Abstract

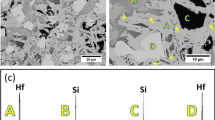

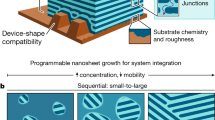

The conventional fabrication of bulk van der Waals (vdW) materials requires a temperature above 1,000 °C to sinter from the corresponding particulates. Here we report the near-room-temperature densification (for example, ∼45 °C for 10 min) of two-dimensional nanosheets to form strong bulk materials with a porosity of <0.1%, which are mechanically stronger than the conventionally made ones. The mechanistic study shows that the water-mediated activation of van der Waals interactions accounts for the strong and dense bulk materials. Initially, water adsorbed on two-dimensional nanosheets lubricates and promotes alignment. The subsequent extrusion closes the gaps between the aligned nanosheets and densifies them into strong bulk materials. Water extrusion also generates stresses that increase with moulding temperature, and too high a temperature causes intersheet misalignment; therefore, a near-room-temperature moulding process is favoured. This technique provides an energy-efficient alternative to design a wide range of dense bulk van der Waals materials with tailored compositions and properties.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All relevant data supporting the findings of this study are available in the Article and its Supplementary Information. All other data that support the findings of this study are available from the corresponding authors upon reasonable request. Source data are provided with this paper.

References

Liu, P. et al. Layered and scrolled nanocomposites with aligned semi-infinite graphene inclusions at the platelet limit. Science 353, 364–367 (2016).

Wei, T.-R. et al. Exceptional plasticity in the bulk single-crystalline van der Waals semiconductor InSe. Science 369, 542–545 (2020).

Mateti, S. et al. Bulk hexagonal boron nitride with a quasi-isotropic thermal conductivity. Adv. Funct. Mater. 28, 1707556 (2018).

Yeh, C. N. et al. Binder-free graphene oxide doughs. Nat. Commun. 10, 422 (2019).

Duan, X. et al. Effect of sintering pressure on the texture of hot-press sintered hexagonal boron nitride composite ceramics. Scr. Mater. 68, 104–107 (2013).

Eichler, J. & Lesniak, C. Boron nitride (BN) and BN composites for high-temperature applications. J. Eur. Ceram. Soc. 28, 1105–1109 (2008).

Steinborn, C. et al. Correlation between microstructure and electrical resistivity of hexagonal boron nitride ceramics. J. Eur. Ceram. Soc. 33, 1225–1235 (2013).

Nieto, A., Lahiri, D. & Agarwal, A. Synthesis and properties of bulk graphene nanoplatelets consolidated by spark plasma sintering. Carbon 50, 4068–4077 (2012).

Yang, H. et al. Low temperature self-densification of high strength bulk hexagonal boron nitride. Nat. Commun. 10, 854 (2019).

Kang, S.-J. L. Sintering: Densification, Grain Growth and Microstructure (Butterworth-Heinemann, 2004).

Wen, G., Wu, G., Lei, T., Zhou, Y. & Guo, Z. Co-enhanced SiO2-BN ceramics for high-temperature dielectric applications. J. Eur. Ceram. Soc. 20, 1923–1928 (2000).

Guo, J. et al. Cold sintering: a paradigm shift for processing and integration of ceramics. Angew. Chem. Int. Ed. 55, 11457–11461 (2016).

Sengul, M. Y., Guo, J., Randall, C. A. & van Duin, A. C. T. Water-mediated surface diffusion mechanism enables the cold sintering process: a combined computational and experimental study. Angew. Chem. Int. Ed. 58, 12420–12424 (2019).

Coleman, J. N. et al. Two-dimensional nanosheets produced by liquid exfoliation of layered materials. Science 331, 568–571 (2011).

Zhang, C. et al. Controllable Co-segregation synthesis of wafer-scale hexagonal boron nitride thin films. Adv. Mater. 26, 1776–1781 (2014).

Geim, A. K. & Grigorieva, I. V. Van der Waals heterostructures. Nature 499, 419–425 (2013).

Liu, Y., Huang, Y. & Duan, X. Van der Waals integration before and beyond two-dimensional materials. Nature 567, 323–333 (2019).

Zhao, B. et al. High-order superlattices by rolling up van der Waals heterostructures. Nature 591, 385–390 (2021).

Tzenov, N. V. & Barsoum, M. W. Synthesis and characterization of Ti3AlC2. J. Am. Ceram. Soc. 83, 825–832 (2000).

