Abstract

This paper offers an efficient tool to define the unknown parameters of electrical transformers. The proposed methodology is developed based on artificial hummingbird optimizer (AHO) to generate the best values of the transformer’s unknown parameters. At initial stage, the parameters’ extraction of the transformer electrical equivalent is adapted as an optimization function along with the associated operating inequality constraints. In which, the sum of absolute errors (SAEs) among many variables from nameplate data of transformers is decided to be minimized. Two test cases of 4 kVA and 15 kVA transformers ratings are demonstrated to indicate the ability of the AHO compared to other recent challenging optimizers. The proposed AHO achieves the lowest SAE’s value than other competing algorithms. At advanced stage of this effort, the capture of percentage of loading to achieve maximum efficiency is ascertained. At later stage, the performance of transformers utilizing the extracted parameters cropped by the AHO to investigate the principal behavior at energization of these transformer units is made. At the end, it can be confirmed that the AHO produces best values of transformer parameters which help much in achieving accurate simulations for steady-state and inrush behaviors.

Similar content being viewed by others

Introduction

The power transformers are one of the essential and major equipment in power systems. Transformers can transfer energy form generation plants to distribution areas via transmission lines with high efficiency reaches 99% based on its parameters and the related losses1. Several research have been introduced to envisage transformer parameters as to minimize its losses, improve its performance and minimize the operational cost. The unknown transformer parameters are nonlinear because of their frequency dependance which makes the transformer modelling accurateness more complex2. Transformer parameters estimation became an immense and mandatory challenge for optimal transformer design to realize compulsory standards and specifications3,4. The transformer non- linear performance has been addressed as in2,5. The determination of transformer unknown parameters is affected by the state of its operation; steady or transient conditions5,6. These parameters can be estimated using different methods: the well-known tests; no-load and short circuit tests7,8, physical sizing of transformer9, manufacturer’s data10, and under various load information7. Primarily, the analytical methods have been used for fast evaluation of the transformer physical sizing based on finite element analysis (FEA). Recently, non-conventional exploratory and/or evolutionary calculation algorithms have been applied11. The evolutionary algorithms have high capability to solve the optimization problems as it can randomly achieve the objective7. The optimization methods have been utilized to extract transformer unknown parameters as well as other electrical devices as electric motors, fuel cells, and storage units in addition to find out the electrical operation parameters as optimal load flow and distribution management systems12,13,14,15. The accuracy of the optimization algorithms is tested by comparing the extracted parameter values against the actual ones16,17,18. A gray box model has been proposed to estimate transformer parameters and study its terminals behaviors at frequencies between 20 kHz to 1 MHz via particle swarm optimization (PSO). This method depends on evaluating the physical dimensions to define winding inductance, capacitance, and loss parameters6. The data driven from load testing has been used to extract both single and three phase power transformer parameters via PSO12 and Forensic-Based algorithm1 has been applied only for single-phase transformer (SPT). Also, slime mold optimizer has been applied to both single and three phase transformers parameter estimation and compared with other optimizers19. The 4 kVA SPT parameters have been extracted using the data driven from load testing via Forensic-based investigation and PSO1 and bacterial foraging20 algorithms and by means of input data through chaotic optimization7. The no load losses have been included in the objective function (OF) using manta rays foraging optimizer (MRFO) and chaotic MRFO3. Other optimizers have been proposed to evaluate transformer parameters and conducted practical tests for confirmation as coyote optimizer for three and single transformers21, and Jellyfish search optimizer, gravitational search algorithm (GSA) and machine learning approach for SPT with 4 kVA rating in10,22,23. Multi-objective evolutionary optimization has been adapted to evaluate the transformer parameters, improved using the FEA and verified by comparing the results with the actual measures and behavior11. Online transformer parameters evaluation using practical measurements, different slow frequencies and involving transformer turns ratio have been applied to get fast results and save the need for high frequency instruments24. Straightforward black-box algorithm through an optimization method with the help of transfer functions estimated by measured voltage ratios has been introduced to extract distribution transformers parameters at frequency between 1 kHz and 1 MHz and in time domain25.

Experimental measures of the nonlinear characteristics of inrush current have been used to calculate transformer parameters with the aid of no-load tests with the help of logic function and load tests via PMU in26.

