Abstract

In the North China Plain (NCP), the utilization efficiency of cultivated land can be improved by transplanted cotton after winter wheat harvest (TCWWH). To understand the growth, water consumption and economic benefit of TCWWH under different irrigation methods, an irrigation experiment was carried out during 2013–2015 to explore the effects of border irrigation (BI), surface drip irrigation (SDI) and micro-sprinkling hose irrigation (MHI) on the plant development, water use efficiency (WUE) and economic benefit of TCWWH. The results showed that the survival rate of cotton seedlings in the SDI treatment was 12% and 7% larger than that in the BI and the MHI treatments, respectively. SDI increased plant height by 19% and 8% and increased leaf area index (LAI) by 24% and 17%, compared with BI and MHI, respectively. The highest seed cotton yield and better fibre quality were obtained in the SDI treatment, compared to the BI and the MHI treatments. Compared with BI and MHI, SDI reduced the soil evaporation and evapotranspiration (ET) in the field, and resulted in the largest WUE. The net profit generated by the SDI treatment exceeded that of the BI and the MHI treatments by 183% and 23%, respectively. Therefore, SDI can promote the growth of TCWWH and can increase the WUE and the economic benefit of TCWWH, compared with BI and MHI.

Similar content being viewed by others

Introduction

The Yellow River Basin in the North China Plain (NCP) is not only a primary cotton-growing region but also an important crop-growing region in general1,2. With economic development and rapid urbanization, cotton is competing with grain crops for cultivated land. A shortage of good-quality cultivated land and fresh water limits the rapid development of the agricultural economy in China, especially in the NCP2. Research shows that the transplanting technique combined with water-saving irrigation methods can improve the utilization efficiency of cultivated land and guarantee the harvest of both grain and cotton crops2,3. Compared with the traditional method of intercropping winter wheat and cotton, transplanting cotton after winter wheat harvest can improve the level of agricultural mechanization and increase winter wheat yield4,5,6. However, the transplanted cotton after winter wheat harvest (TCWWH) is short-season cotton, whose growth period in the NCP is mainly concentrated during the hot summer months (from June to September). While the average daily evapotranspiration (ET) in the TCWWH field is higher compared with the traditional direct-seeded cotton, the TCWWH yield is lower and the quality is worse2,7. The low yield and poor quality led to reduce economic benefit2,8. Thus, an optimal irrigation method must be selected to reduce the ET and improve the yield, quality and economic benefit of TCWWH.

Many researchers have reported that the growth, water consumption and economic benefit of cotton are significantly affected by irrigation methods9,10,11,12. In a study by Cetin and Bilgel9, sprinkler irrigation decreased water use efficiency (WUE) of cotton by 39%, while drip irrigation increased WUE by 26% compared to furrow irrigation (FI). Ibragimov et al.11 indicated that drip irrigation reduced the irrigation quota by 18–42% and increased the WUE of cotton by 35–103% compared to FI in Uzbekistan. Liu et al.13 found the average seasonal ET of transplanted cotton ranged from 358 to 449 mm, and the surface drip irrigation (SDI) reduced the irrigation quota by 33.4% compared with border irrigation (BI) in the NCP. Similar conclusions were summarized by Hodgson et al.14 and Aujla et al.10. Wang et al.12 indicated that the economic benefit of full irrigation reached its maximum value compared with that of medium and low irrigation in the northern Xinjiang of Northwest China. Wang et al.15 found that the single drip line design reduced the total input value by approximately 10% compared with the double drip line design, but the latter method produced more net income. Wang et al.16 compared mulched drip irrigation and flood irrigation to evaluate sustainable irrigation regimes for cotton in north western China. In addition, Lu et al.17 indicated that short-season cotton increased net profit by 69.2% compared with full-season cotton, as the material and labour input by the former was 27.3% less than that of the latter.

