Abstract

The diversity of fungi allows for their colonisation in different environments, including wood destined for power generation, with an ability to degrade or hinder its use. Torrefaction or pre-carbonisation, a low oxygenation heat treatment with temperatures between 200 and 300 °C, accumulates carbon and lignin, decreases hygroscopicity, increases energy efficiency and reduces the wood attractiveness to xylophagous microorganisms. This work aimed to study the resistance of Eucalyptus urophylla wood chips, submitted to torrefaction temperatures of 180, 220 and 260 °C for 20 minutes, to xylophagous fungi, according to the ASTM D-2017 method (2005). The white rot fungi Phanerochaete chrysosporium, Pleurotus ostreatus and Trametes versicolor and the brown rot fungus Gloeophyllum trabeum were used. After 12 weeks of exposure, the mass losses of wood samples in natura and torrified at 180 °C attacked by Pleurotus ostreatus and Trametes versicolor was higher. Torrefaction increased the resistance to fungi; the treatment at 260 °C was the most efficient with lower mass losses caused by fungi attacks and, consequently, greater resistance to the fungi tested.

Similar content being viewed by others

Introduction

Wood is subject to deterioration by xylophagous microorganisms, including fungi, which secrete enzymes that degrade polymers, transforming them into smaller molecules1,2,3. The great diversity of fungi allows them to colonise diverse environments, such as air, soil and trees. The rotting, mould or stain fungi can totally decompose wood or only mage its surface4,5.

Mould and stain fungi are usually the first to colonise the trunk of freshly cut trees and are mainly responsible for patches and changes in the wood surface. Rot fungi, such as basidiomycetes, cause white and brown rot6 and can degrade the cell wall, altering the physical and mechanical properties of the wood7,8. White rot fungi decompose cellulose, hemicellulose and lignin, leaving the wood clear9,10, whereas brown rot fungi degrade cellulose and the cell wall hemicelluloses, altering the mechanical resistance of the material without affecting the lignin, which gives the wood a dark brown appearance11.

Fungi initially colonise the wood core with their hyphae, forming a network that is not always visible to the naked eye, filling the cell lumen and passing through the cell wall from one cell to another8,12. These fungi can destroy the structure of the middle lamella and change the chemical composition, reducing the wood mass and mechanical resistance13. Wood used for power generation is chipped, usually in the field or at the factory. These chips are deposited on patios and stored for approximately 90 days to reduce the wood moisture, when fungus colonisation can modify the wood and reducing its energy potential.

Torrefaction, a heat treatment at controlled temperatures and low oxygenation, can minimise the impacts of rot fungus by increasing the carbon and lignin in the wood14,15,16. This treatment increases the energy density and reduces the hygroscopicity and attractiveness of the material to decomposing microorganisms17,18,19.

The objective of this study was to evaluate the resistance of torrefied Eucalyptus urophylla chips to biological deterioration by xylophage fungi.

Results and Discussion

The equilibrium moisture content (UEH) of the treatments ranged from 5.08 to 12.49% (Table 1), with decreasing values as the torrefaction temperature increased, with lower values from 220 °C. The equilibrium moisture content was 55.96 and 59.33% lower with torrefaction at 220 and 260 °C, respectively, than in the control (in natura). The reduction of wood hygroscopicity is due to the faster degradation of cellulose and hemicellulose at lower temperatures, compared to lignin20, which reduces the water adsorption capacity21,22 and the equilibrium moisture content6,23. This reduction is desirable for energy purposes, since a lower energy quantity will be used to evaporate the water contained in the chips24,25.

Holocellulose was the main wood chemical component that was degraded at high temperatures, with a reduction from 69.21 to 45.64%, compared to the control and a temperature of 260 °C, respectively (Table 1). This compound represents the sum of the cellulose and hemicellulose content, with the latter being degraded at lower temperatures, between 220 and 315 °C, compared to the other primary constituents (cellulose and lignin)26,27. The reduction in holocellulose content is mainly due to hemicellulose degradation, justifying the differences between treatments above 220 °C17. The total lignin content in the treatments submitted to torrefaction increased by 87,38% compared to the in natura and that at 260 °C ones (Table 1). Lignin degradation begins at 160 °C, but traces of this structure can be found at 900 °C17. Lignin is the thermally stable chemical compound of the cell wall and it is desired for energy purposes. Therefore, it increases the calorific value of the material and the gravimetric yield in torrefaction and carbonisation4,26.

