Abstract

One important goal of the current Fenton-like catalysts is to develop highly efficient and pH-universal catalysts that can operate with little performance degradation over multiple recycles. Herein, we report a ternary MoCoB metallic glass (MG) microwire catalyst, which shows exceptional Fenton-like activity for degrading various dyes in a wide pH range (5–10). Moreover, the MoCoB MG catalyst with an ultrahigh glass-transition temperature of 1002 K exhibits excellent reusability and can be used for more than 46 times without a decay in efficiency. It is regarded that the excellent catalytic activity and sustainability of the MoCoB MG catalyst originates from the bimetallic effect involving Mon/Mon+1 and Con+1/Con cycling, which accelerates the electronic transfer kinetics, enabling the generation of multiple reactive oxygen species (•OH and •O2-). First-Principles Calculations revealed again that MG catalysts provide a large electron base for the whole catalytic process.

Similar content being viewed by others

Introduction

Metallic glasses (MGs) exhibit excellent physical and chemical properties due to their atomic disordering arrangement and metastability1. MGs with simultaneously high catalytic activity and unique selectivity have emerged as a kind of competitive candidate catalyst for hydrogen evolution reaction (HER)2,3, and oxygen evolution reaction (OER)4, etc. Especially, their excellent catalytic performance in wastewater treatment has attracted increasing attention in recent years5,6,7. For example, the degradation efficiency of Fe73Si7B17Nb3 MG powders for Direct Blue 6 is 200 times higher than that of commercial iron powder8. The degradation efficiency of Fe78Si9B13 and Fe73.5Si13.5B9Cu1Nb3 MG ribbons is 5–10 times higher than that of their crystalline counterparts9. Beside Fe-based MG system, other MG systems (including Mg-based, Co-based) with high degradation efficiency have also been developed.

Although MGs have shown high catalytic activity in degrading dying wastewater, they still face several challenges and drawbacks. Firstly, most of the MG catalysts reported so far are mainly in the forms of ribbons, the small specific surface area of which usually limits their reactivity10,11,12. Secondly, a trade-off between the catalytic activity and long-term stability remains, that is, the active MG catalysts are not chemically stable while those stable MGs have low catalytic activity. This dilemma typically results in a limited reusability (normally <35 times13). For instance, the catalytic process of the FeSiB MG is always accompanied with surface aging and corrosion, resulting in progressively decreased catalytic efficiency and reaction rate constant (kobs) decreases progressively with the number of cycles14,15. Furthermore, most MGs can only degrade dyes in a narrow pH ranges (2–3.5), and a small change in pH value will cause drastic decay in the degradation rate16,17,18. Although some MG catalyst has been reported to be operate in a wide pH range, the degradation efficiency is actually extremely slow, e.g., the complete degradation of a Direct Blue 2B requires more than 100 h19. Since the industry applications usually involve with neutral or alkaline condition, it is necessary to develop highly reusable, efficient, and pH-universal MG catalysts.

In this work, we demonstrate that a ternary MoCoB MG microwire can be a highly active and stable catalysts for Fenton-like reactions. We found the Mo51Co34B15 MG can exhibit high degradation efficiency towards various dying wastewater within a wide pH range (5–10), and shows negligible degradation after operation for 45 times. We attribute the notable catalytic performance of this Mo51Co34B15 MG to Crystal Violet (CV) dye, as well as the large specific surface area of microwires.

Results and discussion

Synthesis of MoCoB MG microwire and their characterization

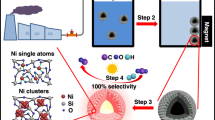

Figure 1a shows a schematic diagram of designing and preparing MG microwire using melt-spinning techniques, raising the micro-sized tube to bring the metal liquid contacted with the edge of the sharp copper rod. The as-fabricated MG wires can be seen in Fig. 1b, and the surface of the prepared Mo51Co34B15 MG microwire is very smooth, as shown in Fig. 1c. The XRD pattern in Fig. 1d exhibits a broad diffuse scattering peak of 43°, without obvious crystalline peaks, indicating the fully amorphous structure within the resolution limit of XRD. The DTA curve shown in Fig. 1e shows that the Mo51Co34B15 MG wires have an obvious glass transition and multi-step crystallization reaction, which further confirms its amorphous nature20,21. It should be noted that the present Mo51Co34B15 MG catalyst exhibits an ultra-high glass transition temperature Tg (1002 K) and crystallization temperature Tx (1070 K), which is far higher than those of FeSiB MG catalysts (Tg = 693 K)22. The excellent thermal stability could endow the MG with long-term stability and reusability under harsh (e.g., high-temperature) wastewater treatment conditions. The specific surface area (SSA) of the MG microwires catalyst is 5.9 m2/g (Fig. 1f), which is 1–2 orders of magnitude higher than that of most reported MG ribbons23. The high SSA is beneficial for exposing more abundant active sites for catalytic reactions.