Inagaki, M., Kang, F., Toyoda, M. & Konno, H. Advanced Materials Science and Engineering of Carbon (Butterworth-Heinemann, 2014).

Wan, S. et al. High-strength scalable MXene films through bridging-induced densification. Science 374, 96–99 (2021).

Okuma, G. et al. 3D multiscale-imaging of processing-induced defects formed during sintering of hierarchical powder packings. Sci. Rep. 9, 11595 (2019).

Lei, W. et al. Boron nitride colloidal solutions, ultralight aerogels and freestanding membranes through one-step exfoliation and functionalization. Nat. Commun. 6, 8849 (2015).

Wan, S. et al. High-strength scalable graphene sheets by freezing stretch-induced alignment. Nat. Mater. 20, 624–631 (2021).

Zhang, Z. et al. Texture and anisotropy of hot-pressed h-BN matrix composite ceramics with in situ formed YAG. J. Adv. Ceram. 11, 532–544 (2022).

Xue, J. X., Liu, J. X., Xie, B. H. & Zhang, G. J. Pressure-induced preferential grain growth, texture development and anisotropic properties of hot pressed hexagonal boron nitride ceramics. Scr. Mater. 65, 966–969 (2011).

Chen, C. et al. Functionalized boron nitride membranes with ultrafast solvent transport performance for molecular separation. Nat. Commun. 9, 1902 (2018).

Li, P. et al. Continuous crystalline graphene papers with gigapascal strength by intercalation modulated plasticization. Nat. Commun. 11, 2645 (2020).

Hermans, J., Hermans, P., Vermaas, D. & Weidinger, A. Quantitative evaluation of orientation in cellulose fibres from the X-ray fibre diagram. Recl. Trav. Chim. Pays-Bas 65, 427–447 (1946).

Zhai, F. R., Lu, M., Shan, K., Yi, Z. Z. & Xie, Z. P. Spark plasma sintering and characterization of mixed h-BN powders with different grain sizes. Solid State Phenom. 281, 414–419 (2018).

Wu, Y. et al. The rise of plastic deformation in boron nitride ceramics. Sci. China Mater. 64, 46–51 (2021).

Menig, R., Meyers, M., Meyers, M. & Vecchio, K. Quasi-static and dynamic mechanical response of Haliotis rufescens (abalone) shells. Acta Mater. 48, 2383–2398 (2000).

Lin, K. et al. Nanoburl graphites. Adv. Mater. 33, 2007513 (2021).

Falin, A. et al. Mechanical properties of atomically thin boron nitride and the role of interlayer interactions. Nat. Commun. 8, 15815 (2017).

Han, E. et al. Ultrasoft slip-mediated bending in few-layer graphene. Nat. Mater. 19, 305–309 (2020).

Briscoe, W. H. et al. Boundary lubrication under water. Nature 444, 191–194 (2006).

Panman, M. R. et al. Water lubricates hydrogen-bonded molecular machines. Nat. Chem. 5, 929–934 (2013).

Lee, W.-C. et al. Enhanced water evaporation from Å-scale graphene nanopores. ACS Nano 16, 15382–15396 (2022).

Li, Y., Alibakhshi, M. A., Zhao, Y. & Duan, C. Exploring ultimate water capillary evaporation in nanoscale conduits. Nano Lett. 17, 4813–4819 (2017).

Secchi, E. et al. Massive radius-dependent flow slippage in carbon nanotubes. Nature 537, 210–213 (2016).

Tocci, G., Bilichenko, M., Joly, L. & Iannuzzi, M. Ab initio nanofluidics: disentangling the role of the energy landscape and of density correlations on liquid/solid friction. Nanoscale 12, 10994–11000 (2020).

Keerthi, A. et al. Water friction in nanofluidic channels made from two-dimensional crystals. Nat. Commun. 12, 3092 (2021).

Chen, K. et al. Graphene oxide bulk material reinforced by heterophase platelets with multiscale interface crosslinking. Nat. Mater. 21, 1121–1129 (2022).

Zhang, X. et al. Ultrathick and highly thermally conductive graphene films by self-fusion. Carbon 167, 249–255 (2020).

Klobčar, D., Kosec, L., Kosec, B. & Tušek, J. Thermo fatigue cracking of die casting dies. Eng. Fail. Anal. 20, 43–53 (2012).

Bickerton, S. & Abdullah, M. Z. Modeling and evaluation of the filling stage of injection/compression moulding. Comp. Sci. Technol. 63, 1359–1375 (2003).