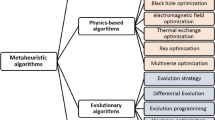

Each one of the metaheuristic optimizers has advantages and some difficulties to solve all the problems. Although, genetic algorithm (GA) can solve the multifaceted problems, but it has some drawbacks as it has early convergence, and its precision depends on many selected terms27. PSO overcomes the slow convergence, but it has the obstacle of local optima for large scale problems and comparatively affects its control parameters28. Ant colony optimizer succeeded in solving dynamic problems, but it has long time for convergence and complicated investigations29,30. Artificial bee colony succeeded in making stability between exploration and exploitation but failed in solving the early convergence problem in last iterations and sometimes inaccuracy31. Cuckoo search introduced a better performance than PSO and GA for the sophisticated optimization problems32 but it has unsatisfactory convergence and local search capability33,34.

The main goal of this work is to accurately identify the optimum SPT unknown parameters via new promising metaheuristic optimizer and to study its performance at steady state and inrush conditions. Artificial hummingbird optimizer (AHO)35 has been adapted to represent and investigate the SPT. The AHO simulates hummingbirds’ skills and behaviour in looking for its food. It exceeds other meta-heuristic optimizers in reaching objectives with higher precision using lesser control parameters. It has a unique property in its specific environmentalism experience35. Zhaoa and el al. have successfully assessed the AHO by applying three tests: fifty mathematical functions with complex characteristics, the IEEE CEC 2014 benchmark functions and ten engineering design problems which proofed the effectiveness of the algorithm35.

In this work, the AHO is applied to 15 kVA7 and 4 kVA1 SPTs, its performance has been studied and compared with other recognized optimizers and works. For more confirmation, the 4 kVA transformer has been simulated using MATLAB/Simulink, comprehensive study has been conducted at steady state and inrush conditions and compared with the calculated well-known behaviour. Also, Interior search algorithm (ISA) has been utilized to investigate the same two cases and held an extensive comparison between the proposed AHO optimizer and other well-known optimizers. The results prove AHO accurateness and its superiority between other optimizers.

The paper contains seven parts: Part 1 declares the Introduction, In Part 2, the SPT mathematical model is introduced. The transformer optimization problem is expressed and adapted in Part 3. In part 4, the AHO procedures are expressed and summarized. The application and assessment of the proposed algorithm to represent SPT and extract its unknown parameters is tested in Part 5. Also, the performance of the proposed algorithm at steady state and at the inrush condition is examined in Part 6. Finally, the remarkable outcomes and conclusions of this search are highlighted in Part 7.

Mathematical modeling of single-phase transformer and statement

The equivalent circuit of SPT refereed to the primary side is shown in Fig. 1. The modelling contains six variable parameters (\({R}_{11}\), \({R}_{21}\), \({X}_{11}\), \({X}_{21}\), \({R}_{m1}\), \({X}_{m1}\)) which are described as follows:

The primary and secondary winding’s resistances, primary and secondary reactance’s, core resistance and magnetizing reactance all of them refereed to primary side, respectively36,37 as framed in Fig. 1.

The primary windings impedance \(\left({Z}_{11}\right)\), secondary windings impedance \(\left({Z}_{21}\right)\) and magnetizing impedance \(\left({Z}_{m1}\right)\) can be calculated from the following (1) to (3):

If the transformer is loaded by impedance \(\left({Z}_{L21}\right)\), with input supply voltage \(\left({V}_{11}\right),\) the equivalent transformer impedance referred to the primary side \(\left({Z}_{eq1}\right)\), the primary current \(\left({I}_{11}\right)\), load current \(\left({I}_{21}\right)\), load output voltage \(\left({V}_{21}\right)\) and voltage regulation (ε) can be formulated by (4) to (8):

Also, the input power \(\left({P}_{in}\right)\), output power \(\left({P}_{out}\right)\), and the corresponding efficiency η are given by (9) to (11).

The inrush current can be generated due to the change of the transformer magnetization voltage. It can be induced if transformer is energized at no load. The magnitude of inrush current can be considered as high fault current38,39. Modelling of the inrush current is mandatory to understand the performance of transformer at energizing operation as has been introduced by Vanti et al.40 and expressed as following (12) and (13).

where \({R}_{11}\) , \({L}_{11}\), and \({R}_{m1}\) are series resistance, series inductance, and the core losses resistance, respectively. \({m}_{1}\) and \({m}_{2}\) are constants which defined the transformer magnetization curve \(.\)

By considering a sinusoidal source as \(V\left(t\right)={V}_{m}\mathrm{sin}(\omega t+\theta )\) the corresponding current can be formulated in time steps as in (14).

