Abstract

The aim of the present study is to evaluate the application of high rate integrated anaerobic-aerobic/biogranular activated carbon sequencing batch reactor (IAnA-BioGACSBR) to treat raw strong leachate from open dumping of municipal solid waste. The influence of two important and effective independent variables, COD concentrations and volumetric filling rate with GAC, onto the leachate treatment were investigated. Three responses such as TKN, BOD and COD were considered for evaluating the interaction of parameters. The results showed that maximum BOD5 removal of 98.9% in anaerobic zone and 99% in aerobic zone was obtained at the highest values of COD (~30000 mg/L) and filling ratio (~50%). The highest values of COD removal efficiency were found to be 98.54% and 98%, at COD rate of 10000 mg/L and GAC of 35%, respectively. The highest removal values of TKN was 77.2% and 78.9% in anaerobic and aerobic zone, respectively. Under optimal conditions, compared with the SBR and the GAC-SBR performances, results reveal that the application of the GAC-SBR has shown better effluent characteristics. Based on the results, it can be asserted that the application of the high rate IAnA-BioGACSBR for the treatment of biodegradable landfill leachate was more effective.

Similar content being viewed by others

Introduction

The special characteristics of municipal landfill leachate (MLL) including high concentrations of inorganic, organic, microbial, and chemical pollutants can potentially have hazardous and toxic effects on the ecosystem and environment1. Fresh MLL is of high strength due to low pH, high amounts of biochemical oxygen demand (BOD)5 and chemical oxygen demand (COD), and high toxic/hazardous contents2. Also, the young leachate may be up to 36 times stronger than raw sewage in regard of the COD content, but the mature leachate can be approximately similar3, 4. For biodegradable MLL, when the BOD5/COD ratio is higher than 0.3, biological techniques are used successfully for simultaneous removal of organic carbon and nitrogen5. For simultaneous treatment of the carbon and nitrogen content of MLL, many biological techniques such as ammonification, nitrification/denitrification and Anammox were investigated6. Due to the complex characteristics of MLL, for the confidence of final usage or discharge into the environment, it is occasionally necessary for MLL to be discharged into the municipal sewage system7, 8. Due to incompatibility of the conventional method with leachate properties, the landfill sites lack a system to treat their wastewater, and also MLL treatment is a difficult and expensive task9. To avoid the adverse impacts, high treatment costs and lower effectiveness of alternative treatment techniques, the biological methods have been used for MLL treatment2, 8, 10. Biological methods can be classified into aerobic, anaerobic and anoxic processes which can be used for treating biodegradable wastewaters, often characterized by a wide variation in composition11. These groups of treatment processes are environment friendly, reliable, simple and high cost-effective, and have been demonstrated historically to be very effective in removing the bulk of MLL with the high ratio of BOD5/COD12. Recently, among the biological methods, conventional activated sludge and sequencing batch reactors (SBRs), biofilters and moving bed processes have attracted major interests. On the other hand, these techniques proved to be quite effective in removing the organic matter and nutrients2, 10. SBRs are of high flexibility, simple to construct, cost-effective in installation and operation, highly efficient, have good settle ability, lower capital cost, and also have the ability for integration with aerobic and anaerobic processes13, 14. New studies and manipulations of SBR are still of high interest. Easy management and effectiveness under different operating conditions [hydraulic retention time (HRT) and organic loading rate] are other special properties that promote wide application of SBR7. It can be seen from the Table 1 that there are numerous operating possibilities for SBR and its combination with other processes for wastewater treatment. In recent years, various combined processes such as anaerobic and aerobic system, coagulation-flocculation, chemical and electrochemical oxidation have been considered for the enhanced treatment of leachate (see Table 1). For example, Aziz et al.15 have reported that simultaneous removal of ammonium and organic carbon from landfill leachate by anaerobic and aerobic systems is possible15. This process combination was supported by some advantages including simplicity, cost-effectiveness, high effluent quality, simultaneous organic and nitrogen removal, lower energy consumption and less sludge production16. In the combination of anaerobic-aerobic processes, though there is some biodegradability resistance, intensive degradation of MLL occurs. In addition, this coupled process can be used as pretreatment of strong wastewater such as MLL to tolerant levels.

