In this paper, we propose a nanostructure with Au nanoparticles (NPs), as electron sinks, located at the most outside layer of CdS sensitized TiO2 nanorod arrays (TiO2 NRAs/CdS/Au). By the introduction of Au NPs, TiO2 NRAs/CdS/Au performs higher visible light photocatalytic capacity in the degradation of unsymmetrical dimethylhydrazine wastewater than TiO2 NRAs/CdS. The optimal deposition time for Au NPs is 30 s. The visible light induced degradation ability of TiO2 NRAs/CdS/Au (30 s) is 1.4 times that of TiO2 NRAs/CdS. The cycling stability of TiO2 NRAs/CdS is greatly enchanced after Au NPs decoration, which can maintain 95.86% after three cycles. Photoluminescence spectra and photoelectrochemical measurements were carried out to reveal the underlying mechanism for the improved visible light photocatalytic capacity of TiO2 NRAs/CdS/Au. This work demonstrates a promising way for the rational design of metal-semiconductor photocatalysts used in decomposition reaction that can achieve high photocatalytic efficiency.

Similar content being viewed by others

Introduction

TiO2 nanostructures, as environmentally friendly materials, have been widely studied for the last several dozen years1,2,3,4,5. However, the wide band gap (>3.0 eV) of TiO2 restricts its utilization of the visible light in the solar spectrum6,7,8, and the low charge-mobility often leads to the high recombination rate of photogenerated electrons and holes in TiO2 9. To overcome the barriers, combining TiO2 with a narrow band-gap semiconductor is of considerable interests for practical application at a low cost10. A typical example is the CdS-TiO2 composite, whose spectral response can be extended to the visible light region owing to the narrow energy band gap (2.4 eV) of CdS11, 12. In addition, the good band gap matching between TiO2 and CdS allows electrons generated from CdS to be transferred to TiO2, which could effectively accelerate the separation of electrons and holes13, 14. In particular, highly ordered one dimensional TiO2 nanorod arrays (TiO2 NRAs) sensitized with CdS nanoparticles (NPs) have better photoelectrochemical and photocatalytic capacity, because the ordered one dimensional nanostructure is more in favor of carriers separation2, 15,16,17,18.

Although the durability of CdS-TiO2 composite is often challenged, its excellent photocatalytic performance still attracts intensive studies. To improve the durability of CdS-TiO2, not at the expense of its photocatalytic capacity, several researches have been carried out. One of the effective methods is to strengthen the interaction between CdS and TiO2, which is closely related with their surface structures19, 20. However, it is relatively hard to precisely control the surface structures in preparation. Coating a thin layer made of stable materials on CdS, such as TiO2 13 and ZnO21, to protect it from photocorrosion is also a good choice. The coating layer could not only prevent CdS to be corroded, but also favor carriers separation due to the bandgap matching between CdS and the coating layer. Therefore, Au enters our line of sight.

Au is very stable and highly resistant to oxidation22. When Au NPs contact with an semiconductor, it can usually help interfacial charge-transfer process23. Therefore, loading Au NPs on the surface of TiO2 NRAs covered by CdS NPs may be a useful way to improve its stability as well as the separation of carriers. Several investigations have been reported about nanocomposites containing Au, CdS and TiO2 24,25,26,27,28. However, Au NPs either are put in the most inside as the nuclears, or placed in the middle of the structures as bridges for the carriers transfer in these literatures. There is still no nanostructure that loading Au NPs, as the most outside layer, on the surface of TiO2 NRAs covered by CdS NPs.

The high-energy unsymmetrical dimethylhydrazine (UDMH) is an excellent propellant primarily used in the space industry as well as the military theme29. However, the frequent use of UDMH in recent years makes a lot of UDMH wastewater. Animal experiments have proved that UDMH is carcinogenic, which poses a serious danger to the environment and human beings30. Traditional methods dealing with UDMH wastewater usually consume much energy and lead to second pollution by adding salts31. Therefore, UDMH was chosen as the model pollutant to test the effect of Au NPs on the photocatalytic performance of TiO2 NRAs/CdS under visible light irradiation. To understand the underlying reason for the improved photocatalytic capacity after Au NPs decoration, photoluminescence (PL) spectra and photoelectrochemical measurements were carried out. Finally, the possible mechanism of charge transfer and the photocatalytic process for TiO2 NRAs/CdS/Au was proposed.