The total extractive content increased with the torrefaction temperature, being greater at 220 °C (Table 1). Hemicellulose degradation generates compounds that remain in the biomass as molecules with fragile fibre connections, which are removed by alcohol/toluene; this increases its extractive content in treatments up to 220 °C28,29. The polar extractives degrade in the 130 to 250 °C range, and together with hemicelluloses that volatilise at high temperatures, this explains the decrease in extractive content in the treatment at 260 °C. An increase in the extractive content in treatments up to 220 °C was also reported for grasses30 and coniferous woods29.

The ash content increased with the torrefaction temperature, being 20.7% higher in the torrified material at 260 °C than in the in natura treatment (Table 1). This may be caused by the organic biomass, such as the degradation and loss of the hemicelluloses, but the ash content varies between plant species and clones31,32. Materials for heat generation must have a low ash content to reduce the potential energy losses and the corrosion of the equipment used for the biomass combustion26,33.

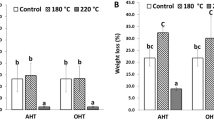

Torrefaction increased the resistance of the material to fungi deterioration and reduced the mass loss as the temperature increased (Table 2). The wood degradation (mass losses) is related to the degradation and chemical alteration of carbohydrates, preventing fungi from feeding on wood34. These results corroborate with the lower mass losses of softwoods and hardwoods by fungi, after thermoretification at high temperatures with longer exposure periods34,35. Torrefaction increased the wood chip resistance to degradation by the xylophagous fungi Trametes sp. and P. ostreatus, with lower mass losses at 260 °C (Table 2). The 1.62% mass loss of non-torrefied wood submitted to T. versicolor was similar to that of Eucalyptus tereticornis with this fungus, which was 2.06% after 12 weeks of exposure36.

Torrefaction reduced the holocellulose contents and increased the extractives and lignin, justifying the higher resistance of the wood chips treated at 260 °C to T. versicolor and P. ostreatus fungi, which preferentially degrades cellulose and hemicellulose6. Exposure to high temperatures chemically modifies the wood due to hemicellulose degradation, which is a source of fungi food, generating extractives with fungicide action37. This alters the material hygroscopicity38,39,40 and leaves it with an acidic pH, hindering the fungi development6,18. The wood chip mass with G. trabeum and P. chrysosporium was similar between treatments, including that of the torrified ones (Table 2). Substances such as extractives make wood more resistant to deterioration by xylophages and the torrefaction of the material generates/accumulates extractives that minimise fungi damage. Extractives have chelating agents, capable of forming complexes with metals, that protect the wood and, if more concentrated, they can be natural preservatives (fungicides and insecticides)37,41. The mass of the torrefied wood chips at 260 °C increased with most fungi (Table 2), may be due to fungi colonisation without the degradation of the chips, with an increase in the mass of their hyphae, which were strongly fixed in the material and not, completely, removed during the chip cleaning process (Fig. 1).

The increase in the wood chip resistance to degradation by white rot fungi (Table 2) is due to the higher lignin contents of this material, caused by torrefaction. Moreover, these fungi decompose holocelulose and lignin, as reported for the wood of Fagus sylvatica4 and Hevea brasiliensis42. Degradation of in natura wood chips was higher with P. ostreatus white rot fungus and lower with Gloeophyllum trabeum, which is due to the lower lignin contents in hardwoods, favouring the development of white rot fungi (P. ostreatus) compared to brown rot fungi (G. trabeum). The mass losses of torrified Eucalyptus urophylla samples varied from 0.37 to 1.01% with the fungus Gloeophyllum trabeum, similar to those reported (from 1.29 to 1.65%) for Corymbia torelliana and Eucalyptus grandis x Eucalyptus urophylla for this brown rot fungus43.

