Abstract

Ni-based hydrogen oxidation reaction (HOR) electrocatalysts are promising anode materials for the anion exchange membrane fuel cells (AEMFCs), but their application is hindered by their inherent instability for practical operations. Here, we report a TiO2 supported Ni4Mo (Ni4Mo/TiO2) catalyst that can effectively catalyze HOR in alkaline electrolyte with a mass activity of 10.1 ± 0.9 A g−1Ni and remain active even up to 1.2 V. The Ni4Mo/TiO2 anode AEMFC delivers a peak power density of 520 mW cm−2 and durability at 400 mA cm−2 for nearly 100 h. The origin for the enhanced activity and stability is attributed to the down-shifted d band center, caused by the efficient charge transfer from TiO2 to Ni. The modulated electronic structure weakens the binding strength of oxygen species, rendering a high stability. The Ni4Mo/TiO2 has achieved greatly improved stability both in half cell and single AEMFC tests, and made a step forward for feasibility of efficient and durable AEMFCs.

Similar content being viewed by others

Introduction

Hydrogen-oxygen fuel cells with high energy efficiency and durability permit a sustainable energy system based on solar or electrical hydrogen converted from renewable energy resources1. With the fast development of low-cost oxygen reduction electrocatalysts at the cathode and alkane chain based anion exchange membranes2,3, enhancing the efficiency and durability of the anodic hydrogen oxidation reaction (HOR) electrocatalysts becomes particularly vital to the anion exchange membrane fuel cells (AEMFCs), as the HOR activity on the best Pt catalyst is two orders of magnitude slower in alkaline than in acidic medium4,5. Higher Pt catalyst loading would thus offset the cost merit brought by the cathode electrocatalysts and the membranes.

Enhancing the HOR activity of electrocatalysts is typically achieved by tuning the electronic structure of materials by alloying Pt with foreign metals. Pt alloys (PtRu, PtFe, PtCo, PtNi and PtCu) show greatly enhanced HOR activity compared to Pt, which is attributed to the optimized hydrogen binding energy (HBE)6,7,8 or potentially together with the optimized surface hydroxyl adsorption energy9,10,11. Similar strategy is also applied to developing non-precious HOR catalysts such as Ni to completely replace Pt group metals. In the few early attempts to improve the HOR activity of Ni, electrodeposited NiMo and CoNiMo thin films show superior activities to Ni, which is attributed to the optimized HBE introduced by the electronic effects between Ni and Mo/CoMo12. Recently, a group of Ni-based bimetallic nanoparticles, which are industry-relevant, have been developed for the HOR in base, showing much improved HOR activity with respect to Ni13,14. Except for tuning HBE on Ni, researchers also ascribe the improved HOR activity partially to the optimized surface hydroxyl group binding strength on foreign metals, which may facilitate the combination of -H and surface -OH group through the bi-functional mechanism13. Despite the debates in understanding the HOR mechanism in base, alloying achieves success in enhancing the overall HOR activities. However, non-precious metal catalysts often fail to meet the stability requirement. For example, the HOR performance on Ni-based catalysts usually dramatically drops at ~0.1 V versus the reversible hydrogen electrode (RHE) due to the Ni surface passivation12,15, while study shows that HOR catalysts should be able to remain stable up to at least 0.3 V for a substantial power density under practical operating conditions16. More severely, the anode potential would be driven up to ~0.8–0.9 V during the start-up and shut-down (SUSD) cycles or upon the H2 starvation events during fuel cell operations17. Recently, the amorphous Ni52Mo13Nb35 metallic glass was reported with the deactivation potential (the potential at which the HOR current starts to decrease) substantially increased to 0.8 V. Yet, the AEMFC using the Ni52Mo13Nb35 anode still shows a significant output cell voltage decay (~38%, from 0.74 to 0.46 V at 200 mA cm−2) in 50 h18. So far, none of the current Ni-based electrocatalysts can survive the harsh anodic conditions. Therefore, with achieved acceptable activity, efforts need to be geared to improve the stability of non-precious electrocatalysts.

The deactivation of HOR on Ni-based electrocatalysts is accompanied with Ni surface oxidation19,20,21, which passivates the catalyst surface and limits the electrochemically active window. Tuning the electronic structure of Ni-based materials for a weaker binding strength of Ni towards O/OH is therefore the most applied strategy. Ni5.2WCu2.2 ternary alloy22 and phase-separated Mo-Ni alloy (PS-MoNi)23 have exhibited elevated deactivation potential to ~0.3 V. Covering a protective layer outside Ni nanoparticles such as a few-layer hexagonal boron nitride (h-BN) could also prevent Ni from oxidation, which was speculated to originate from the weakened binding affinity towards oxygen species24. However, these negligible improvements in stability are not sufficient for practical AEMFC operation, and the stability issue is still the key problem to solve.

The interaction between the metal catalyst and the support also plays a vital role in tuning the reactivity of metal catalysts. Study shows that the interfacial charge transfer from Ni3N to the carbon support can move the deactivation potential from 0.16 V for Ni3N to 0.26 V for Ni3N/C25. Great improvements have been made on Pt group metals using metal oxide as the support. TiO2 partially encapsulated Pt shows extraordinary HOR activity above 1.0 V, wherein Pt alone will be oxidized and lose its HOR activity26. Using TiO2 to support Ru (Ru@TiO2) moves the deactivation potential from 0.2 V (Ru) to 0.9 V (Ru@TiO2)27. The interaction between Pt/Ru and TiO2, known as the metal-support interaction (MSI), enables an efficient charge transfer from TiO2 to metals as TiO2 is intrinsically an electron-rich semiconductor (negative semiconductor)28. Correspondingly, it is reasonable to speculate that the charge transfer introduced by the MSI may also exist between Ni-based non-precious metals and TiO2. Here, we report that the MSI between Ni4Mo and the TiO2 support boosts the durability for HOR up to 1.2 V, enabling a continuous AEMFC power output at 400 mA cm−2 for nearly 100 h, which makes a step forward for the automotive applications of the AEMFCs.

Results

HOR catalytic performance of Ni4Mo/TiO2

We prepared Ni4Mo/TiO2 catalysts through annealing the pre-mixed NiMo hydroxide precursor and the TiO2 support in H2 at 400 °C (see Methods). Optimization was made by adjusting the molar ratio between TiO2 and Ni4Mo according to their HOR performance (Supplementary Fig. S1 and Supplementary Table S1). The HOR catalytic performance of Ni4Mo and Ni4Mo/TiO2 catalysts was evaluated using the rotating disk electrode (RDE) method. Figure 1a shows the positive-going sweeps of the cyclic voltammograms (CVs) of Ni4Mo and the best performing Ni4Mo/TiO2 in both H2 and N2-saturated 0.1 M NaOH. Ni4Mo reaches the limiting current density of 2.65 mA cm−2geo at only 85 mV overpotential, showing a very high HOR activity. Yet, the HOR current quickly drops at 0.2 V, and eventually tracks the CV curve collected in N2, which strongly suggests that the surface oxidation of Ni4Mo blocks the active surface areas and prohibits the hydrogen oxidation. In contrast, while Ni4Mo/TiO2 shows a similar HOR limiting current density of 2.23 mA cm−2geo at 90 mV overpotential, it can catalyze the HOR even up to 1.0 V, with a mere 10% limiting current density decay. There is continuous HOR current at even ~1.4 V before oxygen starts to evolve (Supplementary Fig. S2). The difference in the polarization curves in H2 and N2-saturated electrolytes confirms that the anodic current in the presence of H2 in the full potential window is indeed originated from the H2 oxidation. It is also clearly seen from the CV curves collected in N2-saturated electrolyte that Ni4Mo/TiO2 hardly exhibits any features associated with the surface oxidation as Ni4Mo. Further chronoamperometry measurements verify that Ni4Mo/TiO2 exhibits a stable HOR current at as high as 1.2 V for 8000 s without noticeable decay (Fig. 1b and Supplementary Fig. S3). In comparison, Ni4Mo loses 87% of the HOR current when changing the holding potential from 0.2 to 0.3 V, and demonstrates an unacceptable low activity at 0.3 V (Fig. 1b).

