Abstract

Here we first report results of the start of the solid-state reaction at the Rh/Fe(001) interface and the structural and magnetic phase transformations in 52Rh/48Fe(001), 45Rh/55Fe(001), 68Rh/32Fe(001) bilayers from room temperature to 800 °C. For all bilayers the non-magnetic nanocrystalline phase with a B2 structure (nfm-B2) is the first phase that is formed on the Rh/Fe(001) interface near 100 °C. Above 300 °C, without changing the nanocrystalline B2 structure, the phase grows into the low-magnetization modification αlʹ (MSl ~ 825 emu/cm3) of the ferromagnetic αʹ phase which has a reversible αlʹ ↔ αʺ transition. After annealing 52Rh/48Fe(001) bilayers above 600 °C the αlʹ phase increases in grain size and either develops into αhʹ with high magnetization (MSh ~ 1,220 emu/cm3) or remains in the αlʹ phase. In contrast to αlʹ, the αhʹ ↔ αʺ transition in the αhʹ films is completely suppressed. When the annealing temperature of the 45Rh/55Fe(001) samples is increased from 450 to 800 °C the low-magnetization nanocrystalline αlʹ films develop into high crystalline perfection epitaxial αhʹ(001) layers, which have a high magnetization of ~ 1,275 emu/cm3. αhʹ(001) films do not undergo a transition to an antiferromagnetic αʺ phase. In 68Rh/32Fe(001) samples above 500 °C non-magnetic epitaxial γ(001) layers grow on the Fe(001) interface as a result of the solid-state reaction between the epitaxial αlʹ(001) and polycrystalline Rh films. Our results demonstrate not only the complex nature of chemical interactions at the low-temperature synthesis of the nfm-B2 and αlʹ phases in Rh/Fe(001) bilayers, but also establish their continuous link with chemical mechanisms underlying reversible αlʹ ↔ αʺ transitions.

Similar content being viewed by others

Introduction

An intriguing feature of the equilibrium diagram of the Fe-Rh system is the existence of the low-temperature transition at TKαʺ→αʹ ~ 100 °C between antiferromagnetic (AFM) αʺ and ferromagnetic (FM) αʹ phases in a narrow (0.48 < xRh < 056) concentration interval in chemically ordered B2-FeRh alloys1. This transition is accompanied by an isotropic volume expansion of ~ 1% of the B2-FeRh unit cell, which not only radically changes the magnetic properties, but also changes the entropy2,3 and resistivity4. The magnetostructural αʺ → αʹ (AFM-FM) transition gives existence to the giant magnetostriction5 large magnetoresistance6,7 and magnetocaloric effects8 in B2-FeRh alloys. Numerous studies of bulk samples indicate that the starting temperature TKαʺ→αʹ and characteristics of the αʺ → αʹ transition may be modified by variations the magnetic field9,10, microstructure11, thermal treatment12, energetic ion irradiation13, stress14 and hydrostatic pressure15,16,17 and can also be tuned over a wide temperature range (100–600 K) by chemical substitution9,18. Although bulk B2-FeRh samples exhibit a sharp transition with a small thermal hysteresis, thin films and nanoparticles often have an incomplete and broad asymmetrical hysteresis AFM-FM transition1,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34. The starting transition temperature TKαʺ→αʹ and magnetic properties in B2-FeRh films depend not only on compositional variations26,27,34, but are also highly sensitive to the type of substrate19,24,25,26,29,35, the thickness of the thin film samples20,24,30, the nature underlayers33,36 and the capping layers31. Significant stresses arise at the film/substrate interface20,24, which makes it possible to control the magnetic and electrical transport properties of B2-FeRh films on ferroelectric substrates25,37,38,39,40 by varying the external electric field. Many groups using magnetron sputtering or molecular beam epitaxy achieved epitaxial B2-FeRh(001) films grown on MgO(001) crystalline substrates. In most studies high-temperature heat treatments above 600 °C were used to obtain the high crystalline quality of chemically B2-ordered phase32,33. However, chemical interactions of Rh with Fe and solid-state synthesis of the Rh-Fe phases at the Rh/Fe interface remain completely uninvestigated.

In this work, we describe the solid-state reactions between polycrystalline Rh with epitaxial Fe(001) films in 52Rh/48Fe(001), 45Rh/55Fe(001) and 68Rh/32Fe(001) bilayers with 52Rh:48Fe, 45Rh:55Fe and 68Rh:32Fe atomic ratios, respectively. Under these conditions, the reaction products of 52Rh/48Fe(001) fall into the (0.48 < xRh < 056) concentration interval and the reaction products for 45Rh/55Fe(001) and 68Rh/32Fe(001) samples lie in Fe-rich and Rh-rich regions of the Fe–Rh system. The main purpose of this article is to show the complex and intricate nature of the B2-FeRh phases synthesis, which begins to form on the Rh/Fe interface at ~ 100 °C.

Results

Structural and magnetic phase transformations in 52Rh/48Fe(001) bilayer during annealing up 800 °C

