Abstract

In this work, we report the self-assembled growth of vertically aligned columnar Cu2O + Cu4O3 nanocomposite thin films on glass and silicon substrates by reactive sputtering at room temperature. Microstructure analyses show that each phase in nanocomposite films has the columnar growth along the whole thickness, while each column exhibits the single phase characteristics. The local epitaxial growth behavior of Cu2O is thought to be responsible for such an unusual microstructure. The intermediate oxygen flow rate between those required to synthesize single phase Cu2O and Cu4O3 films produces some Cu2O nuclei, and then the local epitaxial growth provides a strong driving force to promote Cu2O nuclei to grow sequentially, giving rise to Cu2O columns along the whole thickness. Lower resistivity has been observed in such kind of nanocomposite thin films than that in single phase thin films, which may be due to the interface coupling between Cu2O and Cu4O3 columns.

Similar content being viewed by others

Introduction

Nanocomposite thin films have attracted much attention due to their peculiar and tailorable properties in a variety of applications, such as controlling the optical properties1, 2, reducing the dielectric loss3,4,5, tuning the magnetic and electrical transport properties6,7,8,9,10,11,12, enhancing the electrochemical activity13, 14, and increasing the hardness15, 16. The novel architecture, interfacial interplay, and interaction or coupling between the constituents, are thought to be responsible for these peculiar properties and new functionalities. The nanocomposite thin films are typically divided into four types from the viewpoint of microstructure, including nanoparticles in matrix, lamellar multilayer, columns in matrix and vertically aligned nanocomposites17,18,19,20. Among them, vertically aligned nanocomposite, where all the phases have the columnar growth along the film thickness direction, is particularly appealing as its larger interfacial area and high availability of vertical strain control than other types17, 18.

In the past decade, tremendous progress has been made in nanocomposite thin films about designing interface-induced novel functionality. However, most of investigations on vertically aligned oxide nanocomposites are dedicated to epitaxial films (i.e., one perovskite phase with another phase) grown on matched single-crystal oxide substrates at high temperature by pulsed laser deposition3, 5, 8, 9, 11, 13, 17, 18. Such matched single crystal substrates are critical to promote the separated and independent columnar growth for different phases. Furthermore, the cost and the small dimension of the substrate, as well as the low scale from pulsed laser deposition, are not desirable for the large-area devices. Hence, to promote the application of vertically aligned nanocomposite thin films in different areas, it is attractive to deposit such films on unmatched substrates using a low-cost method. Magnetron sputtering is a standard manufacturing process associated with relatively low cost and easy fabrication of large-area films. Sputtered films with single phase usually exhibit the columnar microstructure15, 21, 22. However, this typical columnar structure vanishes with the addition of a second phase15. Therefore, it is challengeable to grow biphase composite thin films with vertically aligned columnar microstructures on unmatched substrates.

Binary copper oxides (Cu2O, Cu4O3 and CuO), as spontaneous p-type semiconductors, have been widely studied23,24,25,26,27,28. More recently, some surprising properties have been observed in the biphase copper oxide composite thin films. For instance, a lower resistivity has been observed in biphase sputtered Cu2O + Cu4O3 thin films than in the single phase Cu2O or Cu4O3 26. In addition, the biphase Cu2O and Cu4O3 thin films can enhance the photovoltaic activity significantly in a binary copper oxide (Cu-O) light absorber27. However, the origin of these peculiar properties remains unknown.

In this work, we demonstrate the vertically aligned columnar microstructure of biphase Cu2O + Cu4O3 nanocomposite thin films grown by reactive magnetron sputtering at room temperature on unmatched glass or silicon substrates. Finally, the unusual electrical properties of biphase thin films are discussed.