Wood chip degradation at 220 °C by the G. trabeum and Trametes sp. fungi differed from the treatments with lower torrefaction temperatures due to variations in the nutritional requirements of each xylophagous fungus6. Brown rot fungi release enzymes that diffuse from the cell lumen, where their hyphae degrade carbohydrates in the secondary cell wall layer S2, S1 and S3, in sequence. On the other hand, white rot fungi gradually attack the cell wall constituents from the lumen outward, first attacking the S3 layer, then progressively attacking the other layers. This explains the correlation between the quantity and characteristics of the carbohydrates and the cell wall resistance to deterioration6,37.

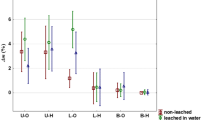

The decay susceptibility indices in the treatments with and without torrefaction were lower than 100, indicating that the studied wood was more resistant than the reference one (Table 3). A low decay susceptibility index indicates greater resistance to degradation because the chemical composition of the substrate is not attractive to fungi due to torrefaction. The changes in the chemical composition of Eucalyptus nitens, Eucalyptus globulus and Alnus incana make wood less susceptible to the Trametes versicolor attack44,45.

Torrefaction reduced the decay susceptibility index of wood samples to P. ostreatus and Trametes sp. due to the decrease in holocellulose content, mainly at the higher temperatures, 220 and 260 °C. On the other hand, high sugar and starch levels stored in the cells increase wood susceptibility to rot fungus6. Wood chip torrefaction increases the energy potential of the product and the resistance to deterioration by xylophagous fungi, as found for Myracrodruon urundeuva or Schinopsis brasiliensis, with higher mass losses of 0.99 and 1.35%, respectively46 and Astronium sp., with a mass loss of 1.97% by the fungus Gloeophyllum trabeum47.

Torrefaction reduced the wood equilibrium moisture content and changed its chemical composition. An increase in temperature decreased the holocellulose content and increased the contents of ash and lignin; the extractive content increased in the treatments up to 220 °C and decreased at 260 °C. Torrefied Eucalyptus urophylla wood chips are resistant to Gloeophyllum trabeum, Phanerochaete chrysosporium, Pleurotus ostreatus and Trametes versicolor fungi according to ASTM D-201748. However, the degradation of the in natura Eucalyptus urophylla chips was higher with Pleurotus ostreatus and lower with Gloeophyllum trabeum. Torrefaction increased the wood chip resistance to the xylophagous fungi, with the treatment at 260 °C being the most efficient for all evaluated fungi.

Methods

Eucalyptus urophylla wood chips in natura and torrified were submitted to xylophage fungi in an accelerated rotting test, according to the American Society for Testing and Materials - ASTM D-201748.

Torrefaction process

The wood chips of seven-year-old E. urophylla were used. These chips were sieved; those that passed through the 31.5 mm sieve, but were retained in the 16 mm sieve, were used in the experiment. The selected chips were oven dried at 103 ± 2 °C to reach 0% moisture and torrified for 20 minutes at 80, 220 and 260 °C.

Torrefaction was performed in an endless screw reactor, developed in the Panels and Wood Energy Laboratory (LAPEM/UFV)15. The metal prototype of this equipment was a semicontinuous screw reactor, which reuses the volatile gases in the heating system (Fig. 2).

Lateral layout of a prototype screw reactor developed by a Brazilian university for thermal treatment of lignocellulosic biomass, where: I- transport system; II- heating system; III- cooling system; 1- motor; 2- input biomass; 3- worm-screw; 4- insulating layer; 5- refractory layer; 6- flow of heating gas; 7- heating gas output; 8- first “chimney”; 9- second “chimney”; 10- connection “chimney” with the burner; 11- connecting burner; 12- water supply; 13- water outlet; 14- exit of torrefied biomass.

Chemical characterization and equilibrium moisture content

The wood equilibrium moisture content of the wood samples was calculated on a dry basis; the wood samples were placed in a climatic chamber at 20 °C and 65% relative humidity until constant mass. Samples were milled with a Standard Wiley knife mill with a 2 mm screen. The material that was sieved with a 40–60 mesh sieve and the retained fraction were used to determine its structural chemical composition, according to the standards of the Technical Association of the Pulp and Paper Industry49, such as the wood preparation for the chemical test (T264)50; extractive content (T204)50; lignin content (T222)50; and cellulose and hemicellulose content (T223)50. The ash content was determined according to NBR 8112/8351.

