Abstract

REBa2Cu3O7-δ (REBCO, RE: rare earth, such as Y and Gd) compounds have been extensively studied as a superconducting layer in coated conductors. Although ErBCO potentially has better superconducting properties than YBCO and GdBCO, little research has been made on it, especially in chemical solution deposition (CSD). In this work, ErBCO films were deposited on IBAD (ion-beam-assisted-deposition) substrates by CSD with low-fluorine solutions. The crystallization process was optimized to achieve the highest self-field critical current density (Jc) at 77 K. Commonly, for the investigation of a CSD process involving numerous process factors, one factor is changed keeping the others constant, requiring much time and cost. For more efficient investigation, this study adopted a novel design-of-experiment technique, definitive screening design (DSD), for the first time in CSD process. Two different types of solutions containing Er-propionate or Er-acetate were used to make two types of samples, Er-P and Er-A, respectively. Within the investigated range, we found that crystallization temperature, dew point, and oxygen partial pressure play a key role in Er-P, while the former two factors are significant for Er-A. DSD revealed these significant factors among six process factors with only 14 trials. Moreover, the DSD approach allowed us to create models that predict Jc accurately. These models revealed the optimum conditions giving the highest Jc values of 3.6 MA/cm2 for Er-P and 3.0 MA/cm2 for Er-A. These results indicate that DSD is an attractive approach to optimize CSD process.

Similar content being viewed by others

Introduction

ErBa2Cu3O7-δ (ErBCO) is one of the REBa2Cu3O7-δ (REBCO, RE: rare earth) compounds with potential as a functional superconducting layer in coated conductors1,2. Indeed, Yoshida et al. have demonstrated ErBCO coated conductor samples of nearly 100 m length with average critical current values, Ic, of ~ 700 A/cm-width3. Most of the film studies on ErBCO were done via PLD4 (pulsed laser deposition) especially regarding possible enhancement of the critical current density, Jc, by perovskite nanoparticles5 and nanorods6. Just occasional ErBCO film studies are reported for other vacuum (MOCVD7, sputtering8) and non-vacuum methods (CSD/MOD (metal–organic deposition)9,10, sol–gel11). Since the ion sizes of Er3+ and Y3+ are very similar, the stability and growth temperatures of ErBCO and YBCO are well comparable12, differing by only ~ ± 10 °C. In this work, since few research has been made on ErBCO CSD process, we prepared ErBCO films on technical IBAD templates13 by CSD14,15, following the TFA-MOD (metal–organic deposition of trifluoroacetates) route with low-fluorine solutions16,17.

In order to find the optimum process conditions for complicated systems such as CSD, one has to deal with numerous parameters, requiring a lot of time and cost for try and error. In particular, the thermal processes involved in CSD have conventionally been optimized in one-factor-at-a-time experiments, i.e., only one of the potentially important parameters is changed, keeping all the others constant. This kind of investigation is extensive and often incomplete because significant parameters, i.e., those influencing and determining the final quality of the films, are often correlated. For example, in CSD, the optimum crystallization temperatures are reported to depend on the oxygen partial pressure18. The one-factor-at-a-time approach often fails to find such interactions and requires many experiments to improve process conditions. Therefore, we adopted a novel design-of-experiment (DOE) technique, Definitive Screening Design (DSD)19 for the first time, to identify significant factors and improve self-field critical current density, \({\varvec{J}}_{{\mathbf{c}}}^{{{\mathbf{sf}}}}\), at 77 K while reducing the number of necessary experiments as much as possible.

DSD was introduced by Jones and Nachtsheim in 201119. It offers the opportunity to investigate many parameters and optimize a process by performing one experiment with a small number of trials20,21. Among the multitude of possible combinations of levels (magnitudes) of the preselected parameters (called “factors”), DSD identifies the few trials to be performed for efficient evaluation of the factors’ effects. Main effects (the first-order effect of a single factor), two-factor interactions (the correlation between two factors), and quadratic effects are estimable at the same time. This feature distinguishes DSD from other, conventional DOE techniques, most of which cannot estimate quadratic effects or need many trials to estimate them. This advantage of DSD makes it possible to find the optimum condition in a large experimental space. By using DSD, one can understand how the target value is changed by the levels of the factors, identify important factors, and finally optimize their levels.