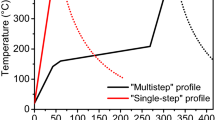

Figure 1a shows a schematic diagram of the phase transformations consistently occurring in 52Rh/48Fe(001) bilayers on a MgO(001) substrate during annealing from room temperature to 800 °C which builds on the X-ray diffraction (XRD) analysis (Fig. 1b) and magnetic measurements (Fig. 1c,d). The transformations consist of the formation of a nonferromagnetic B2-FeRh phase (nfm-B2) thin layer at the Rh/Fe interface of the as-deposited sample, which above 300 °C turns into the αlʹ phase. As will be shown below, the ferromagnetic αʹ phase may have two B2 modifications with similar or equal lattice parameters: a low-ferromagnetic αlʹ having a magnetization ~ 825 emu/cm3 and a fully reversible αlʹ ↔ αʺ (AFM-FM) transition and a high-ferromagnetic αhʹ with a magnetization ~ 1,220 emu/cm3 and with a completely depressed αhʹ → αʺ transition. As the annealing temperature increases above 600 °C the reaction products contain a mixture of epitaxial αlʹ(001) and αhʹ(001) grains. Figure 1b shows the XRD profiles of the as-deposited 52Rh/48Fe(001) film and after annealing at temperatures from room temperature to 800 °C. As-deposited samples show a strong Fe(002) peak, proving the epitaxial Fe(001) film growth on the MgO(001) substrate, and wide and very low diffraction peaks (001), (002) located at ~ 30° and ~ 62°, which are a signature of insignificant mixing, a reaction between the Rh and Fe(001) layers and the synthesis of a very thin epitaxial layer of nanocrystalline B2-ordered FeRh phase. These (001), (002) reflections were greatly broadened, split and their intensity did not change up to 600 °C. This strongly suggests that the reaction starts with the formation of (001)-textured nanograins containing B2—ordered FeRh phases with close lattice parameters and significant lattice distortions. After annealing above 600 °C the Fe(002) peak decreases significantly and practically disappears at 800 °C, which points to the complete termination of the reaction between the Fe and Rh layers. At the same time the (001), (002) peaks grow insignificantly, which is due to the annealing-induced coarsening of the B2—ordered FeRh nanograins. Using Scherrer’s formula the average grain size was estimated to be ~ 10 nm and slightly increased to ~ 40 nm with an increase in temperature from 600 to 800 °C. This means that the final product is a low crystalline quality epitaxial B2—ordered FeRh (001) layer on Mg(001). The asymmetric XRD scans demonstrate the orientation relationship of the B2-FeRh (001)[001] || Fe(001)[001]||MgO(001)[011] (see Supplementary Fig. 1). The order parameter was estimated S = 0.90 ± 0.02 for the synthesized B2-FeRh samples at temperatures in the 600–800 °C range. Figure 1c shows the dependence of the in-plane relative magnetic anisotropy constant K4(Ta)/K40 and the MS(Ta)/MS0 relative magnetization as a function of the annealing temperature Ta {where for 52Rh/48Fe(001) samples K40 = 2.4∙105 erg cm3 and MS0 = 825 emu/cm3, see “Methods”}. With an increase in the annealing temperature Ta the constant K4(Ta) monotonically decreases and becomes zero within experimental accuracy after annealing at 800 °C. This means that the first magnetic anisotropy constant K1 of the B2—ordered FeRh phase is zero or less than the measurement error (0.2 × 104 erg/cm3). A value of K1 ~ 0 is consistent with the FeRh single films exhibiting an in-plane easy axis of magnetization with no measurable magnetocrystalline anisotropy41. Therefore, the K4(Ta)/K40 dependence can be used to find the thickness, magnetization and magnetic moment of the reacted Fe(001) layer after annealing at Ta (Supplementary Note 1). The dependence of the relative magnetization MS/MS0 as a function of annealing temperature Ta (Fig. 1c) has an unusual shape and convincingly shows complex and intricate scenarios of various phase formation and their mutual transformations in the Rh/Fe(001) bilayer during annealing to 800 °C. Within experimental error the relative anisotropy constant K4(Ta)/K40 and the relative magnetization MS(Ta)/MS0 decrease identically as the annealing temperature increases up 300 °C. The synchronous decrease of the K4(Ta)/K40 and MS(Ta)/MS0 values clearly proves the onset of the slow mixing of the Rh and Fe layers and the synthesis of the nonferromagnetic B2-FeRh(001) phase (nfm-B2) on the Rh/Fe(001) interface, whose volume increases with an increase in annealing temperature to 300 °C. Above 300 °C the magnetization increases to MS/MS0 ~ 1, which indicates a phase transformation of the nfm-B2 to the ferromagnetic αlʹ phase. From Fig. 1c follows that the trilayer system Rh/αlʹ/Fe (001) has the magnetization of the initial sample MS0 = 825 emu/cm3 (MS/MS0 ~ 1) in the temperature range (350–500 °C), which means that only the Fe atoms contribute to the saturation magnetization of αlʹ-FeRh. Surprisingly, after annealing at 550 °C, the saturation magnetization decreases to 660 emu/cm3 (~ 20%), but the reaction product layer participates completely in the reversible αlʹ ↔ αʺ transition (Fig. 1d). At annealing temperatures above 500 °C, the films begin to partially peel off from the substrate due to the strong stresses arising during the synthesis of the epitaxial αlʹ-FeRh (001) film at the αlʹ-FeRh(001)/Fe(001) interface. Therefore, a possible explanation is the deformation of some αlʹ-grains with a loss of ferromagnetic order. However, the question about the exact origin of the decrease of MS/MS0 at 550 °C remains open. All of the 52Rh/48Fe (001) samples had the same temperature dependencies of the magnetization MS (Ta) up to 600 °C. However, after annealing above 600 °C the magnetizations of MS sharply increased and assumed values that centered either around MS1 ~ 1,220 emu/cm3 (MS/MS0 ~ 1.47, B-samples) or MS2 ~ 940 emu/cm3 (MS/MS0 ~ 1.15, A-samples) (Fig. 1c).

Low-temperature formation and evolution of B2-FeRh phases in the 52Rh/48Fe(001) bilayer. (a) Schematic of the phase transformations in the 52Rh/48Fe(001) bilayer showing the successive formation of the thin non-magnetic nanocrystalline epitaxial B2-FeRh (nfm-B2) film at ~ 100° C, which evolves into the low-magnetization modification αlʹ of the ferromagnetic αʹ phase above 300 °C. After annealing above 600 °C the αlʹ phase develops either into the αhʹ phase with high magnetization or remains in the αlʹ phase. (b) XRD patterns of B2-FeRh after annealing at different temperatures. (c) Evolution of the magnetization MS/MS0 and anisotropy K4(Ta)/K40 constants as a function of annealing temperature showing the low-temperature formation and mutual transformations of the B2-FeRh phases during the solid-state reaction between the Rh and Fe(001) layers. (d) Temperature dependence of the αlʹ → αʺ transition degree η(Ta) of B2-FeRh in the 52Rh/B2-FeRh/48Fe(001) trilayer confirming that B2-FeRh is a low-magnetization αlʹ phase in the 300–600 °C temperature range.

Temperature dependence of the reversible AFM-FM transition in the 52Rh/48Fe bilayer

In experiments, all 52Rh/48Fe(001) samples, after annealing each in a temperature range of 100–800 °C, were subjected to an investigation of the αʹ ↔ αʺ transition, consisting of measurements of the magnetic moment m(Ta) of the synthesized layer B2-FeRh in the Rh/B2-FeRh/Fe (001) trilayer by the torque method at room temperature, after annealing at temperature Ta and after cooling in liquid nitrogen mN(Ta). To characterize the reversible αʹ ↔ αʺ transition, we introduce the value η = 1 − mN(Ta)/m(Ta) for which η = 0 is absence of transition and η = 1 is perfect transition (see “Methods”). Figure 1d shows the temperature dependence of the degree η(Ta) of the αʹ ↔ αʺ transition which has values (200–300 °C) η = 0, (400–600 °C) η > 0.95 and (700–800 °C) η = 0 for the (B) samples and η = 0.95–0.8 for the (A) samples in the specified temperature ranges. In the temperature interval 200–300 °C, the equality η = 0 is determined by the formation of a non-magnetic nfm-B2 phase. Although the αlʹ (001) layer is located between the Rh and Fe (001) layers and grows epitaxial on the surface of Fe (001) in the (400–600 °C) interval it has a reversible αlʹ ↔ αʺ transition with a low residual magnetization (see Supplementary Fig. . 2). In the (650–800 °C) interval the reaction ends and only the (A) samples reveal a reversible αlʹ ↔ αʺ transition, while this transition does not occur in the (B) samples. We hypothesize that the αʹ phase has two B2-ordered polymorphic modifications having similar lattice parameters, but different magnetic properties. In the first modification the αlʹ phase has a low magnetization about 825 emu/cm3, which is defined only by the Fe atoms with the Rh atoms not contributing to the magnetization, and the αlʹ undergoes a complete reversible αlʹ ↔ αʺ transition (Supplementary Fig. 3a). In contrast, in the second αhʹ modification, which is primarily in the (B) samples, the Fe atoms supposedly polarize the Rh and the Rh atoms make the contribution to the saturation magnetization 1,220 emu/cm3 and in the αhʹ phase the αhʹ ↔ αʺ transition is completely suppressed (Supplementary Fig. 3b). Under such conditions, with an increase in temperature above 650–800 °C, some low-magnetic αlʹ nanograins turn into high-magnetic αhʹ and therefore, the samples have a magnetization between 825 and 1,220 emu/cm3 and exhibit an imperfect reversible transition with a residual magnetization. To summarize, the chemical reaction between Fe and Rh arises on the Fe/Rh interface at a low annealing temperature (~ 100 °C) and with an increase in annealing temperature the phase sequence 52Rh/48Fe → (~ 100 °C) nfm-B2 → (300 °C) αlʹ → (600 °C) αlʹ or αhʹ is formed as shown in Fig. 1a.