Biological assay evaluation

The experiment followed the ASTM standard D-201748,52 procedures. The samples were submitted to the white rot fungi Phanerochaete chrysosporium, Pleurotus ostreatus and Trametes versicolor and to the brown fungus Gloeophyllum trabeum. The wood was dried at 103 °C and all equipment, glassware and soil were autoclaved to prevent contamination. Each 600 mL vase was filled with 300 g sterilized clayey soil at a pH of 6.8 and moistened with 83 mL distilled water with a water retention capacity of 35.68%. The samples were submitted to fungi colonisation for 12 weeks, after which they were removed and the final oven dried weight was obtained.

The accelerated test aims to predict potential for fungal biodeterioration in a shorter period. The time is reduced, only 12 weeks, however, the test provides all conditions for optimal growth of the fungus (temperature, humidity, pH and etc). The sample mass losses in the 12-week test is expected to be similar to that of wood attacked by the fungus in the field, even if the colonization demands a greater period. The resistance class and the decay susceptibility index of the material were evaluated according to the initial and final mass of the specimens, as ASTM D-201748 described, in equation 1:

where: ML = sample mass losses; Mf = final sample mass and Mi = initial sample mass; and equation 2

where: DSI = decay susceptibility index; MLi = mass loss of the sample tested; MLr = mass loss of the reference species (Pinus sp.). Pine wood is used as a reference because it has low resistance to fungi attack, being used as comparative parameter.

The wood resistance to fungal attack was classified according to the average mass losses, as follows: 0–10% (Highly resistant); 11–24% (Resistant); 25–44% (Moderately resistant) and 45 or above (Slightly resistant or non-resistant), as suggested by ASTM standard D-201748,52.

Statistical analysis

The results of the equilibrium moisture content, chemical composition and biological assay in relation to the torrefaction temperature of the E. urophylla chips were analysed in a completely randomised design, with four treatments (in natura and three torrefaction temperatures) and four fungi with six replications. The means were grouped with a Tukey test (p ≤ 0.05). The statistical analyses were performed with STATISTICA 8.0 software53.

References

Kirker, G. et al. Synchrotron-based X-ray fluorescence microscopy enables multiscale spatial visualization of ions involved in fungal lignocellulose deconstruction. Scientific Reports 7, E 41798, https://doi.org/10.1038/srep41798 (2017).

Yuan, J. et al. Fungal community structure of fallen pine and oak wood at different stages of decomposition in the Qinling Mountains, China. Scientific Reports 7, 13866, https://doi.org/10.1038/s41598-017-14425-6 (2017).

Gao, J., Kim, J. S., Terziev, N., Cuccui, I. & Daniel, G. Effect of thermal modification on the durability and decay patterns of hardwoods and softwoods exposed to soft rot fungi. International Biodeterioration & Biodegradation 127, 35–45, https://doi.org/10.1016/j.ibiod.2017.11.009 (2018).

Candelier, K. et al. Comparison of chemical composition and decay durability of heat treated wood cured under different inert atmospheres: Nitrogen or vacuum. Polymer Degradation and Stability 98, 677–681, https://doi.org/10.1016/j.polymdegradstab.2012.10.022 (2013).

Stirling, R., Sturrock, R. N. & Braybrooks, A. Fungal decay of western redcedar wood products - a review. International Biodeterioration & Biodegradation 125, 105–115, https://doi.org/10.1016/j.ibiod.2017.09.001 (2017).

Hiscox, J., O’Leary, J. & Boddy, L. Fungus wars: basidiomycete battles in wood decay. Studies in Mycology 89, 117–124, https://doi.org/10.1016/j.simyco.2018.02.003 (2018).

Reinprecht, L. & Kmet’ová, L. Fungal resistance and physical-mechanical properties of beech plywood having durable veneers or fungicides in surfaces. European Journal of Wood and Wood Products 72, 433–443, https://doi.org/10.1007/s00107-014-0788-6 (2014).

Barré, J. B., Bourrier, F., Brancheriau, L., Bertrand, D. & Rey, F. Effects of fungal decay on elasticity and damping of small-diameter silver fir logs assessed by the transverse vibration resonant method. Wood Science and Technology 52, 403–420, https://doi.org/10.1007/s00226-017-0961-2 (2017).