Results and Discussion

The XRD patterns of TiO2 NRAs/CdS decorated with different amounts of Au NPs are shown in Fig. 1(a). It can be observed that all the samples exhibit diffraction peaks centered at 2θ = 36.078°, 62.750°, 69.010° and 69.795°, indicating the presence of rutile TiO2 (PDF No. 21-1276). Characteristic peaks for CdS are not found in the XRD patterns, which may be due to the well dispersion and low concentration of CdS. After the deposition of Au NPs, a not very sharp peak at 2θ = 44.393° is present, belonging to Au NPs (PDF No. 04-0784). The diffraction peak of Au is very broad, which may indicate its small particle size. It is reported that when the grain size of the material is less than 10 nm, the diffraction peaks in the XRD patterns will be significantly broadened32. The particle size of Au NPs will be confirmed in the following TEM characterization. Other peaks marked by triangles in the XRD patterns are all from the transparent Fluorine-doped tin oxide glass (FTO) substrate (PDF No. 46-1088).

To further confirm the phase composition of the samples, Raman spectra were carried out as displayed in Fig. 1(b). The peaks at ~241.4 cm−1, ~445.6 cm−1 and ~609.5 cm−1 are three characteristic Raman active modes of rutile TiO2 33, which is in accordance with the XRD patterns. The peak at ~302 cm−1 is resulted from the first order scattering of the longitudinal optical phonon mode generated by CdS34, 35, thus it can be proved that CdS is one of the components in the as-prepared samples. The peak at 117 cm−1 is caused by plasma emission of the Ar+ laser in the characterization36.

SEM images of the as-prepared samples are shown in Fig. 2. The morphology of the bare TiO2 NRAs has been characterized by SEM in our previous work37. TiO2 nanorods uniformly grow on the FTO substrate and the typical nanorod is 2.2 μm in length and 60 nm to 120 nm in diameter. After 15 cycles of CdS deposition, big CdS NPs are accumulated on the top of the TiO2 NRAs as shown in Fig. 2(a). By comparing the SEM images in Fig. 2(a,c and e), there is no recognizable change in the surface morphology of the TiO2 NRAs/CdS before and after Au NPs decoration, which may suggest the small particle size and low content of Au NPs. It is hard to discern the CdS distribution along the nanorod from the SEM images, which will be further clarified in the following TEM characterization. The nanorod length in all samples is ca. 2.2 μm according to the cross-section images inset, corresponding with that of the bare TiO2 NRAs as reported in our previous work37. To reveal the different amounts of Au NPs among the samples, energy dispersive X-ray spectrum (EDS) analysis was carried out for the areas corresponding to Fig. 2(a,c and e). From the EDS result, it can be observed that the Au weight ratio is from 0 to ~2.21 when the deposition time increased from 0 s to 60 s, which indicates that more Au NPs were loaded on TiO2 NRAs/CdS. However, the content of Au NPs is still very low even in the TiO2 NRAs/CdS/Au (60 s) sample.

To further clarify the microstructure of TiO2 NRAs/CdS/Au, TEM characterization was carried out. Figure 3(a and b) show the morphology of the binary TiO2 NRAs/CdS. It can be seen that the TiO2 nanorod is covered with a thin layer made of CdS NPs. After ion sputtering Au NPs for 30 s, small Au NPs are dispersed in the relatively large CdS nanocrystals in Fig. 3(c and d). The high resolution TEM in Fig. 3(d) exhibits that the diameters of Au NPs are no more than 5 nm, and a considerable portion are even less than 3 nm. Increasing the ion sputtering time to 60 s, Au NPs grow bigger according to Fig. 3(e and f). Most grow to about 5 nm in diameter, causing some agglomerations. The size distributions of Au NPs in TiO2 NRAs/CdS/Au (30 s) and TiO2 NRAs/CdS/Au (60 s) were counted as shown in Fig. S1. The average particle size for TiO2 NRAs/CdS/Au (30 s) and TiO2 NRAs/CdS/Au (60 s) is 3.41 nm and 4.60 nm, respectively, indicating that Au NPs grow bigger with increase in ion sputtering time. The inserted picture in Fig. 3(e) is the TEM mapping of Au NPs corresponding to the region marked by the red rectangle. It can be seen that Au NPs are not uniformly dispersed in the sample, because they were deposited from the top to the bottom along the nanorod. The distributions of Ti, O, Cd and S in the specific portion selected for the mapping study are displayed in Fig. S2, which are all distributed evenly.

