Abstract

In quantum spin liquid research, thin films are an attractive arena that enables the control of magnetic interactions via epitaxial strain and two-dimensionality, which are absent in bulk crystals. Here, as a promising candidate for the development of quantum spin liquids in thin films, we propose a robust ilmenite-type oxide with a honeycomb lattice of edge-sharing IrO6 octahedra artificially stabilised by superlattice formation using the ilmenite-type antiferromagnetic oxide MnTiO3. Stabilised sub-unit-cell-thick Mn–Ir–O layers are isostructural to MnTiO3 and have an atomic arrangement corresponding to ilmenite-type MnIrO3. By performing spin Hall magnetoresistance measurements, we observe that antiferromagnetic ordering in the ilmenite Mn sublattice is suppressed by modified magnetic interactions in the MnO6 planes via the IrO6 planes. These findings contribute to the development of two-dimensional Kitaev candidate materials, accelerating the discovery of exotic physics and applications specific to quantum spin liquids.

Similar content being viewed by others

Introduction

Recent studies on quantum spin liquids have focused on the development of new candidate materials1. In the materials design, an exactly solvable S = 1/2 spin model on a two-dimensional honeycomb lattice presents a rigorous theoretical framework, which was initially proposed by Kitaev2 and subsequently reformulated with realistic materials by Jackeli and Khaliullin3. An important component of the model is a honeycomb lattice of edge-sharing metal-anion octahedra, comprising Ru3+ or Ir4+ ions with a d5 electron configuration, which produces bond-specific Ising-like interactions, called Kitaev-type interactions, and yields strong quantum fluctuations of (pseudo)spins in the honeycomb lattice1,3,4,5. For α-RuCl3 (refs. 6,7) and iridates such as Na2IrO3 (refs. 8,9), α-, β- and γ-Li2IrO3 (refs. 9,10,11,12,13) and H3LiIr2O6 (ref. 14), the potential of achieving quantum spin liquids via Kitaev-type interactions has been extensively discussed. In addition to theoretical approaches3,4,5, advanced experiments on bulk crystals, such as magnetic resonant X-ray diffraction (XRD)10,13, the thermal Hall effect15 and nuclear magnetic resonance14, have been used to examine complex magnetic phases and identify quantum spin liquid states.

A major challenge in this research field is to incorporate these materials in thin films, especially atomically thin monolayer forms. Thin-film techniques are essential not only for practical applications but also for providing additional degrees of freedom for the control of magnetic interactions. For example, epitaxial strain at the interface and dimensionality control16,17,18 can present opportunities to address the breaking of the expected Kitaev-type interactions by antiferromagnetic ordering due to structural distortion and interlayer coupling6,7,8,9,10,11,12,13,19,20. However, high-quality films of α-RuCl3 (refs. 6,7) and iridates with H and Li (refs. 10,11,12,13,14), which have to date attracted the attention of researchers as bulk candidate materials, are difficult to prepare. This is because their volatile and/or diffusible nature requires the precise control of stoichiometry and the suppression of inter-diffusion to reproduce the bulk properties. Inspired by these problems in known Kitaev candidate materials, we aim to determine a new crystal system that is suitable for thin-film research and focus on ilmenite-type ABO3 compounds (where A and B are metal cations) containing Ir19,20. Recently, Haraguchi et al. proposed a method for the bulk synthesis of ilmenite-type ZnIrO3 and MgIrO3 with honeycomb lattices of edge-sharing IrO6 octahedra in the ab plane19 (e.g., see Fig. 1a, b). The authors discussed an XY-like magnetic anisotropy and a tilting magnetic structure, which may be related to Kitaev-type interactions19.

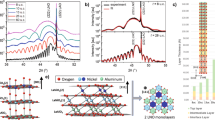

a Crystal structure of ilmenite-type MnBO3 viewed along the \(\left[ {11\bar 20} \right]\) direction, drawn by VESTA (ref. 51). b Honeycomb lattice formed by edge-sharing BO6 octahedra in the ab plane. The black quadrangles in a and b represent the unit cell. c Schematic structure of a Mn−Ir−O(cap)/[dMTO-nm-thick MnTiO3/dMIO-nm-thick Mn−Ir−O]n/MnTiO3(buffer) film grown on Al2O3(0001). d Out-of-plane X-ray diffraction (XRD) pattern of a film with dMTO = 4.3 nm (3 u.c.), dMIO = 0.5 nm and n = 15. The thickness of the MnTiO3 buffer layer was 5.7 nm (4 u.c.). Red arrows and asterisks indicate superlattice reflections and forbidden Al2O3(0003m) reflections, respectively. e Reciprocal space mapping around Al2O3\((02\bar 2\underline {10} )\). f, g In-plane ϕ scan results for \(\left( {10\bar 14} \right)\) peaks of Al2O3 substrate and film, respectively.

