Abstract

O-Sulfation is a vital post-translational modification in bioactive molecules, yet there are significant challenges with their synthesis. Dialkyl sulfates, such as dimethyl sulfate and diisopropyl sulfate are commonly used as alkylation agents in alkaline conditions, and result in the formation of sulfate byproducts. We report herein a general and robust approach to O-sulfation by harnessing the tunable reactivity of dimethyl sulfate or diisopropyl sulfate under tetrabutylammonium bisulfate activation. The versatility of this O-sulfation protocol is interrogated with a diverse range of alcohols, phenols and N-OH compounds, including carbohydrates, amino acids and natural products. The enhanced electrophilicity of the sulfur atom in dialkyl sulfates, facilitated by the interaction with bisulfate anion (HSO4-), accounts for this pioneering chemical reactivity. We envision that our method will be useful for application in the comprehension of biological functions and discovery of drugs.

Similar content being viewed by others

Introduction

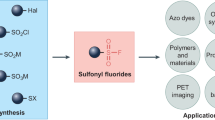

O-Sulfation (also known as sulfurylation) is a crucial post-translational modification with significant implications in developmental biology, immunology, and neurobiology, as well as disease processes such as cancer, inflammation, and central nervous system disorders1,2,3,4. This modification can occur in a diverse range of biomolecules, including polysaccharides, peptides, proteins, natural products, and drug metabolites (Fig. 1A)5,6,7. The unique nature of sulfate group can introduce both specific and non-specific recognition via an electrostatic or a hydrogen bonding interaction, posing challenges in modulating sulfate-protein interactions8,9,10. Sulfation of appropriately designed, non-natural scaffolds expands their structural diversity and provides valuable insights into a wide range of biological functions11,12. Notably, tyrosine sulfate isosteres of CCR5 have been designed as a tool to comprehend HIV-1 entry mechanism13,14. However, one of limiting factors in studying the structure-activity relationships of sulfate modifications in biology is their rather difficult availability15,16.

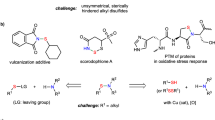

While O-sulfation appears to be a one-step reaction, chemical synthesis of sulfated molecules remains challenging due to their lability to acid and temperature, insolubility in nearly all organic solvents, and limited maneuverability following introduction17,18. As a result, extensive studies and synthetic pathways to organic sulfates are constantly being sought19,20,21,22. Sulfation based on H2SO4 has been successfully applied to simple alkenes and alcohols, but it is unsuitable for compounds containing delicate functional groups, primarily due to the strong acidity of sulfuric acid23,24,25,26. Sulfur trioxide-nitrogen base complexes are the most commonly used reagents for sulfating various molecular motifs containing alcoholic, phenolic, amino, thiol and other functional groups27,28,29,30. Conversely, the synthetic pathway for sulfur trioxide-nitrogen base complexes often necessitates abrasive and severe conditions, which ultimately constrain their synthetic adaptability. An alternative strategy to access the target scaffold in a masked sulfate diesters is the so-called early-stage sulfation, which was deblocked to afford O-sulfate in the final step31,32,33,34,35,36,37. It is complementary to the direct sulfation as the masked sulfate diesters are uncharged, can be usually purified with traditional method, and are stable to the subsequent transformations. Various protecting groups of sulfate diesters were explored in early-stage O-sulfation, such as phenyl and its variants31, neopentyl (nP)32, isobutyl (iBu)32, 2,2,2-trichloroethyl (TCE)33,34,35,36, trifluoroethylene (TFE) groups37. In addition, the sulfitylation-oxidation protocol38 and sulfur (VI) fluoride exchange reaction (SuFEx)31,39,40 could also be used to generate sulfate diesters, making them powerful tools for early-stage sulfation on complex peptides and carbohydrates.