This study explored the effects of BI, SDI and micro-sprinkling hose irrigation (MHI) on the WUE and economic benefit of TCWWH. BI, a traditional irrigation method, is the most widely adopted method in the NCP18. SDI can be used for uniform and frequent water application in many soil and topographic conditions9,19. MHI is advantageous, and because of low investment cost, good anti-clogging performance and simple installation, it has been gradually adopted in the NCP in recent years20. Therefore, these three irrigation treatments (BI, SDI and MHI) were the focus of this study.

In this study, the main objective was to explore the optimal irrigation method for TCWWH from the perspective of WUE and economic benefit; at the same time, the effects of BI, SDI and MHI on WUE and economic benefit were investigated based on survival rate, plant growth, cotton yield, fibre quality, soil evaporation and soil water dynamics. The conclusions of this research are useful for popularizing the cropping pattern of TCWWH.

Materials and Methods

Experimental site

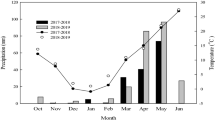

This experiment was conducted from 2013 to 2015 at the Experimental Station of the Farmland Irrigation Research Institute, Chinese Academy of Agricultural Sciences (35°18′N, 113°54′E, altitude 73.2 m). The experimental site is located in a warm temperate climate region and has 220 frost-free days, a mean annual sunshine duration of 2286 h, a mean annual rainfall of 546 mm, and a mean annual temperature of 14.2 °C. The mean annual potential evaporation in the experimental site is 2000 mm, which was calculated using the Penman formulations21; the average groundwater table is below 5 m. The precipitation and ET0 are shown in Fig. 1, while the site’s physical and chemical soil properties are shown in Table 1.

Crop details

The Bt Cotton (Zhongmiansuo 50) was sown in separate cotton plug-seedlings on May 11, 2013; May 6, 2014 and May 6, 2015. The cotton seedlings were greenhouse-raised in substrate and, after approximately one month, were mechanically transplanted to the fields with a row spacing of 70 cm and interplant spacing of 20 cm. The planting density was approximately 71,400 plants ha−1. According to the locally recommended fertilizer practice, 450 kg ha−1 of compound fertilizer was applied to the soil as a basal fertilizer. After the squaring stage, 150 kg ha−1 of urea was applied. The harvest dates were October 20, 2013; October 13, 2014 and October 15, 2015.

Table 2 shows the growth schedule and the days per growth period of TCWWH. Since the TCWWH was short-season cotton, its growth time in the field was less than 130 d.

Experimental design

Conducted through a completely randomized design, the experiment comprised of BI, SDI and MHI treatments; there were three repeated plots per treatment. Considering the marginal effect of different irrigation methods, the 9 plots were separated from adjacent plots by 4-m-wide isolation strips, and the size of each plot was 50.0 m long and 6 m wide. Table 3 shows the technical parameters for BI, SDI and MHI. After cotton seedlings were transplanted, we installed SDI and MHI systems in the field. The micro-sprinkling hoses were placed between two cotton rows, maintaining a spacing of 1.4 m in the MHI treatment. The drip pipe was laid on the cotton row, with each emitter placed beside cotton seedling.

Once the soil water content (SWC) in the root zone of TCWWH was depleted to 70% of field capacity (FC), we applied irrigation for all treatments11,22,23. The irrigation quotas (90 mm for BI, 20 mm for SDI and 60 mm for MHI), which are shown in Fig. 1, were determined both by the practical experience of local farmers and were referenced from other studies9,24,25. We used a water meter to measure the amount of irrigation; the cotton seedlings were irrigated to guarantee their survival after transplantation.

Measurement methods and calculations

Four cotton rows (10 m long) in each treatment plot were selected as the sample area to determine the survival rate (%) of the cotton seedlings. The survival rate was evaluated on the 21st day after transplantation and was calculated as follows:

We randomly selected and labelled five cotton plants in each treatment plot to measure the plant height (cm) of TCWWH7. A ruler (accuracy of 0.1 cm) was used to measure the plant height at 7–10 d intervals from July to September13. A leaf area meter was used for the measurement of leaf area26, after which the leaf area index (LAI) was calculated by the FAO method27.

