Abstract

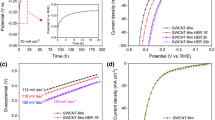

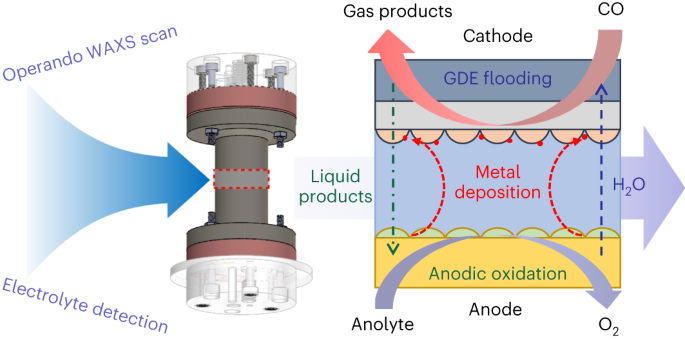

CO electrolysis (COE) has emerged as an important alternative technology to couple with other sustainable techniques for transitioning towards a carbon-neutral future. A large challenge for the deployment of high-rate COE is the limited durability of membrane-electrode assembly (MEA) devices. Here, by using an operando wide-angle X-ray scattering technique and monitoring the change of electrolyte, we identified several degradation mechanisms of the MEA during high-rate COE. Cathodic gas-diffusion electrode (GDE) flooding and Ir contaminants (crossover from anode) are two main issues causing excessive hydrogen evolution, which can be partly alleviated by increasing the polytetrafluoroethylene content in GDEs and using an alkaline stable Ni-based anode. During long-term stability, the dynamic evolution of anolyte became the main issue: the pH would continuously drop due to cathodic acetate formation and anodic ethanol oxidation. By compensating for this issue, we maintained a Faradaic efficiency of C2+ products at more than 70% for 136 hours.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The authors declare that the data supporting the findings of this study are available within the paper and its Supplementary Information. Raw X-ray data generated at the ESRF large-scale facility are available at https://doi.org/10.15151/ESRF-ES-703258873 from 2025. Alternatively, this data can be available from the corresponding author upon request. Source data are provided with this paper.

References

Davis, S. J. et al. Net-zero emissions energy systems. Science 360, eaas9793 (2018).

Jouny, M., Hutchings, G. S. & Jiao, F. Carbon monoxide electroreduction as an emerging platform for carbon utilization. Nat. Catal. 2, 1062–1070 (2019).

Molitor, B. et al. Carbon recovery by fermentation of CO-rich off gases—turning steel mills into biorefineries. Bioresour. Technol. 215, 386–396 (2016).

Ozden, A. et al. Carbon-efficient carbon dioxide electrolysers. Nat. Sustain. 5, 563–573 (2022).

Ma, M. et al. Local reaction environment for selective electroreduction of carbon monoxide. Energy Environ. Sci. 15, 2470–2478 (2022).

Xu, Q. et al. Enriching surface-accessible CO2 in the zero-gap anion-exchange-membrane-based CO2 electrolyzer. Angew. Chem. Int. Ed. 62, e202214383 (2022).

Haas, T., Krause, R., Weber, R., Demler, M. & Schmid, G. Technical photosynthesis involving CO2 electrolysis and fermentation. Nat. Catal. 1, 32–39 (2018).

Song, Y., Zhang, X., Xie, K., Wang, G. & Bao, X. High-temperature CO2 electrolysis in solid oxide electrolysis cells: developments, challenges, and prospects. Adv. Mater. 31, 1902033 (2019).

Li, C. W., Ciston, J. & Kanan, M. W. Electroreduction of carbon monoxide to liquid fuel on oxide-derived nanocrystalline copper. Nature 508, 504–507 (2014).

Wang, L. et al. Electrochemically converting carbon monoxide to liquid fuels by directing selectivity with electrode surface area. Nat. Catal. 2, 702–708 (2019).

Wakerley, D. et al. Gas diffusion electrodes, reactor designs and key metrics of low-temperature CO2 electrolysers. Nat. Energy 7, 130–143 (2022).

Rabiee, H. et al. Gas diffusion electrodes (GDEs) for electrochemical reduction of carbon dioxide, carbon monoxide, and dinitrogen to value-added products: a review. Energy Environ. Sci. 14, 1959–2008 (2021).