Activated carbon is a popular adsorbent due to its unique properties such as large porous surface area, thermo-stability and low acid/base reactivity, controllable pore-structure, ability to remove a wide range of pollutants and is can be used as polishing process following biological treatment2, 17, 18. Integration of activated carbon with a biological process can improve the treatment characteristics of the effluent due to highly available surface area and micro/macro pore for bacterial attachment and biofilm formation. On the other hand, resistant and recalcitrant pollutants can be absorbed in porous site and they are better placed in contact to biofilm and bacterial enzymes and therefore a better degradation is provided. Other advantages for the use of activated sludge together with biological processes include microorganisms protection (both autotrophic and heterotrophic) from organic loading shocks and prevention from bacteria washout, improvement in settleability and dewaterability of sludge, and the activated sludge bioregeneration19. However, the aim of present work is to evaluate the performance of a pilot-scale of the high rate IAnA-BioGACSBR for the treatment of strong MLL. The second aim is the optimization of the leachate treatment process in regard to COD and BOD criteria for discharging the treated effluent in the municipal wastewater collection network. Based on available database, no similar work has been reported so far. To analyze, model and optimize the significant responses [such as total COD, BOD and total kjeldahl nitrogen (TKN) removal] as a function of the two independent variables (COD concentrations and filling percent), full factorial design (FFD) and response surface methodology (RSM) were employed.

Material and Methods

Wastewater properties

Leachate samples were collected from the landfill site in Kermanshah, Iran. The samples were taken from landfill site and stored at 4 °C prior to use by minimizing the biological activity and chemical reactions. MLL characteristics are shown in Table 2.

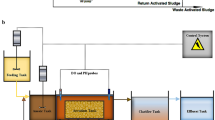

Reactor setup

A cylindrical Plexiglas reactor was used as SBR with a working volume of about 3.6 L (internal diameter ~6 cm and total height ~164 cm). The schematic plan of the combined system is illustrated in Fig. 1. By a preprogrammed timer (multi-Function, 4-OUT) the anaerobic and aerobic conditions were implemented. The reactor content was mixed using a circulator pump, and an aquarium pump (Hailea ACO-9602, China) was placed to supply air through a porous stone diffuser that was located at the bottom of the reactor. The reactor was covered with aluminum foil to prevent evaporation. The dissolved oxygen (DO) amount was maintained about more than 2.5 mg/L. Granular activated carbon (GAC) with a surface area about 900 m2/g and density 1.3 g/cm3 were added to SBR. To achieve the desirable loading rate (10000 < COD < 30000 mg/L), leachate was diluted with distillation water. The reactor has been inoculated with mixed culture of biomass obtained from the wastewater treatment plant of Farabi treatment plant, Kermanshah, Iran. The SBR was initially inoculated with 300 mL of mixed liquor, 20% volume with GAC (400 mL), and 1 L of its empty volume was loaded using diluted MLL and the initial concentration of COD was about 10000 mg/L. To prepare the excess bio-GAC for higher GAC filing ratio percentage of 35% and 50%, a parallel and similar condition was generated separately with IAnA-BioGACSBR and bioGAC. During the start-up period, HRTs in anaerobic as well as aerobic reactor were set equally at 12 h. To achieve high bacteria ability, the activated sludge was acclimatized for 45 days. The reactor was operated in following sequence; filling (5 min), anaerobic agitation (12 h), withdrawal (10 min), aeration (12 h), withdrawal (10 min) and settlement (1 h). In next step, to determine the optimum HRT for maximum COD removal, the system was operated at different anaerobic–aerobic contact times. This phase was performed as follows: anaerobic (24, 48 and 72 h) and aerobic (12, 24 and 36 h).

Experimental design and mathematical modeling

The main part of the study was carried out to investigate the effect of the factors “GAC filling ratio” and “COD concentration”. The operating conditions are summarized in Table 3. FFD and RSM were used for the analysis of data and process optimization. FFD was established through Design Expert Software version 7. To optimize an analysis, independent effective variables with certain ranges including inlet COD concentration (x 1 ) and volumetric filling rate (x 2 ), were selected at three levels. The range and levels of the variables in coded and actual units are given in Table 4. The two operating variables were considered. COD, BOD and TKN removal were measured or calculated as per the response. The obtained experimental conditions and results are shown in Table 5. The results were analyzed by analysis of variance (ANOVA). Three-dimensional plots with the respective contour plots were obtained from the results of the experiments.

