomposition process.

Electrochemical characterizations at 500 mA h g−1 capacity limits.

Voltage profiles of (a) bare CNT and different Co3O4 catalysts loaded CNT: (b) Co3O4 nanocubes, (c) pseudo octahedral Co3O4, (d) {110} facets exposed Co3O4 nanosheets, (e) {112} facets exposed Co3O4 nanolaminars and (f) {111} facets exposed hexagonal Co3O4 nanoplatelets. Blue and red lines represent the first and second cycles, respectively. Current density is 100 mA g−1.

Specifically, with the normal-spinel structure, Co3O4 has two kinds of Co ions: Co2+ and Co3+, the Co2+ occupies one-eighth of the tetrahedral interstices, while the Co3+ ions occupy half of the octahedral interstices as shown in Figure 6a43,44. Obviously, the {100}, {110}, {111} and {112} crystal planes present different atom arrangement, which may result in the different responsible for OER performance. In principle, the nanocrystals' properties are determined by the exposed crystal facets22,38,45,46,47. Metal oxide crystals with particular exposed crystal planes such as high-index facets, could achieve improved chemical or physical performances, because high-index facets have high densities of atom steps, edges, kinks and dangling bonds, which usually have high chemical activity48,49. Furthermore, as confirmed both theoretically50 and experimentally37,51, the Co3+oct is regarded as the active site compare with the Co2+tet. Therefore, the Co3+oct ion density is the critical factor for their catalytic performance of different surfaces.

The refined crystal structure and relaxed side views of the surface atom configurations of {100}, {110}, {111} and {112} crystal planes are shown in Figures 6 b–e. The calculated surface energies based on the density function theory (DFT) for Co3O4 crystals are listed in Table 1. The {100} crystal plane has the lowest surface energy of 0.92 J m−2, suggesting it is the most stable facet. The {110} crystal planes have the second lowest surface energy (1.31 J m−2). The {112} crystal planes show relatively higher surface energy (1.47 J m−2). The most active crystal planes for Co3O4 are the {111} facets, with the highest surface energy of 2.31 J m−2, which is more than two times of {100} crystal planes. Generally, high-energy surfaces have a large density of low-coordinated atoms situated on steps and kinks, with high reactivity52. This favours fast ion transfer between the surface and the interior53,54. As shown in Table 1, the {111} crystal planes also have the highest dangling bonds density (27.70 Å−2, calculated based on the coordinatively unsaturated Co2+ and Co3+, as summarized by Table S1, SI), followed by the {112}, {110} and {100} in order (15.02, 13.02 and 12.27, respectively), which is consisted with their corresponding order on the surface energies ({111} > {112} > {110} > {100}). Interestingly, this tendency is also coordinated with the dangling bonds density of Co3+ ions in different crystal planes, as listed by Table 1, confirming the Co3+oct is the active site by comparison with Co2+tet. Therefore, the {111} crystal planes can provide more reactive sites to facilitate OER during the charge process. Similarly, Co3O4 nanocubes, pseudo octahedral Co3O4, Co3O4 nanosheets and Co3O4 nanolaminars presented the gradually improved catalytic performance on OER due to their exposed facets ({100}, {110}, {112}, respectively), which benefited the decrease on the charge potential.