Results

The diffractograms of copper oxide thin films deposited with different oxygen flow rates are presented in Fig. 1(a). Two main diffraction peaks are always observed at approx. 36° or 42° in these oxygen flow rates. The first peak may be due to the diffraction of Cu2O (111) planes or Cu4O3 (202) ones and the peak located close to 42° may be related to Cu2O (200) or Cu4O3 (220), as the d values in Cu2O and Cu4O3 are quite close in certain planes (see the supporting information). To obtain a more precise structural description of the films, micro-Raman spectrometry was used (Fig. 1(b)). The film deposited with 14 sccm oxygen shows a typical Raman spectrum of Cu2O, where the T2g peak is observed close to 520 cm−1. The bands at 93, 147 and 216 cm−1 are related to defects, non-stoichiometry and resonant excitation in Cu2O29. A new band close to 531 cm−1 is evidenced when the oxygen flow rate is 15 sccm, which has been assigned to A1g mode of Cu4O3 29, 30. Its intensity increases with the increase of oxygen flow rate while other bands related to Cu2O decrease progressively. Hence, these Raman spectra clearly evidence that the films deposited with 15–18 sccm of oxygen are biphase composite Cu2O + Cu4O3 thin films, and that the fraction of Cu4O3 can be controlled by adjusting the oxygen flow rate.

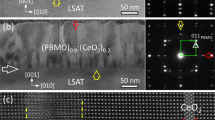

To study the microstructure of the biphase thin films, transmission electron microscopy (TEM) analyses were carried out in cross-section firstly. The cross-sectional TEM images of biphase Cu4O3 and Cu2O thin film deposited with 17 sccm O2 are shown in Fig. 2. Electron diffraction pattern on a large area is presented in Fig. 2(a), which can hardly distinguish Cu2O and Cu4O3 phases since their d values are close to each other (see the supporting information). Surprisingly, the dark and bright field images in Fig. 2(b,c) show notable columnar growth for this biphase film, and the columns start from the film/substrate interface to the top of the film, which is unusual in sputtered composite thin films. Such microstructure is quite similar with that in single phase Cu2O or Cu4O3 thin films29. However, the column width of about 20–40 nm near the top of this biphase film is much smaller than that of 30–70 nm in single phase Cu4O3 thin films29, indicating the existence of competing growth in this biphase thin film. Unfortunately, it is difficult to identify Cu2O and Cu4O3 phases from dark field image by choosing the corresponding diffraction spots, as the d values of main diffraction spots are too close (see Fig. 2(a)).

Furthermore, the microstructure at the initial growth region (close to the substrate) has been studied by high resolution TEM (HRTEM), as shown in Fig. 3. Even at the initial growth region, the biphase film still has the columnar microstructure, with the column width of about 10 nm. The fast Fourier transform (FFT) analyses along the column growth direction have been performed. Figure 3(b–d) show the FFT patterns of square regions named as 1, 2 and 3 in Fig. 3(a), respectively. It is clearly seen that d values of about 2.1 Å have always been observed along the column growth direction, as shown in Fig. 3(b–d). This d value of 2.1 Å could come from Cu2O (200) or Cu4O3 (220), as the information in these patterns is not sufficient to determine the phase structures. To be pointed out here, the poor FFT patterns in Fig. 3(b–d) are typical ones in polycrystalline thin films, which originates from the characteristics of small column width and fiber texture. The thickness of the TEM foil is estimated to be about 50–70 nm by low loss electron energy loss spectroscopy (EELS), much larger than the column width near the substrate, which indicates that there are several columns along the TEM thin foil thickness direction. Besides, the fiber texture observed in pure phase Cu2O and Cu4O3 thin films, may exist in this biphase thin film. Hence, several columns with some rotational degree of freedom around the fiber axis will result in poor diffraction spots. Whatever this diffraction spot belongs to Cu2O or Cu4O3, such analyses indicate that the columnar microstructure in the biphase thin film is formed at the beginning of the growth process, and the columns have almost the same growth orientation along the whole thin film thickness.