Supplementary Fig. S4 shows the HOR polarization curves of Ni4Mo and Ni4Mo/TiO2 at different rotation speeds. Koutecky–Levich plots at 0.05 V exhibit a linear relationship between the inverses of i and ω1/2, with the slopes being 5.38 and 5.15 cm2 mA−1 s−1/2 for Ni4Mo and Ni4Mo/TiO2 (insets of Supplementary Fig. S4c, d). These values match reasonably well with the theoretical value of 4.87 cm2 mA−1 s−1/2 for the 2 e− HOR5, and are also in close agreement with the previous study29. The exchange current density (i0) was extracted by fitting the kinetic current to the Butler–Volmer equation (Supplementary Fig. S5). The mass activity (i0,m,298 K) was then obtained by normalizing i0 to the Ni mass, as shown in Supplementary Table S1 and Supplementary Fig. S6. Ni4Mo has a i0,m,298 K of 9.6 ± 0.5 A g−1Ni, in reasonably good agreement with previously reported values (6.8 A g−1Ni in ref. 13 and 14.1 A g−1Ni in ref. 14). The i0,m,298 K of Ni4Mo/TiO2 first increases, and then decreases with increasing Ti/Ni ratio. At low Ti/Ni ratios (Ti/Ni < 0.4), Ni4Mo/TiO2 follows similar HOR behavior as Ni4Mo that it starts to deactivate at ~0.2 V (Supplementary Fig. S1), despite the slightly higher mass activities. The best performance of Ni4Mo/TiO2 is achieved at Ti/Ni = 0.42, wherein Ni4Mo/TiO2 exhibits a similar i0,m,298 K (10.1 ± 0.9 A g−1Ni) as Ni4Mo, but a more stable HOR current above 1.0 V. When Ti/Ni ratio continues to increase (Ti/Ni > 0.5), in spite of its improved stability, Ni4Mo/TiO2 loses its mass activity significantly, which is most likely due to the lost active surface area by the TiO2 coverage. The HOR activation energies (Ea) on Ni4Mo and Ni4Mo/TiO2, determined from the Arrhenius plots (Supplementary Fig. S7), are 15.9 kJ mol−1 and 19.5 kJ mol−1 respectively, matching well with 18.6 kJ mol−1 for Ni4Mo reported previously13. Both Ni4Mo and Ni4Mo/TiO2 demonstrate decreased Ea with respect to metallic Ni (30.0 kJ mol−1) and partially oxidized Ni (26.0 kJ mol−1)30.

Figure 1c and Supplementary Table S2 summarize recent important progress in the development of Ni-based non-precious metal electrocatalysts for the alkaline HOR. Despite previous efforts in improving the HOR activity by one order of magnitude, achievements in enhancing the deactivation potential remains very limited. With the acceptable high mass activity, the Ni4Mo/TiO2 reaches a new deactivation potential of 1.2 V for the alkaline HOR Fig. 1.

a Positive-going sweeps of the cyclic voltammograms of Ni4Mo and Ni4Mo/TiO2 recorded in H2 and N2-saturated 0.1 M NaOH at 1600 r.p.m with a scanning rate of 0.5 mV s−1. The potentials are iR-corrected; b chronoamperometry curves of Ni4Mo and Ni4Mo/TiO2 at constant potentials in H2-saturated 0.1 M NaOH at 1600 r.p.m. The potentials are not iR-corrected; and c deactivation potentials and mass activities of Ni-based non-precious metal electrocatalysts for the alkaline HOR. Details are listed in Supplementary Table S2. Note 1: The Ni loadings are 477 and 376 μgNi cm−2geo for Ni4Mo and Ni4Mo/TiO2. Note 2: The data of CoNiMo12 and 4.3%N-Ni79 were calculated based on the original data. Note 3: The mass activities of bulky PS-MoNi23 and Ni52Mo13Nb3518 are unavailable. Here we set them at 1 A g−1 for comparison.

AEMFC performance of the Ni4Mo/TiO2 anode catalyst

Encouraged by the excellent intrinsic HOR performance of the Ni4Mo/TiO2 catalyst in the RDE measurements, the assembled single cell test was conducted for AEMFC performance. The Ni4Mo and Ni4Mo/TiO2 were used as the anode catalysts, the commercial Pt/C was employed as the cathode catalyst, and QAPPT was applied as both anion exchange membrane and ionomer to fabricate the membrane electrode assembly (MEA). Figure 2a shows the cell voltage and power density of the cells using Ni4Mo and Ni4Mo/TiO2 as the anode catalysts. Ni4Mo approaches a peak power density (PPD) of 188 mW cm−2, which is prominent in Ni-based non-precious metals and is much higher than the NiMo/KB reported previously (120 mW cm−2)15. Strikingly, Ni4Mo/TiO2 boosts the PPD to 520 mW cm−2, among the best AEMFC performances that have been reported under similar conditions (see Supplementary Table S3 for a summary of AEMFC performance of non-precious metal anode catalysts). In addition, Ni4Mo can only approach a current density of 275 mA cm−2 (at 0.685 V), and fails to operate beyond this point because of the Ni oxidation induced deactivation. However, Ni4Mo/TiO2 is able to deliver a much higher current density of 900 mA cm−2 (at 0.543 V), indicating that Ni4Mo/TiO2 is more resistant to oxidation and remains active at a higher polarization potential. The long-term durability of Ni4Mo/TiO2 was evaluated at a large current density of 400 mA cm−2 (Fig. 2b), and the cell exhibits a stable operation for nearly 100 h. Gao et al. have demonstrated that the Ni@CNx anode AEMFC exhibits a stable performance at 200 mA cm−2 for 100 h, which has been considered as a groundbreaking achievement at a large current density in AEMFCs31. The Ni4Mo/TiO2 anode further elevates the durability to a larger current density of 400 mA cm−2 for nearly 100 h (also see Supplementary Table S3 for Ni-based anode AEMFC durability). Moreover, the Ni4Mo/TiO2 anode can operate at 0.65 V (typical fuel cell operating potential for the automotive applications) for more than 80 h (Fig. 2b), paving the way for progress in the automotive applications of AEMFCs. Furthermore, the cells using Ni4Mo and Ni4Mo/TiO2 as the anode catalysts were discharged consecutively for three times. While the PPD of Ni4Mo is severely degraded from 188 mW cm−2 (1st cycle) to 171 mW cm−2 (2nd cycle) and 77 mW cm−2 (3rd cycle), as shown in Fig. 2c, Ni4Mo/TiO2 demonstrates a mere decrease of 7% in PPD from 520 mW cm−2 (1st cycle) to 480 mW cm−2 (2nd cycle), and retains the performance in the following cycle (Fig. 2d).

a Polarization and power density curves; b AEMFC durability of Ni4Mo/TiO2 at 400 mA cm−2; and c, d polarization and power density curves of Ni4Mo and Ni4Mo/TiO2 AEMFCs discharged for three times. AEMFC performance test conditions (a, c and d): cell temperature at 80 °C under H2 and O2 condition with a backpressure of 0.2 MPa for the anode and cathode, H2 and O2 humidified at 80 °C (100% RH) supplied to the anode and cathode compartments with a flow rate of 1000 sccm. AEMFC durability test conditions (b): H2 and O2 flow rate of 300 sccm and 500 sccm respectively, under otherwise identical conditions. The cell voltages were recorded with no iR-correction. The Ni loadings are 1.35 mgNi cm−2 for Ni4Mo and Ni4Mo/TiO2 at the anode, and the Pt loading is 0.4 mgPt cm−2 for Pt/C at the cathode.