Nagy, L. G. et al. Genetic bases of fungal white rot wood decay predicted by phylogenomic analysis of correlated gene-phenotype evolution. Molecular Biology and Evolution 34, 35–44, https://doi.org/10.1093/molbev/msw238 (2016).

Ruokolainen, A., Shorohova, E., Penttilä, R., Kotkova, V. & Kushnevskaya, H. A continuum of dead wood with various habitat elements maintains the diversity of wood-inhabiting fungi in an old-growth boreal forest. European Journal of Forest Research 137, 707–718, https://doi.org/10.1007/s10342-018-1135-y (2018).

Oramahi, H. A., Yoshimura, T., Diba, F. & Nushaida, D. S. Antifungal and antitermitic activities of wood vinegar from oil palm trunk. Journal of Wood Science 64, 311–317, https://doi.org/10.1007/s10086-018-1703-2 (2018).

Ringman, R., Pilgard, A., Brischke, C. & Richter, K. Mode of action of brown rot decay resistance in modified wood: a review. Holzforschung 68, 239–246, https://doi.org/10.1515/hf-2013-0057 (2014).

Ishizuka, S., Sakai, Y. & Tanaka-Oda, A. Quantifying lignin and holocellulose content in coniferous decayed wood using near-infrared reflectance spectroscopy. Journal of Forest Research 19, 233–237, https://doi.org/10.1007/s10310-012-0386-6 (2014).

Wang, L. et al. Effect of torrefaction on physiochemical characteristics and grindability of stem wood, stump and bark. Applied Energy 227, 137–148, https://doi.org/10.1016/j.apenergy.2017.07.024 (2017).

Silva, C. M. S. et al. Biomass torrefaction for energy purposes - Definitions and an overview of challenges and opportunities in Brazil. Renewable & Sustainable Energy Reviews 82, 2426–2432, https://doi.org/10.1016/j.rser.2017.08.095 (2018).

He, C. et al. Wet torrefaction of biomass for high quality solid fuel production: A review. Renewable & Sustainable Energy Reviews 91, 259–271, https://doi.org/10.1016/j.rser.2018.03.097 (2018).

Van Der Stelt, M. J. C., Gerhauser, H., Kiel, J. H. A. & Ptasinski, K. J. Biomass upgrading by torrefaction for the production of biofuels: A review. Biomass and Bioenergy 35, 3748–3762, https://doi.org/10.1016/j.biombioe.2011.06.023 (2011).

Wang, Y., Zhang, Z., Fan, H. & Wang, J. Wood carbonization as a protective treatment on resistance to wood destroying fungi. International Biodeterioration & Biodegradation 129, 42–49, https://doi.org/10.1016/j.ibiod.2018.01.003 (2018).

Shang, L. et al. Kinetic model for torrefaction of wood chips in a pilot-scale continuous reactor. Journal of Analytical and Applied Pyrolysis 108, 109–116, https://doi.org/10.1016/j.jaap.2014.05.010 (2014).

Waters, C. L., Janupala, R. R., Mallinson, R. G. & Lobban, L. L. Staged thermal fractionation for segregation of lignin and cellulose pyrolysis products: An experimental study of residence time and temperature effects. Journal of Analytical and Applied Pyrolysis 126, 380–389, https://doi.org/10.1016/j.jaap.2017.05.008 (2017).

Skaar, C. J. Water in wood. Syracuse: Syracuse University, 218p (1972).

Engelund, E. T., Thygesen, L. G., Svensson, S. & Hill, C. A. S. A critical discussion of the physics of wood–water interactions. Wood Science and Technology 47, 141–161, https://doi.org/10.1007/s00226-012-0514-7 (2013).

Huang, X., Kocaefe, D., Kocaefe, Y. & Pichette, A. Combined effect of acetylation and heat treatment on the physical, mechanical and biological behavior of jack pine (Pinus banksiana) wood. European Journal of Wood Products 76, 525–540, https://doi.org/10.1007/s00107-017-1232-5 (2018).

Swithenbank, J., Chen, Q., Zhang, X., Sharifi, V. & Pourkashanian, M. Wood would burn. Biomass and Bioenergy 35, 999–1007, https://doi.org/10.1016/j.biombioe.2010.12.026 (2011).