(a) HRTEM image of biphase thin film deposited with 17 sccm O2 at the initial growth region. Along the column growth direction, three square regions are marked as 1, 2 and 3. (b–d) Are the FFT patterns of square regions 1, 2 and 3 in (a), respectively. The red circles in (b–d) represent the diffraction spots along the column growth direction, with the d values of about 2.1 Å.

To capture the microstructure of the biphase thin film unambiguously, TEM investigations have also been performed on foils prepared parallel to the film surface, i. e. from the top-view of the specimen. Electron diffraction patterns have been recorded from many grains, and typical patterns are shown in Fig. 4. Figure 4(a) is the bright field image and Fig. 4(b) is the corresponding dark field image, in which the estimated grain size of about 20–40 nm is consistent with the column width in cross-sectional micrographs. In Fig. 4(a,b), grains referred as # 1 and # 2 have been marked. The micro-diffraction patterns of grains #1 (see Fig. 4(c)) exhibits the single crystal diffraction characteristic of Cu4O3, clearly demonstrating this grain is single phase Cu4O3. The diffraction pattern of grain #2 is displayed in Fig. 4(d), which shows the characteristic of Cu2O as the main diffraction spots can be only indexed by cubic crystal structure, rather than tetragonal structure. As shown in Fig. 4(d), a little vestige of diffraction ring has also been observed, which could be due to the small grain size. Then, the convergent beam electron diffraction (CBED) has been performed using another microscope (Philips CM200). The CBED pattern clearly reveals the single phase of Cu2O grain as the pattern shows notable single crystal characteristic (see the supporting information). The CBED pattern of Cu4O3 also confirms its pure phase for every grain (see the supporting information).

Furthermore, the single phase characteristic of different grains has also been studied by HRTEM. As shown in Fig. 5(a), two grains labelled as #5 and #6 have been chosen to perform FFT analyses. The FFT pattern of #5 (see Fig. 5(c)) demonstrates this grain to be single phase cubic Cu2O, as tetragonal structure does not exhibit the six-fold symmetry. Figure 5(d) is the FFT pattern of grain #6, which is well indexed as tetragonal Cu4O3, indicating its single phase characteristic. Thus, the HRTEM analyses also verify that both Cu2O and Cu4O3 grains are pure phase.

(a) Top-view HRTEM micrograph of biphase Cu4O3 and Cu2O thin film with 17 sccm O2. Two grains referred as #5 and #6, have been marked. The white line roughly describes the grain boundaries of #5. The red square frames represent the selected regions for FFT analysis. (b,c) are the FFT patterns of grains #5 and #6, respectively.

The above TEM micrographs from cross-section and top-view indicate an unusual microstructure in biphase Cu4O3 and Cu2O thin films where the two phases grow independently in columnar shape. It is worth noting that this kind of microstructure has clearly evidenced in biphase Cu4O3 and Cu2O thin films with different oxygen flow rates of 16, 17 and 18 sccm. Such a microstructure is significantly different from the traditional concept that one phase is embedded into the second one that acts as matrix. Hence, the schematic microstructure of this biphase thin film is depicted in Fig. 6; for simplicity, we show an ordered arrangement of phases. As shown in Fig. 6, both phases just grow separately and independently with the columnar microstructure along the whole film thickness. This kind of unusual growth can be understood from the viewpoint of Cu2O local epitaxial growth (LEG) behavior previously reported31. In reactively sputtered growth of Cu2O thin films, the Cu2O seed layer has a strong driving force to promote the subsequent growth with the same growth orientation, independently of the deposition conditions31. Therefore, in this biphase thin film, the growth process can be assumed as follows: (1) due to intermediate oxygen flow rate between those required to grow single phase Cu2O and Cu4O3, some Cu2O nuclei are formed; (2) the strong driving force resulting from the local epitaxial growth induces a selective formation of Cu2O on the nuclei with the same structure; (3) the local decrease of the oxygen concentration induces a segregation of oxygen adatoms towards columns with higher oxygen concentration that crystallizes in the Cu4O3 structure. Consequently, Cu4O3 and Cu2O phases with columnar structures grow independently.