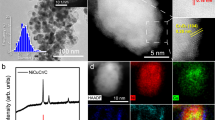

Crystallographic and Morphologic Characteristics of Ni4Mo/TiO2

The X-ray diffraction (XRD) pattern in Fig. 3a shows that the synthesized Ni and Mo alloy exhibits a Ni4Mo phase structure (JCPDS 65-5480), consistent with the ICP-OES results (Supplementary Table S1). The TiO2 distinctly presents both the anatase phase (JCPDS 89-4921) and the rutile phase (JCPDS 89-0552). The high intensity diffraction peaks at 25.3° and 37.8°, indexed to the anatase TiO2 (101) and (004) crystal planes, suggest that the anatase phase is the major composition in the pristine TiO2. Ni4Mo/TiO2 exhibits crystallographic features associated with both Ni4Mo and TiO2. Increasing the Ti/Ni ratio leads to the decreased relative peak intensity of Ni4Mo to TiO2 (Supplementary Fig. S8), corresponding to the gradually decreased Ni4Mo loading on TiO2. The transmission electron microscopy (TEM) image shows an interconnected particle morphology of Ni4Mo with the particle size of about 7.5 nm (Fig. 3b and Supplementary Fig. S9). Aberration-corrected high-angle annular dark-field scanning transmission electron microscope (HAADF-STEM) image of Ni4Mo (Fig. 3c) shows the 0.210 and 0.202 nm-lattice fringes, corresponding to the (121) and (220) planes of Ni4Mo. The corresponding fast Fourier transform (FFT) pattern demonstrate the tetragonal Ni4Mo crystalline phase with Ni4Mo (121), (220) and (330) planes (Fig. 3d). Elemental mappings using energy dispersive X-ray spectroscopy (EDS) further reveal the compositional distributions of Ni and Mo elements, confirming the formation of a uniform alloy (Supplementary Fig. S10). The pristine TiO2 has a rectangular plate morphology with the 0.354 and 0.237 nm-lattice fringes corresponding to the (101) and (004) planes of the anatase phase (Supplementary Fig. S11). TEM and HAADF-STEM images of Ni4Mo/TiO2 show a uniform distribution of spherical Ni4Mo particles with a mean size of 7.6 nm on the TiO2 support (Fig. 3e–g and Supplementary Fig. S12), maintaining the crystallographic characteristics as unsupported Ni4Mo with the lattice fringe interplanar spacings of 0.210 and 0.202 nm for Ni4Mo (121) and (220) planes. Besides, the lattice fringe with a spacing of 0.237 nm for the TiO2 support is consistent with the pristine TiO2, corresponding to the (004) plane. This structure was further identified by the FFT images (Fig. 3h, i). The inverse FFT image in Fig. 3j also show the interface between TiO2 and Ni4Mo, further demonstrating that Ni4Mo is supported on the TiO2.

MSI in Ni4Mo/TiO2

Raman spectroscopy study of TiO2 shows six Raman-active modes at around 140 cm−1 (Eg), 195 cm−1 (Eg), 393 cm−1 (B1g), 511 cm−1 (A1g + B1g) and 635 cm−1 (Eg) (Supplementary Fig. S13a), in good agreement with Raman spectrum of the anatase TiO232. No detectable Raman shift or peak broadening is observed for TiO2 treated at 400 °C in H2 (TiO2-H2-400 in Supplementary Fig. S13b), indicating that there are not enough oxygen vacancies being introduced, as they will cause the blue-shift and peak broadening in the Raman spectra of TiO233,34. When Ni4Mo is decorated on the TiO2 support, there appears to be distinct blue-shift in the vibrational mode of Eg from 140 cm−1 (TiO2) to 150 cm−1 (Ni4Mo/TiO2) and peak broadening (Supplementary Fig. S13b), similar to that for Au or Ag decorated TiO2 in a previous study35. The blue-shift and peak broadening are most likely due to a compressive strain36,37, possibly introduced by lattice mismatch between the metal particles and the TiO2 support. The Raman results, together with the aforementioned electron microscopy study, confirm an interfacial interaction between the Ni4Mo particles and the TiO2 support.

Figure 4a shows that X-ray photoemission spectrum (XPS) of the Ni 2p3/2 level of Ni4Mo contains four peaks, which can be assigned to Ni0 (852.7 eV), Ni2+ (856.1 eV) and their two satellites (858.9 eV for Ni0 satellite and 861.6 eV for Ni2+ satellite)38,39,40. Notably, both of the Ni0 and Ni2+ peaks of Ni4Mo/TiO2 at all Ti/Ni ratios shift negatively to lower binding energies (BE) (Fig. 4a and Supplementary Fig. S14a). XPS spectra of Mo 3d level reveal a complex Mo 3d3/2 and Mo 3d5/2 doublets, with the 3d5/2 peaks centered at 228.0, 229.0, 230.0 and 232.2 eV, corresponding to Mo0, Mo4+, Mo5+ and Mo6+ respectively (Supplementary Fig. S14b)41,42,43. These peaks do not shift when loading Ni4Mo onto TiO2 at all Ti/Ni ratios. Ti 2p doublets of TiO2 show two peaks centered at 458.6 and 464.3 eV, assigned to Ti4+ 2p3/2 and Ti4+ 2p1/2 respectively44, and the Ti4+ in Ni4Mo/TiO2 displays the positive core level shift to 458.9 eV (Ti4+ 2p3/2) and 464.6 eV (Ti4+ 2p1/2), indicating that Ti is in an electron-deficient status with a higher valence state (Fig. 4b). The O 1s spectrum for TiO2 is de-convoluted to two peaks at 529.9 and 531.2 eV (Fig. 4c), associated with the lattice oxygen in TiO2 (Ti-O) and the surface hydroxyl group (H-O)27,44. The O 1s spectrum of Ti-O for Ni4Mo/TiO2 also exhibits a positive BE shift by ~0.2 eV. Note that Ni4Mo/TiO2 experienced high temperature reduction in H2 at 400 °C; both of the Ti 2p and O 1s spectra of the bare TiO2 treated under the same condition (TiO2-H2-400) were also collected, and no significant difference was observed (Supplementary Fig. S15). At all Ti/Ni ratios, both of the Ti 2p and O 1s peaks shift to higher BE. The X-ray absorption fine structure spectroscopy (XAFS) is used to further probe the impact of the TiO2 support on the chemical environment of Ni. Notably, the absorption edge of Ni4Mo/TiO2 displays a slight shift toward the lower photon energy relative to Ni4Mo (Fig. 4d, left inset), indicating the electron enrichment on Ni atoms in Ni4Mo/TiO2. The white line absorption intensity is also weaker than that of Ni4Mo (Fig. 4d, right inset), signifying the lower Ni valence state in Ni4Mo/TiO2 (Supplementary Fig. S16). In addition, as shown in the Fourier-transform of Ni K-edge extended X-ray absorption fine structure (EXAFS) (Fig. 4e), the intensity of the peak at 2.0 Å, assigned to Ni-Ni/Ni-Mo coordination of Ni4Mo/TiO2, is higher than that of Ni4Mo, demonstrating an increased Ni coordination number, which is speculated to originate from the interaction with the TiO2 support. XPS and XAFS results strongly suggest that there exists electronic interaction between Ni4Mo and the TiO2 support through the charge transfer from TiO2 to Ni.