Daily soil evaporation (mm) was measured by micro-lysimeters in 2014 and 2015. The micro-lysimeter was made from galvanized iron and consisted of an inner and outer cylinder of 10 cm and 12 cm, respectively, and 15 cm in length. The outer cylinder was fixed into the soil, its top edge level with the soil surface to avoid disturbing the soil structure. The inner cylinder was pushed into soil until the top was level with the soil surface; its base was sealed with a plastic foil when it was removed. An electronic balance with a 0.1 g precision was used to weigh the inner cylinder daily at 8:00 AM. The soil evaporation is the difference between two adjacent measurements. The soil of inner cylinder was replaced every 2 d as well as after irrigation and rainfall to ensure accuracy of measurement. The micro-lysimeters were installed on the row and the middle of the inter-rows (35 cm from the row); six measurements were carried out for each treatment.

Time domain reflectometry with intelligent microelements (TRIME) was used to measure the SWC (cm3 cm−3) in the root zone of TCWWH at intervals of 20 cm from the soil surface to the maximum root depth every 3–5 d. The gravimetric measurement was employed to calibrate the measurement result28. There were six TRIME tubes in each treatment.

The boll number per labelled plant was recorded before the first harvest. Four cotton rows (10 m long) in each treatment plot were selected as the sample area to determine the seed cotton yield (kg ha−1) at every harvest, and the seed cotton yield was divided by the number of bolls to determine the boll mass (g). The lint percentage (%) was determined by ginning the seed cotton from each harvest13.

The fibre strength (g tex−1), fibre length (mm), micronaire, fibre elongation (%) and fibre uniformity (%) were determined by the high volume instrument system7.

ET (mm) was estimated as follows:

where P is the precipitation (mm), I is the amount of irrigation (mm), U is the upward capillary flow into the root zone (mm), ΔS is the change in the amount of soil moisture storage (mm), DW is the downward drainage out of the root zone (mm), and R is the runoff (mm). Due to the strict control irrigation during the growing seasons, R was never observed in the field. The U and DW were calculated using Darcy’s law as follows:

where q is the unsaturated and vertical one-dimensional soil moisture flux (mm d−1), K (ψm) is the unsaturated hydraulic conductivity (mm d−1), \(\frac{{\rm{d}}\psi }{{\rm{d}}x}\) is the total water potential gradient, ψ is the soil total water potential (cm), and x is the vertical distance (cm). K (ψm) was measured by using the Ku-pF apparatus, while the soil matric potential was measured daily at 9:00 AM by using a tensiometer at soil depths of 90 cm and 110 cm25,27,29. The soil water characteristic curve was measured by using a high speed centrifuge, and RETC software was used to process the test data30.

The calculation for WUE (kg m−3) was as follows13,29:

where Y is the seed cotton yield (kg ha−1).

Statistical analysis

To analyse the data obtained from the different irrigation treatments, the univariate GLM in SPSS Statistics 21.0 was used to make one-way analysis of variance (ANOVA) comparisons. The means were compared using least significant differences (LSD) at the 5% probability level.

Results

Survival rate and plant growth

Table 4 shows the survival rate of cotton seedlings in different irrigation treatments. SDI significantly increased the survival rate of cotton seedlings compared with BI and MHI. On average, SDI increased the survival rate by 12% and 7% compared with BI and MHI, respectively.

The variations in plant height and LAI under different irrigation methods are presented Fig. 2. The changes in plant height and LAI in the seedling stage were small, while the changes in the budding stage were significant. At the beginning of the boll forming stage, the plant height of TCWWH reached its maximum of approximately 80 cm. The LAI of TCWWH reached its maximum (approximately 2.5) in the middle of the boll forming stage, and then gradually decreased. The plant height and LAI in the SDI treatment were the highest during the entire growth period, and lowest in the BI treatment. On average, SDI increased the plant height by 19% and 8% and increased LAI by 24% and 17% compared with BI and MHI, respectively.