This study begins with ilmenite-type MnTiO3, for which the single-crystalline film growth on Al2O3(0001) has been established21,22, and attempts to stabilise Ir at the B-site of the ilmenite-type MnBO3 (Fig. 1a, b). By adopting the epitaxial strain in superlattices with ilmenite-type MnTiO3, which shares the A-site MnO6 plane, we develop a honeycomb lattice of edge-sharing IrO6 octahedra in an ilmenite lattice. This ultrathin-film form of iridate will serve as an intriguing two-dimensional platform for investigations in the physics of Kitaev materials.

Results

Structural characterisation using XRD

The films were grown on Al2O3(0001) substrates (lattice constants are a = 4.759 Å and c = 12.993 Å, JCPDS PDF 00-046-1212) by pulsed-laser deposition using a KrF excimer laser (see “Methods”). Our early attempt to grow ilmenite-type MnIrO3 directly on Al2O3(0001) was unsuccessful and resulted in phase-separated films of Mn3O4 and IrO2 (see Supplementary Fig. 1 in Supplementary Information for the XRD pattern). We then employed a superlattice approach16,17,18 based on ilmenite-type MnTiO3 thin films21,22. In the superlattice structure, the common A-site MnO6 plane is expected to promote the ilmenite-type stacking of MnO6 and IrO6 planes along the c-axis direction (Fig. 1a, b). The schematic structure of a typical superlattice is shown in Fig. 1c, where a MnTiO3 buffer layer with a thickness ranging between 4.3 and 7.8 nm was initially grown on Al2O3(0001), followed by the alternate deposition of much thinner Mn−Ir−O and MnTiO3 layers. A film thickness of 1.4 nm is approximately equal to the order of magnitude of typical c-axis parameters of ilmenite-type oxides. In a 0.5-nm-thick Mn−Ir−O (cap)/[4.3-nm-thick MnTiO3/0.5-nm-thick Mn−Ir−O]15/5.7-nm-thick MnTiO3 (buffer) film (superlattice cycle number n = 15 in Fig. 1c), the overall chemical composition of the film evaluated using energy-dispersive X-ray spectroscopy (EDX) was Mn:Ti:Ir = 50.4:45.1:4.5, which is in good agreement with the ideal composition of Mn:Ti:Ir = 50.0:44.9:5.1, as expected from the design thickness ratio. In the out-of-plane XRD pattern shown in Fig. 1d, four main diffraction peaks are observed from the film and are assigned to (0003m) (m: natural number) of the ilmenite-type structure. The satellite peaks near the (0006) and (00012) peaks (denoted by red arrows) indicate periodic modulation in the X-ray scattering cross-section by the superstructure of MnTiO3 and Mn−Ir−O layers, verifying that no alloy compound of Mn(Ti,Ir)O3 was formed. Assuming an abrupt MnTiO3/Mn−Ir−O interface without inter-diffusion, the average in- and out-of-plane lattice parameters of the single unit of the superlattice, that is, [4.3-nm-thick MnTiO3/0.5-nm-thick Mn−Ir−O], were a = 5.13 Å and c = 14.29 Å from the reciprocal space mapping near \((02\bar 2\underline {10} )\) (Fig. 1e). Because these values differ insignificantly from a = 5.1396 Å and c = 14.29 Å of MnTiO3 (JCPDS PDF No. 00-029-0902), the lattice parameters of Mn−Ir−O are comparable with those of MnTiO3. In addition, the threefold symmetry of the \((10\bar 14)\) diffraction peak was detected in the in-plane azimuthal ϕ scan measurements (Fig. 1f, g), indicating the epitaxial orientation relationship of the film \([10\bar 10]\)(0001)//Al2O3 \([10\bar 10]\)(0001). These results indicate that the film grows as a c-axis-oriented, single-domain, ilmenite-type oxide with a periodically modulated internal structure.