When fully charged and discharged the cells at 200 mA g−1 current density, different capacities were obtained in different Co3O4 catalysts loaded CNT electrodes, as shown in Figure 7. For the bare CNT electrode (Figure 7a), the initial discharge capacity is about 3000 mA h g−1. After the first cycle, its discharge capacity degraded to 2117 mA h g−1. When electrodes were loaded with Co3O4 catalysts, the specific capacity has been significantly improved. As shown in Figure 7b, the CNT with Co3O4 nanocubes cathode delivered a specific capacity of 3958 mA h g−1 in the first cycle. Although there is decrease on the second cycle, the discharge capacity was still maintained at high value (3746 mA h g−1). Along with the improved catalytic property of different Co3O4 nanocrystals, the capacities were increased gradually. With the pseudo octahedral Co3O4, {110} facets exposed Co3O4 nanosheets and {112} facets exposed Co3O4 nanolaminars, the electrodes can achieve ~4127, 4567 and 4719 mA h g−1 discharge capacities, respectively. While the {111} facets exposed hexagonal Co3O4 nanoplatelets reached the maximum of 5229 mA h g−1 capacity, which is 1.7 times over the bare CNT electrode. The cycling performance of the Co3O4 nanoplatelets loaded CNT electrode is shown in Figure S15 (SI). It can be seen that although the discharge capacity decreased upon cycling, the electrode still maintained a discharge capacity of more than 3000 mA h g−1, a high coulombic efficiency of ~95% and relatively low charge-discharge over-potential within the ten cycle.

Electrochemical characterizations.

Voltage profiles of (a) bare CNT and different Co3O4 catalysts loaded CNT: (b) Co3O4 nanocubes, (c) pseudo octahedral Co3O4, (d) {110} facets exposed Co3O4 nanosheets, (e) {112} facets exposed Co3O4 nanolaminars and (f) {111} facets exposed hexagonal Co3O4 nanoplatelets. Blue and red lines represent the first and second cycles, respectively. Current density is 200 mA g−1.

By analysing the profiles of discharge and charge curves, we found that the bare CNT electrode delivered an average discharge voltage of 2.7 V and a charge voltage of 4.3 V; while, the Co3O4 catalysts added electrodes show much lower charge voltage, especially, the Co3O4 nanoplatelets loaded CNT electrode has over-potential of 1.14 V, which is significantly lower than that of the bare CNT electrode (Figure 7f).

Obviously, the improved capacities should be ascribed to the various exposed facets of the as-prepared Co3O4 nanocrystals. The calculated density of states for the {100}, {110}, {111} and {112} crystal planes with the Li and O atoms present that all of them have the interaction with the Li and O atoms because of the overlapped curves in the density of states (Figure 8). The corresponding electrons density plots (insets of Figure 8) demonstrate the electrons distribution between each crystal plane and the Li and O atoms, confirming different crystal planes of Co3O4 could provide reactive sites for the reaction between Li and O atoms. Furthermore, the density of state curves show that {111} crystal planes have the largest interaction with Li and O atoms due to the more overlapped electrons orbits (especially, at the −18.3 eV position), suggesting its highest catalytic property for the Li and O reaction.

Conclusion

In summary, single crystalline Co3O4 nanocrystals exposed with different crystal planes were synthesised, including nanocubes, pseudo octahedrons, nanosheets, hexagonal nanoplatelets and nanolaminar. As confirmed by FESEM and HRTEM analyses, they are exposed with {100}, {110}, {111} and {112} crystal planes, respectively. The electrochemical performance for Li-O2 batteries shows that Co3O4 nanocrystals can significantly reduce the discharge-charge over-potential via the effect on the oxygen evolution reaction (OER) and achieve high specific capacity, leading to a high round-trip efficiency. From the comparison of the catalytic performance of different Co3O4 nanocrystals, it knows that the essential factor to promote the OER of Co3O4 nanocrystals is the surface crystal planes. The correlation of different Co3O4 crystal planes and their effect on reducing charge and discharge over potential was established: {100} < {110} < {112} < {111}, which were verified by theoretical calculations and experiments analyses. The study demonstrates that Co3O4 based nanomaterials could be applied as effective cathode catalysts for high performance Li-O2 batteries.

Methods

Synthesis

All chemicals were analytical grade and were used as received without further purification. And all chemicals were supplied by Sigma-Aldrich. Co(NO3)2·6H2O, LiOH·H2O, H2BO3, poly(vinylpyrrolidone) (PVP), NaOH, urea (CO(NH2)2), cationic surfactant cetyltrimethylammonium bromide (CTAB), H2O2 and KOH all have the high purity (≥97%). The multiwall carbon nanotubes were purchased from Sigma-Aldrich.