a Ni 2p3/2, b Ti 2p and c O 1s level X-ray photoemission spectra; d normalized Ni K-edge X-ray absorption spectra (the left inset is the magnified near-edge, and the right inset is the white line); e Fourier-transform of Ni K-edge EXAFS spectra; and f ultra-violet photoemission spectra of Ni4Mo and Ni4Mo/TiO2.

Work function values determined from ultra-violet photoemission spectroscopy (UPS) measurements also support the charge transfer from TiO2 (3.6 eV) to Ni4Mo (4.3 eV) (Supplementary Fig. S17). To collectively elucidate the electronic interaction between Ni4Mo and TiO2, the d band density of states was further investigated by UPS as shown in Fig. 4f and Supplementary Fig. S18. All samples illustrate intense emission between −3 and −10 eV below the Fermi level (εF), related to O 2p orbitals44,45. TiO2 and TiO2-H2-400 do not show density of states at the εF, but a very weak emission at −0.7 to −0.9 eV, which probably originates from the Ti3+ defect states44. The bands located at 0 to −3 eV are attributed to the Ni 3d states46,47. The Ni 3d band centers are roughly estimated to be −1.31 eV and −1.59 eV for Ni4Mo and Ni4Mo/TiO2 respectively, according to Eq. (1) (see Methods)48,49,50. Clearly, the centroid d band of Ni4Mo/TiO2 is regulated by TiO2, and down shifts away from the εF compared to Ni4Mo. Considering that the UPS measurement only probes the occupied d states, we later performed theoretical density functional theory (DFT) calculations to identify the density of states (DOS) including the unoccupied states in the next section.

Robust structure of Ni4Mo/TiO2 in electrochemical measurements

Post-reaction characterizations were performed to study the structural stability of the Ni4Mo/TiO2 catalyst. After long-term stability test on the RDE, Ni4Mo/TiO2 still shows an interconnected particle morphology (TEM and HR-TEM in Supplementary Figs. S19a, b) with the Ni4Mo phase structure well maintained (selected-area electron diffraction, SAED in Supplementary Fig. S19c), and the Ni, Mo, Ti and O elements also have a uniform spatial distribution (EDS mappings in Supplementary Fig. S19d–h). XPS measurements similarly demonstrate inconspicuous change in the Ni 2p3/2, Mo 3d, Ti 2p and O 1s spectra after long-term stability test (Supplementary Fig. S20). ICP-MS results suggest that Ni and Ti dissolutions are negligible in 0.1 M NaOH. Yet, Mo is found to dissolve from the top surface of Ni4Mo particles (Supplementary Table S4), in good agreement with previously reported Mo dissolution on NiMo alloys51,52,53,54. The TiO2 support does not exhibit an inhibitive effect on Mo dissolution. However, Mo dissolution does not seem to deteriorate the HOR performance, as evidenced by the stable HOR current in the long term CA test (Fig. 1b).

After 100 h durability test in the AEMFC setup, the crystal, morphological, compositional, and electronic structures of Ni4Mo/TiO2 also exhibit negligible change (XRD, TEM, HR-TEM, SAED, EDS and XPS in Supplementary Figs. S21–23). The multiple post-reaction characterizations clearly demonstrate the structural robustness of Ni4Mo/TiO2, which enables its high HOR performance and durability in both RDE and AEMFC tests.

Proposed mechanism for the enhanced stability of Ni4Mo/TiO2

The above results strongly suggest that the MSI between Ni4Mo and the TiO2 support modulate the electronic structure of Ni4Mo, causing a down-shifted d band center, which would weaken the adsorption strength of simple intermediate/molecule on Ni4Mo, such as H, O and CO, according to the d band theory55. Parallel hydrogen-temperature-programmed desorption (H2-TPD) results clearly demonstrate a lower desorption temperature on Ni4Mo/TiO2 than that on Ni4Mo (Supplementary Fig. S24), signifying a weakened hydrogen binding strength on Ni4Mo/TiO2. In line with the reduced hydrogen binding strength, although it is difficult to obtain the specific activity due to the uncertainty in the electrochemical surface area (ECSA) determination, it is reasonable to argue that Ni4Mo/TiO2 would exhibit a higher specific activity than Ni4Mo, as Ni4Mo/TiO2 has a similar Ni4Mo particle size and mass activity, but smaller ECSA due to the coverage of TiO2. Remarkably, oxygen-temperature-programmed oxidation (O2-TPO) results exhibit a much higher oxidation temperature of Ni4Mo/TiO2 than Ni4Mo (Supplementary Fig. S25), indicating a stronger oxidation resistance of Ni4Mo/TiO2, also in agreement with the hypothesis.

Quasi in situ electrochemical XPS and in situ electrochemical Raman experiments were performed to explore the electronic structures and surface conditions of the Ni4Mo and Ni4Mo/TiO2 catalysts during the HOR process. After potential cycling between −0.1 to 0.2 V for a few cycles to active the surface, the Ni 2p3/2 and Ti 2p level XPS spectra were taken at the open circuit potential (OCP) and oxidizing potentials up to 1.2 V (Supplementary Figs. S26 and S27). The Ni 2p3/2 spectrum (Supplementary Fig. S26a) of Ni4Mo collected at OCP shifts by −0.5 eV relative to the ex situ experimental data as the Ni atoms are negatively charged during the surface activation process, and can be described as the electron-enriched Ni metal (Niδ−)56. The BE of Ni0 (Niδ−) 2p3/2 in both Ni4Mo and Ni4Mo/TiO2 stays constant at all potentials, while it is negatively shifted by 0.2-0.3 eV in Ni4Mo/TiO2 with respect to that in Ni4Mo regardless of the applied potentials (Fig. 5a and Supplementary Fig. S26a, b). The Ni2+ content estimated from XPS data is 21% in Ni4Mo at the initial OCP, and dramatically increases to 44% at 1.2 V, while the Ni2+ content is substantially reduced in Ni4Mo/TiO2 (21% at OCP to 33% at 1.2 V, Supplementary Fig. S26c). The correlation between the HOR polarization curves and the Ni0 (Niδ−) percentages shows that the severely decreased current on Ni4Mo at 0.3 V matches relatively well with the decreased Ni0 (Niδ−) content (Supplementary Fig. S26d), indicating that Ni4Mo deactivation is originated from Ni oxidation. The Ti4+ 2p3/2 spectra demonstrate a ~ 0.2 eV positive BE shift from OCP to 1.2 V (Fig. 5b and Supplementary Fig. S27a). Interestingly, a new peak signal in Ti 2p spectra of Ni4Mo/TiO2 emerges at the BE lower than Ti4+ 2p3/2 after the surface activation, which can be assigned to the reductive Ti3+ 2p3/2 species44. The Ti3+ 2p3/2 peak shifts to higher BE (456.5 eV at OCP to 457.2 eV at 1.2 V), and decreases in percentage (34% at OCP to 22% at 1.2 V, Supplementary Fig. S27b) with increasing applied potential. Ti3+ has been verified to boost the efficient charge transfer from TiO2 to metals by decreasing the work function of TiO2 bulk57,58, and thus may also play an important part in constructing the MSI of Ni4Mo/TiO2. The quasi in situ XPS experiments further confirm the existence of the charge transfer from TiO2 to Ni4Mo under the electrochemical conditions.