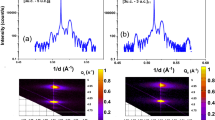

We examined the critical dMIO value to maintain the single-domain film growth by varying the thickness of the Mn−Ir−O layers (dMIO) in the [4.3-nm-thick MnTiO3/dMIO-nm-thick Mn−Ir−O]15 superlattice. As shown in Fig. 2a, b, the films with dMIO = 0.5 nm (identical to the sample in Fig. 1) and 1.0 nm exhibit clear (0006) peaks, which are associated with satellite peaks (red arrows). In particular, for dMIO = 0.5 nm, thickness fringes appear near the (0006) peak, indicating that the total film thickness is uniform over the entire film. Considering the observed satellite peaks as superlattice reflections, the single-unit lengths of the superlattices were calculated to be 4.5 nm and 5.6 nm for dMIO = 0.5 nm and dMIO = 1.0 nm, respectively. This is consistent with the designed values of 4.8 nm (=4.3 + 0.5 nm) and 5.3 nm (=4.3 + 1.0 nm), respectively. However, in the thickest film with dMIO = 1.4 nm (Fig. 2c), superlattice reflections become indiscernible with the occurrence of a diffraction peak of segregated IrO2 impurities; the designed superlattice structure is no longer formed for dMIO = 1.4 nm. The decrease in the (0006) diffraction intensity implies that the basal MnTiO3 layers in the superlattice are disordered. Therefore, the upper bound of dMIO for stabilising the IrO6 planes in the ilmenite lattice is ~1.0 nm, which is smaller than typical c-axis parameters of ilmenite-type oxides (~1.4 nm). The sub-unit-cell-thick Mn–Ir–O layer admits at most two IrO6 planes, indicating the fragile crystalline phase of Mn–Ir–O. Sandwiching between stable MnTiO3 layers in the superlattice structure stabilises the ilmenite-type atomic ordering of Mn–Ir–O ultrathin layers.

Microstructural characterisation by scanning transmission electron microscopy (STEM)

The suitability of our method for the formation of honeycomb-lattice IrO6 planes was verified by cross-sectional STEM observations (see “Methods”). In a [MnTiO3/Mn−Ir−O]8/MnTiO3(buffer) film (no Mn−Ir−O cap; see Supplementary Fig. 2 for the XRD pattern), eight bright layers parallel to the film plane were detected in the wide-area high-angle annular dark-field (HAADF) image, as shown in Fig. 3a. Owing to the Z-contrast nature (Z: atomic number)23, the bright layers should contain a significant amount of Ir, which has the largest Z among the constituent elements (Mn, Ti, Ir and O). Tiny bright island-like regions are observed, which may be due to the presence of segregated Ir-rich impurities. As expected from the large lattice mismatch of ~8% between MnTiO3 and Al2O3 and the observed relaxed growth (e.g., Fig. 1e), geometrical misfit dislocations were formed around the MnTiO3 buffer/Al2O3 substrate interface (Supplementary Fig. 3). A thorough inspection of a single unit of the superlattice (Fig. 3b) revealed that a Mn−Ir−O layer between MnTiO3 layers contains some bright atomic planes along the [0001] direction. Using the atomically resolved HAADF image in Fig. 3c (the area marked by yellow dashed lines in Fig. 3b), we compared each atomic site with a model structure (Fig. 3d). For MnTiO3, the MnO6 (TiO6) plane had a larger (smaller) atomic displacement along the [0001] direction between the in-plane Mn (Ti) ions24. By measuring the atomic displacement in the image, we determined that Ir atoms are located at the B-site, which is occupied by Ti atoms in MnTiO3, as schematically shown in Fig. 3d (also see in the left side of Fig. 3c). In addition, the bright Ir-containing planes are regularly sandwiched between the MnO6 planes and have a similar dumbbell-like characteristic atomic arrangement. From these results, we concluded that a honeycomb lattice of edge-sharing IrO6 octahedra crystallises in the Mn−Ir−O layer with ilmenite-type atomic ordering. Note that the Mn−Ir−O layer comprising two pairs of IrO6 and MnO6 planes corresponds to the 2/3-unit cell (u.c.) of the ilmenite lattice (Fig. 1a). We also performed electron energy loss spectroscopy (EELS) for the Mn L, Ti L and O K edges in the MnTiO3 buffer and Mn−Ir−O layer regions (Supplementary Fig. 4). Although the Mn L-edge spectra of the two regions (i.e., Mn2+) are in good agreement, a partial reduction of Ti4+ to Ti3+ occurred near the Mn−Ir−O layer25,26. Associated with this reduction, the presence of an oxygen deficiency is expected from the O K-edge spectra. We inferred that Mn2+ and Ir4+ are stable under the oxygen pressure of 10 mTorr used for the deposition, whereas Ti4+ is reduced to Ti3+. Charge transfer between B-site TiO6 and IrO6 planes via A-site MnO6 planes may be related to this point, although it is currently unclear.

HAADF-STEM images of a [MnTiO3/Mn−Ir−O]8/MnTiO3(buffer) film (without a Mn−Ir−O cap layer) viewed along the Al2O3\(\left[ {11\bar 20} \right]\) direction. a Wide area; scale bar: 10 nm. b MnTiO3/Mn−Ir−O/MnTiO3 interface region; scale bar: 2 nm. c Atomically resolved images; scale bar: 1 nm (the area marked by yellow dashed lines in b). d Schematic crystal structure corresponding to c. HAADF high-angle annular dark-field, STEM scanning transmission electron microscopy.