As previously reported, the oxygen flow rate allows to tune the phase structure of copper oxide films29. The increase of the oxygen flow rate induces the deposition of Cu2O, Cu4O3 and CuO. Moreover, between these single phases, biphase Cu2O + Cu4O3 and Cu4O3 + CuO films can also be synthesized. The structure and the microstructure of Cu4O3 + CuO films have also been studied by XRD, Raman and TEM. Films deposited with 21 sccm O2 are X-ray amorphous (Fig. 7(a)), but Raman analyses clearly evidence the existence of Cu4O3 A1g mode close to 531 cm−1 and CuO Ag mode at about 288 cm−1 (Fig. 7(b))29, 30. Compared to Cu2O + Cu4O3 biphase films, the Cu4O3 + CuO ones show notably different microstructure. From the cross-sectional TEM images, the columnar growth in biphase Cu4O3 + CuO thin film is not clear (see Fig. 8). Moreover, the top-view electron diffraction patterns can hardly identify the single phase features of grains. Hence, the vertically aligned columnar growth mechanism is not encountered in the biphase Cu4O3 + CuO film anymore. This result can also be explained by taking the LEG effect into account. Indeed, the texture of CuO films is mainly governed by the oxygen partial pressure29. Thus, a local change of the oxygen concentration induces a change of the CuO preferred orientation that comes with a nucleation of a new grain without structural relationship with the previous one. Consequently, there is no LEG behavior in this oxide. In the case of Cu4O3 phase, the [101] orientation deposited at 0.5 Pa does not allow the LEG effect. Considering the occurrence of LEG effect in Cu2O thin films, the vertically aligned columnar growth mechanism in biphase Cu2O + Cu4O3 films can be well described. On the other hand, this growth mechanism is not encountered in biphase Cu4O3 + CuO ones (no LEG effect in these two phases within the present growth conditions). Within this discussion, it is believed that this vertically aligned columnar growth observed in biphase Cu2O + Cu4O3 thin films can also be extended to other materials with certain requirements summarized as below:

-

The system has to contain at least two stable or metastable phases,

-

Each phase has to be deposited in crystalline form within the deposition conditions,

-

The growth rate of each phase has to be similar. Within the Cu-O system, the growth rate of Cu2O is close to that of Cu4O3, while that of CuO is relatively low (poisoning effect of the target)29, 32,

-

At least one phase should be grown independently with a local epitaxial growth mechanism,

-

The chemical compositions of the phases must be close, in order to allow the segregation of one adsorbed element on the growing surface.

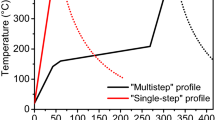

The room temperature resistivity of copper oxide thin films as a function of oxygen flow rate is depicted in Fig. 9, which clearly reveals that the biphase thin film has lower resistivity than single phase films. This result is in agreement with that reported by Meyer et al.26. Since these thin films are deposited at room temperature and the mobility is extremely low, it is difficult to determine the carrier concentration by Hall effect measurements. For the single phase Cu2O or Cu4O3 thin films, the room temperature resistivity decreases with the increase of oxygen flow rate (see Fig. 9), which could be qualitatively understood from the defect mechanism. Taking Cu2O as an example, copper vacancy (\({{\rm{V}}}_{\mathrm{Cu}}^{^{\prime} }\)) is the predominant defects to produce the hole carriers, while the formation energy of copper vacancy decreases in the oxygen rich conditions (higher oxygen flow rate)33,34,35. Then the lower resistivity of single phase Cu2O thin films with higher oxygen flow rate can be interpreted from its larger carrier concentration due to the reduction of copper vacancy formation energy. In the case of biphase Cu2O and Cu4O3 thin film, the oxygen flow rate is higher than that required to synthesis the single phase Cu2O, thus the Cu2O columns may have higher carrier concentration. In contrast, the Cu4O3 columns may have lower carrier concentration as the oxygen sub-stoichiometry. Consequently, the columns with different carrier concentration (high carrier concentration and low carrier concentration) arrange randomly, and their interface coupling may play a role in the establishment of lower resistivity. Further investigations are required to clarify this unusual phenomenon.