Analytical Methods

The chemical oxygen demand (Standard code: 5220D), biological oxygen demand (5210 B), TKN (4500 A), total phosphorous (4500-P A), alkalinity (by titration method), and turbidity (by nephelometric method) were performed according to the standard methods. Gravimetric methods were used for the determination of mixed liquor suspended solids (MLSS) and mixed liquor volatile suspended solids (MLVSS) after filtration and drying at temperatures 105 °C and 550 °C, respectively. For COD, a colorimetric method with closed reflux method was developed. The TKN and the BOD were determined by TKN meter (Gerhardt model) and BOD meter, respectively. A spectrophotometer (DR 5000, Hach, Jenway, USA) at 520 nm was used for measuring NH3-N and TP. Wastewater DO levels were determined by using a DO probe (Oxi, Germany). The pH, conductivity and the oxidation reduction potential (ORP) were monitored by a pH meter (WTW, Germany).

Results and Discussion

Reactor start-up

The primary analysis of MLL showed that the BOD5/COD ratio is higher than 0.7, the samples are highly biodegradable, and therefore the considered landfill is young. At start-up period, acclimatization was completed for 45 days at 20% volumetric GAC, and COD was about 10.000 mg/L. The end-point of start-up was selected by COD removal percentage lower than 5% at the 8th day of operation time (31 to 39 day). At this condition, biological system is reached to a pseudo steady state. These variations can be observed in Fig. 2. Accordingly, the COD removal percentages in anaerobic and aerobic zone were 52% and 54.4%, respectively. The COD declined from 10000 mg/L to 4807 mg/L in anaerobic zone, and to 4561 mg/L in the aerobic zone. An efficiency improvement phase occurred after about 40 to 45 day. This may be related to a system upgrading due to a higher bacterial mass and an accumulation of biodegrading enzymes after the steady state phase. In this improved phase, an opportunity for the production of enzymes via long operation time was provided. At high biodegradable amount of MLL (BOD/COD ~ 0.7) and primary operation time, the cross-link metabolisms occurred successfully. The co-metabolism in the presence of high biodegradable matter can be affected and is completed by operating at the proper contact time. All the required enzymes for biodegradable and resistant compounds in MLL is generated. LaPara et al.20 demonstrated that the specific activity of catabolic enzyme is increased at the proper HRTs20. In steady state phase, the generation of the responsible enzyme for resistant-compounds was improved. Consequently, a high value of removal efficiency for COD is obtained.

Effect of HRT

HRT is one of the important variables that can have significant effects on a biological process, and it provides an adequate reaction time between the biomass/biofilm and the substrate material21. Therefore, determining an optimum HRT for decreasing the treatment costs, and for increasing the system efficiency at different anaerobic–aerobic units is important. Figure 3a and b shows the effect of different HRT in constant loading rate. At this stage, anaerobic unit was operated at 24, 48 and 72 h, while the aerobic unit was operated at 12, 24 and 36 h. Under anaerobic conditions as a function of the operating time, COD removal was in the range of 79.9 ± 2.7, 95.6 ± 1.5 and 96.5 ± 1.19%, respectively. In the anaerobic stage, because the difference in COD removal values between both the HRT (48 and 72 h) was not significant, the HRT~48 h was chosen as optimum HRT with the original loading. At same HRTs (for example 24 h) and in comparison with high rate (for 0.1–10 kg COD/m3/day) anaerobic processes such as Anaerobic Filters (AF), Anaerobic expanded/Fluidized bed rectors, Upflow Anaerobic Sludge Blanket (UASB) reactor, IAnA-BioGACSBR have been reported with notable results (efficiency~80% for 10 kg COD/m3. day). In the aerobic zone, the obtained COD removal was about 95.74 ± 1.5, 93.46 ± 1.34 and 96.7 ± 0.9%, respectively. Due to negligible difference between HRTs at 12 h with 24 and 36 h, the HRT equal to 12 h was selected as the optimal point for HRT. It can be found from aerobic results that a considerable amount of COD (95.74%) was degraded in regard to the conventional treatment methods such as activated sludge modification process.