UV-vis spectra of the as-prepared samples are shown in Fig. 4. There is no obvious change in the visible light absorption of TiO2 NRAs/CdS after Au NPs decoration. The tiny differences in the absorption curves should attribute to the differences of the FTO substrates. It is strange that no plasma resonance absorption occurred after Au NPs decoration, which may be for the small particle size and the low distribution density of Au NPs as shown in the TEM images. Similar to the result in our experiment, it is reported that Au NPs with the diameter below 3 nm in toluene did not exhibit plasma resonance absorption, either38. In order to exclude the plasma resonance absorption from Au to be overwhelmed by the strong adsorption of CdS layer, we recorded the UV-vis absorption of Au NPs decorated TiO2 NRAs. As shown in Fig. S3, without the interference of CdS, TiO2 NRAs/Au (30 s) and TiO2 NRAs/Au (60 s) displayed no plasma resonance absorption, either, which demonstrated that Au NPs loaded on the surface of TiO2 NRAs/CdS truly did not cause the plasma resonance effect in our experiment.

Figure 5(a) shows the photocatalytic performance of TiO2 NRAs/CdS/Au evaluated by the degradation of UDMH wastewater under visible light irradiation. As a comparison, UDMH degradations were also carried out without the addition of any photocatalyst and in the existence of TiO2 NRAs/CdS. Visible light irradiation for 180 min can only get about 2% degradation of UDMH, while the photodegradation rate of UDMH by TiO2 NRAs/CdS reaches 36.77% under the same condition. When employing TiO2 NRAs/CdS/Au as the photocatalyst, apparent enhancement of the photodegradation rates can be observed. By increasing the deposition time of Au NPs from 0 s to 30 s, the photodegradation rate of UDMH is improved moderately from 36.77% to 51.51%. And a 0.4 time increase was achieved by TiO2 NRAs/CdS/Au (30 s) compared with TiO2 NRAs/CdS. Au NPs, as electron sinks, can effectively retard the recombination of photogenerated electron-hole pairs by extracting electrons from CdS. Moreover, the small Au NPs provides huge specific surface area, therefore, electrons have a bigger chance to be trapped by dissolved oxygen and more ·O2 − with strong oxidizing property will be produced. The synergy effects contribute to the improved photocatalytic performance of TiO2 NRAs/CdS/Au (≤30 s). However, the photocatalytic performance deteriorates when continually increasing the deposition time (≥40 s). TiO2 NRAs/CdS/Au (60 s) can only obtain 31.52% degradation of UDMH. When more Au NPs are loaded (≥40 s), it reduces the active surface area in CdS, therefore, the generation of photoelectrons and holes in CdS and the UDMH molecular absorption will be hindered. In addition, the agglomeration of Au NPs aggravates with the increase of the deposition time, acting as recombination centers for carriers39,40,41. As a result, the photocatalytic property declines when overloading of Au NPs (≥40 s). In summary, it is of importance to optimize the amount of Au NPs to obtain an ideal photocatalytic capacity.

The cycling durability of the samples before and after Au NPs decoration was carried out under visible light irradiation and each cycle was conducted for 180 min. As shown in Fig. 5(b), the photodegradation rate of UDMH over TiO2 NRAs/CdS is found to be about 36.77% (once), 31.69% (twice) and 22.63% (third times), respectively, while it is 51.51% (once), 51.03% (twice) and 49.38% (third times) over TiO2 NRAs/CdS/Au (30 s). One can see that the introduction of Au NPs can significantly enhance the photocatalytic stability of TiO2 NRAs/CdS. The cycling stability of the ternary TiO2 NRAs/CdS/Au can maintain 95.86% after three cycles, much higher than 61.54% of the binary TiO2 NRAs/CdS.

To clarify the underlying mechanism for the enhanced photocatalytic capacity of TiO2 NRAs/CdS/Au, PL spectra, photocurrent density versus potential (I-V) and photocurrent density versus time (I-T) curves were measured.

PL spectra of the TiO2 NRAs/CdS/Au are shown in Fig. 6. The peak located at ~425 nm can be ascribed to the self-trapped excitons in TiO2 42. The other one at ~530 nm can be corresponding to the defects forming at the surface of TiO2 NRAs/CdS/Au42,43,44. PL intensity can reflect the separation efficiency of carriers45. Stronger intensity in PL peaks indicates higher recombination rates of carriers46. As we expected, the PL intensity for TiO2 NRAs/CdS/Au decays gradually with the increase in the deposition time (≤30 s), indicating more effective separation of photogenerated hole–electron pairs, thus contributing the enhanced photocatalytic activity for TiO2 NRAs/CdS/Au (≤30 s). When longer deposition time is conducted (≥40 s), the PL intensity for TiO2 NRAs/CdS/Au becomes stronger, suggesting that the separation of photogenerated electrons and holes get worse due to the agglomerated Au NPs as recombination centers. Therefore, the photocatalytic degradation rate began to decrease when the deposition time for Au NPs was more than 30 s.