Cotton yield and fibre quality

Table 5 shows the seed cotton yield, lint yield, lint percentage, boll mass and number of bolls per plant. Compared with SDI and MHI, BI tended to decrease the boll mass and number of bolls per plant and to produce the lowest seed and lint cotton yields. BI significantly decreased the boll mass in 2013 and 2015, but the difference was not significant in 2014. Compared with BI, SDI increased the number of bolls per plant by 27% in 2014 and 18% in 2015 but decreased the number by 4% in 2013. The seed cotton yield of the SDI treatment was also the highest and ranged from 2683 (in 2014) to 3766 kg ha−1 (in 2015). On average, SDI increased the seed cotton yield by 32% and 9% compared with BI and MHI, respectively. The lint yield of the SDI treatment was also 32% and 10% higher than that of the BI and MHI treatments, respectively. For the lint percentage, the differences were not significant in the three experimental years.

Table 6 shows the quality parameters of cotton lint. SDI and MHI significantly increased the fibre length compared with BI. Over the three years, the average fibre length obtained in the SDI and the MHI treatments was 3.8% and 4.6% longer than that of the BI treatment, respectively. The fibre uniformity of the SDI and the MHI treatments was also higher than that of the BT treatment, but the differences were not significant. SDI and MHI significantly increased the fibre strength in 2013 and 2015 compared with BI but produced no significant differences in 2014. The effects of irrigation methods on micronaire and fibre elongation were too inconsistent to be definitively assessed. For all treatments, the average fibre strength, fibre length, fibre uniformity and fibre elongation of cotton lint in 2014 were generally lower than those in 2013 and 2015.

Soil evaporation and water dynamics

Figure 3 shows the diurnal variation in soil evaporation in the different horizontal locations under the three irrigation methods in 2014 and 2015. The line interruption in Fig. 3 was due to the occurrence of rainfall or irrigation, which resulted in the failure of the data. Generally, the soil evaporation in the SDI treatment was the lowest and that in the BI treatment was the highest. Compared with BI and MHI, SDI decreased the soil evaporation on average by 28% and 23% in the cotton row (position A in Fig. 3) and by 51% and 50% in the middle of the inter-rows (position B in Fig. 3), respectively. In the SDI treatment, the soil evaporation at position A was 19% greater than at position B, while in the BI and the MHI treatments, the soil evaporation at position A was 20% and was 22% less than that at position B.

Diurnal variation in soil evaporation in the field of transplanted cotton after winter wheat harvest (TCWWH) in different irrigation methods. A and B represent different horizontal locations: A corresponds to the location on the row, and B corresponds to the location on the middle of the inter-rows.

As similar tendencies for the SWC were observed in the three experimental years, only the 2013 data was selected to show the soil water dynamics under different irrigation methods. In the cotton plant row (Fig. 4A), the average SWC at depths of 0–40 cm in the SDI treatment was the highest and was 7% and 16% higher than that in the BI and the MHI treatments, respectively, in the same soil layer. The average SWC at depths of 40–100 cm in the SDI treatment was the lowest and was 10% and 4% lower than that in the BI and the MHI treatments, respectively, in the same soil layer. As shown in Fig. 4B, in the middle of the inter-rows, the average SWC in the SDI treatment was 16% and 10% lower than that in the BI and the MHI treatments, respectively.

Dynamic change of soil water content (SWC, % cm3 cm−3) in the transplanted cotton field after winter wheat harvest (TCWWH) in different irrigation methods in 2013. A and B represent different horizontal locations: A corresponds to the location on the row, and B corresponds to the location on the middle of the inter-rows. Abbreviations: DAT, days after transplanting.

ET and WUE

The soil water balances of the 100 cm soil layer, ET and WUE in the field of TCWWH are summarized in Table 7. Under the same SWC limit (70% of FC) for different irrigation methods, the total irrigation quota in the BI treatment was 2.51 and 1.50 times larger than that in the SDI and BI treatments, respectively. Meanwhile, the DW in the BI treatment was also the largest. SDI produced the lowest ET of 377.8 mm (in 2015) and significantly decreased the ET compared to BI and MHI. Over the three years, the average ET in the SDI treatment decreased by 19% and 10% compared to BI and MHI, respectively. The highest WUE of 1.00 kg·m−3 was produced in the SDI treatment (in 2015). On average, SDI increased the WUE by 62% and 21% compared to BI and MHI, respectively.