In term of structure components, dialkyl sulfates, such as dimethyl sulfate (DMS) and diisopropyl sulfate (DPS) are typically classified as sulfate diesters41,42,43. They consist of a sulfate group with two alkyl groups attached to it. This specific feature makes them highly effective as alkylation agents under alkaline conditions by a BAL2 (bimolecular, base-promoted, alkyl cleavage, nucleophilic substitution) mechanism (Fig. 1C-i). The sulfate group then acts as a leaving group, resulting in the formation of innocuous sulfate byproducts finally. Inspired by the tunable reactivity of dimethyl carbonate (DMC) for methylation and methoxycarbonylation44, we envisioned that a different activation method to increase the electrophilicity of sulfate group in dialkyl sulfates, which may generate alkyl sulfate monoester B through an ASU2 (bimolecular, acid-promoted, sulfate cleavage, nucleophilic substitution) mechanism (Fig. 1C-ii). This chemical process facilitates the transfer of sulfate groups to target molecules, but it presents significant challenges. A suitable activation system for dialkyl sulfates should also function as the reagent for removal of the alkyl group (methyl or isopropyl) in sulfate monoester B as shown in Fig. 1C, to release the final sulfate product C. Alkyl protected sulfate ester B is always stable, a selective deprotection strategy is not easy to differentiate the fission rate of the two S–O bonds45. Despite a comprehensive study for removal of various protecting groups in sulfate monoesters31,32,33,34,35,36,37, methyl and isopropyl remains elusive. Moreover, the design of activation system should be compatible with acid-labile sulfate C, avoiding its decomposition. Herein, we demonstrated a strategy that utilizes dialkyl sulfates (DMS and DPS) as source of sulfates to achieve O-sulfation under tetrabutylammonium bisulfate activation.

Results

After an extensive optimization campaign based on our working hypothesis, we identified DMS as the optimal sulfate source and Bu4NHSO4 as the ideal activation agent. The reaction between the initial model substrate 1a and DMS (1.2 equiv) under mildly acid conditions (Bu4NHSO4, 1.2 equiv) in CH3CN at 80 °C for 12 h, provided the desired tetrabutylammonium 3-phthalimido-1-propanol sulfate 1 in 84% yield (Table 1, entry 1). Control experiments revealed that DMS and Bu4NHSO4 were both essential for this sulfation (Table 1, entries 2, 3). Without DMS or Bu4NHSO4, the reaction did not proceed at all. The use of Bu4NBF4, Bu4NOAc, or Bu4NI as additive that could potentially release their conjugated acids from the equilibrium with 1a, resulted in lower yield (Table 1, entries 4–6). Similarly, the shift from tetrabutylammonium to other cations was ineffective for this transformation (Table 1, entries 7, 8). These outcome confirmed the crucial role of Bu4NHSO4 for enhanced solubility of sulfate product 1 as tetrabutylammonium salt as well as facile removal of the methyl group in sulfate monoester B46. Not surprisingly, O-methylation rather than sulfation occurred in the presence of sodium hydride (Table 1, entry 9)41,42,43. When the reaction was conducted at lower or higher temperature, a notable decease of yield was observed (Table 1, entries 10, 11). Exposure to air is possible for O-sulfation (Table 1, entry 12), obviating the need for rigorous deoxygenation and dehumidification.

Studies of the scope of this O-sulfation are summarized in Fig. 2. The reaction performed well to a wide range of primary and secondary alcohol substrates. The sulfation of most primary alcohols proceeds effectively with DMS (conditions a), while DPS is more applicable to both primary and secondary alcohols (conditions b). A variety of functional groups are tolerated including amide (1), halides (2, 3, 8), nitrate (4), nitrile (5), ether (7), alkene (11), alkynes (12, 13), boronic ester (15), aldehyde (16), sulfone (17), esters (22, 28), ketone (30), sulfonamide (27), aromatic (9) and heterocycles (18, 29). Despite the likelihood of erosion under acid conditions, anisole (7), alkene (11), and alkynes (12, 13) remained intact. The week nucleophilic trichloroethanol was also a competent partner with acceptable yield of the target product (19). Both cyclic and acyclic secondary alcohols were efficiently transformed into the sulfates (21–29). The structural identity of the target sulfate group was unambiguously established by single crystal X-ray diffraction for compound 8. The practicability of this approach was further demonstrated on the gram scale synthesis of 1. Due to the lability of organic sulfates on chromatography, such as 11, 19 and 25, the purified compound yields were significantly lower than the yields determined by 1H NMR. We could also generalize the transformation beyond primary and secondary sulfates synthesis to include the formation of sulfates from phenols as well as tertiary alcohols and N–OH containing compounds. Their relative weak nucleophilicity compared to common alcohols47 makes them sluggish to attack dialkyl sulfates, even with acid activation. The use of stronger electrophilic sodium pyrosulfate instead of DMS or DPS was crucial to obtain high yields. With this modified protocol, the bulky sulfated product (30) was obtained in 85% yield; N–OH containing compounds are suitable in this system to obtain N–OSO3 products (31, 32) in good yields. Moreover, the reaction performed well with electron-rich to electron-deficient phenols (33–44). This protocol was also successful in producing S-sulfation products 20 and 45 for thiol and thiophenol. However, nitrogen compounds such as amine and imine (Supplementary Table 4) did not yield any desired sulfation products, and all starting materials were recovered.