Experimental

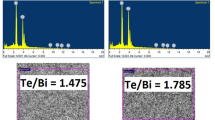

Solution and sample preparation

The low-fluorine solutions of this study are prepared by mixing fluorinated and non-fluorinated precursor salts, namely Er-propionate or Er-acetate, Ba-TFA, and Cu-propionate, in the stoichiometric ratio Er:Ba:Cu = 1:2:3 in anhydrous methanol resulting in a concentration of 1.5 M (sum of metals). Two types of ErBCO samples were prepared from two different solutions depending on the Er precursor salt (“Er-P” samples from Er-propionate and “Er-A” samples from Er-acetate). The solutions were deposited on 10 × 10 mm2 IBAD substrates by spin coating for 30 s at different rotation speeds (2000–4000 rpm). The SuperOx IBAD substrates had the architecture of CeO2/LaMnO3 (LMO)/MgO/Y2O3/Al2O3/Hastelloy C276. The details of the standard pyrolysis and crystallization steps are available in Ref.22. The investigated factors were crystallization temperature (Tcrys), oxygen partial pressure (poxy), dew point (TDew), heating ramp, dwell time, and rotation speed. The investigated ranges of these factors and levels are listed in Table 1. We have chosen these parameters because they are known by experience to be the most important parameters that affect the film growth and are directly controllable with our equipment (furnace and spin coater). Other factors might be considered; however, from our experience, we can assume there are no factors that correlate with the six factors in this experiment. That is, these six factors do not have to be considered with other possible factors at the same time.

Thin-film characterization

The film thicknesses for the rotation speeds of 2000, 3000, and 4000 rpm were 400, 350, and 285 nm, respectively, as analyzed with cross-sectional scanning electron microscopy by a LEO 1530 scanning electron microscope (SEM) with field emission gun (0.1 kV and 30 kV) by Zeiss. Figure 1 shows an example of the cross-section of an Er-P sample deposited with 3000 rpm, and the thickness of ErBCO is 350 ± 30 nm. The variation of the thickness is about 10% of the total thickness. Self-field Jc (\({\text{J}}_{\text{c}}^{\text{sf}}\)) at 77 K was measured inductively with a Cryoscan (Theva, 50 µV criterion).

Definitive screening design and model selection

The design matrix for the investigated factors, Table 2, is generated by using a so-called conference matrix23. Coded units (– 1, 0, and 1) correspond to the levels in Table 1. The trials (runs) are carried out using the parameter sets (rows) specified in Table 2 in random order. The minimum number of runs is 2K + 1 = 13 (K is the number of factors), but the runs with level 0 of all factors (center run) was repeated, see bottom rows of Table 2. This repetition of the center run is necessary to estimate the population variance regardless of significant factors. Without the repetition of this center run or addition of fake factors24, the population variance has to be estimated by the residual sum of squares of the model containing significant parameters; hence, the estimator of the variance will not be unique but dependent on the chosen model.

After obtaining the experimental data, models are built following an appropriate model selection procedure. The data included in the model are the values of the property to be optimized, such as Jc at a certain magnetic field, a ratio of Jc at different fields and/or temperatures, or critical temperature Tc. Although the model and its predictions depend on the selected property, we construct the model regarding \({\varvec{J}}_{{\mathbf{c}}}^{{{\mathbf{sf}}}}\) at 77 K in this work. The best second-order model (containing main, interaction, and quadratic effects) was selected among all the possible second-order models based on the Akaike information criterion with finite correction (AICc). AICc (or generally AIC) is an estimator to select a “good” model avoiding overfitting, which can explain the prediction values well. Supposing that the errors follow independent and identical normal distributions, AICc is expressed in the following equation for the least square estimation23.

where n is the number of observations and \(\hat{\sigma }^{2}\) is the estimator of the variance calculated by

where yi and \(\widehat{{y_{i} }}\) are observed and fitted value, respectively, of the ith factor.