Where \(\Delta \tau ={{t}_{j}-t}_{j-1}\) is the time step, \(\rho =({R}_{m1}+{R}_{11} )/{L}_{11}\), \(\gamma ={R}_{m1}/{L}_{11}\), \(\varphi =arctg(\frac{\omega }{\rho })\), and \(h\left({t}_{j-1}\right)\) is calculated by (15).

The flux calculation is formulated by the formula shown in (16).

Where

Optimization of transformer parameters identification

The key goal of the Transformer modeling is to find the proper equivalent circuit to simulate it precisely for imitating practical operations. This should be done at a minimum error level between the experimental and the calculated dataset points. The OF (\({F}_{obj})\) is defined as minimizing the sum absolute errors (SAEs) among estimated and measured dataset points which is expressed in (17) as follows:

where \({I}_{11act}\), \({I}_{21act}\), \({V}_{21act}\), and \(\eta_{act}\) are the actual data of the primary current, load current, load output voltage, and transformer’s efficiency, respectively. The problem min/max constraints are characterized in (18) for the 6 parameters (\({R}_{11}\), \({R}_{21}\), \({X}_{11}\), \({X}_{21}\), \({R}_{m1}\), \({X}_{m1}\)) to be optimally extracted.

where,\({R}_{11-min}\) and \({R}_{11-max}\) are the min/max values of \({R}_{11}\), \({R}_{21-min}\) and \({R}_{21-max}\) are the min/max of \({R}_{21}\), \({X}_{11-min}\) and \({X}_{11-max}\) are the min/max limits of \({X}_{11}\), \({X}_{21-min}\) and \({X}_{21-max}\) are the min/max of \({X}_{21}\) , \({R}_{m1-min}\) and \({R}_{m1-max}\) are the min/max of \({R}_{m1}\), and \({X}_{m1-min}\) and \({X}_{m1-max}\) are the min/max limits of \({X}_{m1}\),

AHO optimizer procedure

AHO is an original optimizer stimulated based on the amazing behaviour of one of the smallest birds all over the world “Hummingbirds”35. This bird feeds on mosquitoes, weevils, and aphids. It could shatter its wings with high frequency reaches 80 times/second to follow and hunt its prey. So, the hummingbird is in bad need of plentiful energy that is provided by sucking large amounts of flower syrup and sweetened fluid inside plants. The hummingbird movement, behaviour, skills, and memorization capability have been studied and followed to represent the suggested optimizer. The hummingbird activities can be categorized as three ways for food searching, retention of food resources task and the bird flying forms. A certain number has been proposed for each food resource with a specific plant category. The syrup re-suction rate from the food resource is signified by the value of the OF. The higher fitness value, the higher the syrup re-suction rate and vice versa. Each hummingbird is allocated to a certain location with defined food resource. The location, syrup and sweetened fluid re-suction rate are saved in bird mind and shared with the remaining birds within the population. Also, the location of the unused food resources by the bird can be defined by itself and shared with the others in the population. Each food resource utilization and the last time it was used for a specific bird are registered in a lookup table is initiated and updated. The highest utilization of the food resources is taken as indicator to the better resources to be used for high syrup re-suction rate. AHO search performance can be classified into three major categories; directed food search, regional food search, and relocation food search Fig. 2.

Initialization

The hummingbird initial location \({LOC}_{i}\) of food supply “i” can randomly be estimated using (19):

where \(L\) and \(H\) are lower and higher limits for multi-dimensional problem and \(Ran\) is the random matrix of values lie between 0 and 1. The food supply lookup table can be initialized as indicated in (20). Null means the hummingbird is fed from its own food supply and zero means the kth hummingbird is fed from jth food supply.

Directed food search

Hummingbird can fly in omnidirectional, diagonal, and axial to look for the food as in Fig. 3. The used directions \({dir}_{i}\) for the food source \(i\) can be recorded in a matrix and taken as a guide for the birds as represented in (21).

where \(i \epsilon m\), \({Rand}_{i}\{1,m\}\) and \(Rand\_trans(p)\) produce random integer number from 1 to m and from 1 to k respectively but \(Ran1\) is a random number from 1 to 0.