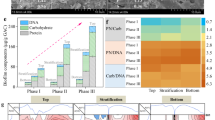

ANOVA and statistical analysis

A FFD of twenty seven runs was conducted in the pilot scale to determine the responses. As a function of x 1 and x 2 , a mathematical equation is drawn. Table 5 illustrates ANOVA and statistical parameters that were obtained based on experimental data. In order to specify the accuracy of fit, ANOVA is used. Usually, the adequacy of the model can be evaluated by diagnostic plots, such as a plot of predicted versus actual values. As illustrated in Fig. 4a–f, the predicted values versus actual values are presented. The predicted values were calculated from the final coded mathematical equations.

To investigate the effects of the considered variables on the COD, BOD5 and TKN removal efficiency, the dependencies of these responses to the variables were analyzed and modeled. A reduced quadratic and Linear model was selected to describe the variation removal efficiency of the COD, BOD and TKN (Table 6). Table 6 summarizes the statistical parameters of the obtained equations. As presented in Table 6, the main effects of the two factors (x 1 : loaded COD and x 2 : GAC filling ratio percentage) are significant model terms. However, the effect of x 2 is much more important than that of x 1 . This effect is more specific for anaerobic process rather than aerobic (see numerical coefficients of x 1 and x 2 ). In comparison with aerobic process, variables effectiveness is so close. From a comprehensive overview of the provided models, it can be seen that Linear and quadratic models were fitted with experimental data. The COD removal models for anaerobic and aerobic processes were confirmed with polynomial (quadratic) models. These findings suggest that the COD removal can be affected by many variables. These variables include operation condition, HRT, COD removal mechanisms (anaerobic/aerobic degradation, adsorption, sedimentation etc.), COD loading, filling ratio, COD/TKN ratio, granule maturation. On the other hand, a quadratic equation can be obtained when both biodegradable and resistant compound are removed simultaneously. The COD removal models with high determination coefficient (R2 = 0.93 for both anaerobic and aerobic zones) demonstrates that there is a desirable conformity between experimental data and models. As seen in BOD removal models, linear model refers to a strong effective parameter or mechanism that has a predominant effect than others. With regard to high ratio of BOD/COD (~0.7), it can be concluded that possibly the biodegradation is the effective mechanisms by the rapid degradation of organic via aerobic process. Also, the linear model for TKN in aerobic process is related to limitation of process by improper amounts of BOD/TKN ratio (>10). When BOD/TKN ratio >4, it provides limited denitrification and under this condition the nitrification is not affected significantly. However, nitrification byproducts accumulation occurs22. At this time, TKN removal is restricted to dissimilation.

Figure 5 illustrates the variation of responses in three dimension plots. According to Fig. 5a and b, the response linearly increased with an increase in the COD concentration and filling ratio percentage [COD removal in anaerobic zone (98.9%) and in aerobic zone (99%)]. In anaerobic and aerobic zone, the maximum values of BOD removal were obtained, 98.54% and 98%, at the highest values of the independent factors (30000 mg/L and 50%), respectively (Fig. 5c and d). Similar pattern for COD and BOD5 is seen in anaerobic as well as aerobic processes. This reveals that the MLL was easily degradable (BOD5/COD 0.7) and anaerobic process successfully removed the higher amount of loaded organic matter. As mentioned, the effect of x 2 (GAC filling ratio percentage) was more effective than loaded COD concentration in the anaerobic zone. These results suggest that the efficiency of anaerobic process increases with higher filling ratio when the system is operated under high rate condition. Significant efficiency for all responses can be related to the high surface area to volume ratio and porosity. As a result, large adsorption capacity of GAC could provide high substrate removal efficiency with high process stability23. Loukidou and Zouboulis reported that the use of GAC moving-bed biofilm SBR process was capable to remove the most biodegradable organic carbon, together with the major fraction of COD2. Anaerobic SBR has been studied by Timur et al.24 for young landfill leachate and they reported COD removal rates of about 64–85%24. To treat the textile dyestuff, an anaerobic–aerobic SBR was used and the significant COD removal (higher than 85%) were obtained for a COD loading of 500 mg/L25. Aziz et al.15 proposed that a powdered activated carbon (PAC)-SBR was able to treat the landfill leachate, and the PAC-SBR displayed superior performance in terms of removal efficiencies compared to single SBR15. Under optimal condition including aeration rate of 1 L/min and contact time of 5.5 h, the PAC-SBR provided about 64.1% of COD removal15. As seen from Fig. 5e and f, the increase in filling ratio percentage caused an increase in the removal efficiency for both anaerobic and aerobic processes. The maximum TKN removal of 77.2% and 78.9% were obtained at COD ~ 10.000 mg/L with a filling ratio of about 35%. Because of the high BOD/TKN ratios (4.7 to 12), it was assumed that nitrifiers were not significantly cultured in the SBR reactor22. It is evident that the nitrogen is likely consumed as a nutrient for the synthesis of new cells via assimilation pathway26. This result suggested that the TKN removal efficiency can also be completed by adsorption into GAC surface and porous area, and also transferred to nitrification byproducts and their accumulations. According to Fig. 5e and f, it can be asserted that the TKN removal rate declined primarily due to the negative interaction between nitrification and heterotrophic bacteria in both anaerobic as well as aerobic units. This negative effect occurs when the carbon to nitrogen ratio (C/N), is improper, and consequently, a small population of nitrogen oxidizing bacteria (such as nitrite oxidizing bacteria) can be active so that nitrite and other nitrification byproducts are accumulated21. After the initial drop of TKN removal efficiency, an ascending removal rate was observed, which could be due to the adequate acclimatization of nitrifying and denitrifying bacteria in the connection with higher COD loading rates. In a similar study reported by Sirianuntapiboon et al.27, they demonstrated that TKN and ammonium in a GAC-SBR system decreased the nitrite accumulation27. The TKN removal rather than COD and BOD removal efficiency via higher filling ratio of GAC was increased gradually, and the COD and BOD removal efficiency was improved rapidly. Similar results reported by Sirianuntapiboon et al.27 showed that organic matter and dye could be removed rapidly with higher efficiency27. They proposed that this fact has been associated with the growth of biosludge (growth association mechanism)28.