Co3O4 nanocube and Co3O4 pseudo octahedrons

Their synthesis followed the PH-control strategy. In a typical synthesis, 1 mmol Co(NO3)2·6H2O were dissolved in a 10 mL distilled water, than 5 mL 0.01 M LiOH·H2O and H2BO3 solution was added. After 20 mins magnetic stirring, the mixture was transfer into a Teflon-lined autoclave (25 mL in capability) sealed by the stainless steel jar. The autoclave was heated to 180°C and maintained at that temperature for 12 h. After cooling to room temperature, the Co3O4 nanocubes were collected by centrifugation and washed thoroughly with distilled water several times. To synthesize Co3O4 pseudo octahedrons, the same procedure was followed, but with manipulation of the concentration of LiOH·H2O and H2BO3: 5 mL of 0.1 M LiOH and H2BO3 solution were dissolved in the 10 mL of 0.1 M Co(NO3)2·6H2O.

{110} facets exposed Co3O4 single crystal nanosheet

It was synthesized by a redox-precipitation route as follows: 5 mL of 30 wt.% H2O2 aqueous solution was added into 10 mL of a 0.02 M Co(NO3)2·6H2O aqueous solution under vigorous stirring. The pH of the solution was adjusted by the addition of a 2 M KOH solution to reach 8.0 slowly (be careful, during this process a vigorous reaction was happened). After that, the mixed solution was then transferred into 25 mL Teflon-lined autoclave and heated to and maintained at 180°C for 16 h. The autoclave was cooled naturally to room temperature. Co3O4 single crystal nanosheets were obtained by filtration, several washing steps with distilled water and ethanol and drying at 60°C for 12 h.

Hexagonal Co3O4 nanoplatelets

Follow the crystal mismatch guided formation mechanism, Co(OH)2 as precursor were prepared by the precipitation and hydrothermal process first. In a typical procedure, 1.2 g of Co(NO3)2·6H2O were dissolved in a 10 mL mixture of ethanol and distilled water with a 1:1 volume. As a surfactant, 1 g of poly(vinylpyrrolidone) (PVP) were added. After 30 mins magnetic stirring, 25 mL of a 0.4 M NaOH aqueous solution was slowly added, taking 1.5 h accompany with the colour evolution from blue to red-pink, indicating the phase change from the α to β phase of Co(OH)2. Then the reaction suspension was quickly transferred into a Teflon-lined autoclave. The autoclave was heated to 120°C and maintained at that temperature for 10 h. After cooling to room temperature, the pink product was collected by centrifugation and washed thoroughly with distilled water several times. The β-Co(OH)2 precursors were obtained after drying for 12 h at 60°C in the vacuum oven. The final mesoporous Co3O4 nanocrystals were prepared by annealing β-Co(OH)2 precursor at 450°C for 2 h in the tube furnace under atmospheric environment with a slow heating rate (2.0°C min−1).

{112} facets exposed Co3O4 nanolaminars55

Similarly, follow the crystal mismatch guided formation mechanism, Co3O4 nanolaminars enclosed by {112} facets were obtained converting from the (NH4)2Co8(CO3)6(OH)6·4H2O nanolaminars single crystals precursor synthesised by the hydrothermal condition. In a typical procedure, 1 mmol Co(NO3)2·6H2O, 4 mmol urea (CO(NH2)2) and 0.2 g cationic surfactant cetyltrimethylammonium bromide (CTAB) as soft template were dissolved in distilled water (20 mL) at room temperature. The mixture was stirred vigorously for several mins until a transparent red solution was formed and then transferred into the Teflon-lined autoclave (25 mL in capability). After heating and maintaining at 140°C for 12 h, the precipitate was cooled down to room temperature naturally, collected and washed with distilled water and ethanol several times. The final product Co3O4 nanolaminars, were obtained by thermal treatment of the above precursors at 450°C for 2 h in the tube furnace under atmospheric environment with a slow heating rate (2.0°C min−1).