Skills of hummingbird leads to reach its food supply goal and nominate the new updated one from the available surrounding sources. The directed food search can be represented as in (22) and (23).

where \({\mu }_{i}(IT+1)\) is the updated location of the ith food supply at iteration \((IT+1)\), \({LOC}_{i}(IT)\) is the existing location of the ith food supply, and \(g\) is the directed factor according to normal distribution \(ND(\mathrm{0,1})\) with the mean value zero and the standard deviation one. The general form of the updated location based on the fitness function can be reformulated as in (24).

Equation (24) shows that the searching for high quality of food resources may start with long distances, but the algorithm tries to go through shorter distances with increasing number of iterations. Hummingbirds is used to transfer to the goal resources with advanced investigations preventing apparent local solutions.

Regional food search

After sucking the available syrup and food at the existing source, the hummingbird starts to look for other sources in the same surrounding as in (25) and (26).

where \(h\) is the regional factor based on the normal distribution \(ND(\mathrm{0,1})\) when the mean value is zero and the standard deviation is one.

Relocation food search

When the modified location \(({\text{MLOC}})\) in the presented region became poor with the food resources, the hummingbird begins to transfer to other locations to search for the required food. Also, if the number of iterations became larger than the relocation factor, the hummingbird located at the positions with lower visit rates will be transferred to a new food resources randomly selected through the hall search area as in (27) and look up table to be revised.

where \({LOC}_{low-rate}\) is the location of the food source with the lower visit rate by hummingbird.

The number of population and iterations are the two important limits affect the process of the AHO. If no replacement food resource is found, the algorithm will start going again to all food resources according to look up table.

At bad conditions, hummingbird may change its food resource goal after two times number of iterations by go to the relocation search stage as per (28).

The complete procedures of the AHO35 are summarized as depicted in Fig. 4.

Applications and validations

The precision of the AHO optimizer to extract the unknown parameters of SPTs is assessed by applying it to two test cases: 4 kVA and 15 kVA SPTs1,7, respectively. For more verifications, the established ISA optimizer is also applied to the two cases and the results of both AHO and ISA compared to other published results in addition to the actual transformers parameters values. Five optimizers are used for the comparisons: PSO16, GA16, imperialist competitive algorithm (ICA)10, chaotic optimization approach (COA) 10, and GSA10 for test case 1. On the other hand, comprehensive comparisons among PSO1, forensic-based investigation (FBI)1, JS21, GA17, ICA10, GSA10, black-hole optimization (BHO)41, and hurricane optimization algorithm (HOA)42 to the AHO for test case 2.

To assure the stabilization of the AHO’s performance, 1000 population members, 1000 iterations and 10 independent trials are used using Intel(R) Core (TM) i7-4710HQ CPU@ 2.5GHZ, and 8 GB RAM PC.

Test case 1

The proposed AHO is executed and applied to 15 kVA SPT based on the nameplate data: 15 kVA, one-phase, 2400 V/240 V, and 50 Hz. The measured transformer currents and voltages at full load are: \({I}_{11act}\) = 6.2 A, \({I}_{21act}\) = 6.2 A, \({V}_{21act}\)= 2383.8 V, and ηact = 99.2%7,10.

Comparisons between the transformer parameters obtained by different algorithms previously published results of ICA, GSA, and COA in10, and PSO and GA in16 are arranged in Table 1. The OF represented by (17) is applied considering the values referred to the primary side of the transformer using standard Z-circuit and short-circuit tests.

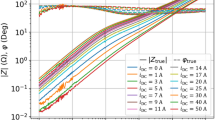

Table 2 indicates the four terms of the OF resulted from AHO and ISA optimizers against other recognized optimizers. It can be concluded that the errors sum is very close to zero where it is in the range between nearly 6 to 12 for the other optimizers. The results prove the superiority of the proposed AHO-based approach for the parameter estimation of a SPT. For more assessment of the of the applied optimizers, the convergence for case 1 is depicted in Fig. 5. The proposed optimizer produces the minimum SAE’s value which equals to 0.033514. on the other hand, the ISA optimizer error is equal to 0.0335284 which assures the high-quality outcome of the AHO.

