Abstract

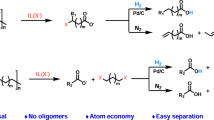

Biodegradable polyesters such as polylactic acid are promising alternatives to conventional plastics as they do not accumulate in the environment upon disposal. However, their biodegradation leads to CO2 emissions. Alternatively, waste biodegradable polyesters could serve as a carbon source for the production of value-added chemicals. Valorization of waste biodegradable polyesters not only avoids CO2 emissions during their biodegradation but also achieves sustainable carbon use. Here, we report a two-step catalytic process to convert polylactic acid waste into methyl methacrylate, a key building-block molecule. Polylactic acid is first transformed into methyl propionate with near-quantitative yields (conversion >99%, selectivity 98%) over the α-MoC catalyst in methanol solution, which is followed by reacting the obtained methyl propionate with formaldehyde to produce methyl methacrylate with a conversion of 81% and selectivity of 90%. This study opens up a new path for managing end-of-life biodegradable polyester plastics and contributing to a circular economy.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Source data are provided with this paper.

References

Zhang, F. et al. Polyethylene upcycling to long-chain alkylaromatics by tandem hydrogenolysis/aromatization. Science 370, 437–441 (2020).

Stubbins, A., Law, K. L., Muñoz, S. E., Bianchi, T. S. & Zhu, L. Plastics in the Earth system. Science 373, 51–55 (2021).

Santos, R. G., Machovsky-Capuska, G. E. & Andrades, R. Plastic ingestion as an evolution trap: toward a holistic understanding. Science 373, 56–60 (2021).

Korley, L. T. J., Epps, T. H., Helms, B. A. & Ryan, A. J. Toward polymer upcycling—adding value and tackling circularity. Science 373, 66–69 (2021).

Liu, S., Kots, P. A., Vance, B. C., Danielson, A. & Vlachos, D. G. Plastic waste to fuels by hydrocracking at mild conditions. Sci. Adv. 7, eabf8283 (2021).

Urbanek, A. K. et al. Isolation and characterization of Arctic microorganisms decomposing bioplastics. AMB Express 7, 148 (2017).

Gómez, E. F. & Michel, F. C. Biodegradability of conventional and bio-based plastics and natural fiber composites during composting, anaerobic digestion and long-term soil incubation. Polym. Degrad. Stab. 98, 2583–2591 (2013).

Macleod, M., Arp, H. P. H., Tekman, M. B. & Jahnke, A. The global threat from plastic pollution. Science 373, 61–65 (2021).

Cabernard, L., Pfister, S., Oberschelp, C. & Hellweg, S. Growing environmental footprint of plastics driven by coal combustion. Nat. Sustain. 5, 139–148 (2022).

Global polylactic acid market report 2021: China led the Asia Pacific market, accounting for nearly 53%—forecast to 2028. PR Newswire https://www.prnewswire.com/news-releases/global-polylactic-acid-market-report-2021-china-led-the-asia-pacific-market-accounting-for-nearly-53—forecast-to-2028-301268987.html (2021).

Illyas, R. A. et al. Polylactic acid (PLA) biocomposite: processing, additive manufacturing and advanced applications. Polymers 13, 1326 (2021).

Tian, S. et al. Catalytic amination of polylactic acid to alanine. J. Am. Chem. Soc. 143, 16358–16363 (2021).

Li, Y. et al. Catalytic transformation of PET and CO2 into high-value chemicals. Angew. Chem. Int. Ed. 61, e202117205 (2022).

Dusselier, M., Wouwe, P. V., Dewaele, A., Jacobs, P. A. & Sels, B. F. Shape-selective zeolite catalysis for bioplastics production. Science 349, 78–80 (2015).

Siparsky, G. L., Voorhees, K. J. & Miao, F. Hydrolysis of polylactic acid (PLA) and polycaprolactone (PCL) in aqueous acetonitrile solutions: autocatalysis. J. Polym. Environ. 6, 31–41 (1998).

Song, X., Wang, H., Zheng, X., Liu, F. & Yu, S. Methanolysis of poly(lactic acid) using acidic functionalized ionic liquid as catalysts. J. Appl. Polym. Sci. 131, 40817 (2014).

Zhang, M. et al. Catalytic strategies for upvaluing plastics wastes. Chem. 8, 2912–2923 (2022).

Global methyl methacrylate (MMA) market report 2021: market to reach $9.8 billion by 2027—a growing market driven by downstream applications. Globe Newswire http://www.globenewswire.com/news-release/2021/08/30/2288047/28124/en/Global-Methyl-Methacrylate-MMA-Market-Report-2021-Market-to-Reach-9-8-Billion-by-2027-A-Growing-Market-Driven-by-Downstream-Applications.html (2021).

Mahboub, M. J. D., Dubois, J.-L., Cavani, F., Rostamizadeh, M., & Patience, G. S. Catalytic for the synthesis of methacrylic acid and methyl methacrylate. Chem. Soc. Rev. 47, 7703–7738 (2018).