Economic benefit

Table 8 shows the output, input value and net profit of TCWWH for different irrigation methods. On average, the output value generated by the SDI treatment was the highest, being 32% and 9% higher than that of the BI and the MHI treatments, respectively. However, SDI also increased the total input value, especially for the material cost, which became 36% and 8% higher than that of the BI and the MHI treatments, respectively. The net profit produced by the SDI treatment exceeded that of the BI and the MHI treatments by 183% and 23%, respectively. Compared to all three years, the net profit in 2014 was the lowest for all treatments.

Discussion

Survival rate and plant growth

The survival rate of cotton seedlings affects the yield and economic benefit of TCWWH31. SDI significantly increased the survival rate compared to BI and MHI. This was because the roots of cotton seedlings were damaged while the cotton seedlings were transplanted in the field3,4, thus affecting their stability. The cotton seedlings were easily washed uprooted by the high velocity flow in BI and MHI, which led to their death. On the other hand, the water flow in the SDI treatment caused minimal damage to the cotton seedlings.

Suitable LAI and plant height are beneficial to ensuring an adequate canopy distribution and improving the utilization of solar energy, as well as the yield and quality of TCWWH1,6,32. The relationship between vegetative growth and yield of TCWWH is different from that of traditionally direct-seeded cotton. As the total growth time of TCWWH was approximately 45 d less than direct-seeded cotton, the plant height and the LAI of TCWWH were all smaller than those of direct-seeded cotton2,4,5. At the same time, many fine roots of cotton seedlings were damaged during field transplantation3,4, which led to the slow vegetative growth of TCWWH during the recovery stage. Poor vegetative growth resulted in the insufficient production of photosynthate, which reduced the yield and quality of cotton. SDI significantly increased the plant height and the leaf area of TCWWH compared with BI and MHI (Fig. 2), which was beneficial to the improvement of yield and quality of TCWWH. In the SDI treatment, soil water, heat, gases and the nutrients were best maintained and utilized for cotton growth, compared to the BI and the MHI treatments7,33; this is the main reason why SDI promoted the plant height and the LAI of TCWWH in this study. Irrigation methods could affect the micro-environment in the field, and the difference in atmospheric relative humidity within the canopy may also affect its growth25.

Cotton yield and fibre quality

The yield and fibre quality of cotton are significantly influenced by irrigation34. In this study, the seed cotton yield of the SDI treatment was 23% larger than that of the BI treatment (Table 5). This was similar to the result reported by Rao et al.35, who reported the seed cotton yield of drip irrigation treatment was 33.5% larger than that in the BI treatment. However, in the study of Hodgson et al.14, SDI decreased seed cotton yield by 3% compared with FI. This was mainly due to the different limits of SWC between SDI and FI; the deficit below the fully-irrigated SWC in the FI treatment was maintained at 90 mm, whereas that in the SDI treatment was maintained at only 45 mm. The seed cotton yields reported by Hu et al.22 and Hu et al.22 were higher than those in this study (Table 5), potentially due to differences in growth time and cotton varieties. This study used the short-season cotton variety whose total growth time was less than 160 d. Lu et al.17 indicated that short-season cotton decreased the seed cotton yield by 14.5% compared to full-season cotton. Cotton yield was also affected by agricultural practices and climate in the different regions. For all treatments, the seed yield of TCWWH as well as the fibre strength, fibre length, fibre uniformity and fibre elongation of cotton lint in 2014 were all lower than those in 2013 and 2015 (Tables 5 and 6). This may be due to the continuous rainfall during the mature and harvest stage in 2014 (Fig. 1).