Test case 2

The capability of the proposed AHO optimizer to evaluate the SPT parameters is also tested by applying it to 4 kVA, one-Phase, 250/125 V, 50 Hz and the obtained parameters compared with other documented works as shown in Table 3. Also, the nominal load currents, voltage, and efficiency at full load of the test system are estimated and compared with the well-known optimizers as in Table 4. It can be observed that the value of SAE achieved by the AHO (i.e., 1.12e-5) is the smallest one among the other algorithms. Figure 6 depicts the convergence trends of both AHO and ISA methods for the tested SPT. In addition to that, comprehensive comparisons among PSO1, FBI1, ICA10, GSA10, GA17, JS21, BHO41, and HOA42 to the AHO as indicated in Tables 3 and 4.

Transformer simulation and performance

For more proof of the precision of the AHO, the transformer model is simulated in MATLAB/Simulink using the extracted parameters by algorithm as in Fig. 7. The simulation is utilized to study case 2 transformer performance, compare the results with the calculated values, actual performance, and another recognized papers with trusted optimizers at steady state and inrush conditions. Figure 7a–b shows the simulation main components and internal components, respectively while Fig. 7c indicate the transformer simulator resistive loading steps.

Transformer steady-state operation

The steady state performance of case 2 transformer with the parameters estimated by the AHO as arranged in Table 3 at unity power factor (UPF) is studied when loading is varied using the mentioned simulator. The effects of load changes on transformer load voltage \({V}_{21}\), current, input/output power, voltage regulation \(\varepsilon\) and efficiency η are studied as shown in Fig. 8.

The same data and analysis are done using the mathematical model in "Mathematical modeling of single‑phase transformer and statement" Section considering unity, 0.8 lagging and 0.8 leading power factors and shown in Fig. 9. The transformer performance under unity, and 0.8 lagging PF loading conditions are announced in Tables 5 and 6. The behaviours of η, \({V}_{21}\) and ε of case 2 transformer using the parameters extracted by the AHO and the simulator is like results calculated by the mathematical model and recognized behaviour which assures the optimizer capabilities. It can be observed from Fig. 9a that the maximum efficiency is achieved at about 45% loading at UPF, and 0.8 lagging PF. As well-known, the transformer loading percentage with respect to full load can be obtained as per (29) and maximum efficiency attained when the cupper losses \(\left({P}_{cu}\right)\) is equal to iron losses \(\left({P}_{ir}\right)\)43.

A closer look to Tables 5 and 6, it can be observed that the calculated loading ratio at UPF and 0.8 lagging PF nearly equals 45% same as noticed from Fig. 9a which proves the perfection of the results generated by the AHO. To avoid lengthy article, the Table for leading PF is not shown, however, the plot trends are indicated in Fig. 9a–c like other cases with different loading%. The reader may note that the values of voltage regulations have a positive value for UPF and 0.8 lagging and a negative value under capacitive loading (i.e., 0.8 leading) as indicated in Fig. 9c.

The same performance of the mentioned transformer using the parameters estimated by recognized papers using trusted optimizers are compared to the performance using the AHO proposed optimizer as shown in Fig. 10. It can be observed that AHO could not only extract transformer parameters with the lowest error but also lead to performance close to the performance delivered based on the actual readings.

Transformer operation at inrush conditions

Case 2 transformer inrush current is investigated considering the transformer inrush data in Table 7 including extracted parameters by the AHO. λ0 is the initial flux linkage value. It is well-known that the study of the inrush current behavior of electric transformer is essential for proper sizing of protective devices to avoid the nuisance tripping during the energization.

The obtained results for current, flux linkage and magnetization curves are shown at Figs. 11, 12 and 13 and 14 which match the expected inrush performance.

In addition to the above, the inrush current behaviour of the 4 kVA transformer using results of another optimizers (e.g., PSO, FBI, JS, and ISA) are compared against the AHO and actual values as depicted in Fig. 14. It can be observed that all of them are close to the actual inrush behaviour.

Human and animal rights

This article does not contain any studies with animals performed by any of the authors.