Whittaker, C. & Shield, I. Factors affecting wood, energy grass and straw pellet durability - A review. Renewable and Sustainable Energy Reviews 71, 1–11, https://doi.org/10.1016/j.rser.2016.12.119 (2017).

Pereira, B. L. C., Carneiro, A. C. O., Carvalho, A. M. M. L., Colodette, J. L. & Oliveira, A. C. Influence of chemical composition of eucalyptus wood on gravimetric yield and charcoal properties. BioResources 8, 4574–92, https://doi.org/10.15376/biores.8.3.4574-4592 (2013).

Yang, H., Yan, R., Chen, H., Lee, D. H. & Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86, 1781–1788, https://doi.org/10.1016/j.fuel.2006.12.013 (2007).

Brito, J. O., Silva, F. G., Leão, M. M. & Almeida, G. Chemical composition changes in Eucalyptus and Pinus woods submitted to heat treatment. Bioresource Technology 99, 8545–8548, https://doi.org/10.1016/j.biortech.2008.03.069 (2008).

Colin, B., Dirion, J. L., Arlabosse, P. & Salvador, S. Quantification of the torrefaction effects on the grindability and the hygroscopicity of wood chips. Fuel 97, 232–239, https://doi.org/10.1016/j.fuel.2017.02.028 (2017).

Wei, Y. et al. The role of phenolic extractives in color changes of locust wood (Robinia pseudoacacia) during heat treatment. BioResources 12, 7041–7055, https://doi.org/10.15376/biores.12.4.7041-7055 (2017).

Couto, A. M., Teodoro, P. E. & Trugilho, P. F. Path analysis of the energy density of wood in eucalyptus clones. Genetics and Molecular Research 16, 1, https://doi.org/10.4238/gmr16019536 (2017).

Souza, F. M. L., Sansigolo, C. A., Pupo, C. H. & Sereghetti, G. C. Wood and pulping properties of Eucalyptus urophylla and its hybrid grown by silvopastoral and conventional forest production models. Cellulose Chemistry and Technology 51, 347–353 (2017).

Zachar, M., Lieskovsky, M., Majlingova, A. & Mitterova, I. Comparison of thermal properties of the fast-growing tree species and energy crop species to be used as a renewable and energy-efficient resource. Journal of Thermal Analysis and Calorimetry 134, 543–548, https://doi.org/10.1007/s10973-018-7194-y (2018).

Esteves, B. M. & Pereira, H. M. Wood modification by heat treatment: A Review. Bioresources 4, 370–404 (2009).

Chaouch, M., Pétrissans, M., Pétrissans, A. & Gérardin, P. Use of wood elemental composition to predict heat treatment intensity and decay resistance of different softwood and hardwood species. Polymer Degradation and Stability 95, 2255–2259, https://doi.org/10.1016/j.polymdegradstab. 2010 09 (2010).

Lazarotto, M. et al. Resistência biológica e colorimetria da madeira termorretificada de duas espécies de eucalipto. Revista Árvore 40, 135–145, https://doi.org/10.1590/0100-67622016000100015 (2016).

Brocco, V. F., Paes, J. B., Costa, L. G., Brazolin, S. & Arantes, M. D. C. Potential of teak heartwood extracts as a natural wood preservative. Journal of Cleaner Production 142, 2093–2099, https://doi.org/10.1016/j.jclepro.2016.11.074 (2017).

Li, T., Cheng, D., Avramidis, S., Wålinder, M. E. P. & Zhou, D. Response of hygroscopicity to heat treatment and its relation to durability of thermally modified wood. Construction and Building Materials 44, 671–676, https://doi.org/10.1016/j.conbuildmat.2017.03.218 (2017).

Thybring, E. E. Water relations in untreated and modified wood under brown-rot and white-rot decay. International Biodeterioration & Biodegradation 118, 134–142, https://doi.org/10.1016/j.ibiod.2017.01.034 (2017).

Bari, E. et al. Assessing the destructive behaviors of two white-rot fungi on beech wood. International Biodeterioration & Biodegradation 114, 129–140, https://doi.org/10.1016/j.ibiod.2016.06.010 (2016).