Catalytic performance

The catalytic performance of the Mo51Co34B15 MG wire catalysts was assessed via degradation of CV solutions (a typical triarylmethane dye in industry). It is found that the current MoCoB MG wires show superior catalytic activity than the typical FeSiB MG ribbons (Fig. 2a), the MoCoB catalysts achieved 99% degradation of the CV solution within 20 min, whereas the latter was only 50%. The degradation reaction follows the pseudo-first-order kinetic model, kobs can be obtained from Eq. (1)

where C0 is the initial concentration of dye, Ct is the concentration at t, and t is the reaction time. The calculated kobs value of Mo51Co34B15 is about 7 times higher than that of Fe78Si9B13, again indicating the excellent degradation performance of the current catalyst. To verify the versatility of the microwire catalysis, three typical dyes of Crystal Violet, Malachite Green and Direct Blue 6 were selected for degradation experiments. As shown in Fig. 2b, Crystal Violet and Direct Blue 6 could be completely removed by the MoCoB wire catalyst within 15 min, and Malachite Green become completely colorless within 10 min. Interestingly, we find that, in our sample of MoCoB MG wire exhibits excellent adaptability to pH changes. It achieves complete degradation of most acidic and alkaline solutions, with a rapid and effective degradation at pH 5–10 (Fig. 2c). This greatly breaks the pH limitation of metallic glasses for dyes degradation and can effectively address the critical issue of degradation under alkaline conditions24,25. Interestingly, unlike other metallic glasses, the degradation rate of current MG microwire catalysts accelerates with increasing pH value of the solution. The breaking of the trade-off between pH and catalytic activity indicates that a catalytic mechanism for this MoCoB MG catalyst, which will be discussed later. To further highlight the excellent catalytic performance of this catalyst, the comparable results of applicable pH value versus kobs for various MG catalysts in wastewater treatment are summarized9,15,16,17,26,27,28,29,30,31 (Fig. 2d), more details can be found at Supplementary Table 1.

a Comparison of degradation efficiency of the current MoCoB MG microwires with Fe78Si9B13 MG ribbons in CV dye. b Removal rate of three dyes. c Removal rate of CV by using the MoCoB as the catalyst under different pH value. d Summary plots comparing with previous literature results in terms of catalytic activity and suitable pH9,15,16,17,26,27,28,29,30,31.

The adaptability of the catalyst under different conditions is of great importance. To scientifically and comprehensively evaluate the effects of temperature, pH, H2O2 dosage and original concentration of the solution, an orthogonal matrix L16 (44) was designed to cover the possible degradation effects obtained under all combinations of factors, with kobs as the final indicator. It is clearly found that kobs with the maximum value is shown in number 13 (Supplementary Table 2), which is the best condition for MG catalysis (i.e., the best value for multi-factor variation), and a series of subsequent degradation experimental parameters are used as a reference. Notably, we also found that pH was the main factor affecting the degradation efficiency (Supplementary Table 3). Catalytic performance for other individual environmental factors also can be seen in Supplementary Fig. 1a–d. The results show that the degradation rate accelerates continuously as the temperature increases from 293 to 333 K. Moreover, the activation energy (ΔE) can be evaluated by the Arrhenius-type Eq. (2):

where R is the gas constant, T is the temperature, and lnA is the proportionality constant. The ΔE of present microwire catalysts of 44.6 KJ/mol is much lower than that of the crystalline catalysts (60–250 KJ/mol), indicating the metallic glasses are more likely to cross the reaction energy barrier for catalytic degradation reactions25,32. It is noticed that the degradation rate increases with increasing H2O2 dosage (Supplementary Fig. 1d). Unlike the conventional Fenton-like system, the current MoCoB/H2O2 system breaks the limitation that H2O2 annihilates hydroxyl radicals instead when added in excess33,34,35. As shown in Supplementary Fig. 1c, the microwire catalyst still exhibits excellent degradation ability over a wide range of concentrations. Apparently, the kobs of the CV solution can be effectively improved by increasing the amount of catalyst, H2O2 and reaction temperature. In addition, the leached Mo/Co ion only contributed less than 10% of dye degradation during the catalytic activity, indicating that the dye degradation was primarily derived from the contribution of the heterogeneous catalyst (Supplementary Fig. 2).