Conclusions

AHO has been utilized to extract the unknown transformer parameters using its equivalent model. The actual transformer nameplate data is used only to achieve this objective by minimizing the sum of absolute errors (SAEs) among some selected variables. Two test cases have been demonstrated complete with necessary comparisons and further validations. The minimum obtained values of SAEs are 0.033514 and 1.12e-5 for 15 kVA and 4 kVA test cases, respectively. To assure the effectiveness of the proposed tool, the obtained parameters have been used to study the transformer behavior and compared with the well-known performance. The percentage of loading to realize the maximum efficiency has been assigned and the inrush behaviors of transformers have been carried out. In addition to that, the performance of voltage regulations under varied loading conditions at different power factors have been emphasized. The results are very close to the practical ones and proves the efficacy of the proposal. It may be suggested to extend this current work by utilizing the empirical and experimental dataset of large scales of power transformers to define more accurate models including the stray capacitors of the equivalent circuits.

Data avaliability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Youssef, H., Kamel, S., Hassan, M. H. New application of forensic-based investigation optimizer for parameter identification of transformer. In 22nd Intern. Mid. East Power Syst. Conf. (MEPCON), (Assiut, Egypt, 2021), doi: https://doi.org/10.1109/MEPCON50283.2021.9686276.

Aguglia, D., Viarouge, P. & Martins, C. D. A. Frequency-domain maximum-likelihood estimation of high-voltage pulse transformer model parameters. IEEE Trans. Ind. Appl. 49(6), 2552–2561. https://doi.org/10.1109/TIA.2013.2265213 (2013).

Ćalasan, M. P., Jovanović, A., Rubežić, V., Mujičić, D. & Deriszadeh, A. Notes on parameter estimation for single-phase transformer. IEEE Trans. Ind. App. 56(4), 3710–3718. https://doi.org/10.1109/TIA.2020.2992667 (2020).

Sung, D. C. Parameter estimation for transformer modeling. Michigan Technological University, a dissertation for Doctor of Philosophy Electrical Eng. (2002) https://doi.org/10.37099/mtu.dc.etds/60.

Shintemirov, A., Tang, W. H. & Wu, Q. H. Transformer core parameter identification using frequency response analysis. IEEE Trans. Magn. 46(1), 141–149. https://doi.org/10.1109/TMAG.2009.2026423 (2010).

Aghmasheh, R., Rashtchi, V. & Rahimpour, E. Gray box modeling of power transformer windings based on design geometry and particle swarm optimization algorithm. IEEE Trans. Power Deliv. 33(5), 2384–2393. https://doi.org/10.1109/TPWRD.2018.2808518 (2018).

Ćalasan, M., Mujičić, D., Rubežić, V. & Radulović, M. Estimation of equivalent circuit parameters of single phase transformer by using chaotic optimization approach. Energies 12(9), 1697. https://doi.org/10.3390/en12091697 (2019).

Koochaki, A. Teaching calculation of transformer equivalent circuit parameters using MATLAB/Simulink for undergraduate electric machinery courses. Indian J. Sci. Techn. 8(17), 1–6. https://doi.org/10.17485/ijst/2015/v8i17/59182 (2015).

Kazemi, R., Jazebi, S., Deswal, D. & León, F. D. Estimation of design parameters of single-phase distribution transformers from terminal measurements. IEEE Trans. Power Deliv. 32(4), 2031–2039. https://doi.org/10.1109/TPWRD.2016.2621753 (2017).

Illias, H. A., Mou, K. J. & Bakar, A. H. O. Estimation of transformer parameters from nameplate data by imperialist competitive and gravitational search algorithms. Swarm Evolut. Comput. 36, 18–26. https://doi.org/10.1016/j.swevo.2017.03.003 (2017).

Adly, A. A. & Abd-El-Hafiz, S. K. A performance-oriented power transformer design methodology using multi-objective evolutionary optimization. J. Adv. Res. 6(3), 417–423. https://doi.org/10.1016/j.jare.2014.08.003 (2015).

Bhowmick, D., Manna, M. & Chowdhury, S. K. Estimation of equivalent circuit parameters of transformer and induction motor from load data. IEEE Trans. Ind. Appl. 54(3), 2784–2791. https://doi.org/10.1109/TIA.2018.2790378 (2018).

El-Sehiemy, R. A., Hamida, M. A. & Mesbahi, T. Parameter identification and state-of-charge estimation for lithium-polymer battery cells using enhanced sun flower optimization algorithm. Int. J. Hydrogen Energy 45(15), 8833–8842. https://doi.org/10.1016/j.ijhydene.2020.01.067 (2020).