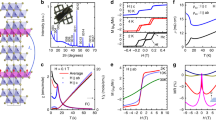

Investigation of surface magnetic order using spin Hall magnetoresistance measurements

Based on these structural analyses, a honeycomb lattice of edge-sharing IrO6 octahedra partly forms a two-dimensional network in a superlattice. In Ir4+-containing oxides, the delicate interplay of moderate electronic correlations and spin–orbit coupling determines whether the electronic structure of a material is metallic (gapless)27,28,29,30,31,32 or insulating (gapped)1,33,34. Our superlattice samples were highly insulating (not shown), indicating the non-metallic electronic structure of Mn−Ir−O. Magnetism in ultrathin films, particularly for cases of antiferromagnetism and quantum spin liquids, is difficult to evaluate using bulk experimental methods10,13,14,15. Thus, we studied the surface magnetic order using the spin Hall magnetoresistance (SMR) method, which enables electrical characterisation of ferromagnetic35 and antiferromagnetic transitions36,37,38, as well as magnetic anisotropy. By measuring the SMR at the interface of Pt and MnTiO3 ultrathin films, we recently demonstrated that bulk Néel temperature TN (~63 K)39 and uniaxial magnetic anisotropy along the c-axis direction persist down to a film thickness of 2.9 nm ~2 u.c. with six MnO6 planes22. For the present experiment, we examined five different heterostructures, as shown in Fig. 4a: Pt/4.3-nm-thick MnTiO3 (~3 u.c., thick MnTiO3), Pt/1.0-nm-thick Mn−Ir−O/4.3-nm-thick MnTiO3 (bilayer) and Pt/1.0-nm-, 1.9-nm- and 4.3-nm-thick MnTiO3/1.0-nm-thick Mn−Ir−O/4.3-nm-thick MnTiO3 samples (trilayers A, B and C, respectively) (see Supplementary Fig. 5 for their XRD patterns). As shown in the inset of Fig. 4b (“Methods”), we simultaneously measured the resistances of the two orthogonal Pt channels (i.e., R1 for channel 1, and R2 for channel 2) under an in-plane magnetic field H applied parallel to channel 1. Figure 4b–d show the temperature (T) dependence of the field-induced resistance variation, ΔR = (R1/R2)0.5 T − (R1/R2)0 T. Here, (R1/R2)0.5 T and (R1/R2)0 T are the resistance ratios measured at μ0H = 0.5 T and 0 T (where μ0 is the vacuum permeability), respectively. If an antiferromagnetic transition occurs in the layer beneath the Pt layer, distinct SMR responses of R1 and R2 below and above TN result in an inflection in ΔR (refs. 22,36,37). In fact, the value of ΔR for both the thick-MnTiO3 monolayer (Fig. 4b) and trilayer C (purple in Fig. 4d) exhibits a sudden increase near T = 60 K upon heating, wherein bulk MnTiO3 undergoes an antiferromagnetic-to-paramagnetic transition36. These results indicate that an antiferromagnetic order develops in the 4.3-nm-thick MnTiO3 top layers (~3 u.c. with nine MnO6 planes) regardless of the underlying Al2O3(0001) substrate or the 1.0-nm-thick Mn−Ir−O/4.3-nm-thick MnTiO3/Al2O3(0001) structure. In stark contrast, the ΔR value for the bilayer (Fig. 4c) and trilayers A and B (green and light blue in Fig. 4d) exhibits a gradual increase with increasing T without definite anomalies. Although A-site spinful MnO6 planes are common to all samples, their magnetic ordering behaviours are completely different. This may indicate the magnetic interactions in Mn−Ir−O, that is, the unique stacking of the honeycomb-lattice IrO6 and MnO6 planes.

a Schematic structures for the 4.3-nm-thick MnTiO3 monolayer (thick MnTiO3), 1.0-nm-thick Mn−Ir−O/4.3-nm-thick MnTiO3 bilayer (bilayer) and 1.0-nm-, 1.9-nm- and 4.3-nm-thick MnTiO3/1.0-nm-thick Mn−Ir−O/4.3-nm-thick MnTiO3 trilayer (trilayer A, B and C, respectively) samples. A thickness of 1.4 nm corresponds to ~1 u.c. height of their ilmenite lattices along the out-of-plane c-axis direction. b–d Field-induced variation (μ0H = 0.5 T) in the resistance ratio of two orthogonal Pt channels, R1/R2, for b, the thick MnTiO3, c the bilayer and d trilayers A, B and C. In the thick-MnTiO3 monolayer (Fig. 4b) and trilayer C (Fig. 4d), SMR responses indicating antiferromagnetic transition were detected. The inset in b shows the measurement setup, where R1 and R2 are measured simultaneously under an in-plane magnetic field H applied parallel to channel 1 with R1 (perpendicular to channel 2 with R2). E1 and E2 are the electrodes used for current injection. e, f Schematic for the spin ordering at Mn sites in the Mn−Ir−O/MnTiO3 bilayer sample expected from the SMR responses. e Metal-oxygen octahedra in the ab plane. Small red spheres represent O ions. Yellow-coloured octahedra are located above the grey coloured octahedra. f Cross-sectional view along the \(\left[ {11\bar 20} \right]\) direction. The pink, light blue and brown spheres represent Ir, Mn and Ti ions, respectively, and are positioned in the oxygen octahedra. Only the localised moments of Mn ions are depicted by black arrows.