Reusability

The sustainability and stability of catalysts is one of the core issues to be considered in practical wastewater remediation. However, most of the reported metallic glasses often suffer from surface aging or product coverage during the catalytic degradation, especially after multiple cycles9,18. In this work, the cycling performance and long-term reactivity of the catalysts in CV solution was systematically investigated. Figure 3 shows the degradation performance of different cycles and compared with other materials, it was found that the degradation efficiency still reaches more than 80% after 46 cycles and the degradation rate always maintains at a stable level, as shown in Fig. 3a. Figure 3b summarizes the comparison graph of kobs versus reusability of reported metallic glasses for wastewater remediation, with more details presented in Supplementary Table 19,17,28,29,31,36,37,38,39. It can be seen that such a durable catalyst with high catalytic activity show great potential for practical wastewater treatment applications.

Reaction mechanism

The current MoCoB catalysts exhibit excellent catalytic performance in terms of catalytic activity, pH adaptation and reusability. To decode the catalytic mechanism of MoCoB MG microwires, we used different methods to analyze the degradation mechanism, Fig. 4 shows the corresponding experimental results of different methods. EPR analysis were conducted using DMPO and TEMP as the spin-trapping agents (see Fig. 4a). Surprisingly, in addition to •OH (1:2:2:1), superoxide radicals •O2− (1:1:1:1) was also produced during the catalytic process. It should be particularly emphasized that we also found singlet oxygen 1O2 (1:1:1), which has never been reported previously in amorphous alloy/H2O2 systems for wastewater treatment. To further clarify the role of each reactive intermediate in the degradation process, quenching experiments were performed with tertbutanol (TBA) and p-benzoquinone (pBQ). Strikingly, •OH only assumed a weak effect, while a small amount of pBQ was able to terminate more than 50% of the degradation reaction (see Fig. 4b). In other words, •O2− plays a dominant role in the whole catalytic degradation, and the advanced oxidation mechanism based on the combined action of •O2− and 1O2 enables the rapid degradation of dyes. According to the Haber–Weiss cycle, 1O2 is generated by the further oxidation of the reactive species •O2–40. Moreover, with the increasing of solution pH (from 3.5–10), the content of •O2− and the rate of their deprotonation to produce 1O2 are also increasing. This fully confirms the nature of the current system that degrades at a faster rate under alkaline conditions than acidic conditions, a similar phenomenon was observed in Fe2O3@FCNT41. This confirms why the current MG catalyst can function in acidic media as well as achieve rapid degradation in most alkaline conditions.

In order to gain insight into the catalytic mechanism of the MG in the degradation process, density functional theory (DFT) was applied in simulations, Fig. 5 shows the decomposition process of H2O2 at different sites on the amorphous surface calculated by first principles. The Mo site and Co site were chosen respectively (Fig. 5a, b). It can be concluded that once H2O2 is adsorbed by the catalyst, the O-O bond is rapidly elongated to form two hydroxyl radical. Under the strong oxidation of the amorphous matrix, the two •OH quickly turn into H2O, which is in excellent agreement with the EPR and quenching results obtained in Fig. 4. To better understand the effect of the atoms on the catalytic process, the absorption energy of H2O2 is calculated with Eads (Mo) = −0.53 eV and Eads (Co) = −0.50 eV, which indicates a stronger adsorption capacity of Mo atom. It can be seen from Fig. 5c that the energy is progressively lower during this process, indicating that the transition is completely spontaneous in the presence of the metallic glass catalyst. With respect to the Mo site (Fig. 5d), it was found that significant charge transfer occurs at the catalysis and O-O, respectively. The corresponding electron transfers are 0.4e and 0.6e. These findings indicate that MG catalysts provide a large electronic basis for the catalytic process. Moreover, we also found that the most stable state of O-O is in the triangular structure of Mo/Co atoms, which is once again emphasized the synergistic effect of bimetals.