The in situ Raman spectra were also collected after the surface activation (Fig. 5c, d). The bands at 310 and 893 cm−1, which could be respectively assigned to the Mo = O stretching mode and bending mode in the MoO42− tetrahedron (see Supplementary Table S5 for the band assignment), exist in the full potential window investigated from the OCP to 1.2 V for both Ni4Mo and Ni4Mo/TiO2, owing to the oxidation of Mo in Ni4Mo to MoO42−52. The peak at 483 cm−1 is indexed to the symmetric stretching mode of bridging Mo-O-Mo bond in Mo2O72−, formed from the MoO42− dimerization52,59. Furthermore, the band at 460 cm−1 starting from 0.1 V and the one at 939 cm−1 starting from 1.0 V on Ni4Mo (Fig. 5c), attributed to the Ni-OH symmetric stretching mode of Ni(OH)260,61,62,63 and Mo-O stretching mode of NiMoO459,64 respectively, indicate the formation of hydroxide and oxide of Ni and Mo during the HOR from 0.1 to 1.2 V. Interestingly, these peaks associated with Ni-OH or Mo-O vibrations disappear on Ni4Mo/TiO2, and only when the potential reaches 1.0 V is the Ni-OH vibration marginally visible (Fig. 5d), revealing that most of the Ni surface atoms likely exist in the form of Ni0 (Niδ−). These experimental results clearly suggest that Ni4Mo/TiO2 has great resistance to oxidation to endure the harsh oxidative conditions at high anodic potentials. This high oxidation resistance is likely due to the strong electronic modulation between Ni4Mo and TiO2, which renders a down-shifted d band center, and in turn weakened OH adsorption energy. DFT calculations also demonstrate a similar trend (Supplementary Fig. S28), in line with the hypothesis.

There have been debates as to the role of the surface hydroxyl species in the alkaline hydrogen oxidation on Pt group metal-based electrocatalysts, wherein the surface OH may (bi-functional mechanism9) or may not (HBE mechanism4,65) directly participate in the HOR process. However, on Ni-based non-precious materials, it is rather difficult to differentiate the role of the surface OH, as Ni-based materials usually exhibit complicated surface conditions in a broad potential regime, and there is by far no experimental evidence regarding the direct participation of surface OH in the HOR yet. In our opinion, the surface OH most likely acts as the spectator, which deteriorates the HOR activity by blocking the active surface area. This speculation is supported by the observations that the HOR current decrease on Ni4Mo and the metal surface oxidization occur concurrently (Fig. 1a and Supplementary Fig. S2), and the appearance of Raman bands associated with Ni(OH)2 and NiMoO6 in the Raman spectra of Ni4Mo. Therefore, it becomes very straightforward to weaken the OH binding strength in designing the HOR catalysts to enhance their anti-oxidation ability. By introducing the MSI using TiO2 as the support, the d band center of Ni4Mo is downwards shifted, causing a weakened binding strength to surface O or OH. It is clearly seen from Supplementary Fig. S29, the CV of Ni4Mo/TiO2 is mainly composed of the capacitive current, demonstrating much mitigated surface oxidation. Therefore, we hypothesize that the surface OH plays the role as the blocking species on Ni4Mo, and attribute the improved anti-oxidation ability of Ni4Mo/TiO2 to its much weakened OH adsorption strength.

CO-tolerance of Ni4Mo/TiO2

The modulated d band of Ni4Mo by the TiO2 support not only weakens the OH binding strength, but may also reduce the CO binding energy55. As shown in Supplementary Fig. S30, the CO-stripping peak on Ni4Mo/TiO2 moves negatively to 0.50 V in comparison with 0.70 V on Ni4Mo. Moreover, Ni4Mo/TiO2 exhibits HOR activity with a negligible decay in the presence of 2000 p.p.m CO, compared to a ~14% decrease in the HOR limiting current density of Ni4Mo (Supplementary Fig. S31a). Chronoamperometry measurements at 0.2 V also demonstrate that the HOR current on Ni4Mo/TiO2 in the presence of 2000 p.p.m CO only decays 14% after 8000 s, much improved than a ~40% decay on Ni4Mo (Supplementary Fig. S31b). The satisfying CO-tolerant capability of Ni4Mo/TiO2 is attributed to its weakened CO binding strength, which originates from the modulated electronic structure of Ni4Mo by the TiO2 support.

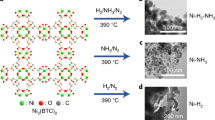

Applicability of the MSI to other Ni-based electrocatalyst

We further investigated whether the MSI between the metal catalyst and the TiO2 support can be applied to other Ni-based electrocatalysts for the enhanced stability. Despite its excellent HOR activity, Ni2W also loses the HOR activity at potentials higher than 0.2 V, in line with the surface oxidation in this potential regime (Fig. 6a). Optimized Ni2W/TiO2 (Ti/Ni = 0.46) not only exhibits good HOR activity at a low overpotential, but maintains the activity at a very small degradation rate (Fig. 6a and Supplementary Fig. S32, also see Methods, Supplementary Table S6, Supplementary Figs. S33–36 for detailed information on the synthesis and material structure). Although W is also found to slightly leach from the surface of Ni2W nanoparticles in the alkaline electrolyte under the experimental conditions (Supplementary Table S7), long-term stability tests confirm that Ni2W/TiO2 can remain stable activity towards hydrogen oxidation at 1.2 V (Fig. 6b and Supplementary Fig. S37). This finding highlights the strategic importance of the MSI in tailoring the electronic structure of Ni-based electrocatalysts to elevate the HOR stability in alkaline electrolytes.

a Positive-going sweeps of the cyclic voltammograms of Ni2W and Ni2W/TiO2 recorded in H2 and N2-saturated 0.1 M NaOH at 1600 r.p.m with a scanning rate of 0.5 mV s−1. The potentials are iR-corrected; and b chronoamperometry curves of Ni2W and Ni2W/TiO2 in H2-saturated 0.1 M NaOH at 1600 r.p.m. The potentials are not iR-corrected. The Ni loadings are 349 and 312 μgNi cm−2geo for Ni2W and Ni2W/TiO2.