Kim, S. et al. Recent advances in hydrodeoxygenation of biomass-derived oxygenates over heterogeneous catalysts. Green Chem. 21, 3715–3743 (2019).

Zhao, C., He, J., Lemonidou, A. A., Li, X. & Lercher, J. A. Aqueous-phase hydrodeoxygenation of bio-derived phenols to cycloalkanes. J. Catal. 280, 8–16 (2011).

Xia, Q. et al. Direct hydrodeoxygenation of raw woody biomass into liquid alkanes. Nat. Commun. 7, 11162 (2016).

Leiva, K. et al. Hydrodeoxygenation of 2-methoxyphenol over different Re active phases supported on SiO2 catalysts. Appl. Catal. A 490, 71–79 (2015).

Liao, Q. et al. Gold catalyst anchored to pre-reduced Co3O4 nanorods for the hydrodeoxygenation of vanillin using alcohols as hydrogen donors. ACS Appl. Mater. Interfaces 14, 3939–3948 (2022).

Vasiliadou, E. S. & Lemonidou, A. A. Catalytic glycerol hydrodeoxygenation under inert atmosphere: ethanol as a hydrogen donor. Catalysts 4, 397–413 (2014).

Iida, T. et al. Encapsulation of molybdenum carbide nanoclusters inside zeolite micropores enables synergistic bifunctional catalysis for anisole hydrodeoxygenation. ACS Catal. 7, 8147–8151 (2017).

Lin, L. et al. Low-temperature hydrogen production from water and methanol using Pt/α-MoC catalysts. Nature 554, 80–83 (2017).

Zhang, X. et al. A stable low-temperature H2-production catalyst by crowding Pt on α-MoC. Nature 589, 396–401 (2021).

Lin, L. et al. Atomically dispersed Ni/α-MoC catalyst for hydrogen production from methanol/water. J. Am. Chem. Soc. 143, 309–317 (2021).

Yao, S. et al. Atomic-layered Au clusters on α-MoC as catalysts for the low-temperature water–gas shift reaction. Science 357, 389–393 (2017).

Guo, Z., Zhang, G., Wang, L., Li, P. & Li, C. Fe-modified Cs-P/γ-Al2O3 catalysts for synthesis of methyl methacrylate from methyl propionate and formaldehyde. Ind. Eng. Chem. Res. 59, 3334–3341 (2020).

Tai, J. & Davis, R. J. Synthesis of methacrylic acid by aldol condensation of propionic acid with formaldehyde over acid-base bifunctional catalysts. Catal. Today 123, 42–49 (2007).

Li, B. et al. Synthesis of methyl methacrylate by aldol condensation of methyl propionate with formaldehyde over acid-base bifunctional catalysts. Catal. Lett. 143, 829–839 (2013).

Gao, Z., Li, A., Ma, D. & Zhou, W. Electron energy loss spectroscopy for single atom catalysis. Top. Catal. 65, 1609–1619 (2002).

Ravel, B. & Newville, M. ATHNA, ARTEMIS, HEPHAESTUS: data analysis for X-ray absorption spectroscopy using IFEFFIT. J. Synchrotron Rad. 12, 537–541 (2005).

Acknowledgements

This work received financial support from the Natural Science Foundation of China (22072002, 21725301, 22232001, 21932002, 21821004), the National Key R&D Program of China (2021YFA1501102) and China Post-doctoral Science Foundation (2021M690004, 2021T140005). We thank B. Xu for discussion. W.Z. acknowledges support from the Beijing Outstanding Young Scientist Program (BJJWZYJH01201914430039). D.M. acknowledges support from the Tencent Foundation through the XPLORER PRIZE. The XAFS was conducted at Beijing Synchrotron Radiation Facility.

Author information

Authors and Affiliations

Contributions

D.M. and Meng Wang conceived the project. B.S., J.Z. and Maolin Wang performed most of the reactions. Maolin Wang, Y.X. and S.T. performed the X-ray-related characterizations (XAS, XPS) and analysis. S.Y., Z.G. and W.Z. performed the electron microscopy study. B.S., Meng Wang, D.X., G.L. and D.M. wrote the paper. All authors contributed to the discussion and revision of the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Sustainability thanks Jinwen Zhang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–26 and Tables 1–5.

Source data

Source Data Fig. 1

Original data.

Source Data Fig. 2

Original data.

Source Data Fig. 3

Original data.

Source Data Fig. 4

Original data.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sun, B., Zhang, J., Wang, M. et al. Valorization of waste biodegradable polyester for methyl methacrylate production. Nat Sustain 6, 712–719 (2023). https://doi.org/10.1038/s41893-023-01082-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41893-023-01082-z

This article is cited by

-

Catalytic recycling of polyesters via a binuclear catalyst

Science China Chemistry (2024)

-

Plastics upcycling made more sustainable and practical

Nature Sustainability (2023)

-

Co-upcycling of polyvinyl chloride and polyesters

Nature Sustainability (2023)

-

On the plastics crisis

Nature Sustainability (2023)