To fundamentally analyze the role of Mo/Co bimetals in the excellent stability, XPS analysis of the samples were performed at different cycles, and all the results were corrected with the C peak (284.8 eV). Figure 6a shows the Mo3d pattern, wherein the Mo0 are transformed into Mo4+ and Mo6+ in the recycling microwires. Similarly, Co0 in the original catalysts gradually evolves to Co2+ and Co3+ as the reused (Fig. 6b). The transformation of two metallic elements indicating that the Mo0/Co0 is the electron supplier during the catalytic performance. Additionally, the oxidation process from Mo4+ to Mo6+ and Co2+ to Co3+ is the important process for the generation of reactive species. It is well known that from thermodynamics aspect, the higher valence is very difficult to return to the lower valence state again, which greatly limits the production of reactive species. However, in this work, a Co2+-rich surface was found to be stable on the cycling catalyst because of the reductive Mo6+. To confirm this issue, the ratios of two elements are purposefully summarized in Fig. 6c. As can be seen, the ratio of Mo4+/Mo6+ and Co3+/Co2+ gradually decreases with the cycles. It is worth noting that the trends in the ratios of the two metal elements are completely opposite. This implies that the stable presence of a Co2+-rich surface is necessarily linked to Mo4+. In other words, Mo4+ acts as a reducing agent and electron transfer medium to accelerate the redox cycle from Co3+ to Co2+, as in Eq. 3. Figure 6d also shows the schematic diagram of electron transfer in the catalytic process. The bimetal forms a closed internal cycling system, which becomes the key reason for the current MoCoB MG microwire with 46 cycles. More importantly, the electron enriched MoCoB catalyst allows •OH to further react with H2O2 to produce •O2- and 1O2 (Eqs. 4 and 5)42. That is also the reason why •OH can be detected in the EPR (Fig. 4a), but does not directly degrade the wastewater.

The long-term reactivity of the catalyst is mainly related to the chemical reaction and stability of the alloy surface. As can be seen in Fig. 7a, the MoCoB shows a stable charge-transfer resistance (Rct = 860–881 Ω.cm2) after reused compared to the origin catalysts (Rct = 1732 Ω.cm2). Moreover, the catalysts activated by H2O2 have significantly lower Rct, indicating the important role of activators in stimulating catalytic activity. The double-layer capacitance (Cdl) results and electrochemical surface area (ECSA) values are shown in Fig. 7b and Supplementary Fig. 3. The ECSA result for the original catalyst was 13.8 μF/cm2. After 5 to 46 cycles, the ECSA was maintained at 14.5–20.2 μF/cm2. Figure 7c analyzes the variation of Rct and ECSA with the number of cycles. Such results reveal from an electrochemical point of view why the current MG has high reusability. Figure 7d indicates the evolution of the surface morphologies of the catalysts at different cycles, showing some rounded precipitates and nanoparticles after 5 and 10 cycles. In particular, the catalysts display a self-reconfiguration ability to its original smooth state after 46 cycles, which is mainly related to the special structure of the metallic glasses39. The EDS results after different cycles show a uniform distribution, except for a very small amount of Mo deprivation after 5 cycles. In particular, it should be noted that O elements did not significantly aggregate after multiple cycles, implying that the reactivity of the catalyst is not limited by the dense oxide layer.

Conclusion

In summary, the ternary MoCoB MG microwire with high specific surface area were prepared by melt spinning techniques, which showed ultra-high catalytic performance and reusability in wastewater degradation. The results show that the electron enriched Mo-based catalysts also exhibit surprisingly high stability over a wide pH range (5–10), overcoming the limitation in alkaline conditions. Due to the special amorphous structure and alloy system, Mo can accelerate the reduction process of Co3+ to Co2+ on the surface forming a bimetallic internal circulation mechanism. The catalytic mechanism and reactive species are discussed in detail both from experiments and DFT calculations, and the dominant role of •O2− provide a perspective for the subsequent research of the metallic glasses/H2O2 system in wastewater treatment. It also provides insights into practical applications of MG catalysts, making Mo-based MG microwires potential candidate for environmental treatment.

Methods

Material and fabrication process

The Mo51Co34B15 (at. %) MG microwires were manufactured by melt-spinning techniques with a wire speed of ~40 m/s for copper wheels. Before that, high-purity molybdenum (99.9 wt. %), cobalt (99.9 wt. %), and boron (99.5 wt. %) were made into a master alloy ingot by arc melting, which was melted at least 5 times to ensure chemical homogeneity.