Cerqueira, A. E. S. et al. Amazon basin pasture soils reveal susceptibility to phytopathogens and lower fungal community dissimilarity than forest. Applied Soil Ecology 131, 1–11, https://doi.org/10.1016/j.apsoil.2018.07.004 (2018).

Severo, E. T. D., Calonego, F. W., Sansígolo, C. A. & Bond, B. Changes in the chemical composition and decay resistance of thermally-modified Hevea brasiliensis wood. PLoS One 11, e0151353, https://doi.org/10.1371/journal.pone.0151353 (2016).

Lopes, D. J. V., Paes, J. P. & Bobadilha, G. S. Resistance of Eucalyptus and Corymbia treated woods against three fungal species. BioResources 13, 4964–4972, https://doi.org/10.15376/biores.13.3.4964-4972 (2018).

Tupciauskas, R., Irbe, I., Janberga, A. & Buksans, E. Moisture and decay resistance and reaction to fire properties of self-binding fibreboard made from steam-exploded grey alder wood. Wood Material Science & Engineering 12, 63–71, https://doi.org/10.1080/17480272.2015.1022876 (2017).

González, N., Elissetche, J., Pereira, M. & Fernández, K. Extraction of polyphenols from Eucalyptus nitens and Eucalyptus globulus: Experimental kinetics, modeling and evaluation of their antioxidant and antifungical activities. Industrial Crops and Products 109, 737–745, https://doi.org/10.1016/j.indcrop.2017.09.038 (2017).

Paes, J. B., Melo, R. F. & Lima, C. R. Natural resistance of seven woods to xylophogous fungi and termites under laboratory condition. Cerne 13, 160–169 (2007).

Alves, M. V. S., Costa, A. F., Espig, D. S. & Vale, A. T. Natural decay resistance of six Amazon wood species in soil block tests. Ciência Florestal 16, 17–26, https://doi.org/10.5902/198050981884 (2006).

American Society for Testing and Materials - ASTM. D2017: Standard method for accelerated laboratory test of natural decay resistance for woods. West Conshohocken: ASTM International (2005).

Technical Association of Pulp and Paper Industry. Technical Divisions and Committees. TAPPI test methods, Atlanta: Tappi Press (1998).

Technical Association of Pulp and Paper Industry. TAPPI test methods T 204 om-88: solvent extractives of wood and pulp. Atlanta: Tappi Technology Park, v.1. (1996).

Associação Brasileira de Normas Técnicas - ABNT. NBR 8112. Carvão vegetal - análise imediata. Rio de Janeiro (19083).

American Society for Testing and Materials - ASTM. Standard methods of evaluating properties of wood-base fiber and particles materials. Philladelphia (1982).

Statsoft Inc. Statistica data analysis system version 8.0. Tulsa: Statsoft Inc (2007).

Acknowledgements

The authors would like to thank the Brazilian agencies “Conselho Nacional de Desenvolvimento Cientifico e Tecnológico (CNPq), Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES), Fundação de Amparo à Pesquisa do Estado de Minas Gerais (FAPEMIG)” and “Programa Cooperativo sobre Proteção Florestal (PROTEF) do Instituto de Pesquisas e Estudos Florestais (IPEF)” for the scholarships and financial support. The English of this manuscript has been revised by Proof-Reading-Service.com.

Author information

Authors and Affiliations

Contributions

V.C. and M.P.C.F. conducted the experiment and statistical analyses; A.J.V.Z. and P.G.S. analyzed the results; A.J.V.Z., J.C.Z., A.C.O.C., P.G.S., B.R.V. and V.C. wrote the manuscript and reviewed the final manuscript. All authors approved the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Castro, V.R.d., de Castro Freitas, M.P., Zanuncio, A.J.V. et al. Resistance of in natura and torrefied wood chips to xylophage fungi. Sci Rep 9, 11068 (2019). https://doi.org/10.1038/s41598-019-47398-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-47398-9

This article is cited by

-

Torrefaction of kraft pulp mills sludges

Scientific Reports (2023)

-

Energetic characterization and radiographic analysis of torrefied coated MDF residues

Scientific Reports (2021)

-

Characterization of wood from Schizolobium parahyba var. amazonicum Huber × Ducke trees from a multi-stratified agroforestry system established in the Amazon rainforest

Agroforestry Systems (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.