I-V characteristics of TiO2 NRAs/CdS/Au are shown in Fig. 7(a). Photocurrent densities can be neglected for all samples without visible light irradiation. And the photocurrent density of TiO2 NRAs/CdS/Au decreases gradually with the increase of Au NPs under visible light irradiation. In addition, the open circuit potential (Voc) of the ternary TiO2 NRAs/CdS/Au becomes more positive compared with that of the binary TiO2 NRAs/CdS. More Au NPs deposited makes the Voc more positive. Figure 7(b) plots I-T characteristics of TiO2 NRAs/CdS/Au samples. All films exhibit a quick response to the on/off of the incident light. Under visible light irradiation, the photocurrent density descending trend for TiO2 NRAs/CdS/Au is in accordance with that in the I-V characteristics. It is strange that TiO2 NRAs/CdS/Au in our experiment displayed improved photocatalytic performance while deteriorative photoelectrochemcial property. According to previous reports, better photocatalytic performance is usually correlated with higher photocurrent density and more negative change of Voc47,48,49. To exclude the abnormal photoelectrochemcial property in our experiment was interfered by the difference in CdS among different samples, I-V curves of four TiO2 NRAs/CdS samples, which were prepared by the same method, were recorded in Fig. S4. It can be seen that the difference between the photocurrent densities is not significant. Error bars (inset in Fig. S4) were plotted by selecting statistics at −0.1 V, −0.2 V, −0.3 V, −0.4 V, −0.5 V, −0.6 V, −0.7 V and −0.8 V in the I-V characterization, whose errors are confined to about 0.2 mA/cm2. While as shown in Fig. 7(a), the photocurrent density difference between TiO2 NRAs/CdS and TiO2 NRAs/CdS decorated with different amounts of Au nanoparticles is obviously greater than 0.2 mA/cm2. It indicates that the abnormal phenomenon of the photocurrent density in Fig. 7 is not caused by the difference in CdS among different samples, rather, Au NPs should be responsible for it by extracting electrons from CdS. The following section will discuss the reason for the abnormal phenomenon in details.

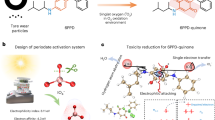

Based on the results in our experiment as well as previous literatures43, 50,51,52, the possible schematic of carriers transfer and degradation of UDMH process for TiO2 NRAs/CdS/Au is shown in Fig. 8. Under visible light irradiation, only CdS can be excited to generate electron and hole pairs. Since the Fermi energetic level of Au and the conduction band (CB) of TiO2 are both lower than the CB of CdS38, 53 as displayed in Fig. 8, electrons in the CB of CdS will transfer along two directions, i.e. to the Au NPs and to the CB of TiO2. And electrons in the CB of CdS seems to flow into Au NPs more easily, because the Fermi energetic level of Au is lower than the CB of TiO2 38, 53. Meanwhile, a Schottky barrier at the interface of Au-CdS will be formed39, which can prevent the electrons flow back to CdS from Au NPs. Due to Au NPs extracting electrons from CdS, it should be noted that fewer electrons will be transferred to the CB of TiO2 in the ternary TiO2 NRAs/CdS/Au compared with that in the binary TiO2 NRAs/CdS. Therefore, fewer electrons will be transferred to the external circuit from TiO2, leading to the decreased photocurrent density in the ternary TiO2 NRAs/CdS/Au. It is reported that the electrons accumulated in the CB of TiO2 lead to the negative shift of the Fermi level38. If fewer electrons are accumulated in TiO2, we would expect a less negative shift of the Fermi level. So is the same with the Fermi level of TiO2 NRAs/CdS/Au, which will have a less negative shift compared with that of TiO2 NRAs/CdS. Accordingly, the Fermi level can be used to compare the Voc38, therefore, the Voc in the ternary TiO2 NRAs/CdS/Au will have a less negative shift than that in the binary TiO2 NRAs/CdS, i.e., the Voc will be more positive in the ternary TiO2 NRAs/CdS/Au than in the binary TiO2 NRAs/CdS. This abnormal photoelectrochemical results indicate that the TiO2-CdS-Au structure in our research is not helpful in energy output by converting solar energy.

Through aforementioned charge transfer process, the excited electron-hole pairs in CdS could be effectively separated. The electrons transferred to Au NPs and the CB of TiO2 could be trapped by dissolved oxygen molecules and then superoxide radical anions (·O2 −) are generated54. ·O2 − could further react with electrons to form highly reactive hydroxyl radicals (·OH)55. The positive holes in the VB of CdS can oxide OH− in the aqueous solution to yield ·OH56. ·O2 −, ·OH and holes are all strong oxidizing free radicals, which can degrade UDMH into final products.