The phase and magnetic evolution in the 45Rh/55Fe(001) bilayer during annealing up 800 °C

The schematic diagram in Fig. 2a is based on the results presented in Fig. 2b–d and shows the same nonferromagnetic nfm-B2 phase which was formed in the 45Rh/55Fe and 52Rh/48Fe bilayers during annealing from room temperature to 300 °C. Above 300 °C the nfm-B2 phase consistently turns into ferromagnetic low-magnetization αlʹ, which above 450 °C grows into the high-magnetization αhʹ phases. As shown in Fig. 2b after annealing above 400 °C the (001) and (002) peaks start to grow and become very strong above 500 °C, which indicates the formation of high structural quality epitaxial αhʹ(001) layers on the MgO(001) surface. The K4(Ta)/K40 and MS/MS0 dependencies (where for 45Rh/55Fe(001) samples K40 = 2.5 × 105 erg cm3 and MS0 = 875 emu/cm3, see “Methods”) presented in Fig. 2c show that the nanocrystalline phase αlʹ(001) with low magnetization (MS/MS0 ~ 1.0) grows into the high quality epitaxial phase αhʹ(001) with high magnetization (MS/MS0 ~ 1.47) above 450 °C. The high quality of the chemical ordering of the αhʹ(001) films after annealing at 500 °C and 800 °C supports the order parameter S = 0.96 ± 0.02, which is more than the S = 0.90 ± 0.02 for αlʹ in 52Rh/48Fe films. This result is unexpected, since the αlʹ exists in a narrow composition range of nearly equiatomic concentration and must have a more complete B2 order than the Fe-rich αhʹ phase. The αhʹ(001) and αlʹ(001) films have the same orientation relationship with the substrate MgO(001) (Supplementary Fig. 1). Above 500 °C the Fe has completely reacted with the Rh as evidenced by the K4(Ta)/K40 dependence (Fig. 2c). As can be seen from Fig. 2d the degree of the AFM-FM transition η ~ 0.9, which means the αlʹ phase exists in a narrow temperature range (300–450 °C) and the AFM-FM transition has a relatively low residual magnetization (see Supplementary Fig. 4). Figure 2d shows the absence of the AFM-FM transition (η = 0), which indicates the formation of a αhʹ phase from the αlʹ phase after annealing above 450 °C (see also Supplementary Fig. 5). From these facts it transpires that the Fe-rich αhʹ phase formed from the equiatomic αlʹ compound above 450 °C by the solid-state reaction αlʹ + Fe → (~ 450 °C) αhʹ. Finally, we proved that even a slight Fe doping of αlʹ causes a chemical reaction between Fe and αlʹ and the start of the synthesis of the αhʹ phase. This suggests that the high magnetization αhʹ phase occurring in the 52Rh/48Fe(001) bilayer (B samples) also has more Fe content than αlʹ and explains the compositional heterogeneity arising as a result of the nonequilibrium reaction processes. Thus, we show the phase evolution 45Rh/55Fe → (~ 100 °C) nfm-B2 → (300 °C) αlʹ → (450 °C) αhʹ is induced by the solid-state-reaction method and the final reaction product is a highly B2-ordered phase αhʹ, which has a high magnetization of 1,270 emu/cm3 and in which the reversible αhʹ ↔ αʺ transition is completely suppressed.

Evolution of the B2-FeRh phases in the 45Rh/55Fe(001) bilayer under annealing. (a) Schematic of the phase transformations in the 52Rh/48Fe(001) bilayer, also showing the same nfm-B2 and αʹ phase formation in 45Rh/55Fe(001) up to 450 °C. After annealing above 450 °C the αlʹ develops into the αhʹ phase as a result of the solid-state reaction αlʹ + Fe → (~ 450 °C) αhʹ. (b) Temperature-dependent XRD of the 45Rh/55Fe(001) bilayer from room temperature to 800 °C, indicating the phase transition from nanocrystalline αlʹ to the highly crystalline αhʹ phase above 450 °C. (c) Temperature-dependent magnetization MS/MS0 and anisotropy K4(Ta)/K40 constants confirming the sequential formation of the non-magnetic nfm-B2, low-magnetization αlʹ and high-magnetization αhʹ phases. (d) Temperature dependence of the αlʹ → αʺ transition degree η(Ta) indicating the existence of αlʹ in the 300–450 °C temperature range.

Phase formation sequence, magnetic and structural development in the 68Rh/32Fe(001) bilayer during annealing up 800 °C

Figure 3a shows a schematic of the phase sequence formation in the 68Rh/32Fe(001) bilayer based on data presented in Fig. 3b–d. Figure 3a shows the same phase sequence including the sequential formation of the nanocrystalline nonferromagnetic nfm-B2 and the low-magnetization αlʹ phases during annealing up to 500 °C in the 68Rh/32Fe, 52Rh/48Fe (Fig. 1a) and 55Rh/45Fe (Fig. 2a) bilayers. After annealing above 500 °C the epitaxial paramagnetic γ(001) phase starts to grow at the Rh/αlʹ (001) interface (Fig. 3a). The XRD patterns show that after annealing at 400 °C the Fe layer forms an epitaxial αl′(001) layer in the Rh/αlʹ(001) bilayer system (Fig. 3b, see Supplementary Fig. 6). Annealing above 500 °C the epitaxial γ(001) layer starts to grow on the αl′(001) surface originating from the solid-state reaction Rh + αlʹ → (500 °C) γ. As shown in Fig. 3b the reaction is fully completed after 800 °C and the final reaction product is the γ(001) layer which has a cube-on-cube orientation relationship γ (001)[100]||MgO(001)[100] with the MgO(001) substrate. (Supplementary Fig. 7). The relative magnetization MS(Ta)/MS0, and the K4(Ta)/K40 dependence presented in Fig. 3c confirm the sequential formation of nonferromagnetic nfm-B2 at about 100 °C, ferromagnetic αlʹ above 300 °C and the paramagnetic γ phases above 500 °C. As follows from Fig. 3d, the ferromagnetic αlʹ phase exists and undergoes a reversible AFM-FM transition (η ~ 0.9) in the 300–500 °C temperature range (Supplementary Fig. 6). Finally, we reveal the phase formation sequence 68Rh/32Fe → (~ 100 °C) nfm-B2 → (300 °C) αlʹ → (500 °C)γ during thermal annealing up to 800 °C and the final reaction product contains only an epitaxial γ(001) layer on the MgO(001) surface.