Structural and physical characterization

The phase and crystallographic structure of as-prepared Co3O4 nanocrystals were characterized by powder X-ray diffraction (XRD) using a Siemens D5000 diffractometer equipped by a Cu Kα1 radiation (λ = 1.54056 Å) with 2θ ranging from 15° to 85° at a scanning step of 0.02° sec−1. The size and morphology was analysed by high resolution field emission scanning electron microscopes (FESEM) Zeiss Supra 55VP. The microscope was operated at a working distance of 2 mm with an acceleration voltage of 10 kV and an in-lens detector was used for the imaging. The crystal structural details were further characterized by high-resolution transmission electron microscopy (HRTEM) FEGTEM 3000 (JEOL 300 KV Atomic Resolution Transmission Electron Microscope (0.192 nm resolution)) worked at an accelerating voltage of 300 kV. The bright field image (BF) and selected area electron diffraction (SAED) patterns were recorded by a Gatan CCD camera in a digital format. The surface area information was collected by N2 adsorption isotherm using a Quadrasorb SI analyzer at 77 K. Brunauer–Emmett–Teller (BET) surface areas were calculated using experimental points at a relative pressure of P/P0 = 0.05–0.25. The pore size distribution was calculated by the Barret–Joyner–Halenda (BJH) method.

Electrochemical testing

A Swagelog-type cell was designed to investigate the charge and discharge properties and cyclability in Li-O2 batteries, which consisted of a stainless steel cylinder plunger to support a Li foil anode (3 mm × ø 15 mm) and a special stainless steel tube to allow oxygen access to the back side of the cathode. The oxygen electrodes were prepared as follows: catalyst slurry was-prepared by mixing the as-prepared catalysts (90 wt. %) with poly(tetrafluoroethylene) (PTFE) (10 wt. %) in isopropanol. The mixture was then coated on a glass fibre separator. The cathode film was punched into discs with a diameter of 14 mm and dried at 110°C in a vacuum oven for 12 h. The typical loading of the air electrode is about 1 mg carbon cm−2. The cathode was placed onto the separator and a thin open 316 stainless steel mesh was placed on top to act as a current collector. The entire cell was gastight except for the stainless steel mesh window exposed the porous cathode to the O2 atmosphere. The Li-O2 cells were assembled in an Ar filled glove box (Unilab, MBRAUN, Germany) with water and oxygen level less than 0.1 ppm. A glass microfiber filter (Whatman, ø 21 mm) separator will be used, soaked in 1 M LiNO3 (99.99%, Sigma-Aldrich) in dimethyl sulfoxide (DMSO, anhydrous, >99.9%, Sigma-Aldrich) electrolyte. The cell was gas-tight except for the stainless steel mesh window that exposed the porous cathode film to the oxygen atmosphere. All measurements were conducted in 1 atm dry oxygen atmosphere to avoid any negative effects of humidity and CO2. Galvanostatic discharge charge was conducted on a Neware battery testing system. Because the as-prepared Co3O4 nanocrystals present different surface areas, to avoid the inconformity affect, when the electrodes were prepared, the surface area of different Co3O4 samples has been normalized, which means the different mass of different Co3O4 nanocrytals were added into the CNT to keep that the total exposed crystal planes of different Co3O4 nanocrystals have the same area. Especially, for the {111} facets exposed hexagonal Co3O4 nanoplatelets and {112} facets exposed Co3O4 nanolaminars, because they show mesoporous architecture feature, the pore areas of them were subtracted from the surface areas. The specific capacity was calculated based on the mass of CNT in the cathode electrodes.