aReaction conditions a as shown in Table 1. bDPS (1.2 equiv) and Bu4NHSO4 (2.0 equiv) were used in reaction conditions b. cNMR yields were determined by using CH2Br2 as an internal standard. dNa2S2O7 (2.0 equiv) and Bu4NHSO4 (1.1 equiv) were used. Note: The liquid DMS and DPS are volatile and toxic. Exercise extreme caution when handling the liquid. DPS, diisopropyl sulfate.

Hydroxyl groups are not only prevalent in large quantity as alcohols and phenols, but they are also present in a wide variety of complex natural products and drugs. The mild reaction conditions described in this method make it applicable to a large variety of carbohydrates, amino acids and steroids, as shown in Fig. 3. Various sugar derivatives with different protecting groups and glycosidic bonds were successfully sulfated under these conditions. Armed (46–48, 53) and disarmed glucoside (49), mannoside (52), idose (54), iduronic acid (55) and glucosamine derivatives (56) reacted smoothly to form the corresponding 6-O and 4-O sulfated products in yields of 38–81%. This method was also applied to molecules containing different hydroxyl moieties within the same structure, enabling site-selective O-sulfation among primary and secondary/tertiary hydroxyl groups in glycoside (57), glucosamine (58), galactoside (59) and 60. The selectivity in these reactions appears to be mainly controlled by steric effects, as no distinction was observed among substrates with similar hindrance (Supplementary Fig. 7). Moreover, the selectivity profile of this method extends to differentiate between phenols and alcohols, as exemplified by the selective sulfation of a primary alcohol over a phenol in compound 61. Amino acids, such as proline (62) and serine (63) were viable in this O-sulfation. Furthermore, we examined this sulfation reaction within various densely functionalized architectures. Notably, pharmaceuticals and repellents like picaridin (64), aloe emodin (65), and ospemifene (66) were amenable to this reaction. In addition, natural steroid hormone derivatives, such as testosterone (67), diosgenin (68), and cholesterol (69), were also competent substrates, allowing for the synthesis of desired products in high yields. These results highlight the broad utility of this sulfation method for late-stage modifications of bioactive molecules.

aStandard conditions as shown in Table 1. bDMS (2.0 equiv) and Bu4NHSO4 (2.0 equiv) were used. c24 h instead of 12 h. dBu4NHSO4 (2.0 equiv) was used. eDPS (1.2 equiv) and Bu4NHSO4 (1.2 equiv) were used. fNMR yields were determined by using CH2Br2 as an internal standard.

Next, a series of control experiments were carried out to obtain further insight into the reaction mechanism (Fig. 4). On-line reaction monitoring by NMR was performed to detect reaction intermediates and their reactivity (Fig. 4A). When the mixture of alcohol 1a and DMS was activated with 1.2 equiv of Bu4NHSO4, NMR spectra showed generation of desired sulfate 1 is concomitantly accompanied by formation of methyl monosulfates 1-B and methyl sulfate D/D′ respectively. As the reaction progressed, these intermediate species were converted to some extent into the final sulfate product. Notably, the release of MeOH was also observed during the reaction. This results promoted us to investigate the additional role of these key intermediates in the sulfation. DMS reacts with tetrabutylammonium bisulfate (Bu4NHSO4) to yield a mixture of D and D′ (Fig. 4B) rather than SO3 complex, which substantiates the possible path b in the reaction (Fig. 1C-ii). The higher yield of 1, in comparison to the stoichiometric amount of any individual sulfur source, suggests that the sulfate group in product originates from both of DMS/DPS, and Bu4NHSO4 (Fig. 4C). Treatment of methyl monosulfates (1-B) with Bu4NHSO4 or Bu4NOAc resulted in the formation of the sulfated product 1 with high yields, indicating both bisulfate (HSO4−) and acetate (AcO-) are effective nucleophilile to cleave the methyl protecting group in monosulfates 1-B (Fig. 4D)46. On the contrary, the reactivity of methyl sulfate D′ with 1a differed significantly between tetrabutylammonium bisulfate and tetrabutylammonium acetate (Fig. 4E). The proton in tetrabutylammonium bisulfate was found to activate the sulfate group of methyl sulfate D′, enhancing the electrophilicity of sulfur atoms, as well as facilitating the leaving of the methyl group. The transformation of methyl sulfate D′ to the final product is crucial for the easier purification of our reaction, as it eliminates potential contamination of the desired sulfate product with its similar polarity. To further elucidate the reaction pathway and the source of oxygen in the final product, we conducted 18O-labeling experiment with compound 70a, which resulted in the successful isolation of alcohol 18O-70 in 46% yield with a nearly identical level of 18O enrichment (Fig. 4F). Given the formation of S–SO3 product 20 rather than O–SO3, the intact C–S bond demonstrated that the sulfation of R–OH proceeds via the formation of O–SO3 bond rather than C–OSO3, as the C–S bond is much weaker than C–O. Most importantly, the stereoselective retention of various chiral substrates (46-59, 67-69) in Fig. 3 clearly verifies the formation of O–SO3 bond.