Crystal Violet (C25H30ClN3), Malachite Green (C23H25ClN2) and Direct Blue 6 (C32H20N6Na4O14S4) dyes were purchased from Chongqing Titanium New Chemical Co. The pH values of the organic solutions were adjusted with 1 M HCl and 1 M NaOH. All the reagents were analytically pure except 30% H2O2 without further purified.

Structure characterization method

The structure of the amorphous catalysts was characterized by X-ray diffraction (XRD, SHIMADZU XRD-6100) using Cu-Kα radiation. The thermal stability was studied by differential thermal analysis (DTA, STA409PC) under Ar2 atmosphere at a heating rate of 20 K/min. The specific surface area of the prepared catalysts was tested by BET (JW-BK400) under N2 atmosphere.

Catalytic experiment method

During the catalytic experiments, the temperature of the solution was controlled with a water bath and magnetic stirring was maintained. During the reaction, 3 mL of the solution was drawn with a syringe at predetermined time intervals (e.g., 2, 5, 10, 12, 15 min, etc.) and the absorbance of the corresponding solution was measured with a UV-visible photometer (Spectrophotometer U-3310). The reusability of the samples was assessed by cycling experiments, which was performed in 20 ppm of CV solution. After one cycle, the catalysts were removed and washed three times with deionized water, then blown dry and continued in a fresh CV solution to start the next cycle, repeating this process until a significant change in catalytic efficiency was observed. Molybdenum chloride (MoCl5) and cobalt chloride hexahydrate (CoCl2.6H2O) were employed as homogeneous catalysts to assess the effect of leached metal ions on the degradation of the dye during the catalytic process. The concentration of metal ions was measured by inductively coupled plasma atomic emission spectrometry (ICP- OES, OPTIMA 8000DV).

The effect of external factors including temperature, pH value, H2O2 dosage and concentration of the solution on the catalytic performance was evaluated using an orthogonal experimental system. If not specifically mentioned, the following conditions were chosen: dye concentration of 20 ppm, catalyst dosage of 2 g/L, H2O2 addition of 0.1 M, and temperature of 323 K. The electrochemical impedance and cyclic voltammetry curve of the samples were tested in CV solution using a standard three-electrode system consisting of a Pt electrode, a saturated calomel electrode, and the catalysts. The surface morphologies and elemental distribution of the catalysts before and after the reaction were observed by scanning electron microscopy (SEM, JSM-6610) with energy spectrum analysis (EDS). Then, the reaction mechanism was comprehensively and deeply analyzed by X-ray photoelectron spectroscopy (XPS, AXIS SUPRA+) and electron paramagnetic resonance (EPR, EMXplus-9.5/12).

First-principles calculation process

The First-Principles Calculations were performed by the CASTEP module. The projector augmented wave (PAW) pseudopotential was adopted for the comprehensive density functional theory (DFT) calculations, and the generalized gradient approximation (GGA) using Perdew–Burke–Ernzerhof (PBE) was applied for the description of the electron exchange correlation43,44. The structure of MoCoB MG was built by Ab initio molecular dynamics (AIMD) simulations via a traditional melted and quenched process. The k points of Monkhorst–Pack was set to be 2 × 3 × 1 and the energy cutoff was set to be 300 eV, and a DFT-D approach with the Ortmann–Bechstedt–Schmidt (OBS) vdW correction was selected to take into account vdW interactions45,46. The energy and maximum force convergence criteria during geometry optimizations were set at 10−5 eV /atom and 0.03 eV/Å, respectively, and a vacuum zone measuring 25 Å was applied to prevent the interaction between periodical layers.

Data availability

The authors declare that the data supporting the findings of this study are included within the paper and available from the corresponding author on reasonable request.

References

Wang, W. H. Bulk metallic glasses with functional physical properties. Adv. Mater. 21, 4524–4544 (2009).

Hu, Y. C. et al. A highly efficient and self-stabilizing metallic-glass catalyst for electrochemical hydrogen generation. Adv. Mater. 28, 10293–10297 (2016).

Wang, Z. J. et al. Low-iridium-content IrNiTa metallic glass films as intrinsically active catalysts for hydrogen evolution reaction. Adv. Mater. 32, e1906384 (2020).

Hu, F. et al. Amorphous metallic NiFeP: a conductive bulk material achieving high activity for oxygen evolution reaction in both alkaline and acidic media. Adv. Mater. 29, 1606570 (2017).