Computational methods

The calculations were performed based on the density-functional theory (DFT) approach56 with the ABINIT57,58. The exchange-correlation energy function was represented by the local-density approximation (LDA) employing ultra-soft pseudopotential (USPP) formalism59. We used an energy cutoff of 350 eV. Different Monkhorst-Pack k-point sets were used. The maximum self-consistent field convergent tolerance was less than 2 × 10−6 eV atom−1. All calculations were performed in reciprocal space. For the surface energy calculation, the surface region is composed of a finite number of two-dimensional infinite planes formed by cutting the crystal along a particular Miller index (hkl) plane. In each plane, a two-dimensional cell represents every site in the plane. Following the approach of Tasker60, several of these cells in successive planes comprise the basic repeat unit that contains the composition of the bulk crystal unit cell. The surface energy per unit area,  , of a particular surface is calculated from the difference between the energy of the surface block, Esurface block and the energy of the same number of bulk ions, Ebulk, per unit area, A (cross-sectional), thus

, of a particular surface is calculated from the difference between the energy of the surface block, Esurface block and the energy of the same number of bulk ions, Ebulk, per unit area, A (cross-sectional), thus

For slab model construction, enough layers were used and the depths of the surface regions were chosen to be large enough to ensure full relaxation of the surface ions and convergence of the surface energy. In each of case, surface structures were fully relaxed until the total energy difference was converged within 0.001 eV.

References

Bruce, P. G., Freunberger, S. A., Hardwick, L. J. & Tarascon, J.-M. Li-O2 and Li-S batteries with high energy storage. Nat. Mater. 11, 19–29 (2012).

Girishkumar, G., McCloskey, B., Luntz, A., Swanson, S. & Wilcke, W. Lithium-air battery: promise and challenges. J. Phys. Chem. Lett. 1, 2193–2203 (2010).

Christensen, J. et al. A critical review of Li/air batteries. J. Electrochem. Soc. 159, R1–R30 (2011).

Li, F., Zhang, T. & Zhou, H. Challenges of non-aqueous Li-O2 batteries: electrolytes, catalysts and anodes. Energy Environ. Sci. 6, 1125–1141 (2013).

Zhang, L. et al. High aspect ratio γ-MnOOH nanowires for high performance rechargeable nonaqueous lithium–oxygen batteries. Chem. Commun. 48, 7598–7600 (2012).

Zhu, D., Zhang, L., Song, M., Wang, X. & Chen, Y. An in situ formed Pd nanolayer as a bifunctional catalyst for Li-air batteries in ambient or simulated air. Chem. Commun. 49, 9573–9575 (2013).

Raghu, S. C., Ulaganathan, M., Aravindan, V. & Lim, T. M. Palladium- and Gold-Nanoparticle-Modified Porous Carbon as a High-Power Anode for Lithium-Ion Batteries. ChemPhysChem 14, 3887–3890 (2013).

Lei, Y. et al. Synthesis of Porous Carbon Supported Palladium Nanoparticle Catalysts by Atomic Layer Deposition: Application for Rechargeable Lithium-O2 Battery. Nano Lett. 13, 4182–4189 (2013).

Cao, R. et al. Promotion of oxygen reduction by a bio-inspired tethered iron phthalocyanine carbon nanotube-based catalyst. Nat. Commun. 4, 2076 (2013).

Hsieh, Y.-C. et al. Ordered bilayer ruthenium–platinum core-shell nanoparticles as carbon monoxide-tolerant fuel cell catalysts. Nat. Commun. 4, 2466 (2013).

Laoire, C., Mukerjee, S., Plichta, E. J., Hendrickson, M. A. & Abraham, K. Rechargeable Lithium/TEGDME-LiPF6/O2 Battery. J. Electrochem. Soc. 158, A302–A308 (2011).

Peng, Z., Freunberger, S. A., Chen, Y. & Bruce, P. G. A reversible and higher-rate Li-O2 battery. Science 337, 563–566 (2012).