Soil evaporation and water dynamics

As only the cotton row was irrigated and the irrigation amount was sufficiently low (20 mm) in the SDI treatment, the SWC on the inter-rows or in deep soil depths was lower than that in the BI and the MHI treatments. This distribution characteristics of SWC in the SDI treatment reduced soil evaporation and prevented deep infiltration, reducing the loss of water and nutrients36. The soil moisture distribution in the SDI treatment was the most favourable for cotton root growth compared with BI and MHI22,37; the developed root then promoted the growth of the cotton canopy. This is also the reason why SDI promoted the yield and fibre quality of TCWWH.

ET and WUE

As freshwater shortage limits the sustainable development of agriculture in the NCP38,39, it is very important to study the water-saving irrigation methods for TCWWH. SDI significantly decreased the ET compared with BI and MHI (Table 7). Rao et al.35 reported a similar result of water in the drip irrigation treatment to be 30% less than that in the BI treatment. SDI increased the WUE compared with both BI and MHI (Table 7), which was similar to the results observed by Cetin and Bilgel9 and Ibragimov et al.11. The WUE in the SDI treatment in this study varied from 0.71 to 1.00 kg m−3; this was higher than the results reported by Cetin and Bilgel9 and Yazar et al.40. Although a greater seed cotton yield was obtained, more water was consumed and lower WUEs were obtained in their studies.

Economic benefit

In the Yellow River Basin of the NCP, farmers have gradually abandoned the traditional method of intercropping winter wheat and cotton and are adopting the model of TCWWH2. In this region, the industrialized production of cotton seedlings has begun to emerge, and farmers widely use machinery to complete agricultural activities such as winter wheat harvesting, land ploughing and cotton seedlings transplantation. TCWWH is more conducive to mechanization and can reduce labour expenditure, compared with cotton intercropped with winter wheat2,4,5,6. Lu et al.8 indicated that transplanted cotton increased net profit by 10.9% and 31.8% in the low and high fertility field, respectively, compared with mono cropped cotton. The net profit of TCWWH produced by the SDI treatment was the highest compared to that of the BI and the MHI treatments, even though the total input value for the SDI treatment was also the highest (Table 8). The increased profit produced by the SDI treatment was mainly attributed to the high seed cotton yield (Table 5). In 2014, the seed cotton yield was very low due to the influence of continuous rainfall during the boll maturing stage of TCWWH (Fig. 1), and the net profit this year was also the lowest. SDI and MHI consumed more material input but less labour and machinery input than BI due to the very high depreciation cost of irrigation equipment in the SDI and the MHI treatments, while BI needed additional labour and machinery input for irrigation management and land leveling12,15,17.

Conclusions

This study showed that SDI can increase the WUE and economic benefit of TCWWH compared with BI and MHI. The survival rate of cotton seedlings in the SDI treatment was larger than that in the BI and the MHI treatments. Compared with BI and MHI, SDI improved the plant height, LAI and yield of TCWWH and decreased the soil evaporation and ET in the field; it also improved the fibre quality compared to the other treatments. Therefore, SDI is the optimal irrigation method for the TCWWH in the NCP.

References

Dong, H. Z. et al. Yield, quality and leaf senescence of cotton grown at varying planting dates and plant densities in the Yellow River Valley of China. Field Crops Res. 98, 106–115 (2006).

CRI (Cotton Research Institute Chinese Academy of Agricultural Sciences). Cultivation of Cotton in China. (Shanghai Science and Technology Press, 2013).

Dong, H. Z., Li, W. J., Tang, W., Li, Z. H. & Zhang, D. M. Enhanced plant growth, development and fiber yield of Bt transgenic cotton by an integration of plastic mulching and seedling transplanting. Ind. Crops Prod. 26, 298–306 (2007).

Dong, H. Z., Li, W. J., Tang, W., Li, Z. H. & Zhang, D. M. Increased yield and revenue with a seedling transplanting system for hybrid seed production in Bt cotton. J. Agron. Crop Sci. 191, 116–124 (2005).

Zhang, L., van der Werf, W., Zhang, S., Li, B. & Spiertz, J. H. J. Growth, yield and quality of wheat and cotton in relay strip intercropping systems. Field Crops Res. 103, 178–188 (2007).