Discussion

Comparing the SMR results, we discuss the possible magnetic properties of Mn−Ir−O. In the thick-MnTiO3 monolayer and trilayer C terminated with 3-u.c.-thick MnTiO3 top layers, nine MnO6 layers are positioned beneath the Pt layer. The TN (the inflection in ΔR) detected in the thick samples is consistent with the robust antiferromagnetic ordering in MnTiO3 monolayers previously reported22. The absence of such signatures in the bilayer indicates locally modified super-exchange interactions in the MnO6 planes by intervening in the IrO6 planes. Considering the strong spin–orbit coupling, which is inherent to heavy Ir (refs. 1,27,28,29,30,31,32,33,34), a disruption of the antiferromagnetic order may occur. Figure 4e, f schematically show a possible picture of spin interactions between the Mn sites (black arrows) in the bilayer, where the antiferromagnetic order develops in the MnTiO3 bottom layer, except the overgrown Mn−Ir−O layer. In the thin-MnTiO3 top layers (« 2 u.c.) of trilayers A and B, a similar spin fluctuation may be caused by the neighbouring IrO6 planes.

Extrinsic contributions, such as the surface roughness and the effect of size (refs. 40,41,42), should also be considered to understand the suppression of antiferromagnetic order in thin-MnTiO3 (« 2 u.c.) and Mn−Ir−O top layers. Firstly, all measured samples had smooth surfaces with root-mean-square roughness values ranging from 0.2 to 1.0 nm, which cannot exclusively account for the distinct SMR responses. Furthermore, despite its island-like film morphology with increased surface roughness, the 2-u.c.-thick thin-MnTiO3 monolayer exhibits a bulk-like TN as in thicker and flatter samples (≥ 3 u.c.)22, supporting the negligible role of the surface roughness. Secondly, the total film thicknesses of the heterostructures (including MnTiO3 and Mn−Ir−O layers) are significantly thicker than the 2 u.c.; therefore, a sufficiently large volume of the Mn sublattice is guaranteed for the entire heterostructure. This also helps minimise the potential influence of domain disconnection, which is generally pronounced in ultrathin films. In stark contrast, there is a systematic recovery of antiferromagnetic SMR responses with an increase in the thickness of the MnTiO3 top layer from trilayer A (2/3 u.c.), B (4/3 u.c.) and C (3 u.c.), which indicates the intrinsic origin that is responsible for spin interactions in a characteristic length. Notably, the clear difference observed between the antiferromagnetic 2-u.c.-thick thin-MnTiO3 monolayer22 and the non-antiferromagnetic trilayer B (4/3-u.c.-thick MnTiO3 and 2/3-u.c.-thick Mn−Ir−O (2 u.c. in total) on the MnTiO3 buffer) indicates that the insertion of honeycomb-lattice IrO6 planes affects the spin interactions between nearby Mn sites. Such a spin-disordered (or spin-frustrated) state may be associated with quantum spin liquids, although the experimental identification of the featureless magnetic ground state in ultrathin films presents a great challenge43,44,45. The next step is to understand the spin structures (including the Ir sites) and the excited-state properties in Mn−Ir−O using recently advanced diagnostics such as Raman spectroscopy1,5,46 and in-plane spin transport measurements47,48,49,50. In addition, the structural quality of a sample is important for the formation of pure Kitaev materials. In particular, the interface roughness (Fig. 3b), oxygen vacancies (Supplementary Fig. 4) and possible inter-diffusion can be the source of local structural distortions that destroy Kitaev-type interactions via the non-ideal splitting of Ir 5d orbitals20. Nevertheless, the suppression of the strong antiferromagnetic order in the Mn sublattice is promising for demonstrating the feasibility of controlling spin interactions by artificially engineered ilmenite-type oxides.