Conclusion

In summary, we proposed a TiO2 NRAs/CdS/Au nanostructure that Au NPs, as the outermost layer, were loaded on the surface of TiO2 NRAs decorated by a thin layer of CdS. Due to the small particle size and the low distribution density, Au NPs could not cause obvious surface plasma resonance effect, therefore, the visible light absorption of TiO2 NRAs/CdS/Au was not improved. Rather, the deposited Au NPs working as electron sinks to extract electrons from CdS and accelerate the charge separation. As such, the ternary TiO2 NRAs/CdS/Au exhibits enhanced visible light photocatalytic ability. The best photocatalytic degradation rate of UDMH is obtained by the TiO2 NRAs/CdS/Au (30 s) sample, which is 1.4 times that by the binary TiO2 NRAs/CdS. The cycling stability of TiO2 NRAs/CdS is greatly improved after Au NPs decoration, whose photocatalytic capacity can maintain 95.86% after three cycles. An unexpected finding is that this structure is not conducive to the conversion of solar energy to electric energy owing to the Schottky barrier at the interface of the Au-CdS. This work may provide valuable preference in rational design of energy- and environment-related photocatalysts.

Methods

Sample preparation

Hydrothermal method was employed to grow vertically orientated TiO2 NRAs on FTO substrates (area 4.5 cm2). The detailed procedure is the same with our previous work37.

CdS NPs were successfully deposited on TiO2 nanorods through a Successive Ionic Layer Adsorption and Reaction (SILAR) method based on our previous work31. The TiO2 NRAs decorated by CdS NPs through 15 cycles of SILAR is chosen as the subject in this manuscript, which has been proved to achieve the best photocatalytic performance.

Au NPs were deposited on the surface of TiO2 NRAs/CdS films by ion sputtering (EMITECH, K550X). Through controlling the sputtering time, different amounts of Au NPs can be obtained.

Characterization

X-ray diffraction (XRD, PANalytical) with Cu-Kα (λ = 0.15401 nm) radiation (40 kV, 40 mA) was collected to characterize the structure and crystallinity of the samples. The scanning speed of 5° min−1 was operated in a 2θ range of 20–80°. Raman spectra were measured to further clarify the composition of the samples using Ar+ (532 nm) laser excitation. Scanning electron microscopy (SEM) images were recorded on VEDAIIXMUINCN, and its energy dispersive X-ray spectroscopy (EDS) system was used to test the elementary composition. The microstructures of TiO2 NRAs/CdS/Au were studied by transmission electron microscopy (TEM) using a JEM-2100F transmission electron microscopy. The UV-vis absorption spectra were performed on a UV 1800 spectrophotometer (Shimadzu) with an FTO substrate as a blank. A Fluoromax-4 spectrophotometer was employed to record the photoluminescence (PL) spectra for samples with excitation wavelength at 350 nm.

Photocurrent curves were obtained under solar-simulated (AM 1.5 G filtered, 100 mW/cm2, CEL-HXF300) light source with a UV cutoff filter (providing visible light with λ ≥ 420 nm). A three-electrode configuration was used in a 250 mL quartz cell, including the prepared sample as the working electrode, a Pt foil as the counter electrode and a saturated Ag/AgCl as the reference electrode. Na2S aqueous solution (0.1 M) was used as the electrolyte. The working electrode was illuminated within an area of about 1.5 cm2 at zero bias voltage versus the Ag/AgCl electrode.

Photocatalytic degradation of UDMH

Under visible light irradiation (λ ≥ 420 nm), the degradation of UDMH aqueous solution was carried out in an open reactor, which was placed in circulating cooling water with the temperature of 4 °C. The TiO2 NRAs/CdS/Au film with an area about 6 cm2 was used as the photocatalyst. During the photodegradation process, the concentration of UDMH left in the aqueous was measured by spectrophotometry every 30 min. Before measurement, UDMH should first react with amino ferrocyanide sodium in a weakly acidic aqueous solution, and a red complex was formed with its maximum absorbance at 500 nm. The color depth of the red complex is proportional to the content of UDMH. Therefore, the concentration of UDMH left in the aqueous can be obtained by measuring the red complex. Detailed procedures for the photocatalytic degradation and the measurement of UDMH have been reported in our previous study31.

References

Hwang, Y. J., Hahn, C., Liu, B. & Yang, P. Photoelectrochemical properties of TiO2 nanowire arrays: a study of the dependence on length and atomic layer deposition coating. ACS Nano 6, 5060–5069 (2012).

Tao, J. et al. Enhanced photocatalytic and photoelectrochemical properties of TiO2 nanorod arrays sensitized with CdS nanoplates. Ceramics International 42, 11716–11723 (2016).