Optimization

Table 7 presents the option criteria for discharging MLL effluent to municipal wastewater and the corresponding values of the independent variables. In this regard, the quality of MLL effluent has to comply with increasing stringent discharge standard. It is clear that the performance of the high rate IAnA-BioGACSBR can be used for discharging MLL effluent to municipal wastewater network. The optimum zone was obtained based on responses of COD in the range 500–600 mg/L and BOD in the range 200–300 mg/L. Figure 6 illustrates the achieved optimum zone.

Effect of GAC addition

To evaluate the effect of GAC-SBR versus SBR, this phase of experiment under same condition was conducted. The results obtained for the test of GAC addition are shown in Fig. 7. Accordingly, the COD removal efficiencies of two systems were analyzed and it was found that high rate IAnA-BioGACSBR has clearly significant effect on COD biodegradation as compared to others. The average efficiencies of COD removal from MLL in the SBR and the GAC-SBR were determined at about 95.17% and 86.68% (with p-value < 0.001), respectively.

Conclusions

The treatability of MLL was studied by using a novel IAnA-BioGACSBR. Under anaerobic and aerobic conditions HRTs (48 and 12 h) were selected as optimum HRT with highest COD removal as 95.6 ± 1.5%, 95.74 ± 1.5, respectively. In order to model and optimize this SBR, experiments were conducted based on FFD and RSM. The results showed that the maximum BOD removal obtained was about 98.9 and 99% when the COD is 30.000 mg/L and the filling ratio is 50%. The maximum COD removal percentages were found over 98% (at COD ~ 10000 mg/L and GAC of 35%). Under these conditions the highest removal of TKN was 77.2% and 78.9%, respectively. Under optimum zone, the MLL can be appropriately discharged into municipal wastewater.

References

Englehardt, J. D. et al. Options for managing municipal landfill leachate: Year 1 development of iron-mediated treatment processes. Project Report# 0432024-06. Hinkley Center for Solid and Hazardous Waste Management, Florid (2006).

Loukidou, M. X. & Zouboulis, A. I. Comparison of two biological treatment processes using attached-growth biomass for sanitary landfill leachate treatment. Environ Pollut 111, 273–281 (2001).

Bohdziewicz, J. & Kwarciak, A. The application of hybrid system UASB reactor-RO in landfill leachate treatment. Desalination 222, 128–134 (2008).

Kurniawan, T. A. & Lo, W.-H. Removal of refractory compounds from stabilized landfill leachate using an integrated H2O2 oxidation and granular activated carbon (GAC) adsorption treatment. Water Res 43, 4079–4091 (2009).