In conclusion, by applying the MSI between NiM alloys and the TiO2 support, we successfully synthesized Ni4Mo/TiO2 and Ni2W/TiO2 electrocatalysts with enhanced HOR stability. The catalysts not only maintain good HOR mass activities (10.1 ± 0.9 A g−1Ni for Ni4Mo/TiO2 and 6.8 ± 0.2 A g−1Ni for Ni2W/TiO2), but also show stable HOR current at as high as 1.2 V. AEMFC tests, using Ni4Mo/TiO2 as the anode catalyst, demonstrate a good performance with a peak power density of 520 mW cm−2 and durability at 400 mA cm−2 for nearly 100 h. Detailed structural and electronic analyses confirm the existence of the MSI through charge transfer from the TiO2 support to NiM metals. Modulated electronic structure of NiM weakens the adsorption strength of H, O/OH and CO on NiM surfaces, rendering a high anti-oxidation ability of NiM/TiO2. These results highlight the significance of the MSI in improving the catalyst stability, and evidence the intriguing promise of Ni4Mo/TiO2 as an efficient and robust anode catalyst, making a step forward in the applications of the AEMFC technology.

Methods

Material synthesis

The Ni4Mo/TiO2 catalysts were synthesized through a three-step method. Firstly, the NiMo hydroxide precursor was prepared by a solvothermal method14. In brief, 735 mg Ni(NO3)2·6H2O (98%, Sinopharm) and 81 mg (NH4)6Mo7O24·4H2O (99%, Alfa Aesar) were dissolved in 2.5 mL ultra-pure H2O (18.2 MΩ cm, Millipore), followed by addition of 12.5 mL ethylene glycol (99%, Innochem) and 1 mL NH3·H2O (18% NH3 basis, Sigma-Aldrich). After stirring for 2 h, the solution was transferred into a Teflon-lined stainless steel autoclave and heated at 190 °C for 1 h. When cooling down to the room temperature, the synthesized green powder was washed using ethyl alcohol (99.5%, Innochem) and ultra-pure H2O (1:1 in volume) for five times, and collected by centrifugation. Secondly, six batches of the green precipitate were mixed with 100, 67, 50, 33, 25 and 20 mg TiO2 (Aeroxide® P25, Acros Organic) respectively, and then dispersed in 50 mL ethyl alcohol by magnetically stirring for 20 h. Subsequently, the mixture was collected by vacuum filtration, and grounded in a mortar for 20 min after drying at 50 °C in vacuum (2.13 × 104 Pa). Finally, the collected substance was heated up to 400 °C at 3 °C min−1 in a reductive atmosphere (H2/N2 = 1:5 in volume) and remained at 400 °C for 1 h to obtain the Ni4Mo/TiO2 catalysts. Ni4Mo was prepared using the same method without adding TiO2 in the second step.

Ni2W and Ni2W/TiO2 catalysts were synthesized by the same procedure, except that the initial Ni and W precursors were 735 mg Ni(NO3)2·6H2O (98%, Sinopharm) and 177.5 mg (NH4)2WO4 (99.99%, Alfa Aesar), and the final heat-treatment temperature was 500 °C.

Physical characterizations

Electron microscopy

High-resolution transmission electron microscopy (HR-TEM) measurement was conducted on the FEI Talos 200X and JEOL JEM-2100F transmission electron microscopes at the accelerating voltage of 200 kV. Aberration-corrected high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) measurement was carried out on an atomic-resolution analytical microscope (thermalfisher scientific titan themsis Z) equipped with a probe spherical aberration corrector at an acceleration voltage of 300 kV. Energy dispersive X-ray spectroscopy was collected on the Oxford Instruments X-Max 80 T. The sample was made through dispersing the catalysts in ethyl alcohol by sonication. The dispersion was then dropped on an ultrathin carbon grid, and dried in air for few minutes.

Powder X-ray diffraction (XRD)

XRD measurement was performed on a D8 Advance X-ray diffractometer (Bruker) using Cu Kα radiation (λ = 0.15418 nm) at 40 kV and 40 mA. The data were collected with 2θ ranged from 10° to 90° at a scanning rate of 10° min−1.

Raman spectroscopy

Raman experiment was carried out with a confocal microscope Raman spectrometer (DXR3, Thermo Scientific). The excitation wavelength was 532 nm.

X-ray photoemission spectroscopy (XPS)

The states of Ni, Mo, Ti and O in the catalysts were examined on a ThermoFischer ESCALAB 250Xi X-ray photoelectron spectrometer equipped with Al X-ray source (Al Kα, 1486.6 eV). All spectra were processed using the Shirley background correction, and calibrated with the C 1s component at 284.8 eV. The Gaussian–Lorentzian line shape was adopted to fit the spectra.

X-ray absorption fine structure spectroscopy (XAFS)

The XAFS measurements were performed at 1W1B station in Beijing Synchrotron Radiation Facility, operated at 2.5 GeV with a maximum current of 250 mA. The spectra were collected in the fluorescence mode using a Lytle detector. Samples were pelletized with diameter of 8 mm and thickness of 1 mm using the PVDF powder as the binder. The acquired Ni K-edge extended X-ray absorption fine structure (EXAFS) data were processed according to the standard procedures using the Athena and Artemis implemented in the IFEFFIT software packages66. The EXAFS spectra were subtracted by the post-edge background from the overall absorption, and normalized with respect to the edge-jump step. The χ(k) data were Fourier transformed to real (R) space using a hanning window (dk = 1.0 Å−1) to separate the EXAFS contributions from different coordination shells. Least-squares curve fitting was performed using the Artemis module of IFEFFIT software packages to obtain the quantitative structural parameters. In the fitting, the amplitude reduction factor S02 was fixed, and the internal atomic distances R, Debye-Waller factor σ2, and the edge-energy shift ΔE0 were allowed to run freely.

Ultraviolet photoemission spectroscopy (UPS)

Surface electronic structure of the catalysts was investigated on the PHI5000 VersaProbe III electron spectrometer (Scanning ESCA Microprobe) at UV photon energy of 21.2 eV (He I) under ultra-high vacuum (4 ×10−6 Pa). The total energy resolution was 0.10 eV. Shirley background was subtracted as described in the previous study48. The band between −3 eV and −10 eV centered at −4.9 eV for the Ni4Mo sample was assigned to the O 2p states due to inevitable oxidation upon exposure to air45, while the band in the same window centered at −6.0 eV for the Ni4Mo/TiO2 sample was O 2p states mainly originated from TiO244. The bands ranged from 0 to −3 eV in both samples were assigned to the Ni 3d photoemission46. The d band center energy relative to the Fermi level was calculated based on the following equation48,49,50

where N(ε) is the density of states, and ε is the energy of states.

For the work function calculation, the valence band spectra were also collected at the same spectrometer with a − 5 V bias voltage applied to the sample. The work function (\(\varphi\)) could be calculated from the following equation67

where hν is the energy of the UV photon (He I, 21.2 eV), and Ecutoff is the energy of the secondary-electron cutoff.

H2-temperature programmed desorption (H2-TPD)

Surface property towards H adsorption/desorption of the catalyst was measured using a ChemBET instrument (Quantachrome). The signal was determined by a thermal conductivity detector (TCD). 100 mg catalyst was placed in a quartz tube, and heated from the room temperature up to 400 °C at a ramping rate of 10 °C min−1 with flowing He. The sample was kept at 400 °C for 30 min, and then cooled down to the room temperature under He-flow. Subsequently, H2 was introduced into the tube for adsorption until a stable TCD signal. After removing H2 with flowing He, the sample was heated up to 400 °C with a ramping rate of 10 °C min−1.

O2-temperature programmed oxidation (O2-TPO)

Surface property towards binding strength of oxygen-related species was measured on the same instrument as H2-TPD. 100 mg catalyst was placed in a quartz tube, and heated from the room temperature up to 400 °C at a ramping rate of 10 °C min−1 with flowing He. The sample was kept at 400 °C for 30 min, and then cooled down to the room temperature under He-flow. Subsequently, the sample was gradually oxidized from the room temperature to 400 °C at a ramping rate of 10 °C min−1 in the presence of 3% O2 in He.