Shui, J.-L., Karan, N. K., Balasubramanian, M., Li, S.-Y. & Liu, D.-J. Fe/N/C Composite in Li-O2 Battery: Studies of Catalytic Structure and Activity toward Oxygen Evolution Reaction. J. Am. Chem.Soc. 134, 16654–16661 (2012).

Li, F. et al. Carbon supported TiN nanoparticles: an efficient bifunctional catalyst for non-aqueous Li–O2 batteries. Chem. Commun. 49, 1175–1177 (2013).

Ryu, W.-H. et al. Bifunctional Composite Catalysts Using Co3O4 Nanofibers Immobilized on Nonoxidized Graphene Nanoflakes for High-Capacity and Long-Cycle Li-O2 Batteries. Nano Lett. 13, 4190–4197 (2013).

Yilmaz, E., Yogi, C., Yamanaka, K., Ohta, T. & Byon, H. R. Promoting Formation of Noncrystalline Li2O2 in the Li-O2 Battery with RuO2 Nanoparticles. Nano Lett. 13, 4679–4684 (2013).

Zhong, L. et al. In Situ Transmission Electron Microscopy Observations of Electrochemical Oxidation of Li2O2 . Nano Lett. 13, 2209–2214 (2013).

Xu, J.-J., Wang, Z.-L., Xu, D., Zhang, L.-L. & Zhang, X.-B. Tailoring deposition and morphology of discharge products towards high-rate and long-life lithium-oxygen batteries. Nat. Commun. 4, 2438 (2013).

Yang, H. G. et al. Anatase TiO2 single crystals with a large percentage of reactive facets. Nature 453, 638–641 (2008).

Leng et al. Polyhedral 50-Facet Cu2O Microcrystals Partially Enclosed by {311} High-Index Planes: Synthesis and Enhanced Catalytic CO Oxidation Activity. J. Am. Chem. Soc. 132, 17084–17087 (2010).

Mou, X. et al. Rod-Shaped Fe2O3 as an Efficient Catalyst for the Selective Reduction of Nitrogen Oxide by Ammonia. Angew. Chem. Int. Ed. 51, 2989–2993 (2012).

Xie, X., Li, Y., Liu, Z.-Q., Haruta, M. & Shen, W. Low-temperature oxidation of CO catalysed by Co3O4 nanorods. Nature 458, 746–749 (2009).

Ji & Zeng, H. C. Size-Controlled Growth of Co3O4 Nanocubes. Chem. Mater. 15, 2829–2835 (2003).

Xu & Zeng, H. C. Mechanistic Investigation on Salt-Mediated Formation of Free-Standing Co3O4 Nanocubes at 95°C. J. phys chem. B 107, 926–930 (2003).

Xie et al. Synthesis of Nanorod-Shaped Cobalt Hydroxycarbonate and Oxide with the Mediation of Ethylene Glycol. J. Phys. Chem. C 114, 2116–2123 (2010).

Xu, R. & Zeng, H. C. Dimensional Control of Cobalt-hydroxide-carbonate Nanorods and Their Thermal Conversion to One-Dimensional Arrays of Co3O4 Nanoparticles. J. Phys. Chem. B 107, 12643–12649 (2003).

Li, Y. et al. Iodine-ion-induced Size-tunable Co3O4 Nanowires and the Size-dependent Catalytic Performance for CO Oxidation. ChemCatChem 5, 3576–3581 (2013).

Hou, Y. L., Kondoh, H., Shimojo, M., Kogure, T. & Ohta, T. High-yield preparation of uniform cobalt hydroxide and oxide nanoplatelets and their characterization. J. Phys. Chem. B 109, 19094–19098 (2005).

He, T., Chen, D. R., Jiao, X. L. & Wang, Y. L. Co3O4 nanoboxes: Surfactant-templated fabrication and microstructure characterization. Adv. Mater. 18, 1078–1082 (2006).

Yang, J., Liu, H., Martens, W. N. & Frost, R. L. Synthesis and Characterization of Cobalt Hydroxide, Cobalt Oxyhydroxide and Cobalt Oxide Nanodiscs. J. Phys. Chem. C 114, 111–119 (2010).