Phase evolution during solid-state reactions in the 68Rh/32Fe(001) bilayer. (a) Schematic of the phase transformations in the 68Rh/32Fe(001) bilayer as well as 45Rh/55Fe(001) and 52Rh/48Fe(001) bilayers, showing the same nfm-B2 and αʹ phase formation up to 550 °C. After annealing above 600 °C the epitaxial γ(001) layer begins to form on the Rh/αlʹ(001) interface following the solid-state reaction Rh + αlʹ → (550 °C) γ. (b) Temperature-dependent XRD indicating that only the epitaxial layer γ(001) is the final reaction product in the 68Rh/32Fe(001) bilayer. (c) Temperature-dependent magnetization MS/MS0 and anisotropy K4(Ta)/K40 constants confirming the sequential non-magnetic nfm-B2 and low-magnetization αlʹ phase formation and the completion of the reaction between the Rh and Fe(001) layers after annealing at 500 °C. (d) Temperature dependence of the αlʹ → αʺ transition degree η(Ta) indicating the existence of αlʹ in the 300–600 °C temperature range.

Kinetic growth of the nanocrystalline nfm-B2 layer during thermal aging at 110 °C

To gain a better understanding of the origin and formation of the very thin nanocrystalline nfm-B2 layer at the Rh/Fe(001) interface at the temperature of the αlʹ → αʺ transition, the synthesis kinetics of the nfm-B2 layer during isothermal aging at 110 °C was investigated. As stated above, deposition of Rh on Fe(001) at room temperature at any ratio of thicknesses between Rh and Fe leads to the formation of a thin interfacial nanocrystalline nfm-B2 layer. However, slight heating to 100 °C during sputtering cannot be excluded, therefore, aging of as-deposited samples was investigated at 110 °C. XRD data from the as-deposited Rh/Fe(001) bilayer and after aging up to 360 h shows a small broadened (001) superlattice and the fundamental (002) peaks of the nfm-B2 phase which did not change from aging time to 360 h (Fig. 4a). This means that long-time aging does not lead to the nfm-B2 grains coarsening and clearly demonstrates the inherent nanocrystalline nature of nfm-B2, which is also inherited by the αlʹ phase. Figure 4b shows the TEM image and EDX line scan results of the Rh/Fe(001) bilayer aged at 110 °C for 360 h. The elemental profile obtained by the EDX line scan across the Rh/nfm-B2/Fe(001) trilayer shows an interfacial nfm-B2 thin film beside the initial Rh and Fe layers. The TEM image displays a compositional contrast that is proportional to the difference in the average atomic number of the respective areas. As a consequence, the reaction product nfm-B2 can be easily distinguished in the interfacial region from the initial Rh and Fe(001) areas. This allows one to estimate the thickness of the interfacial nfm-B2 hnfm-B2 ~ 15 nm (Fig. 4b). Figure 4c shows the thickness dFe of the Fe(001) layer, which entered into a reaction with Rh at 110 °C, as a function of aging time. There is a large experimental error in the thickness dFe measurements and therefore the dependence dFe(t) is impossible to describe by an unambiguous kinetic equation, which suggests a possible growth mechanism. As shown in Fig. 4c the thickness dFe after aging for 360 h at 110 °C is ~ 8 nm, which corresponds to the thickness dnfm-B2 ~ 17 nm of the nfm-B2 layer (Supplementary Fig. 8a). This value agrees well with the estimated dnfm-B2 ~ 15 nm obtained from TEM‐EDX analysis. These findings are in good agreement with a previous report42 which showed and discussed the tendency towards intermixing and interfacial Rh–Fe alloy formation at the Rh/Fe interface at room temperature.

Direct evidence of the low-temperature synthesis of the thin interfacial nanocrystalline nfm-B2 layer in 52Rh/48Fe bilayers. (a) XRD pattern of the 52Rh/48Fe bilayer after aging at 110 ºC between 60 and 360 h. (b) TEM image of the cross-section and the EDS element mapping of the Fe and Rh in the 52Rh/48Fe bilayer after aging at 110 °C for 360 h. (c) The dependence of the reacted layer thickness hFe during aging up to 360 h at 110 °C.

Phase transition from nfm-B2 to αl′ at 300 °C

For a further understanding of the reactivity of Fe and Rh during the transition from nfm-B2 to αlʹ around 300 °C, we investigated the evolution of the temperature dependencies of the magnetization and the thickness of the interfacial hB2-FeRh layer in the 52Rh/B2-FeRh/48Fe(001) trilayer after annealing at 280 °C, 300 °C and 350 °C. Figure 5a shows the M–T curves for the 52Rh/nfm-B2/48Fe(001) trilayer after annealing at 280 °C which do not contain changes in either the forward or the reverse direction. This clearly demonstrates that the B2-FeRh interlayer remains a non-ferromagnetic nanocrystalline nfm-B2 layer after annealing in the 110–280 °C temperature interval. From the cross-sectional TEM image and the EDS line-scan (Fig. 5a), it can be seen that the dnfm-B2 interlayer in the 48Rh/nfm-B2/52Fe(001) trilayer increases to a thickness around dnfm-B2 ~ 30 nm after annealing at 280 °C. (Supplementary Fig. 8b). As shown in Fig. 5a,b slight increase in the annealing temperature to 300 °C leads to the appearance a road FM-AFM transition with a temperature hysteresis of magnetization about 80 K and a small increase in the dB2-FeRh thickness of the B2-FeRh interlayer to ~ 40 nm (Supplementary Fig. 8c). The change in magnetization at the AFM-FM transition gives a rough estimate of the thickness d(αlʹ) ~ 20 nm of the αlʹ layer in the B2-FeRh interlayer. This clearly proves that after annealing at 300 °C the B2-FeRh interlayer contains a mixture of 50% nfm-B2 and 50% αlʹ phases (Supplementary Note 2). Figure 5c shows that the thickness dB2-FeRh grows quickly to 135 nm as the annealing temperature increases to 350 °C (Supplementary Fig. 8d). This value is in good agreement with the estimate obtained from the K4(Ta)/K40 dependence (Fig. 1c, see Supplementary Note 3). EDS analysis gives the average value of the atomic concentration ratio of Fe and Rh at about 1.0, which confirms that the reaction product layer is the B2-FeRh phase. Pores are visible on the Fe/nfm-B2 interface (Fig. 5c, Supplementary Fig. 8d), which are well known as Kirkendall voids. The explanation of the Kirkendall effect is based on the difference in rates of the reacting atoms and it proves that Fe is the dominant diffusing species during B2-FeRh formation. Figure 5c shows the M–T curve having a road FM-AFM transition with large thermal hysteresis width about 100 K, which often occurs in thin film system. This may be due to inhomogeneities of composition, stresses and nanocrystalline growth as a result of non-equilibrium synthesis of the B2-FeRh phases. Thus, this is proof that the reactivity of Fe and Rh is very low at 110 °C and begins to increase greatly during the transition nfm-B2 → αlʹ above 300 °C. This causes strong temperature dependencies up to 500 °C of the relative magnetic anisotropy constant K4 (Ta)/K40 (Figs. 1, 2, 3) and electrical resistance (Supplementary Fig. 9).