Wang, H., You, T., Shi, W., Li, J. & Guo, L. Au/TiO2/Au as a Plasmonic Coupling Photocatalyst. Journal of Physical Chemistry C 116, 6490–6494 (2012).

Wang, M., Ioccozia, J., Sun, L., Lin, C. & Lin, Z. Inorganic-modified semiconductor TiO2 nanotube arrays for photocatalysis. Energy & Environmental Science 7, 2182–2202 (2014).

Pan, J. et al. Construction of Mn0.5Zn0.5Fe2O4 modified TiO2 nanotube array nanocomposite electrodes and their photoelectrocatalytic performance in the degradation of 2,4-DCP. Journal of Materials Chemistry C 3, 6025–6034 (2015).

Mangham, A. N. et al. Photochemical Properties, Composition, and Structure in Molecular Beam Epitaxy Grown Fe “Doped” and (Fe, N) Codoped Rutile TiO2(110). Journal of Physical Chemistry C 115 (2011).

Vaiano, V. et al. Enhanced visible light photocatalytic activity by up-conversion phosphors modified N-doped TiO2. Applied Catalysis B Environmental 176–177, 594–600 (2015).

Li, Y., Xiang, Y., Peng, S., Wang, X. & Zhou, L. Modification of Zr-doped titania nanotube arrays by urea pyrolysis for enhanced visible-light photoelectrochemical H2 generation. Electrochimica Acta 87, 794–800 (2013).

Chen, H., Chen, K. F., Lai, S. W., Dang, Z. & Peng, Y. P. Photoelectrochemical oxidation of azo dye and generation of hydrogen via C N co-doped TiO2 nanotube arrays. Separation & Purification Technology 146, 143–153 (2015).

Li, G. S., Zhang, D. Q. & Yu, J. C. A new visible-light photocatalyst: CdS quantum dots embedded mesoporous TiO2. Environmental Science & Technology 43, 7079–7085 (2009).

Li, Y., Wang, H. & Peng, S. Tunable Photodeposition of MoS2 onto a Composite of Reduced Graphene Oxide and CdS for Synergic Photocatalytic Hydrogen Generation. Journal of Physical Chemistry C 118, 19842–19848 (2014).

Li, Y., Hu, Y., Peng, S., Lu, G. & Li, S. Synthesis of CdS Nanorods by an Ethylenediamine Assisted Hydrothermal Method for Photocatalytic Hydrogen Evolution. Journal of Physical Chemistry C 113, 9352–9358 (2009).

Xie, Z. et al. Enhanced photoelectrochemical and photocatalytic performance of TiO2 nanorod arrays/CdS quantum dots by coating TiO2 through atomic layer deposition. Nano Energy 11, 400–408 (2014).

Peng, S., Huang, Y. & Li, Y. Rare earth doped TiO2-CdS and TiO2-CdS composites with improvement of photocatalytic hydrogen evolution under visible light irradiation. Materials Science in Semiconductor Processing 16, 62–69 (2013).

Hui, L., Xia, Z., Chen, J., Liang, L. & Xing, J. Constructing ternary CdS/reduced graphene oxide/TiO2 nanotube arrays hybrids for enhanced visible-light-driven photoelectrochemical and photocatalytic activity. Applied Catalysis B Environmental 168–169, 105–113 (2015).

Zhang, J., Xiao, F. X., Xiao, G. & Liu, B. Linker-assisted assembly of 1D TiO2 nanobelts/3D CdS nanospheres hybrid heterostructure as efficient visible light photocatalyst. Applied Catalysis A General 521, 50–56 (2016).

Yang, X. et al. Preparation of CdS/TiO2 nanotube arrays and the enhanced photocatalytic property. Ceramics International 42, 7192–7202 (2016).

Zhu, Y. et al. Visible light induced photocatalysis on CdS quantum dots decorated TiO2 nanotube arrays. Applied Catalysis A General 498, 159–166 (2015).

He, D. et al. Enhanced cyclability of CdS/TiO2 photocatalyst by stable interface structure. Superlattices & Microstructures 51, 799–808 (2012).

Huo, Y., Yang, X., Jian, Z. & Li, H. Highly active and stable CdS–TiO2 visible photocatalyst prepared by in situ sulfurization under supercritical conditions. Applied Catalysis B Environmental 106, 69–75 (2011).

Zhang, A. Y., Wang, W. K., Pei, D. N. & Yu, H. Q. Degradation of refractory pollutants under solar light irradiation by a robust and self-protected ZnO/CdS/TiO2 hybrid photocatalyst. Water Research 92, 78–86 (2016).

Sreethawong, T. & Yoshikawa, S. Comparative investigation on photocatalytic hydrogen evolution over Cu-, Pd-, and Au-loaded mesoporous TiO2 photocatalysts. Catalysis Communications 6, 661–668 (2005).