Zhang, L. et al. Light interception and utilization in relay intercrops of wheat and cotton. Field Crops Res. 107, 29–42 (2008).

Liu, H. et al. Responses of yield, water use efficiency and quality of short-season cotton to irrigation management: interactive effects of irrigation methods and deficit irrigation. Irrig. Sci. 35, 125–139 (2017).

Lu, F. et al. Effects of planting pattern on growth and yield and economic benefits of cotton in a wheat-cotton double cropping system versus monoculture cotton. Field Crops Res. 213, 100–108 (2017).

Cetin, O. & Bilgel, L. Effects of different irrigation methods on shedding and yield of cotton. Agric. Water Manag. 54, 1–15 (2002).

Aujla, M. S., Thind, H. S. & Buttar, G. S. Cotton yield and water use efficiency at various levels of water and N through drip irrigation under two methods of planting. Agric. Water Manag. 71, 167–179 (2005).

Ibragimov, N. et al. Water use efficiency of irrigated cotton in Uzbekistan under drip and furrow irrigation. Agric. Water Manag. 90, 112–120 (2007).

Wang, H. et al. Coupling effects of water and fertilizer on yield, water and fertilizer use efficiency of drip-fertigated cotton in northern Xinjiang, China. Field Crops Res. 219, 169–179 (2018).

Liu, H. et al. Responses of yield, water use efficiency and quality of short-season cotton to irrigation management: interactive effects of irrigation methods and deficit irrigation. Irrig. Sci. https://doi.org/10.1007/s00271-016-0526-4 (2016).

Hodgson, A. S., Constable, G. A., Duddy, G. R. & Daniells, I. G. A comparison of drip and furrow irrigated cotton on a cracking clay soil. 2. Water use efficiency, waterlogging, root distribution and soil structure. Irrig. Sci. 11, 143–148 (1990).

Wang, R., Wan, S., Kang, Y. & Dou, C. Assessment of secondary soil salinity prevention and economic benefit under different drip line placement and irrigation regime in northwest China. Agric. Water Manag. 131, 41–49 (2014).

Wang, Z. M., Jin, M. G., Simunek, J. & van Genuchten, M. T. Evaluation of mulched drip irrigation for cotton in arid Northwest China. Irrig. Sci. 32, 15–27 (2014).

Lu, H. Q. et al. Yield and economic benefits of late planted short-season cotton versus full-season cotton relayed with garlic. Field Crops Res. 200, 80–87 (2017).

Kang, Y. H. et al. Effects of different water levels on cotton growth and water use through drip irrigation in an arid region with saline ground water of Northwest China. Agric. Water Manag. 109, 117–126 (2012).

Min, W. et al. Root distribution and growth of cotton as affected by drip irrigation with saline water. Field Crops Res. 169, 1–10 (2014).

Man, J. G. et al. Effects of supplemental irrigation with micro-sprinkling hoses on water distribution in soil and grain yield of winter wheat. Field Crops Res. 161, 26–37 (2014).

Donohue, R. J., McVicar, T. R. & Roderick, M. L. Assessing the ability of potential evaporation formulations to capture the dynamics in evaporative demand within a changing climate. J. Hydrol. 386, 186–197 (2010).

Hu, X. T., Chen, H., Wang, J., Meng, X. B. & Chen, F. H. Effects of Soil Water Content on Cotton Root Growth and Distribution Under Mulched Drip Irrigation. Agric. Sci. China 8, 709–716 (2009).

Guan, H. J., Li, J. S. & Li, Y. F. Effects of drip system uniformity and irrigation amount on cotton yield and quality under arid conditions. Agric. Water Manag. 124, 37–51 (2013).

Lv, G. H., Kang, Y. H., Li, L. & Wan, S. Q. Effect of irrigation methods on root development and profile soil water uptake in winter wheat. Irrig. Sci. 28, 387–398 (2010).

Lv, G. H. et al. Effects of different irrigation methods on micro-environments and root distribution in winter wheat fields. J. Integr. Agric. 14, 1658–1672 (2015).