Shafik, M. B. et al. Adequate topology for efficient energy resources utilization of active distribution networks equipped with soft open points. IEEE Access 7, 99003–99016. https://doi.org/10.1109/ACCESS.2019.2930631 (2017).

Ghoneim, S. S. M., Kotb, M. F., Hasanien, H. M., Alharthi, M. M. & El-Fergany, A. A. Cost minimizations and performance enhancements of power systems using spherical prune differential evolution algorithm including modal analysis. Sustainability 13(14), 8113. https://doi.org/10.3390/su13148113 (2021).

Bhowmick, D., Manna, M., Chowdhury, S. K. Estimation of equivalent circuit parameters of transformer and induction motor using PSO. In IEEE Int. Conf. Power Electron., Drives Energy Syst. (Trivandrum, India, 2016). https://doi.org/10.1109/PEDES.2016.7914531.

Mossad, M. I., Mohamed, A. & Abu-Siada, A. Transformer parameters estimation from nameplate data using evolutionary programming techniques. IEEE Trans. Power Deliv. 29, 2118–2123. https://doi.org/10.1109/TPWRD.2014.2311153 (2014).

Rahimpour, E., Bigdeli, M. Simplified transient model of transformer based on geometrical dimensions used in power network analysis and fault detection studies. In Proceedings of the International Conference on Power Engineering, Energy and Electrical Drives, (Lisbon, Portugal, 2009). https://doi.org/10.1109/POWERENG.2009.4915148

El-Dabah, M. A., Agwa, A., Elattar, E. & Elsayed, S. K. Slime mold optimizer for transformer parameters identification with experimental validation. Intell. Auto. Soft Comput. 28(3), 639–651. https://doi.org/10.32604/iasc.2021.016464 (2021).

Padma, S. & Subramanian, S. Parameter estimation of single phase core type transformer using bacterial foraging algorithm. Eng. 2, 917–925. https://doi.org/10.4236/eng.2010.211115 (2010).

Abdelwanis, M. I., Abaza, A., El-Shiemy, R. A., Ibrahim, M. N. & Rezk, H. Parameter estimation of electric power transformers using coyote optimization algorithm with experimental verification. IEEE Access 8, 50036–50044. https://doi.org/10.1109/ACCESS.2020.2978398 (2020).

Youssef, H., Kamel, S., Hassan, M. H. Parameter estimation of single-phase transformer using jellyfish search optimizer algorithm. In Int. Conf. on Auto./XXIV Congr. Chilean Assoc. Automatic Control (ICA-ACCA), (Valparaíso, Chile, 2021) https://doi.org/10.1109/ICAACCA51523.2021.9465279.

Karmakar, S., Subhasmita, S. S., Firdous, G., Mohanty, S., Mohapatra T. K. Machine learning approach to estimation of internal parameters of a single phase transformer. In International Conf. Emerging Technol. (INCET), (Belgaum, India, 2020). https://doi.org/10.1109/INCET49848.2020.9154161.

Zhang, Z., Kang, N., Mousavi, M. J. Real-time transformer parameter estimation using terminal measurements. In IEEE Power & Energy Society General Meeting, (Denver, CO, USA, 2015). https://doi.org/10.1109/PESGM.2015.7285958

Papadopoulos, T. A., Chrysochos, A. I., Nousdilis, A. I. & Papagiannis, G. K. Simplified measurement-based black-box modeling of distribution transformers using transfer functions. Electr. Power Syst. Res. 121, 77–88. https://doi.org/10.1016/j.epsr.2014.12.003 (2015).

Bogarra, S. M., Font, A., Candela, I. & Pedra, J. Parameter estimation of a transformer with saturation using inrush measurements. Electr. Power Syst. Res. 79, 417–425. https://doi.org/10.1016/j.epsr.2008.08.009 (2009).

Thilagar, S. H. & Rao, G. S. Parameter estimation of three winding transformer using genetic algorithm. Eng. Appl. Art. Intell. 15(5), 429–437. https://doi.org/10.1016/S0952-1976(02)00087-8 (2002).

Gogna, A. & Tayal, A. Metaheuristics: Review and application. J. Exp. Theor. Artif. Intell. 25(4), 503–526. https://doi.org/10.1080/0952813X.2013.782347 (2013).

Zhang, Y., Wang, S. & Ji, G. A comprehensive survey on particle swarm optimization algorithm and its applications. Math. Probl. Eng. 2015, 9312556. https://doi.org/10.1155/2015/931256 (2015).