And, M. J., Levanon, H. & Kamat, P. V. Charge Distribution between UV-Irradiated TiO2 and Gold Nanoparticles: Determination of Shift in the Fermi Level. Nano Letters 3, 353–358 (2003).

Tada, H., Mitsui, T., Kiyonaga, T., Akita, T. & Tanaka, K. All-solid-state Z-scheme in CdS-Au-TiO2 three-component nanojunction system. Nature Materials 5, 782–786 (2006).

Fang, J. et al. Au@TiO2–CdS Ternary Nanostructures for Efficient Visible-Light-Driven Hydrogen Generation. Acs Applied Materials & Interfaces 5, 8088–8092 (2013).

Li, J. et al. Solar Hydrogen Generation by a CdS-Au-TiO2 Sandwich Nanorod Array Enhanced with Au Nanoparticle as Electron Relay and Plasmonic Photosensitizer. Journal of the American Chemical Society 136, 8438–8449 (2014).

Zarazua, I. et al. Effect of the electrophoretic deposition of Au NPs in the performance CdS QDs sensitized solar Cells. Electrochimica Acta 188, 710–717 (2015).

Nguyen, V. M., Cai, Q. & Grimes, C. A. Towards efficient visible-light active photocatalysts: CdS/Au sensitized TiO2 nanotube arrays. Journal of Colloid & Interface Science 483, 287–294 (2016).

Angaji, M. T. & Ghiaee, R. Cavitational decontamination of unsymmetrical dimethylhydrazine waste water. Journal of the Taiwan Institute of Chemical Engineers 49, 142–147 (2015).

Lunn, G. & Sansone, E. B. Oxidation of 1,1-dimethylhydrazine (UDMH) in aqueous solution with air and hydrogen peroxide. Chemosphere 29, 1577–1590 (1994).

Gao, X. et al. Photodegradation of Unsymmetrical Dimethylhydrazine by TiO2 Nanorod Arrays Decorated with CdS Nanoparticles Under Visible Light. Nanoscale research letters 11 (2016).

Zhu, Y. Characterization and Testing Technology of Nanomaterials. (Chemical Industry Press, 2006).

Ma, H. L. et al. Raman study of phase transformation of TiO2 rutile single crystal irradiated by infrared femtosecond laser. Applied Surface Science 253, 7497–7500 (2007).

Mali, S. S. et al. CdS-sensitized TiO2 nanocorals: hydrothermal synthesis, characterization, application. Photochemical & Photobiological Sciences Official Journal of the European Photochemistry Association & the European Society for Photobiology 10, 1652–1658 (2011).

Wang, Z. Q. et al. Direct synthesis and characterization of CdS nanobelts. Applied Physics Letters 89, 033102-033102-033103 (2006).

Robert, T. D., Laude, L. D., Geskin, V. M., Lazzaroni, R. & Gouttebaron, R. Micro-Raman spectroscopy study of surface transformations induced by excimer laser irradiation of TiO2. Thin Solid Films 440, 268–277 (2003).

Gao, X., Liu, X., Zhu, Z., Wang, X. & Xie, Z. Enhanced photoelectrochemical and photocatalytic behaviors of MFe2O4 (M = Ni, Co, Zn and Sr) modified TiO2 nanorod arrays. Scientific reports 6 (2016).

Subramanian, V., Wolf, E. E. & Kamat, P. V. Catalysis with TiO2/gold nanocomposites. Effect of metal particle size on the Fermi level equilibration. Journal of the American Chemical Society 126, 4943–4950 (2004).

Khan, M. R., Tan, W. C., Yousuf, A., Chowdhury, M. N. K. & Cheng, C. K. Schottky barrier and surface plasmonic resonance phenomena towards the photocatalytic reaction: study of their mechanisms to enhance photocatalytic activity. Catalysis Science & Technology 5, 2522–2531 (2015).

Colmenares, J. C., Aramendia, M. A., Marinas, A., Marinas, J. M. & Urbano, F. J. Synthesis, Characterization and Photocatalytic Activity of Different Metal-Doped Titania Systems. Applied Catalysis A General 306, 120–127 (2006).

Liu, S. X., Qu, Z. P., Han, X. W. & Sun, C. L. A mechanism for enhanced photocatalytic activity of silver-loaded titanium dioxide. Catalysis Today 9395, 877–884 (2004).

Shuang, S., Lv, R., Zheng, X. & Zhang, Z. Surface Plasmon Enhanced Photocatalysis of Au/Pt-decorated TiO2 Nanopillar Arrays. Scientific reports 6 (2016).