Discussion

In summary, the discovery of an alternative activation method for dimethyl sulfate and diisopropyl sulfate allows for the versatile synthesis of organic sulfates. This work represents a notable advancement in the utilization of traditional reagents for significant chemical transformations. The mild reaction conditions and broad functional group tolerance make this method a powerful addition to the toolbox for late-stage sulfation of complex bioactive molecules. We anticipate that the generality of this O-sulfation and the ready availability of the materials used in the transformation will broaden the application of organic sulfates in the comprehension of biological function and drug discovery.

Methods

General procedure for O-sulfation

To a 4.0 mL borosilicate vial equipped with a stir bar was added hydroxyl substrate (0.2 mmol, 1.0 equiv), dimethyl sulfate or diisopropyl sulfate or sodium pyrosulfat (0.24 mmol, 1.2 equiv) and tetrabutylammonium bisulfate (81.5 mg, 0.24 mmol, 1.2 equiv). The vial was evacuated and backfilled with argon for three times, then CH3CN (1.0 mL, C = 0.2 M) was added. After stirring for 12 h at 80 °C, dibromomethane (14.0 μL, 0.2 mmol, 1.0 equiv) was added as an internal standard. The reaction mixture was diluted with CDCl3, and the yield of tetrabutylammonium sulfates was determined by 1H NMR integration relative to the internal standard (standard: δ 4.94 ppm). To isolate the products, the concentrated reaction mixture was purified by flash chromatography on silica gel or plate chromatography on silica gel, to afford the product tetrabutylammonium sulfate salts.

Data availability

The data reported in this paper are available within the article and its Supplementary Information files. Crystallographic data for the structures reported in this Article have been deposited at the Cambridge Crystallographic Data Centre, under deposition numbers CCDC2290725 (8). Copies of the data can be obtained free of charge via https://www.ccdc.cam.ac.uk/structures/. All data are available from the corresponding author upon request.

References

Hemmerich, S. Protein sulfation. In Handbook of Neurochemistry and Molecular Neurobiology: Neural Protein Metabolism and Function. (eds Lajtha, A. & Banik, N.) 283–302 (Springer US, 2007).

Yang, Y.-S. et al. Tyrosine sulfation as a protein post-translational modification. Molecules 20, 2138–2164 (2015).

Chapman, E., Best, M. D., Hanson, S. R. & Wong, C.-H. Sulfotransferases: structure, mechanism, biological activity, inhibition, and synthetic utility. Angew. Chem. Int. Ed. 43, 3526–3548 (2004).

Bowman, K. F. & Bertozzi, C. R. Carbohydrate sulfotransferases: medliators of extracellular communication. Chem. Biol. 6, R9–R22 (1999).

Ernst, B. & Magnani, J. L. From carbohydrate leads to glycomimetic drugs. Nat. Rev. Drug Discov. 8, 661–677 (2009).

Kauffman, F. C. Sulfonation in pharmacology and toxicology. Drug Metab. Rev. 36, 823–843 (2004).

Carvalhal, F., Correira-da-Silva, M., Sousa, E., Pinto, M. & Kijjoa, A. Sulfationpathways: sources and biological activities of marine sulfated steroids. J. Mol. Endocrinol. 61, T211–T231 (2018).

Olson, S. T. et al. Role of the antithrombin-binding pentasaccharide in heparin acceleration of antithrombin-proteinase reactions. Resolution of the antithrombin conformational change contribution to heparin rate enhancement. J. Biol. Chem. 267, 12528–12538 (1992).