In summary, we have materialised a honeycomb lattice of edge-sharing IrO6 octahedra by using a superlattice formation with ilmenite-type MnTiO3. Systematic SMR measurements indicated the absence of antiferromagnetic order in the surface Mn−Ir−O layer grown on antiferromagnetic MnTiO3. Although A-site MnO6 planes are common to these oxides, the spin interactions between the Mn sites are different. Spin fluctuations induced by strong spin–orbit interactions in the IrO6 planes can disrupt the antiferromagnetic ordering in the Mn−Ir−O layer and the neighbouring regions of the MnTiO3 layers. The stabilisation of a two-dimensional IrO6 honeycomb lattice using the superlattice technique, as well as the potential control of the magnetism via dimensionality and the proximity effect, is expected to trigger the development of ilmenite-based Kitaev materials that produce exotic physical phenomena.

Methods

Thin-film growth

The Mn−Ir−O target was prepared from MnO2 and IrO2 powders by spark-plasma-sintering at 50 MPa and 900 °C. The target composition, as measured by EDX, was Mn:Ir = 0.90:1 (atomic ratio). The MnTiO3 buffer layer was grown at a substrate temperature of 850 °C and an oxygen pressure of 10 mTorr using the Mn−Ti−O target22. Subsequently, Mn−Ir−O and MnTiO3 layers were alternately deposited for n cycles at 800 °C and 10 mTorr for the formation of a [Mn−Ir−O/MnTiO3]n superlattice. The crystal structure and composition of the films were characterised by XRD using Cu Kα radiation and EDX, respectively.

SMR measurements

A Pt film with a thickness of ~2 nm was deposited on the film surface by radio-frequency magnetron sputtering at 150 °C. The heterostructure film was then patterned into an L-shaped multiterminal device structure using photolithography and Ar ion milling, followed by the electron-beam evaporation of Au/Ti electrodes. The resistance was measured by the four-probe method using a semiconductor parameter analyser (Agilent 4155C) and a nano-volt metre (Keithley 2182A) in a physical property measurement system (Quantum Design, Inc.) equipped with a one-axis sample rotator. The direction (polarity) of the current I was varied during the measurements, and the averaged resistance values, \(R_j = \frac{{R_j\left( { + I} \right) + R_j\left( { - I} \right)}}{2}\,(j = 1\,{\mathrm{and}}\,2)\), were used for the analysis. Details of the measurement scheme and analysis are reported in ref. 22.

Electron microscopy

To obtain an electron-transparent thin specimen, the thin film with the substrate was mechanically polished, and Ar ion beam milling was performed at 0.5 kV in the final stage. For the atomic and electronic structure analyses, an aberration-corrected STEM system (JEOL ARM300CF) equipped with a DELTA corrector, cold-field emission gun and EELS spectrometer (Quantum, Gatan, Inc.) operated at 300 kV was used. The probe-forming aperture was 30 mrad, and the collection semi-angle for HAADF was 85–200 mrad.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Takagi, H., Takayama, T., Jackeli, G., Khaliullin, G. & Nagler, S. E. Concept and realization of Kitaev quantum spin liquids. Nat. Phys. Rev. 1, 264–280 (2019).

Kitaev, A. Anyons in an exactly solved model and beyond. Ann. Phys 321, 2–111 (2006).

Jackeli, G. & Khaliullin, G. Mott insulators in the strong spin-orbit coupling limit: from Heisenberg to a quantum compass and Kitaev models. Phys. Rev. Lett. 102, 017205 (2009).

Savary, L. & Balents, L. Quantum spin liquids: a review. Rep. Prog. Phys. 80, 016502 (2017).

Motome, Y. & Nasu, J. Hunting Majorana fermions in Kitaev magnets. J. Phys. Soc. Jpn. 89, 012002 (2020).

Sears, J. A. et al. Magnetic order in α-RuCl3: a honeycomb-lattice quantum magnet with strong spin-orbit coupling. Phys. Rev. B 91, 144420 (2015).

Cao, H. B. et al. Low-temperature crystal and magnetic structure of α-RuCl3. Phys. Rev. B 93, 134423 (2016).

Singh, Y. & Gegenwart, P. Antiferromagnetic Mott insulating state in single crystals of the honeycomb lattice material Na2IrO3. Phys. Rev. B 82, 064412 (2010).

Singh, Y. et al. Relevance of the Heisenberg-Kitaev model for the honeycomb lattice iridates A2IrO3. Phys. Rev. Lett. 108, 127203 (2012).

Biffin, A. et al. Unconventional magnetic order on the hyperhoneycomb Kitaev lattice in β-Li2IrO3: full solution via magnetic resonant x-ray diffraction. Phys. Rev. B 90, 205116 (2014).

Takayama, T. et al. Hyperhoneycomb iridate β-Li2IrO3 as a platform for Kitaev magnetism. Phys. Rev. Lett. 114, 077202 (2015).