The nfm-B2 to αl′ phase transformation. TEM images of the cross-section, the EDS element mapping and the temperature dependent magnetization curves of the 52Rh/48Fe bilayer after aging (a) at 280 °C, (b) 300 °C, (c) 350 °C. The appearance of a loop in the M–T curve in (b) indicates the start of the ferromagnetic αlʹ phase formation at 300 °C.

Discussion

Numerous experiments have proved that as temperature rises, only one phase appears on the interface of bilayer film systems, which is called the first phase43,44,45. The initiation temperatures Tin of the first phase for most bilayers lie below 400 °C. However, many thin-film reactions are initiated near room temperature and even occur at cryogenic temperatures. At such low temperatures diffusion is extremely small and cannot provide atomic transfer in a solid state46,47,48. This suggests an alternative view, in which not diffusion, but chemical interactions play a crucial role in the initiation and kinetics of solid state interfacial reactions. Under the influence of chemical interactions that arise above the initiation temperature Tin, the chemical bonds break in the reactants, and the reacting atoms migrate into the reaction zone to synthesize new compounds. Previously, it was shown that the initiation temperatures Tin are close to or coincide with the solid-state transformation temperatures Tk of several reagent-based binary systems, such as order–disorder transitions, the superionic transition, the spinodal decomposition, martensitic transformations and others46,47,48. This suggests that the same chemical interactions underlie and control both the solid-state thin-film reactions and the corresponding solid-state transformations. The equality Tin = Tk indicates that low-temperature solid-state thin-film reactions in A/B bilayers occur only in A–B binary systems, which have corresponding low-temperature solid-state transformations. Therefore, the study of reactions in A/B bilayers with different layer ratios is a study of the low-temperature part of the A–B phase diagram.

It is well established that ordered B2 alloys, such as NiTi, AuCd, NiAl have reversible low-temperature martensitic transformations, in which the high-temperature austenite B2-phase develops into a low-temperature martensitic phase through a complex process of the formation of intermediate phases. We have shown earlier the initiation temperatures Tin(Ti/Ni) < 150 °C49, Tin(Ni/Al) ~ 180 °C50, Tin(Cd/Au) = 67 °C51 in Ti/Ni, Ni/Al, Cd/Au bilayers, respectively. These temperatures are close to or coincide with the reverse martensitic transformation starting temperatures As(B2-TiNi) ~ 100 °C, As(B2-NiAl) ~ 180 °C, As(B2-CdAu) = 67 °C. The reversible αlʹ ↔ αʺ transition in B2-FeRh possesses all the characteristics of a martensitic transformation (αl′-austenite, αʺ-martensite), because it can pass at high speeds52,53, has isotropic volume changes at the transition1, can be induced by the application of stress19,20,24,25,37,38,39,40 and magnetic field1,9,10, has martensitic instabilities36,54 and the αlʹ and αʺ lattices have a cube-on-cube orientation relationship. According to the phase diagram, the transition αlʹ ↔ αʺ has a minimum temperature Tk ~ 100 °C among other structural transformations in the Fe-Rh system. From the above, we have concluded that the initiation temperature of the reaction Tin(Rh/Fe) in the Rh/Fe bilayer coincides with the martensitic-like transition temperature TK ~ 100 °C in B2-FeRh. The coincidence of the starting temperature of the reaction between Fe and Rh and the temperature of the magnetostructural AFM-FM transition suggests common chemical mechanisms behind both phenomena, but that connection remains to be confirmed by additional experimentation.

As mentioned above, the formation of compounds at the Rh/Fe interface starts in the temperature range 100–300 °C from the synthesis of the non-ferromagnetic nfm-B2 phase. Since this phase has only (001) and (002) B2-FeRh reflections, this means that nfm-B2 is either a martensitic-like antiferromagnetic αʺ-phase or a non-ferromagnetic martensitic variant which is stabilized by strains resulting from the non-equilibrium synthesis of the nfm-B2 phase. B2-FeRh, similar to other B2 phases of NiTi, AuCd, NiAl alloys, experiences premartensitic instabilities with the subsequent formation of the different structural variants of martensite. Our hypothesis is the amorphous phase appears above 100 °C at the Rh/Fe interface, which is then transformed into a nanocrystalline state containing B2 nanograins of martensite variants with lattice parameters close to αʺ martensite. This is consistent with the possible existence of various structural phases of FeRh, predicted by ab initio calculations54,55 and found in the experimental study36. Competition between the αlʹ and αʺ phases during the partial crystallization suppresses grain growth and stabilizes the nano-grained B2 structures in an amorphous matrix. The formation of an amorphous phase is a quite common phenomenon in the initial stage of solid-state reactions in bilayers and multilayers, although the nature of this phenomenon is still a subject of dispute57,58. It is interesting to note the general features of the initial stage of the synthesis of B2 phases in Ti/Ni and Rh/Fe thin films. In Ti/Ni multilayers the amorphous phase starts near the martensitic transition temperature (~ 100 °C), which turns into B2-NiTi59,60 at annealing temperatures above 350 °C. Similar to Ti/Ni, the reaction in the Rh/Fe(001) bilayer starts at ~ 100 °C with the formation of the interfacial amorphous phase, which partially crystallizes. From this point the as-deposited films consist of nanocrystalline B2 grains dispersed in the amorphous matrix. This strongly suggests that both amorphous phases are amorphous martensite, which may be a universal phenomena of the solid-state synthesis of martensitic phases61. This scenario is different from the synthesis of B2-NiAl and B2-AuCd, which begin to form in Al/Ni50 and Cd/Au51 bilayers at martensitic transformation temperatures without the formation of an intermediate amorphous martensite.

Analysis of the general thermodynamic characteristics and features of B2-FeRh and B2-NiTi suggests the possibility of a fabrication of the B2-FeRh compound by self-propagating synthesis (Supplementary Note 3). Our approach assumes ~ 100 °C is the starting temperature of the formation of the B2 phase, which is associated with the reversible AFM-FM transition, and the synthesis temperatures Tin(αhʹ) = ~ 450 °C and Tin(γ) = ~ 500 °C of the αhʹ and γ phases coincide with the phase transition temperatures in the Fe-rich and Rh-rich regions of the Fe–Rh system, respectively. Such an approach is justified by us for the well-studied Fe–Ni system62 and made it possible to predict phase transformations in other binary metallic systems46,47,48. Therefore, further study of solid-state reactions in Rh/Fe films, depending on the composition, will make it possible to specify the low-temperature part of the Fe–Rh phase diagram, which still remains unknown63.