Zhao, Z., Geng, F., Bai, J. & Cheng, H.-M. Facile and controlled synthesis of 3D nanorods-based urchinlike and nonosheets-based flowerlike cobalt basic salt nanostructures. J. Phys. Chem. C 111, 3848–3852 (2007).

Cao, A.-M. et al. Hierarchically structured cobalt oxide (Co3O4): The morphology control and its potential in sensors. J. Phys. Chem. B 110, 15858–15863 (2006).

King, S., Hyunh, K. & Tannenbaum, R. Kinetics of nucleation, growth and stabilization of cobalt oxide nanoclusters. J. Phys. Chem. B 107, 12097–12104 (2003).

Feng, J. & Zeng, H. C. Size-Controlled Growth of Co3O4 Nanocubes. Chem. Mater. 15, 2829–2835 (2003).

Chen, L., Hu, J., Richards, R., Prikhodko, S. & Kodambaka, S. Synthesis and surface activity of single-crystalline Co3O4 (111) holey nanosheets. Nanoscale 2, 1657–1660 (2010).

Tang, X., Li, J. & Hao, J. Synthesis and characterization of spinel Co3O4 octahedra enclosed by the {111} facets. Materials Research Bulletin 43, 2912–2918 (2008).

Petitto, S. C., Marsh, E. M., Carson, G. A. & Langell, M. A. Cobalt oxide surface chemistry: The interaction of CoO(100), Co3O4(110) and Co3O4(111) with oxygen and water. Journal of Molecular Catalysis A: Chemical 281, 49–58, 10.1016/j.molcata.2007.08.023 (2008).

Hu, Peng & Li, Y. Selective Synthesis of Co3O4 Nanocrystal with Different Shape and Crystal Plane Effect on Catalytic Property for Methane Combustion. J. Am. Chem. Soc. 130, 16136–16137 (2008).

Wang, Y. et al. Crystal-match guided formation of single-crystal tricobalt tetraoxygen nanomesh as superior anode for electrochemical energy storage. Energy Environ. Sci. 4, 1845–1854 (2011).

Zhou, Z.-Y., Tian, N., Li, J.-T., Broadwell, I. & Sun, S.-G. Nanomaterials of high surface energy with exceptional properties in catalysis and energy storage. Chem. Soc. Rev. 40, 4167–4185 (2011).

Li, L. S. et al. Topotactic transformation of single-crystalline precursor discs into disc-like Bi2S3 nanorod networks. Adv. Func. Mater. 18, 1194–1201 (2008).

Crossland, E. J. et al. Mesoporous TiO2 single crystals delivering enhanced mobility and optoelectronic device performance. Nature 495, 215–219 (2013).

Masaoki & Hirokawa, K. X-ray photoelectron spectroscopy of Co3O4, Fe3O4, Mn3O4 and related compounds. J. Electron Spectrosc. 8, 475–481 (1976).

Charles, D. & Spencer, D. S. Mössbauer study of several cobalt spinels using Co57 and Fe57. Phys. Rev. B 9, 3658–3665 (1974).

Prades, J. D., Cirera, A. & Morante, J. R. First-principles study of NOx and SO2 adsorption onto SnO2 (110). J. Electrochem. Soc. 154, H675–H680 (2007).

Tian, N., Zhou, Z. Y. & Sun, S. G. Platinum Metal Catalysts of High-Index Surfaces: From Single-Crystal Planes to Electrochemically Shape-Controlled Nanoparticles. J. Phys. Chem. C 112, 19801–19817 (2008).

Tian, N., Zhou, Z. Y. & Sun, S. G. Electrochemical preparation of Pd nanorods with high-index facets. Chem. Commun. 1502–1504 (2009).

Han, X. G. et al. Controlling Morphologies and Tuning the Related Properties of Nano/Microstructured ZnO Crystallites. J. Phys. Chem. C 113, 584–589 (2009).