Li, X. Y., Shi, H. B., Šimůnek, J., Gong, X. W. & Peng, Z. Y. Modeling soil water dynamics in a drip-irrigated intercropping field under plastic mulch. Irrig. Sci. 33, 289–302 (2015).

Allen, R. G., Pereira, L. S., Raes, D. & Smith, M. Crop evapotranspiration guidelines for computing crop water requirements. FAO Irrigation and Drainage Paper 56 (1998).

Weitz, A. M., Grauel, W. T., Keller, M. & Veldkamp, E. Calibration of time domain reflectometry technique using undisturbed soil samples from humid tropical soils of volcanic origin. Water Resour. Res. 33, 1241–1249 (1997).

Li, C. X., Zhou, X. G., Sun, J. S., Wang, H. Z. & Gao, Y. Dynamics of root water uptake and water use efficiency under alternate partial root-zone irrigation. Desalination Water Treat. 52, 2805–2810 (2014).

van Genuchten, M. T. A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil Sci. Soc. Am. J. 44, 892–898 (1980).

Boquet, D. J. & Clawson, E. L. Cotton Planting Date: Yield, Seedling Survival, and Plant Growth. Agron. J. 101, 1123 (2009).

Bauer, P. J., Frederick, J. R., Bradow, J. M., Sadler, E. J. & Evans, D. E. Canopy photosynthesis and fiber properties of normal- and late-planted cotton. Agron. J. 92, 518–523 (2000).

Kang, Y. H., Wang, F. X., Liu, H. J. & Yuan, B. Z. Potato evapotranspiration and yield under different drip irrigation regimes. Irrig. Sci. 23, 133–143 (2004).

Feng, L., Mathis, G., Ritchie, G. & Han, Y. Optimizing Irrigation and Plant Density for Improved Cotton Yield and Fiber Quality. Agron. J. 106, 1111–1118 (2014).

Rao, S. S., Tanwar, S. P. S. & Regar, P. L. Effect of deficit irrigation, phosphorous inoculation and cycocel spray on root growth, seed cotton yield and water productivity of drip irrigated cotton in arid environment. Agric. Water Manag. 169, 14–25 (2016).

Ning, S. R., Shi, J. C., Zuo, Q., Wang, S. & Ben-Gal, A. Generalization of the root length density distribution of cotton under film mulched drip irrigation. Field Crops Res. 177, 125–136 (2015).

Zhang, H. et al. Root Development of Transplanted Cotton and Simulation of Soil Water Movement under Different Irrigation Methods. Water 9, 503 (2017).

Dai, J. L. & Dong, H. Z. Intensive cotton farming technologies in China: Achievements, challenges and countermeasures. Field Crops Res. 155, 99–110 (2014).

Luo, H. H., Tao, X. P., Hu, Y. Y., Zhang, Y. L. & Zhang, W. F. Response of cotton root growth and yield to root restriction under various water and nitrogen regimes. J. Plant Nutr. Soil Sci. 178, 384–392 (2015).

Yazar, A., Sezen, S. M. & Sesveren, S. LEPA and trickle irrigation of cotton in the Southeast Anatolia Project (GAP) area in Turkey. Agric. Water Manag. 54, 189–203 (2002).

Acknowledgements

This work is supported jointly by the Key Laboratory of Crop Water Use and Regulation, Ministry of Agriculture, P.R. China (FIRI2019-03-0102) and the National Modern Agricultural Cotton Industry Technology System of China (CARS-15-13).

Author information

Authors and Affiliations

Contributions

H.Z., H.L. and X.G. performed the experiments. X.G. carried out the data analysis. H.Z. wrote the manuscript. S.W., L.G. and J.S. reviewed the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, H., Liu, H., Wang, S. et al. Variations in growth, water consumption and economic benefit of transplanted cotton after winter wheat harvest subjected to different irrigation methods. Sci Rep 9, 14972 (2019). https://doi.org/10.1038/s41598-019-51391-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-51391-7

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.