Conclusions

An unusual microstructure has been observed in biphase Cu2O + Cu4O3 nanocomposite thin films grown on glass and silicon substrates by reactive sputtering at room temperature, where two phases grow separately and independently with vertically aligned columnar microstructure along the whole film thickness. Such a microstructure may relate to the local epitaxial growth of Cu2O. The intermediate oxygen flow rate between those required to grow pure phase Cu2O and Cu4O3 thin films produce some Cu2O nuclei, and then the strong driving force resulting from the local epitaxial growth induces a selective formation of Cu2O on the nuclei with the same structure, giving rise to this kind of unusual vertically aligned columnar microstructure on unmatched substrates. Such peculiar microstructure can also be extended to other materials with certain requirements. This vertically aligned columnar Cu2O + Cu4O3 nanocomposite thin film exhibits much lower resistivity than single phase thin films, which may be due to the strong interface coupling between Cu2O and Cu4O3 columns.

Methods

Film growth

Copper oxide thin films were deposited on glass substrates (microscopy slides) and (100) silicon single crystal substrates by reactive pulsed-DC magnetron sputtering in Ar-O2 reactive mixtures. The amorphous SiO2 layer on silicon single crystal substrate was not removed, giving rise to the same characteristics of silicon and glass substrates. Thus, the substrates had no effect on the growth orientation and phase structure of thin films. No intentional heating was applied to the substrates, and the deposition temperature was close to room temperature. The argon flow rate was fixed at 25 sccm, while the oxygen flow rate varied in the range of 12–21 sccm with a step of 1 sccm. The accuracy of gas flow controller (Air Liquide) is +/− 0.1 sccm in this work. A pulsed-DC supply (Pinnacle + Advanced Energy) was used to sputter the copper target (50 mm diameter and 3 mm thick with a purity of 99.99%). The current applied to target was fixed to 0.3 A, the frequency and the off-time were 50 kHz and 4 µs, respectively. The distance between the substrate and the target was fixed at 60 mm.

Characterizations

X-ray diffraction (XRD, Brucker D8 Advance with CuKα1 radiation (λ = 0.15406 nm) in Bragg Brentano configuration) and micro-Raman spectrometry (Horiba LabRAM HR using a 532 nm laser) were employed together to identify the phase structures. Transmission electron microscopy (TEM) investigations were performed by a JEOL ARM 200-Cold FEG (point resolution 0.19 nm) fitted with a GIF Quantum ER. For this purpose, the TEM cross-section and top-view specimens of composite thin films deposited on silicon substrates were prepared in a focused ion beam (FIB)-scanning electron microscope (SEM) dual beam system (FEI Helios 600) using the ‘in situ’ lift-out technique. Final thinning was done with low voltage milling (5 kV) to reduce any possible preparation artifacts. The convergent beam electron diffraction (CBED) analyses were done by another TEM (Philips CM200). Besides, the top-view microstructure was also studied by TEM specimens prepared by diamond tip cleave. Electrical resistivity measurements were performed at room temperature using the four-point probe method.

References

Sanchez, C., Lebeau, B., Chaput, F. & Boilot, J. P. Optical properties of functional hybrid organic–inorganic nanocomposites. Adv. Mater. 15, 1969–1994 (2003).

Brust, M., Bethell, D., Kiely, C. J. & Schiffrin, D. J. Self-assembled gold nanoparticle thin films with nonmetallic optical and electronic properties. Langmuir 14, 5425–5429 (1998).