Wang, Z. L. Zinc oxide nanostructures: growth, properties and applications. J. Phys-Condens. Mat. 16, R829–R858 (2004).

Broqvist, P., Panas, I. & Persson, H. A DFT study on CO oxidation over Co3O4 . J. Catal. 210, 198–206 (2002).

Jansson, J. et al. On the Catalytic Activity of Co3O4 in Low-Temperature CO Oxidation. J. Catal. 211, 387–397 (2002).

Lebedeva, N. P., Koper, M. T. M., Feliu, J. M. & van Santen, R. A. Role of crystalline defects in electrocatalysis: Mechanism and kinetics of CO adlayer oxidation on stepped platinum electrodes. J. Phys. Chem. B 106, 12938–12947 (2002).

Zhang, D. Q. et al. Microwave-Induced Synthesis of Porous Single-Crystal-Like TiO2 with Excellent Lithium Storage Properties. Langmuir 28, 4543–4547 (2012).

Chen, J. S., Liu, H., Qiao, S. Z. & Lou, X. W. Carbon-supported ultra-thin anatase TiO2 nanosheets for fast reversible lithium storage. J. Mater. Chem. 21, 5687–5692 (2011).

Cui, L., Li, J. & Zhang, X.-G. Preparation and properties of Co3O4 nanorods as supercapacitor material. J. Appl. Electrochem. 39, 1871–1876 (2009).

Amadon, B., Jollet, F. & Torrent, M. gamma and beta cerium: LDA + U calculations of ground-state parameters. Phys. Rev. B 77, 155104(155101)–155104(155110) (2008).

Gonze, X. et al. ABINIT: First-principles approach to material and nanosystem properties. Comput. Phys. Commun. 180, 2582–2615 (2009).

Gonze, X. et al. A brief introduction to the ABINIT software package. Z Kristallogr 220, 558–562 (2005).

Perdew, J. P. & Wang, Y. Accurate and Simple Analytic Representation of the Electron-Gas Correlation-Energy. Phys. Rev. B 45, 13244–13249 (1992).

Tasker, P. W. Stability of Ionic-Crystal Surfaces. J. Phys. C Solid State 12, 4977–4984 (1979).

Acknowledgements

This original research was proudly supported by Commonwealth of Australia through the Automotive Australia 2020 Cooperative Research Centre (AutoCRC). The authors acknowledge use of facilities within the UOW Electron Microscopy Centre.

Author information

Authors and Affiliations

Contributions

D.-W.S. performed the experiments. S.-X.D. and G.-X.W. conceived the study. D.-W.S. wrote the manuscript. All authors discussed the results on the manuscript and reviewed the manuscript. All authors revised the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Revised Supplementary Information for Single Crystalline Co3O4 Nanocrystals Exposed with Different Crystal Planes for Li-O2 Batteries

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 4.0 International License. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/4.0/

About this article

Cite this article

Su, D., Dou, S. & Wang, G. Single Crystalline Co3O4 Nanocrystals Exposed with Different Crystal Planes for Li-O2 Batteries. Sci Rep 4, 5767 (2014). https://doi.org/10.1038/srep05767

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep05767

This article is cited by

-

Rational construction of high-active Co3O4 electrocatalysts for oxygen evolution reaction

Nano Research (2023)

-

Magnetic properties of exchange-biased FeCo/CoO bilayer and its electronic structure

Applied Physics A (2022)

-

Recent progress in cathode catalyst for nonaqueous lithium oxygen batteries: a review

Advanced Composites and Hybrid Materials (2022)

-

Redirecting dynamic surface restructuring of a layered transition metal oxide catalyst for superior water oxidation

Nature Catalysis (2021)

-

Competing ferro- and antiferromagnetic exchange drives shape-selective \(\hbox{Co}_3\hbox{O}_4\) nanomagnetism

Scientific Reports (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.