Liang, S. X. et al. Selective laser melting manufactured porous Fe -based metallic glass matrix composite with remarkable catalytic activity and reusability. Appl. Mater. Today 19, 100543 (2020).

Liang, S. X. et al. Compelling rejuvenated catalytic performance in metallic glasses. Adv. Mater. 30, 1802764 (2018).

Liang, S. X. et al. A laser-based synthesis route for magnetic metallic glass nanoparticles. Scr. Mater. 203, 114094 (2021).

Wang, J. Q. et al. Rapid degradation of azo dye by fe-based metallic glass powder. Adv. Funct. Mater. 22, 2567–2570 (2012).

Jia, Z. et al. Surface aging behaviour of Fe-based amorphous alloys as catalysts during heterogeneous photo Fenton-like process for water treatment. Appl. Catal. B Environ. 204, 537–547 (2017).

Jia, Z. et al. Disordered atomic packing structure of metallic glass: toward ultrafast hydroxyl radicals production rate and strong electron transfer ability in catalytic performance. Adv. Funct. Mater. 27, 1702258 (2017).

Tang, Y. et al. Insight into the high reactivity of commercial Fe-Si-B amorphous zero-valent iron in degrading azo dye solutions. RSC Adv. 5, 34032–34039 (2015).

Chen, S. Q. et al. Excellent long-term reactivity of inhomogeneous nanoscale Fe-based metallic glass in wastewater purification. Sci. China Mater. 63, 453–466 (2020).

Jia, Z. et al. Attractive in situ self-reconstructed hierarchical gradient structure of metallic glass for high efficiency and remarkable stability in catalytic performance. Adv. Funct. Mater. 29, 1807857 (2019).

Jia, Z. et al. Amorphous Fe78Si9B13 alloy: an efficient and reusable photo-enhanced Fenton-like catalyst in degradation of cibacron brilliant red 3B-A dye under UV–vis light. Appl. Catal. B Environ. 192, 46–56 (2016).

Jiang, J. L. et al. Synergistic function of iron and cobalt in metallic glasses for highly improving persulfate activation in water treatment. J. Alloy. Compd. 822, 153574 (2020).

Li, Z. et al. Cu-based metallic glass with robust activity and sustainability for wastewater treatment. J. Mater. Chem. A 8, 10855–10864 (2020).

Zhao, B. et al. Highly efficient and stable CuZr-based metallic glassy catalysts for azo dye degradation. J. Mater. Sci. Technol. 46, 88–97 (2020).

Wang, Q. et al. Investigation of FePC amorphous alloys with self-renewing behaviour for highly efficient decolorization of methylene blue. J. Mater. Chem. A 6, 10686–10699 (2018).

Wang, P. et al. Fast decolorization of azo dyes in both alkaline and acidic solutions by Al-based metallic glasses. J. Alloy. Compd. 701, 759–767 (2017).

Lai, L. et al. High-temperature Mo-based bulk metallic glasses. Scr. Mater. 203, 114095 (2021).

Lai, L. M. et al. Ternary Co-Mo-B bulk metallic glasses with ultrahigh strength and good ductility. J. Non-Cryst. Solids 524, 119657 (2019).

Song, X. C. et al. Ultrasonic welding of Fe78Si9B13 metallic glass. Mater. Sci. Forum 809–810, 348–353 (2015).

Li, R. et al. Flexible glassy grid structure for rapid degradation of azo dye. Mater. Des. 155, 346–351 (2018).

Zhao, B. et al. Performance enhancement and catalytic mechanism identification of Cu-based composite for degradation of organic contaminants. Powder Technol. 389, 11–20 (2021).

Zhang, L. C. et al. A review of catalytic performance of metallic glasses in wastewater treatment: recent progress and prospects. Prog. Mater. Sci. 105, 100576 (2019).

Liu, P. et al. Synthesis of an Fe rich amorphous structure with a catalytic effect to rapidly decolorize Azo dye at room temperature. ACS Appl Mater. Interfaces 6, 5500–5505 (2014).

Zhang, C. et al. Rapid reductive degradation of azo dyes by a unique structure of amorphous alloys. Chin. Sci. Bull. 56, 3988–3992 (2011).

Yang, W. et al. A novel thermal-tuning Fe-based amorphous alloy for automatically recycled methylene blue degradation. Mater. Des. 161, 136–146 (2019).

Liang, S. X. et al. Surface reactivation of FeNiPC metallic glass: a strategy for highly enhanced catalytic behavior. J. Phys. Chem. Solids 132, 89–98 (2019).