Ab Wahob, M. N., Nefti-Meziani, S. & Atyabi, A. A comprehensive review of swarm optimization algorithms. PLoS ONE 10(5), e0122827. https://doi.org/10.1371/journal.pone.0122827 (2015).

Yan, G. & Li, C. An effective refinement artificial bee colony optimization algorithm based on chaotic search and application for PID control tuning. J. Comput. Inf. Syst. 7(9), 3309–3316 (2011).

Yang, X. S. & Deb, S. Engineering optimization by cuckoo search. Int. J. Math. Model. Numer. Optim. 1(4), 330–343. https://doi.org/10.1504/IJMMNO.2010.035430 (2010).

El-Fergany, A. A. & Abdelaziz, A. Y. Capacitor allocations in radial distribution networks using cuckoo search algorithm. IET Gen. Transm. Distrib. 8(2), 223–232. https://doi.org/10.1049/iet-gtd.2013.0290 (2014).

Wang, J., Zhou, B. & Zhou, S. An improved cuckoo search optimization algorithm for the problem of chaotic systems parameter estimation. Comput. Intell. Neurosci. 2016(2), 1–8. https://doi.org/10.1155/2016/2959370 (2016).

Zhao, W., Wang, L. & Mirjalili, S. Artificial hummingbird algorithm: A new bio-inspired optimizer with its engineering applications. Comput. Methods Appl. Mech. Eng. 388, 114194. https://doi.org/10.1016/j.cma.2021.114194 (2022).

Martinez, J. A. & Mork, B. A. Transformer modeling for low-and mid-frequency transients–a review. IEEE Trans. Power Deliv. 20(2), 1625–1632. https://doi.org/10.1109/TPWRD.2004.833884 (2005).

Ayasun, S. & Nwankpa, C. O. Transformer tests using MATLAB/Simulink and their integration into undergraduate electric machinery courses. Computer Applic. Eng. Education 14(2), 142–150. https://doi.org/10.1002/cae.20077 (2006).

Kulkarni S.V., Khaparde S.A. Transformer Engineering design, technology, and diagnostics. (CRC Press, Taylor, 2013) ISBN-13: 978–1–4398–5418–1 (ebook).

Karsai K., Kerenyi D., Kiss L. Large power transformers, studies in electrical and electronic engineering. (Elsevier, 1987) ISBN-13: 978–0444995117, ISBN-10: 0444995110.

Sonnemann, W. K., Wagner, C. L. & Rockefeller, G. D. Magnetizing inrush phenomena in transformer banks. AIEE Trans Part III 77, 884–892. https://doi.org/10.1109/AIEEPAS.1958.4500053 (1958).

Arenas-Acuña, C. A., Rodriguez-Contreras, J. A., Montoya, O. D. & Rivas-Trujillo, E. Black-hole optimization applied to the parametric estimation in distribution transformers considering voltage and current measures. Computers 10(10), 124. https://doi.org/10.3390/computers10100124 (2021).

Cortés-Caicedo, B., Montoya, O. D. & Arias-Londoño, A. Application of the hurricane optimization algorithm to estimate parameters in single-phase transformers considering voltage and current measure. Computers 11, 55. https://doi.org/10.3390/computers11040055 (2022).

Theraja B.L., Theraja A.K. A Textbook of Electrical Technology. Chand (2008), ISBN-10: 8121924413, ISBN-13: 978-8121924412.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

All authors have participated in (a) conception and design, or analysis and interpretation of the data; (b) drafting the article or revising it critically for important intellectual content; and (c) approval of the final version.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kotb, M.F., El-Fergany, A.A. & Gouda, E.A. Estimation of electrical transformer parameters with reference to saturation behavior using artificial hummingbird optimizer. Sci Rep 12, 19623 (2022). https://doi.org/10.1038/s41598-022-24122-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-022-24122-8

This article is cited by

-

A Survey of Artificial Hummingbird Algorithm and Its Variants: Statistical Analysis, Performance Evaluation, and Structural Reviewing

Archives of Computational Methods in Engineering (2024)

-

Characterization of electrical 1-phase transformer parameters with guaranteed hotspot temperature and aging using an improved dwarf mongoose optimizer

Neural Computing and Applications (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.