Kusunose, T. & Sekino, T. Thermal conductivity of hot-pressed hexagonal boron nitride. Scr. Mater. 124, 138–141 (2016).

Xu, L. et al. A malleable composite dough with well-dispersed and high-content boron nitride nanosheets. ACS Nano 17, 4886–4895 (2023).

Guerra, V., Wan, C. & McNally, T. Thermal conductivity of 2D nano-structured boron nitride (BN) and its composites with polymers. Prog. Mater. Sci. 100, 170–186 (2019).

Han, J., Du, G., Gao, W. & Bai, H. An anisotropically high thermal conductive boron nitride/epoxy composite based on nacre-mimetic 3D network. Adv. Funct. Mater. 29, 1900412 (2019).

Zhi, C., Bando, Y., Tang, C., Kuwahara, H. & Golberg, D. Large-scale fabrication of boron nitride nanosheets and their utilization in polymeric composites with improved thermal and mechanical properties. Adv. Mater. 21, 2889–2893 (2009).

Rasul, M. G., Kiziltas, A., Arfaei, B. & Shahbazian-Yassar, R. 2D boron nitride nanosheets for polymer composite materials. npj 2D Mater. Appl. 5, 56 (2021).

Buttay, C. et al. State of the art of high temperature power electronics. Mater. Sci. Eng. B 176, 283–288 (2011).

Loeblein, M. et al. High-density 3D-boron nitride and 3D-graphene for high-performance nano-thermal interface material. ACS Nano 11, 2033–2044 (2017).

Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995).

Weismiller, M. R., Van Duin, A. C., Lee, J. & Yetter, R. A. ReaxFF reactive force field development and applications for molecular dynamics simulations of ammonia borane dehydrogenation and combustion. J. Phys. Chem. A 114, 5485–5492 (2010).

Senftle, T. P. et al. The ReaxFF reactive force-field: development, applications and future directions. npj Comput. Mater. 2, 15011 (2016).

Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO—the Open Visualization Tool. Model. Simul. Mat. Sci. Eng. 18, 015012 (2009).

Verma, A., Zhang, W. & van Duin, A. C. T. ReaxFF reactive molecular dynamics simulations to study the interfacial dynamics between defective h-BN nanosheets and water nanodroplets. Phys. Chem. Chem. Phys. 23, 10822–10834 (2021).

Acknowledgements

This research was primarily supported by the National Key Research and Development Program of China (no. 2022YFA1205300 to Y.S.), the National Natural Science Foundation of China (no. 52188101 to H.-M.C. and no. 12232016 to H.W.), the Young Scientist Fund of the National Natural Science Foundation of China (no. 52102363 to J.Z.), the Scientific Research Start-up Funds of Tsinghua SIGS (QD2021026C to Y.S.), Peacock Team project (KQTD20210811090112002 to Y.S.) and Shenzhen Geim Graphene Center. F.W. acknowledges the support from the Youth Innovation Promotion Association CAS (no. 2020449). The numerical calculations were performed on the supercomputing system in the Hefei Advanced Computing Center.

Author information

Authors and Affiliations

Contributions

Y.S., H.-M.C. and J.Z. conceived the idea and supervised the project. Y.S., J.Z. and F.L. designed and performed the experiments and analysed the results. H.L. and D.X. performed the moulding of bulk graphite from rGO nanosheets. J.T. performed the transmission electron microscopy examination. J.D. helped with the compression tests. S.W. performed the nano-CT measurements; Z.L. performed the focused ion beam measurements; and Y.H., F.W. and H.W. performed the MD simulation. All authors analysed the data. Y.S., J.Z. and H.-M.C. wrote the paper with input from all authors.

Corresponding authors

Ethics declarations

Competing interests

J.Z., Y.S. and H.-M.C. report a Chinese patent (CN113929430A). The other authors declare no competing interests.

Peer review

Peer review information

Nature Materials thanks Adri Van Duin, Chong Rae Park and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Sections 1–9, Figs. 1–9, Tables 1 and 2 and Discussion.

Supplementary Video 1

Mechanically strong densified bulk hBN.

Source data

Source Data Fig. 2

Source data for Fig. 2.

Source Data Fig. 3

Source data for Fig. 3.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhu, J., Li, F., Hou, Y. et al. Near-room-temperature water-mediated densification of bulk van der Waals materials from their nanosheets. Nat. Mater. (2024). https://doi.org/10.1038/s41563-024-01840-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41563-024-01840-0