Inductively coupled plasma-optical emission spectrometry (ICP-OES)

The chemical contents of Ni, Mo and Ti were examined by ICP-OES on Agilent-730-OES. In brief, the catalyst was mixed with 5 mL HNO3 (67%, Sinopharm), 1 mL HF (40%, Sinopharm) and 1 mL HCl (37%, Sinopharm) in a Teflon-lined stainless steel autoclave, followed by heating at 180 °C for 8 h. After cooling down to the room temperature, the solution was transferred to a 25-mL volumetric flask, and diluted with ultra-pure H2O to the metered volume for ICP measurement.

Inductively coupled plasma mass spectrometry (ICP-MS)

ICP-MS (Aglient-7700) was used to detect the Ni, Mo, W and Ti dissolution in the alkaline electrolyte after electrochemical measurements.

Electrochemical measurement

All electrochemical measurements were performed on the electrochemical workstation (VSP-300, Biologic). The temperature was set at 25 ± 0.5 °C, unless otherwise emphasized. The catalyst ink was prepared by dispersing and sonicating the catalyst in a mixture of 750 μL isopropanol (99.5%, Innochem), 200 μL ultra-pure H2O and 50 μL Nafion (5 wt%, Sigma-Aldrich) with a final concentration of 6-8 mgNi mL−1. 10 μL catalyst ink was deposited on a glassy carbon electrode (5 mm in diameter, Tianjin Aida), which was pre-polished with 50 nm alumina slurry (99.0%, Tianjin Aida), and dried in air at the room temperature, resulting in the Ni loading of ~400 μgNi cm−2geo (see Supplementary Tables S1 and S6 for the specific loadings). The catalyst thin film electrode was then mounted onto a rotator (Pine Instrument), serving as the working electrode. A KCl-saturated calomel electrode (SCE, Tianjin Aida) and a graphite rod (spectral purity, Tianjin Aida) were used as the reference and counter electrodes, respectively. All potentials reported in this paper were referenced to the reversible hydrogen electrode (RHE), which was calibrated by measuring the HER/HOR on a Pt disk (5 mm in diameter, Pine Instrument) in H2-saturated 0.1 M NaOH (99.99% metal trace, Sigma-Aldrich).

Cyclic voltammetry measurement

Surface properties of the as-prepared electrocatalysts were investigated using the cyclic voltammetry (CV) method from −0.3 V to 1.8 V versus RHE with a rotating speed of 1600 r.p.m and a scanning rate of 20 mV s−1 in N2-saturated 0.1 M NaOH.

Rotating disk electrode measurement

HOR performances of the as-prepared electrocatalysts were examined using the RDE technique. The catalyst thin film electrodes were first activated by CV in H2-saturated 0.1 M NaOH between −0.1 and 0.2 V versus RHE at 20 mV s−1 for several cycles until a steady polarization curve was obtained. The HOR polarization curves were then collected with a rotating speed of 400, 900, 1600 and 2500 r.p.m and a scanning rate of 0.5 mV s−1 to minimize the capacitive charge contribution.

The HOR kinetic current (iK) was calculated based on the Koutecky–Levich equation68

where i is the measured current, and iD is the diffusion limited current.

The HOR exchange current (i0) was obtained subsequently by fitting iK to the Butler–Volmer equation69

where i0 is the HOR exchange current, αa is transfer coefficient for the HOR, F is the Faraday constant (96485 C mol−1), R is the universal gas constant (8.314 J mol−1 K−1), T is the temperature, and η is the overpotential. αa was between ~0.1 and ~0.4.

Activation energy (Ea) of the HOR was measured at different temperatures from 2 °C to 30 °C. The Ea can be calculated from the Arrhenius equation

where i0 (mA cm−2) is the exchange current density at different temperatures, Ea is the activation energy (J mol−1), R is the universal gas constant (8.314 J mol−1 K−1), and T is the temperature (K).

Chronoamperometry measurement

Chronoamperometry (CA) experiment was taken at a constant potential for 8000 s in H2/N2-saturated 0.1 M NaOH with a rotating speed of 1600 r.p.m for stability test.

CO stripping and CO tolerance measurement

CO stripping was conducted using the CA and CV methods. The potential was held at 0.1 V versus RHE for 30 min, during which time the electrolyte was purged with CO, allowing for complete CO adsorption, followed by 20 min-purging with N2 to remove the remaining CO in the electrolyte. Then CO stripping was performed by taking CV from 0 to 1.2 V versus RHE at a scanning rate of 20 mV s−1 for 2 cycles. CO tolerance experiment was performed using the RDE technique and CA method in H2-saturated 0.1 M NaOH at 0.2 V versus RHE in the presence of 2000 p.p.m CO.

Electrochemical impedance spectroscopy (EIS) measurement

Solution resistance was obtained after each RDE test by EIS measurement. The EIS spectra were taken at 0 V vs. open circuit potential (OCP) with a 10 mV voltage perturbation, and the frequency was from 100 mHz to 200 kHz. The real part of the resistance at 1 kHz was taken as the solution resistance (R ≈ 40 Ω).

In situ electrochemical Raman spectroscopy test

The in situ electrochemical Raman test was performed on a Renishaw Via Raman microscope with a 532 nm excitation wavelength and a 50× objective. The sample ink was prepared by dispersing the catalyst in a mixture of ultra-pure H2O, isopropanol and Nafion, and then dropped on a piece of carbon paper (CP, 15 × 15 mm2), serving as the working electrode. Prior to collecting the Raman data, the Ni4Mo and Ni4Mo/TiO2 working electrodes were scanned between −0.1 and 0.2 V versus RHE for 10 cycles in H2-saturated 0.1 M NaOH in a home-made Raman cell (Supplementary Fig. S38), equipped with a platinum counter electrode and a SCE reference electrode. The solution resistance was ~26 Ω for the in situ Raman setup. The working electrode was held at each potential (OCP and 0–1.5 V versus RHE at an interval of 0.1 V) for 2 min for the Raman spectra collection. The laser intensity was set to be 10% with a collection time of 50 s for each spectrum.

Quasi in situ electrochemical X-ray Photoemission Spectroscopy test

Quasi in situ electrochemical XPS measurement was carried out on the ThermoFischer ESCALAB 250Xi instrument by applying a monochromatic Al Kα X-ray source (1486.8 eV) operating at 12.5 kV and 16 mA under ultra-high vacuum (8 × 10−10 Pa). The total energy resolution was 0.10 eV. The catalyst ink was prepared by dispersing the catalyst in a mixture of ultra-pure H2O, ethyl alcohol and Nafion, and then dropped on a glassy carbon (GC) electrode (4 mm in diameter), serving as the working electrode. Before collecting the XPS data, the Ni4Mo and Ni4Mo/TiO2 working electrodes were scanned between −0.1 and 0.2 V versus RHE for 10 cycles in H2/N2 mixture-saturated 0.1 M NaOH in a home-made cell (Supplementary Fig. S39), equipped with a platinum counter electrode and a SCE reference electrode. The solution resistance was ~10 Ω for the quasi in situ XPS setup. The working electrode was first held at each potential (OCP, 0, 0.2, 0.3, 0.4, 0.5, 0.6, 0.8, 1.0 and 1.2 V versus RHE) for 2 min, then vacuumed in the preparation chamber, and finally transferred to the test chamber for XPS spectrum collection without exposure to the air. All spectra were processed using the Shirley background correction, and calibrated with the C 1s component at 284.8 eV. The Gaussian–Lorentzian line shape was adopted to fit the spectra.