In conclusion, we have uncovered that regardless of the Rh and Fe thicknesses the thin nonmagnetic nanocrystalline B2-FeRh layer starts to form at ~ 100 °C and grows up to 300 °C on the Rh/Fe interface. Above 300 °C the nonmagnetic phase is converted into a low-ferromagnetic B2 αlʹ modification of the αʹ phase with a magnetization ~ 825 emu/cm3 without changing the nanocrystalline structure. Above 500 °C the αlʹ reacted with Fe and formed B2 αhʹ with a magnetization ~ 1,270 emu/cm3 in the 45Rh/55Fe(001) samples and the αlʹ reacted with Ph and formed the non-ferromagnetic γ phase in the 68Rh/32Fe(001)samples. Magnetic analysis has revealed that only the αlʹ undergoes the complete reversible αlʹ ↔ αʺ transition and there’s no transition in the αhʹ samples. Thus, our work not only provides an idea of how phase sequences start and develop depending on the composition of the Fe/Rh bilayers, but also suggests the interesting possibility that a similar chemical mechanism may be at play behind the low-temperature reaction of Fe and Rh and the AFM-FM transition in B2-FeRh.

Methods

52Rh/48Fe(001), 45Rh/55Fe(001) and 68Rh/32Fe(001) bilayers preparation and characterization

At first the epitaxial Fe(001)/MgO(001) films were grown on single-crystal MgO(001) substrates by a thermal evaporation method in a vacuum chamber at a pressure of 10–6 mbar. To obtain high-quality Fe(001) films, the substrates was previously outgassed at 300 °C for 1 h and the Fe layers were deposited at 250 °C. Epitaxial Fe (001) films had the orientation ratio Fe(001),[100]||MgO(001),[110] with the MgO(001) substrate and the magnetocrystalline anisotropy constant K4, which coincided with the value of bulk iron K1 = 4.9 × 105 erg/cm3. The constant K4 in the (001) plane was determined by a torque magnetometer in a magnetic field H = 12 kOe. The torque curve Lǀǀ(φ) in the (001) plane was determined according to the equation 2Lǀǀ(φ) = K4Vsin4φ + 2 Ku VSin(2φ + γ), in which, in addition to the dominant 4φ-term, there is a minor 2φ-term Ku term due to the surface roughness of the MgO(001) substrate and a slight misorientation of the Fe(001) grains. In the equation Ku is uniaxial anisotropy constant, V is the volume of the film, φ is the angle between the easy axis of fourfold anisotropy and the magnetization MS, γ is the angle between the easy axis of fourfold anisotropy and the axis of the uniaxial anisotropy. The K4V value was calculated from the torque curve Lǀǀ(φ) at the maximum of the 4φ-term: 2Lmax = K4V. High quality epitaxial Fe(001)/MgO(001) films also can be obtained by various other methods as reported in the literature.

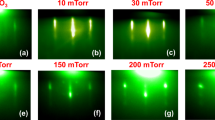

The starting Rh/Fe(001) bilayers were obtained by the evaporation of the Rh layers on Fe(001)/MgO(001) samples using dc sputtering in a magnetron sputtering system. The base pressure of the chamber was less than ~ 1 × 10–6 mbar, and a working pressure of ~ 1 mTorr Ar was used during sputtering. To prevent a reaction between Rh and Fe, the Rh layer was deposited at room temperature. Under such deposition conditions the polycrystalline Rh layer was formed on the Fe(001) surface. Three different types of samples were prepared for the experiments, namely Rh/Fe (001) bilayers with Rh-rich, approximately 1Fe:1Rh and Fe-rich atomic ratios, each with a total thickness about 300 nm. The elemental chemical composition determined by energy dispersion X-ray (EDX) analysis showed sample compositions of Rh68Fe32, Rh52Fe48 and Rh45Fe55, respectively. The saturation magnetization MS0 and the magnetic fourfold anisotropy constants K40 were determined for the total volume of the 52Rh/48Fe, 45Rh/55Fe and 68Rh/32Fe bilayers, which turned out to be MS0 = 825 emu/cm3, K40 = 2.2 × 105 erg/cm3 for the 52Rh/48Fe bilayers, MS0 = 875 emu/cm3, K40 = 2.4 × 105 erg/cm3 for the 45Rh/55Fe bilayers and MS0 = 450 emu/cm3, K40 = 1.25 × 105 erg/cm3 for the 68Rh/32Fe bilayers.

The reversible AFM-FM phase transitions were checked using a superconducting quantum interference device (SQUID) magnetometer. Magnetic fields of H = 1.0 kOe were applied along the in-plane [100] MgO direction, which coincides with the easy axis of the Rh/Fe (001) bilayers, at all measurements in the 77–400 K temperature interval. The saturation magnetization MS and the coercivity HC were measured with a vibration magnetometer in magnetic fields up to 22 kOe. All saturation magnetization measurements were monitored using the torque method64.

The formed phases were identified with a DRON-4-07 diffractometer (CuKa radiation). The epitaxial relationships between MgO(001) and the B2, γ layers that formed in the reaction products were X-ray studied with a PANalytikal X'Pert PRO diffractometer with a PIXctl detector. CuKa radiation monochromatized by a secondary graphite monochromator was used in the instrument. The order parameter for the synthesized samples at temperatures in the 600–800 °C range was estimated using the equation S = (I001/I002)1/2/1.07, where I001 and I002 are experimental integrated intensities of superstructural (001) and fundamental (002) reflections65.

The cross-sectional samples for TEM studies were prepared by a focused ion beam (single-beam FIB, Hitachi FB2100) at 40 kV. In order to protect the surface of interest from milling by the Ga + ion beam during sample preparation, a Ge layer was deposited onto the Fe-Rh film before cross-sectional sample preparation by FIB. TEM studies were carried out using a Hitachi HT7700 TEM (acceleration voltage 100 kV, W source) equipped with a STEM system and a Bruker Nano XFlash 6T/60 energy dispersive X-ray (EDX) spectrometer. The imaging and EDX spectroscopy line scans and mapping were carried out in STEM mode with an electron probe of diameter ~ 30 nm.

Characterization of solid-state phase transformations

The starting 52Rh/48Fe, 45Rh/55Fe and 68Rh/32Fe bilayers were annealed at temperatures ranging from 50 to 800 °C in increments of 50 °C. The samples were held at each temperature at a pressure of 10−6 Torr for 1 h. To characterize the phase transformations the crystal structure, the magnetic moments m0(Ta) (where m0(300 K) = MS0V), the magnetic fourfold anisotropy constants K4(Ta) and the degree of the αʹ → αʺ transition η(Ta) were determined for all bilayers after annealing at each temperature Ta. In order to fully characterize the phase transformations, cross-sectional SEM images and an elemental analysis of the phases of several samples using EDX were carried out.