Li, H.-s., Zhou, S.-q., Sun, Y.-b. & Feng, P. Advanced treatment of landfill leachate by a new combination process in a full-scale plant. J Hazard Mater 172, 408–415 (2009).

Wiszniowski, J., Robert, D., Surmacz-Gorska, J., Miksch, K. & Weber, J. V. Landfill leachate treatment methods: A review. Environ Chem Letters 4, 51–61 (2006).

Bu, L. et al. Characterization of dissolved organic matter during landfill leachate treatment by sequencing batch reactor, aeration corrosive cell-Fenton, and granular activated carbon in series. J Hazard Mater 179, 1096–1105 (2010).

Pirsaheb, M. et al. Evaluating the efficiency of electrochemical process in removing COD and NH4-N from landfill leachate. Desalin Water Treat 57, 6644–6651 (2016).

Xu, Z. Y. et al. Biological treatment of landfill leachate with the integration of partial nitrification, anaerobic ammonium oxidation and heterotrophic denitrification. BioresTechnol 101, 79–86 (2010).

Renou, S., Givaudan, J. G., Poulain, S., Dirassouyan, F. & Moulin, P. Landfill leachate treatment: Review and opportunity. J Hazard Mater 150, 468–493 (2008).

Mangimbulude, J. C., van Breukelen, B. M., Krave, A. S., van Straalen, N. M. & Röling, W. F. M. Seasonal dynamics in leachate hydrochemistry and natural attenuation in surface run-off water from a tropical landfill. Waste Manage 29, 829–838 (2000).

Kulikowska, D., Klimiuk, E. & Drzewicki, A. BOD5 and COD removal and sludge production in SBR working with or without anoxic phase. Biores Technol 98, 1426–1432 (2007).

Ahmadi, M. et al. Application of the central composite design for the treatment of soft drink factory wastewater in two-stage aerobic sequencing batch reactors combined with ozonation. Desalin Water Treat 57, 19077–19086 (2016).

Cho, Y. H. & Kwon, L. H. Effective Treatment System for the Leachate from a Small-Scale Municipal Waste Landfill. Korean J Environ Health Sci 28, 51–65 (2002).

Aziz, S. Q., Aziz, H. A., Yusoff, M. S. & Bashir, M. J. K. Landfill leachate treatment using powdered activated carbon augmented sequencing batch reactor (SBR) process: Optimization by response surface methodology. J Hazard Mater 189, 404–413 (2011).

Sun, H. et al. Advanced removal of organic and nitrogen from ammonium-rich landfill leachate using an anaerobic-aerobic system. Chinese J Chem Eng 23, 1047–1051 (2015).

Lakdawala, M. M. & Lakdawala, J. M. Comparative Study of Effect of PAC and GAC on Removal of COD Contributing Component of Sugar Industry waste water. Res J Recent Sci 2, 90–97 (2013).

Li, Z. et al. Granular activated carbon supported iron as a heterogeneous persulfate catalyst for the pretreatment of mature landfill leachate. RSC Advances 6, 987–994 (2016).

Skouteris, G., Saroj, D., Melidis, P., Hai, F. I. & Ouki, S. H. The effect of activated carbon addition on membrane bioreactor processes for wastewater treatment and reclamation -A critical review. Biores Technol 185, 399–410 (2015).

LaPara, T., Konopka, A., Nakatsu, C. & Alleman, J. Thermophilic Aerobic Wastewater Treatment in Continuous-Flow Bioreactors. J Environ Eng 126, 739–744 (2000).

Hossini, H., Rezaee, A., Ayati, B. & Mahvi, A. H. Simultaneous nitrification and denitrification using a polypyrrole/microbial cellulose electrode in a membraneless bio-electrochemical system. RSC Advances 5, 72699–72708 (2015).

Pak, D.-W., Jung, J.-Y. & Jung, Y.-C. Nitrite Accumulation and Removal in a Sequencing Batch Reactor. Environ Eng Res 1, 37–37 (1996).

Muhamad, M. H., Abdullah, S. R. S., Mohamad, A. B., Rahman, R. A. & Kadhum, A. A. H. Application of response surface methodology (RSM) for optimisation of COD, NH 3-N and 2, 4-DCP removal from recycled paper wastewater in a pilot-scale granular activated carbon sequencing batch biofilm reactor (GAC-SBBR). J Environ Manage 121, 179–190 (2013).