Modic, K. A. et al. Realization of a three-dimensional spin–anisotropic harmonic honeycomb iridate. Nat. Commun. 5, 4203 (2014).

Biffin, A. et al. Noncoplanar and counterrotating incommensurate magnetic order stabilized by Kitaev interactions in γ-Li2IrO3. Phys. Rev. Lett. 113, 197201 (2014).

Kitagawa, K. et al. A spin–orbital-entangled quantum liquid on a honeycomb lattice. Nature 554, 341–345 (2018).

Kasahara, Y. et al. Majorana quantization and half-integer thermal quantum Hall effect in a Kitaev spin liquid. Nature 559, 227–231 (2018).

Schlom, D. G., Chen, L.-Q., Pan, X., Schmehl, A. & Zurbuchen, M. A. A thin film approach to engineering functionality into oxides. J. Am. Ceram. Soc. 91, 2429–2454 (2008).

Bhattacharya, A. & May, S. J. Magnetic oxide heterostructures. Annu. Rev. Mater. Res. 44, 65–90 (2014).

Boschker, H. & Mannhart, J. Quantum-matter heterostructures. Annu. Rev. Condens. Matter Phys. 8, 145–164 (2017).

Haraguchi, Y. et al. Magnetic ordering with an XY-like anisotropy in the honeycomb lattice iridates ZnIrO3 and MgIrO3 synthesized via a metathesis reaction. Phys. Rev. Materials 2, 054411 (2018).

Haraguchi, Y. & Aruga Katori, H. Strong antiferromagnetic interaction owing to a large trigonal distortion in the spin-orbit-coupled honeycomb lattice iridate CdIrO3. Phys. Rev. Materials 4, 044401 (2020).

Toyosaki, H., Kawasaki, M. & Tokura, Y. Atomically smooth and single crystalline MnTiO3 thin films with a ferrotoroidic structure. Appl. Phys. Lett. 93, 072507 (2008).

Miura, K., Fujiwara, K., Shiogai, J., Nojima, T. & Tsukazaki, A. Electrical detection of the antiferromagnetic transition in MnTiO3 ultrathin films by spin Hall magnetoresistance. J. Appl. Phys. 127, 103903 (2020).

Kim, E. S. & Jeon, C. J. Microwave dielectric properties of ATiO3 (A = Ni, Mg, Co, Mn) ceramics. J. Eur. Ceram. Soc. 30, 341–346 (2010).

Pennycook, S. J. & Boatner, L. A. Chemically sensitive structure-imaging with a scanning transmission electron microscope. Nature 336, 565–567 (1988).

Calvert, C. C., Rainforth, W. M., Sinclair, D. C. & West, A. R. Characterisation of grain boundaries in CaCu3Ti4O12 using HREM, EDS and EELS. J. Phys.: Conf. Ser. 26, 65–68 (2006).

Moatti, A., Sachan, R., Gupta, S. & Narayan, J. Vacancy-driven robust metallicity of structurally pinned monoclinic epitaxial VO2 thin films. ACS Appl. Mater. Interfaces 11, 3547–3554 (2019).

Matsuhira, K. et al. Metal–insulator transition in pyrochlore iridates Ln2Ir2O7 (Ln = Nd, Sm, and Eu). J. Phys. Soc. Jpn. 76, 043706 (2007).

Cao, G. et al. Non-Fermi-liquid behavior in nearly ferromagnetic SrIrO3 single crystals. Phys. Rev. B 76, 100402(R) (2007).

Jang, S. Y. et al. The electronic structure of epitaxially stabilized 5d perovskite Ca1−xSrxIrO3 (x = 0, 0.5, and 1) thin films: the role of strong spin–orbit coupling. J. Phys.: Condens. Matter 22, 485602 (2010).

Hirata, Y. et al. Complex orbital state stabilized by strong spin–orbit coupling in a metallic iridium oxide IrO2. Phys. Rev. B 87, 161111(R) (2013).

Takayama, T. et al. Spin-orbit coupling induced semi-metallic state in the 1/3 hole-doped hyper-kagome Na3Ir3O8. Sci. Rep. 4, 6818 (2014).

Fujioka, J. et al. Strong-correlation induced high-mobility electrons in Dirac semimetal of perovskite oxide. Nat. Commun. 10, 362 (2019).

Kim, B. J. et al. Novel Jeff = 1/2 Mott state induced by relativistic spin–orbit coupling in Sr2IrO4. Phys. Rev. Lett. 101, 076402 (2008).

Schaffer, R., Lee, E. K.-H., Yang, B.-J. & Kim, Y. B. Recent progress on correlated electron systems with strong spin–orbit coupling. Rep. Prog. Phys. 79, 094504 (2016).