Results and discussion

Table 3 shows the \({\varvec{J}}_{{\mathbf{c}}}^{{{\mathbf{sf}}}}\) values at 77 K of Er-P and Er-A samples for the DSD experiment (Samples 1–14) together with pilot trials (Samples 15–30) that were obtained before starting the DSD experiment and used for confirmation of the equations (models) later. In the DSD experiment, the \({\varvec{J}}_{{\mathbf{c}}}^{{{\mathbf{sf}}}}\) values at 77 K ranged from 0 to 3.67 MA/cm2 for Er-P, and from 0 to 3.30 MA/cm2 for Er-A. Considering the measured thickness variation of about ± 30 nm (~ 10% of ErBCO layer), the Jc values also have an uncertainty of about ± 10%.

Among all the possible second-order models containing main, interaction, and quadratic effects, the models with minimum AICc, Eqs. (3) and (4), were selected for Er-P and Er-A respectively. Samples 1–14 were used to create these models.

Table 4(a) and (b) list the important factors of these models for \({\varvec{J}}_{{\mathbf{c}}}^{{{\mathbf{sf}}}}\) at 77 K with P values of the coefficients (the smaller the P value is, the more likely the coefficient is not zero, hence, significant). The significant main factors for Er-P are Tcrys, poxy, and TDew, while for Er-A only Tcrys and TDew. Dwell time, heating ramp, and rotation speed are not significant for both sets of samples. The quadratic effect of poxy is significant for Er-P, and the quadratic effect of Tcrys for Er-A. Neither of the two sets of samples showed any sign of two-factor interactions. Since at least some of the factors are usually correlated (e.g., the interaction between Tcrys and poxy is certainly present18), we conclude that the investigated range in this work was not wide enough to detect such interactions.

Based on these models, Eqs. (3) and (4), the dependencies of Jc (Er-P) and Jc (Er-A) on TDew and Tcrys are visualized in Fig. 2. Figure 2a shows that lower Tcrys and lower TDew are crucial for improving Jc (Er-P) with the optimal poxy = 256 ppm (0.413 in coded unit), whereas Fig. 2b shows intermediate Tcrys and lower TDew to be crucial for Jc (Er-A). The major differences between both sample types are that the desirable Tcrys is lower for Er-P than for Er-A, and poxy is a significant parameter (in the investigated range) for Er-P but not for Er-A.

To confirm the validity of the Jc (Er-P) model Eq. (3), further twelve Er-P samples were selected (Samples 15–26 in Table 3) and their \({\varvec{J}}_{{\mathbf{c}}}^{{{\mathbf{sf}}}}\) values at 77 K measured. Figure 3a shows these Jc (Er-P) values together with their 95% prediction intervals (PI95%). Most of the data fall inside this prediction interval. Hence, the model is considered useful to predict Jc (Er-P). Furthermore, the model suggests that the maximum range of \({\varvec{J}}_{{\mathbf{c}}}^{{{\mathbf{sf}}}}\) at 77 K (2.9–4 MA/cm2) can be obtained with Tcrys = 770 °C, poxy = 256 ppm, TDew = 16 °C (other parameters are arbitrary values). The samples made with these conditions are Sample 25 (3.2 MA/cm2) and Sample 26 (3.6 MA/cm2), which are indeed the highest level (considering 10% uncertainty of Jc) and inside the prediction interval in Fig. 3a Similarly, the validation of Jc (Er-A) has been checked using Sample 15, and Samples 27–31 in Fig. 3b The optimal samples are Samples 30 and 31 prepared with Tcrys = 778.5 °C and TDew = 16 °C (other parameters are not important). Samples 30 and 31 certainly outperformed the other Er-A samples.