Chen, Q., Wu, S. & Xin, Y. Synthesis of Au–CuS–TiO2 nanobelts photocatalyst for efficient photocatalytic degradation of antibiotic oxytetracycline. Chemical Engineering Journal 302, 377–387 (2016).

PijushCh, D. & Ratan, D. Photoluminescence quenching in ligand free CdS nanocrystals due to silver doping along with two high energy surface states emission. Journal of Luminescence 183, 368–376 (2017).

Li, G. et al. Photoelectrocatalytic degradation of organic pollutants via a CdS quantum dots enhanced TiO2 nanotube array electrode under visible light irradiation. Nanoscale 5, 2118–2125 (2013).

Zhang, Y., Zhang, N., Tang, Z. R. & Xu, Y. J. Improving the photocatalytic performance of graphene-TiO2 nanocomposites via a combined strategy of decreasing defects of graphene and increasing interfacial contact. Physical Chemistry Chemical Physics 14, 9167–9175 (2012).

Xie, Z. et al. Enhanced photoelectrochemical properties of TiO2 nanorod arrays decorated with CdS nanoparticles. Science & Technology of Advanced Materials 15 (2014).

Yu, J., Dai, G. & Cheng, B. Effect of Crystallization Methods on Morphology and Photocatalytic Activity of Anodized TiO2 Nanotube Array Films. J. phys. chem. c 114, 19378–19385 (2010).

Pan, J. et al. Construction of Mn0.5Zn0.5Fe2O4 modified TiO2 nanotube array nanocomposite electrodes and their photoelectrocatalytic performance in the degradation of 2,4-DCP. J. mater. chem. c 3, 6025–6034 (2015).

Li, Y. F. et al. Mechanistic Study of Codoped Titania with Nonmetal and Metal Ions: A Case of C + Mo Codoped TiO2. ACS Catalysis 2, 391–398 (2012).

Liu, M. et al. Enhanced Photoactivity with Nanocluster-Grafted Titanium Dioxide Photocatalysts. ACS Nano 8, 7229–7238 (2014).

Rajkumar, K. et al. Visible-light-driven SnO2/TiO2 nanotube nanocomposite for textile effluent degradation. RSC Advances 5, 20424–20431 (2015).

Singh, R. & Pal, B. Highly enhanced photocatalytic activity of Au nanorod–CdS nanorod heterocomposites. Journal of Molecular Catalysis A Chemical 378, 246–254 (2013).

Ryu, J. & Choi, W. Effects of TiO2 surface modifications on photocatalytic oxidation of arsenite: the role of superoxides. Environmental Science & Technology 38, 2928–2933 (2004).

Jin, S. et al. Highly selective photocatalytic and sensing properties of 2D-ordered dome films of nano titania and nano Ag2+ doped titania. Journal of Materials Chemistry 22, 1469–1476 (2012).

Yatmaz, H. C., Akyol, A. & Bayramoglu, M. Kinetics of the Photocatalytic Decolorization of an Azo Reactive Dye in Aqueous ZnO Suspensions. Industrial & Engineering Chemistry Research 43, 6035–6039 (2004).

Acknowledgements

The authors are grateful to the financial support by China Postdoctoral Science Foundation (grant No. 2016M600084).

Author information

Authors and Affiliations

Contributions

X.G., X.L. and Z.X. designed the study. X.G. and Z.X. wrote the manuscript. X.G., Z.X., X.L., M.Z. and F.Z. performed the experiments, analyzed the data, and prepared figures. X.G., Z.X. and M.Z. revised the manuscript. Y.G. and Q.W. gave many suggestions during this work process. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gao, X., Liu, X., Zhu, Z. et al. Enhanced visible light photocatalytic performance of CdS sensitized TiO2 nanorod arrays decorated with Au nanoparticles as electron sinks. Sci Rep 7, 973 (2017). https://doi.org/10.1038/s41598-017-01124-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-01124-5

This article is cited by

-

The Construction of a ZnO/CdS Heterostructure with Synergistic Enhanced Effect in Photocatalytic and Self-Cleaning Performance

Journal of Electronic Materials (2021)

-

Influence of annealing temperature on microstructure and photoelectric properties of ternary CdSe@CdS@TiO2 core–shell heterojunctions

Journal of Solid State Electrochemistry (2019)

-

Graphitic Carbon Nitride as a New Sensitive Material for Electrochemical Determination of Trace Amounts of Tartrazine in Food Samples

Food Analytical Methods (2018)

-

Plasmon-Enhanced Photoelectrochemical Current and Hydrogen Production of (MoS2-TiO2)/Au Hybrids

Scientific Reports (2017)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.