Olson, S. T. & Björk, I. Predominant contribution of surface approximation to the mechanism of heparin acceleration of the antithrombin-thrombin reaction. Elucidation from salt concentration effects. J. Biol. Chem. 266, 6353–6364 (1991).

Desai, U. R., Petitou, M., Björk, I. & Olson, S. T. Mechanism of heparin activation of antithrombin: evidence for an induced-fit model of allosteric activation involving two interaction subsites. Biochemistry 37, 13033–13041 (1998).

Hooper, L. V., Manzella, S. M. & Baenziger, J. U. From legumes to leukocytes: biological roles for sulfated carbohydrates. FASEB J. 10, 1137–1146 (1996).

Blakemore, D. C. et al. Organic synthesis provides opportunities to transform drug discovery. Nat. Chem. 10, 383–394 (2018).

Huang, C. et al. Structures of the CCR5 N terminus and of a tyrosine-sulfated antibody with HIV-1 gp120 and CD4. Science 317, 1930–1934 (2007).

Lam, S. N., Acharya, P., Wyatt, R., Kwong, P. D. & Bewley, C. A. Tyrosine-sulfate isosteres of CCR5 N-terminus as tools for studying HIV-1 entry. Bioorg. Med. Chem. 16, 10113–10120 (2008).

Stone, M. J. & Payne, R. J. Homogeneous sulfopeptides and sulfoproteins: synthetic approaches and applications to characterize the effects of tyrosine sulfation on biochemical function. Acc. Chem. Res. 48, 2251–2261 (2015).

Wang, L. et al. Efficient platform for synthesizing comprehensive heparan sulfate oligosaccharide libraries for decoding glycosaminoglycan–protein interactions. Nat. Chem. 15, 1108–1117 (2023).

Liang, A., Thakkar, J. N. & Desai, U. R. Study of physico-chemical properties of novel highly sulfated, aromatic, mimetics of heparin and heparan sulfate. J. Pharm. Sci. 99, 1207–1216 (2009).

Jandik, K. A., Kruep, D., Cartier, M. & Linhardt, R. J. Accelerated stability studies of heparin. J. Pharm. Sci. 85, 45–51 (1996).

Al-Horani, R. A. & Desai, U. R. Chemical sulfation of small molecules advances and challenges. Tetrahedron 66, 2907–2918 (2010).

Young, T. & Kiessling, L. L. A Strategy for the synthesis of sulfated peptides. Angew. Chem., Int. Ed. 41, 3449–3451 (2002).

Tully, S. E. et al. A chondroitin sulfate small molecule that stimulates neuronal growth. J. Am. Chem. Soc. 126, 7736–7737 (2004).

Lee, J.-C., Lu, X.-A., Kulkami, S. S., Wen, Y.-S. & Hung, S.-C. Synthesis of heparin oligosaccharides. J. Am. Chem. Soc. 126, 476–477 (2004).

Carey, F. A. & Sundberg, R. J. Advanced Organic Chemistry, Part B: Reactions and Synthesis. 5th edn. (Springer, 2007).

Deno, N. C. & Newman, M. S. Mechanism of sulfation of alcohols. J. Am. Chem. Soc. 72, 3852–3856 (1950).

Mumma, R. O. Preparation of sulfate esters. Lipids 1, 221–223 (1996).

Hoiberg, C. P. & Mumma, R. O. Preparation of sulfate esters. Reactions of various alcohols, phenols, amines, mercaptans, and oximes with sulfuric acid and dicyclohexylcarbodiimide. J. Am. Chem. Soc. 91, 4273–4278 (1969).

Gilbert, E. E. The Reactions of sulfur trioxide, and of its adducts, with organic compounds. Chem. Rev. 62, 549–589 (1962).

Gill, D. M., Male, L. & Jones, A. M. Sulfation made simple: a strategy for synthesising sulfated molecules. Chem. Commun. 55, 4319–4322 (2019).

Xu, P., Laval, S., Guo, Z. & Yu, B. Microwave-assisted simultaneous O,N-sulfation in the synthesis of heparin-like oligosaccharides. Org. Chem. Front. 3, 103–109 (2016).

Vo, Y. et al. A rapid and mild sulfation strategy reveals conformational preferences in therapeutically relevant sulfated xylooligosaccharides. Chem. Eur. J. 27, 9830–9838 (2021).

Liu, C. et al. A general approach to o-Sulfation by a sulfur(VI) fluoride exchange reaction. Angew. Chem. Int. Ed. 59, 18435–18441 (2020).