Timur, H. & Özturk, I. Anaerobic sequencing batch reactor treatment of landfill leachate. Water Res 33, 3225–3230 (1999).

Kapdan, I. K. & Oztekin, R. The effect of hydraulic residence time and initial COD concentration on color and COD removal performance of the anaerobic-aerobic SBR system. J Hazard Mater 136, 896–901 (2006).

Bae, T.-H., Han, S.-S. & Tak, T.-M. Membrane sequencing batch reactor system for the treatment of dairy industry wastewater. Process Biochem 39, 221–231 (2003).

Sirianuntapiboon, S. & Sansak, J. Treatability studies with granular activated carbon (GAC) and sequencing batch reactor (SBR) system for textile wastewater containing direct dyes. J Hazard Mater 159, 404–411 (2008).

Sirianuntapiboon, S. & Srisornsak, P. Removal of disperse dyes from textile wastewater using bio-sludge. Biores Technol 98, 1057–1066 (2007).

Wang, K., Wang, S., Zhu, R., Miao, L. & Peng, Y. Advanced nitrogen removal from landfill leachate without addition of external carbon using a novel system coupling ASBR and modified SBR. Biores Technol 134, 212–218 (2013).

Sun, H. et al. Achieving the nitrite pathway using FA inhibition and process control in UASB-SBR system removing nitrogen from landfill leachate. Sci China Chem 53, 1210–1216 (2010).

Lin, S. H. & Chang, C. C. Treatment of landfill leachate by combined electro-Fenton oxidation and sequencing batch reactor method. Water Res 34, 4243–4249 (2000).

Wang, Y., Peng, Y. & Stephenson, T. Effect of influent nutrient ratios and hydraulic retention time (HRT) on simultaneous phosphorus and nitrogen removal in a two-sludge sequencing batch reactor process. Biores Technol 100, 3506–3512 (2009).

Su, K.-Z. & Yu, H.-Q. Formation and characterization of aerobic granules in a sequencing batch reactor treating soybean-processing wastewater. Environ Sci Technol 39, 2818–2827 (2005).

Venkata Mohan, S., Lalit Babu, V. & Sarma, P. N. Anaerobic biohydrogen production from dairy wastewater treatment in sequencing batch reactor (AnSBR): Effect of organic loading rate. Enzyme Microb Technol 41 , 506–515 (2007).

Ruscalleda, M. et al. Heterotrophic denitrification on granular anammox SBR treating urban landfill leachate. Water Sc. Technol 58, 1749–1755 (2008).

Ganigué, R. et al. Long-term operation of a partial nitritation pilot plant treating leachate with extremely high ammonium concentration prior to an anammox process. Biores Technol 100, 5624–5632 (2009).

Jung, J.-Y., Chung, Y.-C., Shin, H.-S. & Son, D.-H. Enhanced ammonia nitrogen removal using consistent biological regeneration and ammonium exchange of zeolite in modified SBR process. Water Res 38, 347–354 (2004).

Yu, Y.-C., Tao, Y. & Gao, D.-W. Effects of HRT and nitrite/ammonia ratio on anammox discovered in a sequencing batch biofilm reactor. RSC Advances 4, 54798–54804 (2014).

Acknowledgements

The authors gratefully acknowledge the Research Council of Kermanshah University of Medical Sciences (Grant Number: 93297) for the financial support. This work was performed in partial fulfillment of the requirement for M.Sc. of Environmental Health Engineering of (Molouk Parvaneh), School of Public Health, Kermanshah University of Medical Sciences, Kermanshah, Iran.

Author information

Authors and Affiliations

Contributions

M.P., M.S.S. and M.P. conceived, designed and performed the experiments. H.H. and G.M.A. analyzed the data and wrote the manuscript. All authors reviewed and approved the manuscript.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Pirsaheb, M., Hossini, H., Secula, M.S. et al. Application of high rate integrated anaerobic-aerobic/biogranular activated carbon sequencing batch reactor (IAnA-BioGACSBR) for treating strong municipal landfill leachate. Sci Rep 7, 3109 (2017). https://doi.org/10.1038/s41598-017-02936-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-02936-1

This article is cited by

-

Recent technologies for leachate treatment: a review

Euro-Mediterranean Journal for Environmental Integration (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.