Measurement of the αl′ → α″ transition degree

In experiments, the degree η(Ta) of the FM-AFM phase transition was determined for all 52Rh/48Fe, 45Rh/55Fe and68Rh/32Fe samples after annealing at each temperature in the range of 100–800 °C . The magnetic moments m0(Ta) were measured by the torque method64, after annealing at temperature Ta and cooling in liquid nitrogen mN(Ta), to find the value of the degree η(Ta). The magnetic moment m(Ta) of the synthesized αlʹ—FeRh layer in the Rh/αlʹ—FeRh/Fe(001) trilayer after annealing at temperature Ta is equal to the difference m(Ta) = m0(Ta)—K4(Ta)m0/K40 of the magnetic moments of the m0(Ta) film and the K4(Ta)m0/K40 unreacted layer of the Fe(001) layer, where K4(Ta)m0/K40 is the magnetic moments of the unreacted Fe(001) layer. After placing the sample in liquid nitrogen, only the ferromagnetic αlʹ—FeRh phase in the Rh/αlʹ—FeRh/Fe(001) trilayer is subjected to the transition into the antiferromagnetic αʺ phase and the magnetic moment m(Ta) is reduced to mN(Ta). The quantity η = 1 − mN(Ta)/m(Ta) is a quantitative characteristic of the degree of the αlʹ → αʺ transition, where η = 0 and η = 1 mean the absence of and the complete FM → AFM transition (residual magnetization is zero), respectively.

References

Lewis, L. H., Marrows, C. H. & Langridge, S. Coupled magnetic, structural, and electronic phase transitions in FeRh. J. Phys. D Appl. Phys. 49, 323002 (2016).

Annaorazov, M. P. et al. Anomalously high entropy change in FeRh alloy. J. Appl. Phys. 79, 1689–1695 (1996).

Cooke, D. W. et al. Thermodynamic measurements of Fe–Rh alloys. Phys. Rev. Lett. 109, 255901 (2012).

Mankovsky, S. et al. Temperature-dependent transport properties of FeRh. Phys. Rev. B 95, 155139 (2017).

Ibarra, M. R. & Algarabel, P. A. Giant volume magnetostriction in the FeRh alloy. Phys. Rev. B 50, 4196–4199 (1994).

Suzuki, I., Naito, T., Itoh, M., Sato, T. & Taniyama, T. Clear correspondence between magnetoresistance and magnetization of epitaxially grown ordered FeRh thin films. J. Appl. Phys. 109, 07C717 (2011).

Chen, X. Z. et al. Tunneling anisotropic magnetoresistance driven by magnetic phase transition. Nat. Commun. 8, 449 (2017).

Nikitin, S. A. et al. The magnetocaloric effect in Fe49Rh51 compound. Phys. Lett. A 148, 363–366 (1990).

Kouvel, J. S. Unusual nature of the abrupt magnetic transition in FeRh and its pseudobinary variants. J. Appl. Phys. 37, 1257–1258 (1996).

Onodera, R. et al. Observation of a metamagnetic transition of FeRh alloy under high magnetic fields and high temperatures. J. Jpn. Inst. Met. Mater. 80, 186–191 (2016).

Chirkova, A. et al. The effect of the microstructure on the antiferromagnetic to ferromagnetic transition in FeRh alloys. Acta Mater. 131, 31–38 (2017).

Takahashi, M. & Oshima, R. Annealing effect on phase transition of equiatomic FeRh alloy. Mater. Trans. JIM 36, 735–742 (1995).

Hashimoto, A. et al. Effect of high temperature annealing on non-thermal equilibrium phases induced by energetic ion irradiation in FeRh and Ni3V intermetallic compounds. Jpn. J. Appl. Phys. 53, 05FC08 (2014).

Takahashi, M. & Oshima, R. Stress induced phase transition of iron–rhodium alloys. J. Phys. IV 05, C8-491-C8-496 (1995).

Zakharov, A. I., Kadomtseva, A. M., Levitin, R. Z. & Ponyatovskii, E. G. Magnetic and magnetoelastic properties of a metamagnetic iron–rhodium alloy. Sov. Phys. JETP 19, 1348–1353 (1964).

Heeger, A. J. Pressure dependence of the FeRh first-order phase transition. J. Appl. Phys. 41, 4751–4752 (1970).

Vinokurova, L. I., Vlasov, A. V. & Pardavi-Horváth, M. Pressure effects on magnetic phase transitions in FeRh and FeRhIr alloys. Phys. Status Solidi B 78, 353–357 (1976).

Barua, R., Jiménez-Villacorta, F. & Lewis, L. H. Predicting magnetostructural trends in FeRh-based ternary systems. Appl. Phys. Lett. 103, 102407 (2013).

Xie, Y. et al. Effect of epitaxial strain and lattice mismatch on magnetic and transport behaviors in metamagnetic FeRh thin films. AIP Adv. 7, 056314 (2017).

Barton, C. W. et al. Substrate induced strain field in FeRh epilayers grown on single crystal MgO (001) substrates. Sci. Rep. 7, 44397 (2017).

Chen, J., Gao, Y., Wu, L., Ma, J. & Nan, C.-W. A magnetic glass state over the first-order ferromagnetic-to-antiferromagnetic transition in FeRh film. Mater. Res. Lett. 5, 329–334 (2017).

Suzuki, I., Hamasaki, Y., Itoh, M. & Taniyama, T. Controllable exchange bias in Fe/metamagnetic FeRh bilayers. Appl. Phys. Lett. 105, 172401 (2014).

Yap, Q. J. et al. Phase ordering and its effect on magnetic and structural properties of FeRh ultrathin films. J. Appl. Phys. 116, 043902 (2014).

Ceballos, A. et al. Effect of strain and thickness on the transition temperature of epitaxial FeRh thin-films. Appl. Phys. Lett. 111, 172401 (2017).

Bennett, S. P. et al. Giant controllable magnetization changes induced by structural phase transitions in a metamagnetic artificial multiferroic. Sci. Rep. 6, 22708 (2016).

Han, G. C. et al. Suppression of low-temperature ferromagnetic phase in ultrathin FeRh films. J. Appl. Phys. 113, 123909 (2013).

Jiang, M. et al. Influence of film composition on the transition temperature of FeRh films. J. Cryst. Growth 438, 19–24 (2016).

Gatel, C. et al. Inhomogeneous spatial distribution of the magnetic transition in an iron–rhodium thin film. Nat. Commun. 8, 15703 (2017).

Ye, J. et al. Magnetic properties of ordered polycrystalline FeRh thin films. RSC Adv. 7, 44097–44103 (2017).

Suzuki, I., Koike, T., Itoh, M., Taniyama, T. & Sato, T. Stability of ferromagnetic state of epitaxially grown ordered FeRh thin films. J. Appl. Phys. 105, 07E501 (2009).

Loving, M. G. et al. Strain-tuning of the magnetocaloric transition temperature in model FeRh films. J. Phys. D Appl. Phys. 51, 024003 (2018).

Yamada, S. et al. Low-temperature B2 ordering and magnetic properties of Fe100−x Rhx films on bcc alloys. Phys. Rev. B 92, 094416 (2015).

Kande, D., Pisana, S., Weller, D., Laughlin, D. E. & Zhu, J.-G. Enhanced B2 ordering of FeRh thin films using B2 NiAl underlayers. IEEE Trans. Magn. 47, 3296–3299 (2011).

Cher, K. M., Zhou, T. J. & Chen, J. S. Compositional effects on the structure and phase transition of epitaxial FeRh thin films. IEEE Trans. Magn. 47, 4033–4036 (2011).

Yamada, S. et al. Exchange coupling in metallic multilayers with a top FeRh layer. AIP Adv. 6, 056115 (2016).