Simpson, L. S. & Widlanski, T. S. A comprehensive approach to the synthesis of sulfate esters. J. Am. Chem. Soc. 128, 1605–1610 (2006).

Liu, Y., Lien, I.-F. F., Ruttgaizer, S., Dove, P. & Taylor, S. D. Synthesis and protection of aryl sulfates using the 2,2,2-trichloroethyl moiety. Org. Lett. 6, 209–212 (2004).

Ingram, L. J. & Taylor, S. D. Introduction of 2,2,2-trichloroethyl-protected sulfates into monosaccharides with a sulfuryl imidazolium salt and application to the synthesis of sulfated carbohydrates. Angew. Chem. Int. Ed. 45, 3503–3506 (2006).

Ingram, L. J., Desoky, A., Ali, A. M. & Taylor, S. D. O- and N-Sulfations of carbohydrates using sulfuryl imidazolium salts. J. Org. Chem. 74, 6479–6485 (2009).

Desoky, A. Y. & Taylor, S. D. Multiple and regioselective introduction of protected sulfates into carbohydrates using sulfuryl imidazolium salts. J. Org. Chem. 74, 9406–9412 (2009).

Karst, N. A., Islam, T. F. & Linhardt, R. J. Sulfo-protected hexosamine monosaccharides: potentially versatile building blocks for glycosaminoglycan synthesis. Org. Lett. 5, 4839–4842 (2003).

Gao, Y. & Sharpless, K. B. Vicinal diol cyclic sulfates: like epoxides only more reactive. J. Am. Chem. Soc. 110, 7538–7539 (1988).

Chen, W. et al. Synthesis of sulfotyrosine-containing peptides by incorporating fluorosulfated tyrosine using an fmoc-based solid-phase strategy. Angew. Chem. Int. Ed. 55, 1835–1838 (2016).

Liu, C. et al. Fluorosulfate as a latent sulfate in peptides and proteins. J. Am. Chem. Soc. 145, 20189–20195 (2023).

Chen, Y. Recent advances in methylation: a guide for selecting methylation reagents. Chem. Eur. J. 25, 3405–3439 (2019).

Weisenberger, K., Mayer, D. & Sandler, S. R. Dialkyl sulfates and alkylsulfuric acids. Wiley Online Library. Ullmann’s Encyclopedia of Industrial Chemistry (Wiley-VCH, 2000).

Nazareth, A., Joppich, M., Panthani, A., Fisher, D. & Giese, R. W. Alkylation with dialkylsulfate and diisopropylethylamine. J. Chromatogr. 319, 382–386 (1985).

Tundo, P. & Selva, M. The chemistry of dimethyl darbonate. Acc. Chem. Res. 35, 706–716 (2002).

Younker, J. M. & Hengge, A. C. A mechanistic study of the alkaline hydrolysis of diaryl sulfate diesters. J. Org. Chem. 69, 9043–9048 (2004).

Kowalska, J., Osowniak, A., Zuberek, J. & Jemielity, J. Synthesis of nucleoside phosphosulfates. Bioorg. Med. Chem. Lett. 22, 3661–366 (2012).

Brown, H. C., Mcdaniel, D. H. & Häfliger, O. In Determination of Organic Structures by Physical Methods (eds Braude, E. A. & Nachod, F. C.) (Academic Press, New York, 1955).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant NO. 22001067 (J.L.), 22101081 (S.C.) and 22177125 (P.X.)), the Natural Science Foundation of Hunan Province (Grant NO. 2021JJ20022 (J.L.)) and the Youth Innovation Promotion Association of CAS (Grant NO.2020258 (P.X.)).

Author information

Authors and Affiliations

Contributions

J.L. and S.Y. conceived and designed the experiments. S.Y., G.D. and Y.Z. performed the experiments. J.L., C.S., P.X., B.Y. and S.Y. analyzed the results. J.L. wrote the paper and directed the project.

Corresponding authors

Ethics declarations

Competing interests

J.L., S.Y., P.X. and G.D. are inventors on a patent application (number 202311012144.4, China), dealing with the use of dimethyl sulfate (DMS) and diisopropyl sulfate (DPS) for sulfation. The remaining authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Alan Jones, Min Zhou and the other anonymous reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yue, S., Ding, G., Zheng, Y. et al. Dimethyl sulfate and diisopropyl sulfate as practical and versatile O-sulfation reagents. Nat Commun 15, 1861 (2024). https://doi.org/10.1038/s41467-024-46214-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-46214-x

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.