Jouny, M., Luc, W. & Jiao, F. High-rate electroreduction of carbon monoxide to multi-carbon products. Nat. Catal. 1, 748–755 (2018).

Overa, S. et al. Enhancing acetate selectivity by coupling anodic oxidation to carbon monoxide electroreduction. Nat. Catal. 5, 738–745 (2022).

Ji, Y. et al. Selective CO-to-acetate electroreduction via intermediate adsorption tuning on ordered Cu–Pd sites. Nat. Catal. 5, 251–258 (2022).

Li, J. et al. Constraining CO coverage on copper promotes high-efficiency ethylene electroproduction. Nat. Catal. 2, 1124–1131 (2019).

Li, J. et al. Copper adparticle enabled selective electrosynthesis of n-propanol. Nat. Commun. 9, 4614 (2018).

Zhuang, T.-T. et al. Copper nanocavities confine intermediates for efficient electrosynthesis of C3 alcohol fuels from carbon monoxide. Nat. Catal. 1, 946–951 (2018).

Li, J. et al. Effectively increased efficiency for electroreduction of carbon monoxide using supported polycrystalline copper powder electrocatalysts. ACS Catal. 9, 4709–4718 (2019).

Sullivan, I. et al. A hybrid catalyst-bonded membrane device for electrochemical carbon monoxide reduction at different relative humidities. ACS Sustain. Chem. Eng. 7, 16964–16970 (2019).

Ripatti, D. S., Veltman, T. R. & Kanan, M. W. Carbon monoxide gas diffusion electrolysis that produces concentrated C2 products with high single-pass conversion. Joule 3, 240–256 (2019).

Luc, W. et al. Two-dimensional copper nanosheets for electrochemical reduction of carbon monoxide to acetate. Nat. Catal. 2, 423–430 (2019).

Pang, Y. et al. Efficient electrocatalytic conversion of carbon monoxide to propanol using fragmented copper. Nat. Catal. 2, 251–258 (2019).

Zhu, P. et al. Direct and continuous generation of pure acetic acid solutions via electrocatalytic carbon monoxide reduction. Porc. Natl Acad. Sci. USA 118, e2010868118 (2021).

Yadegari, H. et al. Glycerol oxidation pairs with carbon monoxide reduction for low-voltage generation of C2 and C3 product streams. ACS Energy Lett. 6, 3538–3544 (2021).

Zhou, Y., Ganganahalli, R., Verma, S., Tan, H. R. & Yeo, B. S. Production of C3–C6 acetate esters via CO electroreduction in a membrane electrode assembly cell. Angew. Chem. Int. Ed. 61, e202202859 (2022).

Yan, Y. et al. Interface regulation promoting carbon monoxide gas diffusion electrolysis towards C2+ products. Chem. Commun. 58, 3645–3648 (2022).

Wang, X. et al. Efficient electrosynthesis of n-propanol from carbon monoxide using a Ag–Ru–Cu catalyst. Nat. Energy 7, 170–176 (2022).

Ji, Y., Guan, A. & Zheng, G. Copper-based catalysts for electrochemical carbon monoxide reduction. Cell Rep. Phys. Sci. 3, 101072 (2022).

Kastlunger, G. et al. Using pH dependence to understand mechanisms in electrochemical CO reduction. ACS Catal. 12, 4344–4357 (2022).

Wang, L. et al. Electrochemical carbon monoxide reduction on polycrystalline copper: effects of potential, pressure, and pH on selectivity toward multicarbon and oxygenated products. ACS Catal. 8, 7445–7454 (2018).

Heenen, H. H. et al. The mechanism for acetate formation in electrochemical CO(2) reduction on Cu: selectivity with potential, pH, and nanostructuring. Energy Environ. Sci. 15, 3978–3990 (2022).

Li, D. et al. Durability of anion exchange membrane water electrolyzers. Energy Environ. Sci. 14, 3393–3419 (2021).

Xu, Q. et al. Anion exchange membrane water electrolyzer: electrode design, lab-scaled testing system and performance evaluation. EnergyChem. 4, 100087 (2022).

Moss, A. B. et al. Versatile high energy X-ray transparent electrolysis cell for operando measurements. J. Power Sources 562, 232754 (2023).

Moss, A. B. et al. In operando investigations of oscillatory water and carbonate effects in MEA-based CO2 electrolysis devices. Joule 7, 350–365 (2023).