MacManus-Driscoll, J. L. et al. Strain control and spontaneous phase ordering in vertical nanocomposite heteroepitaxial thin films. Nat. Mater. 7, 314–320 (2008).

Yang, H. et al. Vertical interface effect on the physical properties of self-assembled nanocomposite epitaxial films. Adv. Mater. 21, 3794–3798 (2009).

Harrington, S. A. et al. Thick lead-free ferroelectric films with high Curie temperatures through nanocomposite-induced strain. Nat. Nanotechnol. 6, 491–495 (2011).

Liao, S. C. et al. Misorientation control and functionality design of nanopillars in self-assembled perovskite-spinel heteroepitaxial nanostructures. ACS Nano 5, 4118–4122 (2011).

Liao, Z. et al. Tuning properties of columnar nanocomposite oxides. Appl. Phys. Lett. 103, 2011–2015 (2013).

Ning, X., Wang, Z. & Zhang, Z. Large, temperature-tunable low-field magnetoresistance in La0.7Sr0.3MnO3:NiO nanocomposite films modulated by microstructures. Adv. Funct. Mater. 24, 5393–5401 (2014).

Chen, A. et al. Tunable low-field magnetoresistance in (La0.7Sr0.3MnO3)0.5:(ZnO)0.5 self-assembled vertically aligned nanocomposite thin films. Adv. Funct. Mater. 21, 2423–2429 (2011).

Zheng, H. et al. Multiferroic BaTiO3/CoFe2O4 nanostructures. Science 303, 661–663 (2004).

Dix, N. et al. On the strain coupling across vertical interfaces of switchable BiFeO3- CoFe2O4 multiferroic nanostructures. Appl. Phys. Lett. 95, 062907 (2009).

Gao, Y., Cao, G., Zhang, J. & Habermeier, H.-U. Intrinsic and precipitate-induced quantum corrections to conductivity in La2/3Sr1/3MnO3 thin films. Phys. Rev. B 85, 195128 (2012).

Ma, W. et al. Vertically aligned nanocomposite La0.8Sr0.2CoO3/(La0.5Sr0.5)2CoO4 cathodes-electronic structure, surface chemistry and oxygen reduction kinetics. J. Mater. Chem. A 3, 207–219 (2015).

Yoon, J. et al. Vertically aligned nanocomposite thin films as a cathode/electrolyte interface layer for thin-film solid oxide fuel cells. Adv. Funct. Mater. 19, 3868–3873 (2009).

Vepřek, S. The search for novel, superhard materials. J. Vac. Sci. Technol. A 17, 2401 (1999).

Vepřek, S. et al. Recent progress in the superhard nanocrystalline composites: towards their industrialization and understanding of the origin of the superhardness. Surf. Coatings Technol. 108–109, 138–147 (1998).

MacManus-Driscoll, J. L. Self-assembled heteroepitaxial oxide nanocomposite thin film structures: Designing interface-induced functionality in electronic materials. Adv. Funct. Mater. 20, 2035–2045 (2010).

Chen, A., Bi, Z., Jia, Q., MacManus-Driscoll, J. L. & Wang, H. Microstructure, vertical strain control and tunable functionalities in self-assembled, vertically aligned nanocomposite thin films. Acta Mater. 61, 2783–2792 (2013).

Ni, Y., Rao, W. & Khachaturyan, A. G. Pseudospinodal mode of decomposition in films and formation of chessboard-like nanostructure. Nano Lett. 9, 3275–3281 (2009).

Zhou, D. et al. Materials News: Interfacial chemistry and atomic arrangement of ZrO2− La2/3Sr1/3MnO3 pillar-matrix structures. APL Mater. 2, 127301 (2014).

Anders, A. A structure zone diagram including plasma-based deposition and ion etching. Thin Solid Films 518, 4087–4090 (2010).

Petrov, I., Barna, P. B., Hultman, L. & Greene, J. E. Microstructural evolution during film growth. J. Vac. Sci. Technol. A 21, S117 (2003).