Model confirmation for (a) Jc (Er-P) and (b) Jc (Er-A). The conditions of the samples are described in Table 3. Samples 25 and 26 are optimal Er-P samples, Samples 30 and 31 are optimal Er-A samples. Note that measured Jc values have an uncertainty of about 10% because of the thickness uncertainty.

Moreover, since not all the factors have quadratic effects, the global optimum seems to exist outside of the investigated range in this work. However, a one-factor-at-a-time approach for further improvement is acceptable because the interactions between the significant factors (Tcrys, poxy, and TDew) are not likely to be present near the investigated range.

Conclusion

The crystallization process of ErBCO films deposited with CSD on SuperOx IBAD substrates was optimized via DSD, a novel design-of-experiment technique. This approach allowed investigating the effects of six crystallization parameters (Tcrys, poxy, TDew, dwell time, heating ramp, and rotation speed) with a considerably reduced number of trials compared to conventional one-factor-at-a-time approach. The crystallization was optimized regarding \({\varvec{J}}_{{\mathbf{c}}}^{{{\mathbf{sf}}}}\) at 77 K. Two types of ErBCO samples, Er-P and Er-A, prepared from the solutions containing Er-propionate and Er-acetate, respectively, were studied. Only 14 samples per sample type were necessary for this DSD experiment. The models based on the experiment reveal that Tcrys, poxy, and TDew are significant factors for Jc (Er-P), and only Tcrys and TDew for Jc (Er-A) in the investigated range of the factors. As expected from the model for Jc (Er-P), a maximum of ~ 3.6 MA/cm2 was obtained with Tcrys = 770 °C, poxy = 256 ppm, and TDew = 16 °C. Similarly, a maximum Jc (Er-A) of ~ 3.0 MA/cm2 was obtained with Tcrys = 778.5 °C and TDew = 16 °C. Both models were confirmed by additional samples. These results indicate that DSD is a very attractive approach to optimize the properties of CSD-grown films. It could also be a powerful tool for the development of long-tape coated conductors as it could enormously reduce the effort in the optimization of the different process steps.

References

Obradors, X. et al. Coated conductors for power applications: materials challenges. Supercond. Sci. Technol. 27, 044003 (2014).

Bondarenko, S. I., Koverya, V. P., Krevsun, A. V. & Link, S. I. High-temperature superconductors of the family (RE) Ba2Cu3O7-δ and their application. Low Temp. Phys. 43, 1125–1151 (2017).

Yoshida, T. et al. Fabrication of 93.7 m long PLD-EuBCO+ BaHfO3 coated conductors with 103 A/cm W at 77 K under 3 T. Phys. C Supercond. Appl. 518, 54–57 (2015).

Ohazama, T. et al. Growth of high-quality ErBa2Cu3O7-δ thin films. Physica C Supercond. Appl. 412–414, 1301–1305 (2004).

Ito, M. et al. Microstructure of ErBa2Cu3O7-δ films with BaZrO3 dispersion pinning centers for high JC applications. Phys. C Supercond. Appl. 426–431, 1415–1418 (2005).

Kai, H. et al. Superconducting properties and microstructure of PLD-ErBa2Cu3O7-δ film with BaNb2O6. Phys. C Supercond. Appl. 463–465, 895–899 (2007).

Takemoto, J. H. et al. Microstrip resonators using two-sided metalorganic chemical vapor deposited Er–Ba–Cu–O thin films. Appl. Phys. Lett. 58, 1109–1111 (1991).

Mochiku, T., Kanke, Y., Wen, Z., Iguchi, I. & Yamaka, E. Effect of substrate temperature on the crystalline state of Ba2ErCu3O7-x superconducting thin films by RF magnetron sputtering. Jpn. J. Appl. Phys. 27, L1679–L1682 (1988).