Nakayama, H. et al. Spin Hall magnetoresistance induced by a nonequilibrium proximity effect. Phys. Rev. Lett. 110, 206601 (2013).

Schlitz, R. et al. Evolution of the spin hall magnetoresistance in Cr2O3/Pt bilayers close to the Néel temperature. Appl. Phys. Lett. 112, 132401 (2018).

Iino, T. et al. Resistive detection of the Néel temperature of Cr2O3 thin films. Appl. Phys. Lett. 114, 022402 (2019).

Lebrun, R. et al. Anisotropies and magnetic phase transitions in insulating antiferromagnets determined by a spin-Hall magnetoresistance probe. Commun. Phys. 2, 50 (2019).

Stickler, J. J., Kern, S., Wold, A. & Heller, G. S. Magnetic resonance and susceptibility of several ilmenite powders. Phys. Rev 164, 765 (1967).

Abarra, E. N., Takano, K., Hellman, F. & Berkowitz, A. E. Thermodynamic measurements of magnetic ordering in antiferromagnetic superlattices. Phys. Rev. Lett. 77, 3451–3454 (1996).

Park, S. et al. Strain control of Morin temperature in epitaxial α-Fe2O3(0001) film. EPL 103, 27007 (2013).

Pati, S. P., Al-Mahdawi, M., Ye, S., Shiokawa, Y., Nozaki, T. & Sahashi, M. Finite-size scaling effect on Néel temperature of antiferromagnetic Cr2O3 (0001) films in exchange-coupled heterostructures. Phy. Rev. B 94, 224417 (2016).

Liu, J. et al. Heterointerface engineered electronic and magnetic phases of NdNiO3 thin films. Nat. Commun. 4, 2714 (2013).

King, P. D. C. et al. Atomic-scale control of competing electronic phases in ultrathin LaNiO3. Nat. Nanotechnol. 9, 443–447 (2014).

Bovo, L., Rouleau, C. M., Prabhakaran, D. & Bramwell, S. T. Phase transitions in few-monolayer spin ice films. Nat. Commun. 10, 1219 (2019).

Wulferding, D., Choi, Y., Lee, W. & Choi, K.-Y. Raman spectroscopic diagnostic of quantum spin liquids. J. Phys.: Condens. Matter 32, 043001 (2020).

Cornelissen, L. J., Liu, J., Duine, R. A., Youssef, J. B. & vanWees, B. J. Long-distance transport of magnon spin information in a magnetic insulator at room temperature. Nat. Phys. 11, 1022 (2015).

Lebrun, R. et al. Tunable long-distance spin transport in a crystalline antiferromagnetic iron oxide. Nature 561, 222 (2018).

Koga, A., Minakawa, T., Murakami, Y. & Nasu, J. Spin transport in the quantum spin liquid state in the S = 1 Kitaev model: role of the fractionalized quasiparticles. J. Phys. Soc. Jpn. 89, 033701 (2020).

Minakawa, T., Murakami, Y., Koga, A. & Nasu, J. Majorana-mediated spin transport in Kitaev quantum spin liquids. Phys. Rev. Lett. 125, 047204 https://journals.aps.org/prl/abstract/10.1103/PhysRevLett.125.047204 (2020).

Momma, K. & Izumi, F. VESTA 3 for three-dimensional visualization of crystal, volumetric and morphology data. J. Appl. Cryst. 44, 1272–1276 (2011).

Acknowledgements

The authors are grateful to K. Harata, S. Ito and N. Saito for their experimental supports, Y. Motome for the stimulating discussions, and NEOARK Corporation for the use of the maskless lithography system PALET. This work was performed under the Inter-University Cooperative Research Program of the Institute for Materials Research, Tohoku University, Japan (Proposal No. 19G0410). This work was supported by JST CREST (JPMJCR18T2) and JSPS KAKENHI (15H058053 and 19H02423). K.N., R.I. and N.S. acknowledge support received from JSPS KAKENHI (19H05788) and the Research Hub for Advanced Nano Characterisation (No. 12024046) by MEXT, Japan.

Author information

Authors and Affiliations

Contributions

K.M. grew the films and performed the SMR measurements along with K.F. K.N., R.I. and N.S. conducted the STEM analysis. K.F., K.M. and A.T. wrote the paper with input from the other authors. All authors discussed the results. A.T. supervised the project.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Miura, K., Fujiwara, K., Nakayama, K. et al. Stabilization of a honeycomb lattice of IrO6 octahedra by formation of ilmenite-type superlattices in MnTiO3. Commun Mater 1, 55 (2020). https://doi.org/10.1038/s43246-020-00059-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s43246-020-00059-1