Wang, Y. et al. Transmittance enhancement and optical band gap widening of Cu2O thin films after air annealing. J. Appl. Phys. 115, 073505 (2014).

Zhang, Q. et al. CuO nanostructures: Synthesis, characterization, growth mechanisms, fundamental properties, and applications. Prog. Mater. Sci. 60, 208–237 (2014).

Fortunato, E., Barquinha, P. & Martins, R. Oxide semiconductor thin-film transistors: A review of recent advances. Adv. Mater. 24, 2945–2986 (2012).

Meyer, B. K. et al. Binary copper oxide semiconductors: From materials towards devices. Phys. Status Solidi B 249, 1487–1509 (2012).

Anderson, A. Y. et al. Quantum efficiency and bandgap analysis for combinatorial photovoltaics: Sorting activity of Cu-O compounds in all-oxide device libraries. ACS Comb. Sci. 16, 53–65 (2014).

Wang, Y. et al. Electronic structures of Cu2O, Cu4O3 and CuO: a joint experimental and theoretical study. Phys. Rev. B 94, 245418 (2016).

Wang, Y. et al. Tuning the structure and preferred orientation in reactively sputtered copper oxide thin films. Appl. Surf. Sci. 335, 85–91 (2015).

Debbichi, L. M., de Lucas, M. C., Pierson, J. F. & Kruger, P. Vibrational properties of CuO and Cu4O3 from first-principles calculations, and Raman and infrared spectroscopy. J. Phys. Chem. C 116, 10232–10237 (2012).

Wang, Y. et al. Controlling the preferred orientation in sputter-deposited Cu2O thin films: Influence of the initial growth stage and homoepitaxial growth mechanism. Acta Mater. 76, 207–212 (2014).

Pierson, J. F., Thobor-Keck, A. & Billard, A. Cuprite, paramelaconite and tenorite films deposited by reactive magnetron sputtering. Appl. Surf. Sci. 210, 359–367 (2003).

Raebiger, H., Lany, S. & Zunger, A. Origins of the p-type nature and cation deficiency in Cu2O and related materials. Phys. Rev. B 76, 045209 (2007).

Soon, A., Cui, X. Y., Delley, B., Wei, S. H. & Stampfl, C. Native defect-induced multifarious magnetism in nonstoichiometric cuprous oxide: First-principles study of bulk and surface properties of Cu2O. Phys. Rev. B 79, 035205 (2009).

Scanlon, D. O., Morgan, B. J., Watson, G. W. & Walsh, A. Acceptor levels in p-type Cu2O: Rationalizing theory and Experiment. Phys. Rev. Lett. 103, 096405 (2009).

Acknowledgements

Y. Wang would like to thank the European Commission for ‘Erasmus Mundus’ PhD fellowship with the DocMASE project. Y. Wang was partially supported by the Funding of Southwest University of Science and Technology (16zx7165), the Open Project of State Key Laboratory Cultivation Base for Nonmetal Composites and Functional Materials (13zxfk10) and Program for Young Science and Technology Innovation Team of Sichuan Province (2017TD0020). F. Mücklich would like to thank the EFRE Funds of the European Commission for support of activities within the AME-Lab project.

Author information

Authors and Affiliations

Contributions

Y.W. carried out main parts of the experiments and wrote the first version of this paper. Y.W. and J.F.P. proposed the concept. J.F.P. directed the whole study. J.G. and S.B. performed TEM analyses. F.S., D.H. and F.M. contributed to the analysis and discussion for the results. All authors commented on the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, Y., Ghanbaja, J., Bruyère, S. et al. Room temperature self-assembled growth of vertically aligned columnar copper oxide nanocomposite thin films on unmatched substrates. Sci Rep 7, 11122 (2017). https://doi.org/10.1038/s41598-017-10540-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-10540-6

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.