Yang, K., Kas, R., Smith, W. A. & Burdyny, T. Role of the carbon-based gas diffusion layer on flooding in a gas diffusion electrode cell for electrochemical CO2 reduction. ACS Energy Lett. 6, 33–40 (2021).

Wang, Z., Guo, X., Montoya, J. & Nørskov, J. K. Predicting aqueous stability of solid with computed Pourbaix diagram using SCAN functional. NPJ Comput. Mater. 6, 160 (2020).

Disch, J. et al. High-resolution neutron imaging of salt precipitation and water transport in zero-gap CO2 electrolysis. Nat. Commun. 13, 6099 (2022).

Xing, Z., Hu, L., Ripatti, D. S., Hu, X. & Feng, X. Enhancing carbon dioxide gas-diffusion electrolysis by creating a hydrophobic catalyst microenvironment. Nat. Commun. 12, 136 (2021).

Wu, Y. et al. Mitigating electrolyte flooding for electrochemical CO2 reduction via infiltration of hydrophobic particles in a gas diffusion layer. ACS Energy Lett. 7, 2884–2892 (2022).

Garg, S., Giron Rodriguez, C. A., Rufford, T. E., Varcoe, J. R. & Seger, B. How membrane characteristics influence the performance of CO2 and CO electrolysis. Energy Environ. Sci. 15, 4440–4469 (2022).

Vass, Á., Kormányos, A., Kószó, Z., Endrődi, B. & Janáky, C. Anode catalysts in CO2 electrolysis: challenges and untapped opportunities. ACS Catal. 12, 1037–1051 (2022).

Xu, Q. et al. Fluorination-enabled reconstruction of NiFe electrocatalysts for efficient water oxidation. Nano Lett. 21, 492–499 (2021).

Lai, S. C. S. et al. Effects of electrolyte pH and composition on the ethanol electro-oxidation reaction. Catal. Today 154, 92–104 (2010).

Monyoncho, E. A., Woo, T. K. & Baranova, E. A. in Electrochemistry Vol. 15 (eds Banks, C. & McIntosh, S.) 1–57 (The Royal Society of Chemistry, 2019).

Guo, J., Chen, R., Zhu, F.-C., Sun, S.-G. & Villullas, H. M. New understandings of ethanol oxidation reaction mechanism on Pd/C and Pd2Ru/C catalysts in alkaline direct ethanol fuel cells. Appl. Catal. B 224, 602–611 (2018).

Hasa, B. et al. Benchmarking anion-exchange membranes for electrocatalytic carbon monoxide reduction. Chem. Catal. 3, 100450 (2023).

Larrazábal, G. O., Okatenko, V., Chorkendorff, I., Buonsanti, R. & Seger, B. Investigation of ethylene and propylene production from CO2 reduction over copper nanocubes in an MEA-type electrolyzer. ACS Appl. Mater. Interfaces 14, 7779–7787 (2022).

Ashiotis, G. et al. The fast azimuthal integration Python library: pyFAI. J. Appl. Crystallogr. 48, 510–519 (2015).

Acknowledgements

The research leading to these results has received funding from the ECOEthylene project from Innovation Fund Denmark (grant no. 8057-00018B), and the Villum Center for the Science of Sustainable Fuels and Chemicals grant no. 9455. We thank the ESRF for providing the high-energy X-ray beam and ID31 beamline staff for experimental support.

Author information

Authors and Affiliations

Contributions

Q.X. and S.G. are the lead authors. Q.X. wrote the manuscript with input from all coauthors. S.G. helped revise the manuscript and participated in all results discussions. Q.X., S.G. and A.B.M. carried out beamline electrochemical measurements and conducted X-ray data analysis. M.M. and J.D. assisted in performing in operando experiments at ESRF. J.D., I.C. and B.S. guided the project and oversaw its development. B.S. set the overall direction of the project and helped edit the overall manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Catalysis thanks the anonymous reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–31, Note 1 and Tables 1 and 2.

Source data

Source Data Fig. 3

Statistical source data.

Source Data Fig. 4

Statistical source data.

Source Data Fig. 5

Statistical source data.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, Q., Garg, S., Moss, A.B. et al. Identifying and alleviating the durability challenges in membrane-electrode-assembly devices for high-rate CO electrolysis. Nat Catal 6, 1042–1051 (2023). https://doi.org/10.1038/s41929-023-01034-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41929-023-01034-y

This article is cited by

-

Copper-based catalysts for carbon monoxide electroreduction to multicarbon products

Science China Materials (2024)