Witte, R. et al. Epitaxial strain-engineered self-assembly of magnetic nanostructures in FeRh thin films. J. Phys. D Appl. Phys. 50, 025007 (2017).

Lee, Y. et al. Large resistivity modulation in mixed-phase metallic systems. Nat. Commun. 6, 5959 (2015).

Chen, J. et al. Strain modulated ferromagnetic to antiferromagnetic transition in FeRh/BaTiO3(001) heterostructures. J. Appl. Phys. 121, 194101 (2017).

Fina, I. et al. Electric-field-adjustable time-dependent magnetoelectric response in martensitic FeRh alloy. ACS Appl. Mater. Interfaces 9, 15577 (2017).

Cherifi, R. O. et al. Electric-field control of magnetic order above room temperature. Nat. Mater. 13, 345–351 (2014).

Thiele, J.-U., Maat, S. & Fullerton, E. E. FeRh/FePt exchange spring films for thermally assisted magnetic recording media. Appl. Phys. Lett. 82, 2859–2861 (2003).

Busch, M., Gruyters, M. & Winter, H. Spin polarization, structure and chemical composition of the Rh/Fe(100) interface. Surf. Sci. 2005(582), 31–41 (2005).

Poate, J. M. et al. (eds) Thin Films-Interdiffusion and Reaction (Willey-Intersciense, New York, 1978).

Colgan, J. E. G. A review of thin-film alumitide formation. Mater. Sci. Rep. 5, 1–44 (1990).

Pretorius, R., Theron, C. C., Vantomme, A. & Mayer, J. W. Compound phase formation in thin film structures. Crit. Rev. Solid State Mater. Sci. 24, 1–62 (1999).

Myagkov, V. G. et al. Solid state synthesis of Mn5Ge3 in Ge/Ag/Mn trilayers: Structural and magnetic studies. J. Solid State Chem. 246, 379–387 (2017).

Myagkov, V. et al. Long-range chemical interactions in solid-state reactions: Effect of an inert Ag interlayer on the formation of L10-FePd in epitaxial Pd(001)/Ag(001)/Fe(001) and Fe(001)/Ag(001)/Pd(001) trilayers. Philos. Mag. 94, 2595–2622 (2014).

Myagkov, V. G., Zhigalov, V. C., Bykova, L. E. & Bondarenko, G. N. Long-range chemical interaction in solid-state synthesis: Chemical interaction between Ni and Fe in epitaxial Ni(001)/Ag(001)/Fe(001) trilayers. Int. J. SHS 18, 117–124 (2009).

Myagkov, V. G., Bykova, L. E., Li, L. A., Turpanov, I. A. & Bondarenko, G. N. Solid-phase reactions, self-propagating high-temperature synthesis, and martensitic transformations in thin films. Dokl. Phys. 47, 95–98 (2002).

Myagkov, V. G., Bykova, L. E., Zharkov, S. M. & Bondarenko, G. N. Formation of NiAl shape memory alloy thin films by solid-state reaction. Solid State Phenom. 138, 377–384 (2008).

Myagkov, V. G., Bykova, L. E. & Bondarenko, G. N. Solid-state synthesis and martensitic transformations in thin films. Dokl. Phys. 48, 30–33 (2003).

Radu, I. et al. Laser-induced generation and quenching of magnetization on FeRh studied with time-resolved X-ray magnetic circular dichroism. Phys. Rev. B 81, 104415 (2010).

Ünal, A. A. et al. Laser-driven formation of transient local ferromagnetism in FeRh thin films. Ultramicroscopy 183, 104–108 (2017).

Zarkevich, N. A. & Johnson, D. D. FeRh ground state and martensitic transformation. Phys. Rev. B 97, 014202 (2018).

Kim, J., Ramesh, R. & Kioussis, N. Revealing the hidden structural phases of FeRh. Phys. Rev. B 94, 180407(R) (2016).

Aschauer, U., Braddell, R., Brechbuhl, S. A., Derlet, P. M. & Spaldin, N. A. Strain-induced structural instability in FeRh. Phys. Rev. B 94, 014109 (2016).

Chen, L. J. Solid state amorphization in metal/Si systems. Mater. Sci. Eng. R Rep. 29, 115–152 (2000).

Zhu, Y., Liao, G., Shi, T., Tang, Z. & Li, M. Highly choreographed atomic motion and mechanism of interface amorphization. Acta Mater. 125, 69–80 (2017).

Bhatt, P., Chaudhari, S. M. & Fahlman, M. Influence of Ti layer thickness on solid state amorphization and magnetic properties of annealed Ti/Ni multilayer. J. Phys. Condens. Matter 19, 376210 (2007).

Cho, H., Kim, H. Y. & Miyazaki, S. Alloying process of sputter-deposited Ti/Ni multilayer thin films. Mater. Sci. Eng. A 438–440, 699–702 (2006).

Zhang, L. et al. Amorphous martensite in β-Ti alloys. Nat. Commun. 9, 506. https://doi.org/10.1038/s41467-018-02961-2 (2018).

Myagkov, V. G., Zhigalov, V. C., Bykova, L. E. & Bondarenko, G. N. Solid-state synthesis and phase transformations in Ni/Fe films: Structural and magnetic studies. J. Magn. Magn. Mater. 305, 534–545 (2006).

Ohnuma, I., Gendo, T., Kainuma, R., Inden, G. & Ishida, K. Phase equilibria and thermodynamic evaluation approximating short-range ordering energy in the Fe–Rh binary system. ISIJ Int. 49, 1212–1219 (2009).

Chikazumi, S. Epitaxial growth and magnetic properties of single-crystal films of iron, nickel, and permalloy. J. Appl. Phys. 32, S81–S82 (1962).

de Vries, M. A. et al. Hall-effect characterization of the metamagnetic transition in FeRh. New J. Phys. 15, 013008 (2013).

Acknowledgements

The authors thank L.A. Solovyov for their help on the orientation relationships measurements and I.V. Nemtsev for assisting with the measurements of the samples’ composition. This work was supported by RFBR together with the Government of the Krasnoyarsk Territory, the Krasnoyarsk Regional Fund of Science (project № 19-43-240003). The work is partially based upon the experiments performed on Krasnoyarsk Regional Center of Research Equipment of Federal Research Center «Krasnoyarsk Science Center SB RAS».

Author information

Authors and Affiliations

Contributions

A.A.I. and V.S.Z. prepared the samples and characterized them. V.S.Z. carried out annealing experiments. D.A.V. characterized the samples by SQUID magnetometry. M.N.V. performed TEM experiments. L.E.B. and A.A.M planed and performed resistance measurements. G.N.B. carried out the X-ray diffraction experiments. V.G. initiated the study and wrote the manuscript with inputs from L.E.B. and A.A.M. All authors contributed to the manuscript and the interpretation of the date.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Myagkov, V.G., Ivanenko, A.A., Bykova, L.E. et al. Solid-state synthesis, magnetic and structural properties of interfacial B2-FeRh(001) layers in Rh/Fe(001) films. Sci Rep 10, 10807 (2020). https://doi.org/10.1038/s41598-020-67837-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-67837-2

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.