Deng, Z. et al. Fe-based metallic glass catalyst with nanoporous surface for azo dye degradation. Chemosphere 174, 76–81 (2017).

Miao, F. et al. Excellent reusability of FeBC amorphous ribbons induced by progressive formation of through-pore structure during acid orange 7 C degradation. J. Mater. Sci. Technol. 38, 107–118 (2020).

Yang, Y. et al. The preparation of Fe2O3-ZSM-5 catalysts by metal-organic chemical vapour deposition method for catalytic wet peroxide oxidation of m-cresol. R. Soc. Open Sci. 5, 171731 (2018).

Jia, Z. et al. Heterogeneous photo Fenton-like degradation of cibacron brilliant red 3B-A dye using amorphous Fe78Si9B13 and Fe73.5Si13.5B9Cu1Nb3 alloys: the influence of adsorption. J. Taiwan Inst. Chem. Eng. 71, 128–136 (2017).

Yin, Y. et al. Ultrafine copper nanoclusters and single sites for Fenton-like reactions with high atom utilities. Environ. Sci. Nano 7, 2595–2606 (2020).

Liang, S. X. et al. Tailoring surface morphology of heterostructured iron-based Fenton catalyst for highly improved catalytic activity. J. Colloid Interface Sci. 581, 860–873 (2021).

Ganiyu, S. O. et al. A hierarchical CoFe-layered double hydroxide modified carbon-felt cathode for heterogeneous electro-Fenton process. J. Mater. Chem. A 5, 3655–3666 (2017).

Wang, J. et al. In-situ incorporation of iron-copper bimetallic particles in electrospun carbon nanofibers as an efficient Fenton catalyst. Appl. Catal. B Environ. 207, 316–325 (2017).

Ge, Y. X. et al. Remarkably enhanced Fenton-like catalytic activity and recyclability of Fe-based metallic glass by alternating magnetic field: mechanisms and industrial applications. J. Mater. Chem. A 10, 23314–23322 (2022).

Yang, C. et al. Three-dimensional hierarchical porous structures of metallic glass/copper composite catalysts by 3D printing for efficient wastewater treatments. ACS Appl. Mater. Interfaces 13, 7227–7237 (2021).

Khan, A. U. et al. Singlet molecular oxygen in the Haber-Weiss reaction. Proc. Natl Acad. Sci. USA 91, 12365–12367 (1994).

Yang, Z. et al. Singlet oxygen mediated iron-based Fenton-like catalysis under nanoconfinement. Proc. Natl Acad. Sci. USA 116, 6659–6664 (2019).

Zhao, M. et al. MoS2 co-catalysis promoted CaO2 Fenton-like process: performance and mechanism. Sep. Purif. Technol. 276, 119289 (2021).

Perdew, J. P. et al. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865 (1996).

Perdew, J. P. et al. Atoms, molecules, solids, and surfaces: applications of the generalized gradient approximation for exchange and correlation. Phys. Rev. B 46, 6671 (1992).

Ortmann, F. et al. Semiempirical van der Waals correction to the density functional description of solids and molecular structures. Phys. Rev. B 73, 205101 (2006).

Li, C. et al. Theoretical anchoring effect of new phosphorus allotropes for lithium–sulfur batteries. Nanoscale 12, 11095–11111 (2020).

Acknowledgements

This work was financially supported by National Natural Science Foundation of China (No. 52071276), State Key Laboratory of Materials Processing and Die & Mould Technology, Huazhong University of Science and Technology (No. P2022–007), Natural Science Foundation of Chongqing, China (No. CSTB2022NSCQ-MSX0440) and Fundamental Research Funds for the Central Universities (SWU-XDJH202313).

Author information

Authors and Affiliations

Contributions

M.T.: validation, investigation, data curation, methodology, formal analysis, writing—original draft preparation, visualization. L.L.: methodology, data curation, visualization, investigation. C.S.: validation, investigation. C.L.: software. C.Z.: investigation, writing—reviewing and editing. S.G.: supervision, conceptualization, methodology, writing—reviewing and editing, funding acquisition.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tang, M., Lai, L., Su, C. et al. MoCoB metallic glass microwire catalysts for highly efficient and pH-universal degradation of wastewater. npj Mater Degrad 7, 73 (2023). https://doi.org/10.1038/s41529-023-00390-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41529-023-00390-1