Iguchi, T. et al. Metal–organic deposition of RE–Ba–Cu–O (RE=Dy, Ho, Er, and Tm) films using trifluoroacetates. Physica C Supercond. Appl. 392–396, 900–904 (2003).

Manuela, E. & Cayado, P. Comparative study of CSD-grown REBCO films with different rare earth elements—part one: processing windows and Tc. Supercond. Sci. Technol. 11, 1–12 (2020).

El-Kawni, M. I., Mutlu, I. H., Aslanoglu, Z., Akin, Y. & Hascicek, Y. S. Nonvacuum Er-123 films on buffer layered Ni tapes: processing, growth, and properties. J. Supercond. Nov. Magn. 15, 191–194 (2002).

Salinas-Sanchez, A., Garcia-Muñoz, J. L., Rodriguez-Carvajal, J., Saez-Puche, R. & Martinez, J. L. Structural characterization of R2BaCuO5 (R = Y, Lu, Yb, Tm, Er, Ho, Dy, Gd, Eu and Sm) oxides by X-ray and neutron diffraction. J. Solid State Chem. 100, 201–211 (1992).

Lee, S. et al. Development and production of second generation high T c superconducting tapes at SuperOx and first tests of model cables. Supercond. Sci. Technol. Supercond. Sci. Technol 27, 9 (2014).

Obradors, X. et al. Progress towards all-chemical superconducting YBa2Cu3O7-coated conductors. Supercond. Sci. Technol. 19, S13–S26 (2006).

Izumi, T. et al. Progress in development of advanced TFA-MOD process for coated conductors. Phys. C Supercond. Appl. 463, 510–514 (2007).

Li, M. et al. Rapid pyrolysis of SmBa2Cu3O7-δ films in CSD-MOD using extremely-low-fluorine solutions. Coatings 10, 31 (2020).

Palmer, X. et al. Solution design for low-fluorine trifluoroacetate route to YBa2Cu3O7 films. Supercond. Sci. Technol. 29, 024002 (2016).

Cayado, P. et al. Chemical solution deposition of Y1-:XGdxBa2Cu3O7-δ–BaHfO3 nanocomposite films: combined influence of nanoparticles and rare-earth mixing on growth conditions and transport properties. RSC Adv. 8, 42398–42404 (2018).

Jones, B. & Nachtsheim, C. J. A class of three-level designs for definitive screening in the presence of second-order effects. J. Qual. Technol. 43, 1–15 (2011).

Libbrecht, W. et al. Optimization of soft templated mesoporous carbon synthesis using definitive screening design. Chem. Eng. J. 259, 126–134 (2015).

Tai, M., Ly, A., Leung, I. & Nayar, G. Efficient high-throughput biological process characterization: definitive screening design with the Ambr250 bioreactor system. Biotechnol. Prog. 31, 1388–1395 (2015).

Erbe, M. et al. Improved REBa2Cu3O7−x (RE = Y, Gd) structure and superconducting properties by addition of acetylacetone in TFA-MOD precursor solutions. J. Mater. Chem. A 2, 4932 (2014).

Burnham, K. P. & Anderson, D. R. Multimodel inference. Sociol. Methods Res. 33, 261–304 (2004).

Montgomery, D. C. Design and Analysis of Experiments (Wiley, Hoboken, 2019).

Acknowledgements

We acknowledge support by the KIT Publication Fund of the Karlsruhe Institute of Technology, the Japan Student Services Organization and Tohoku University.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

R.H., P.C. and J.H. wrote the main manuscript text and M.E. and W.F. contributed to conducting the experiments and analyzing the results. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hayasaka, R., Cayado, P., Erbe, M. et al. Investigation of the crystallization process of CSD-ErBCO on IBAD-substrate via DSD approach. Sci Rep 10, 19934 (2020). https://doi.org/10.1038/s41598-020-76848-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-76848-y

This article is cited by

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.