Membrane-electrode assembly and AEMFCs test

The as-synthesized Ni4Mo or Ni4Mo/TiO2 was used as the anode catalyst and the commercial Pt/C (60 wt%, Johnson-Matthey) was used as the cathode catalyst. The self-designed QAPPT [quaternary ammonia poly (N-methyl-piperidine-co-p-terphenyl)] was applied as both anion exchange membrane and ionomer in the electrodes70. For the anode catalyst, the ink was prepared by adding Ni4Mo or Ni4Mo/TiO2, Vulcan XC-72 carbon and 20 mg mL−1 ionomer (16 wt%) solution into isopropanol and then sonicated for 30 min. The weight ratio of Ni4Mo or Ni4Mo/TiO2 to Vulcan XC-72 carbon was 4:1. For the cathode catalyst, Pt/C and the 20 wt% ionomer solution was mixed in isopropanol and then sonicated for 15 min. To make the catalyst-coated membrane (CCM), the catalyst ink was sprayed onto the membrane (25 μm), which was heated at 70 °C to remove the isopropanol. The anode and cathode catalyst loadings were 1.35 mgNi cm−2 and 0.4 mgPt cm−2 respectively, and the catalyst sprayed area was fixed to 4 cm2. In order to exchange the anion of the membrane and ionomer to OH−, the CCM was soaked in 1 M KOH at 60 °C for 24 h, and meanwhile hydrogen was purged into the KOH solution to prevent the catalyst oxidation. Subsequently, the CCM was washed with ultra-pure H2O for several times to remove the excess KOH. The membrane electrode assembly (MEA) was assembled by placing the CCM between two pieces of carbon paper (AvCarb GDS3250) used as gas diffusion layer without hot-pressing. The AEMFC performance test was conducted on an 850E Multi Range fuel cell test station (Scribner Associates, USA). The test was operated at 80 °C under H2 and O2 condition with a backpressure of 0.2 MPa on the anode and cathode. H2 and O2 humidified at 80 °C (100% RH) were supplied to the anode and cathode compartments with a flow rate of 1000 sccm. The durability test was conducted with the flow rate of H2 and O2 being 300 and 500 sccm under otherwise identical conditions.

Density functional theory calculations

The density functional theory (DFT) calculations were carried out using the Vienna Ab-initio Simulation Package (VASP)71,72 with the projector augmented wave (PAW) method73 and the Perdew-Burke-Ernzerhof (PBE)74,75 exchange-correlation functional. Dispersion interactions were described using the DFT-D3 method proposed by Grimme76,77. The hetero-structure was created by the vaspkit code78. A 1 × 1 × 1 k-point grid with a cutoff energy of 450 eV was used for the slab optimization and the density of states (DOS) calculation. Convergence was reached when the change in energy per electron step was less than 1 × 10−5 eV. The conjugate gradient algorithm was used to relax all optimizable atoms until the force applied on them was less than 0.02 eV Å−1 for the slabs.

The anatase TiO2 (100) surface and Ni4Mo (211) surface were chosen for a better lattice match to create the hetero-structure using the slab model with a vacuum layer along the z-axis set to 15 Å. Two layers of TiO2 (100) \((2\sqrt{5}\times \sqrt{7})\) surface were used as the substrate, and frozen during the optimization procedure, while the Ni4Mo (211) \((\sqrt{10}\times 3)\) surface with a thickness of 6.15 Å above the TiO2 substrate was cut by \(\frac{1}{3}\) along the y-axis to expose the interface of the hetero-structure, which was allowed for optimization during the whole calculation. The lattice mismatch for this hetero-structure was kept as low as 0.011%.

Adsorbates were added on the interface of the hetero-structure. The binding energy of H atom and OH species was calculated using the flowing formula:

Where \({E}_{{{{{\rm{H}}}}} \, {{{{\rm{adsorb}}}}}}\) and \({E}_{{{{{\rm{OH}}}}} \, {{{{\rm{adsorb}}}}}}\) are the adsorption energies of H atom and OH species, \({E}_{{{{{\rm{slab}}}}}+{{{{\rm{H}}}}}}\) and \({E}_{{{{{\rm{slab}}}}}+{{{{\rm{OH}}}}}}\) are the total energies of the compositions, \({E}_{{{{{\rm{H}}}}}2}\) and \({E}_{{{{{\rm{OH}}}}}}\) are the energies of hydrogen molecule and OH species, and \({E}_{{{{{\rm{slab}}}}}}\) is the energy of the slab.

Data availability

All data in the article and supplementary information are available from the corresponding authors upon request.

References

Wang, Y. et al. PEM fuel cell and electrolysis cell technologies and hydrogen infrastructure development-a review. Energy Environ. Sci. 15, 2288–2328 (2022).

Gottesfeld, S. et al. Anion exchange membrane fuel cells: current status and remaining challenges. J. Power Sources 375, 170–184 (2018).

Yang, Y. et al. Electrocatalysis in alkaline media and alkaline membrane-based energy technologies. Chem. Rev. 122, 6117–6321 (2022).

Durst, J. et al. New insights into the electrochemical hydrogen oxidation and evolution reaction mechanism. Energy Environ. Sci. 7, 2255–2260 (2014).

Sheng, W., Gasteiger, H. A. & Shao Horn, Y. Hydrogen oxidation and evolution reaction kinetics on platinum: acid vs alkaline electrolytes. J. Electrochem. Soc. 157, B1529–B1536 (2010).

Lu, S. & Zhuang, Z. Investigating the influences of the adsorbed species on catalytic activity for hydrogen oxidation reaction in alkaline electrolyte. J. Am. Chem. Soc. 139, 5156–5163 (2017).

Scofield, M. E. et al. Role of chemical composition in the enhanced catalytic activity of Pt-based alloyed ultrathin nanowires for the hydrogen oxidation reaction under alkaline conditions. ACS Catal. 6, 3895–3908 (2016).

Wang, Y. et al. Pt-Ru catalyzed hydrogen oxidation in alkaline media: oxophilic effect or electronic effect? Energy Environ. Sci. 8, 177–181 (2015).

Strmcnik, D. et al. Improving the hydrogen oxidation reaction rate by promotion of hydroxyl adsorption. Nat. Chem. 5, 300–306 (2013).

Wang, Y. H. et al. Spectroscopic verification of adsorbed hydroxy intermediates in the bifunctional mechanism of the hydrogen oxidation reaction. Angew. Chem.-Int. Ed. 60, 5708–5711 (2021).

Alia, S. M., Pivovar, B. S. & Yan, Y. Platinum-coated copper nanowires with high activity for hydrogen oxidation reaction in base. J. Am. Chem. Soc. 135, 13473–13478 (2013).

Sheng, W. et al. Non-precious metal electrocatalysts with high activity for hydrogen oxidation reaction in alkaline electrolytes. Energy Environ. Sci. 7, 1719–1724 (2014).

Duan, Y. et al. Bimetallic nickel-molybdenum/tungsten nanoalloys for high-efficiency hydrogen oxidation catalysis in alkaline electrolytes. Nat. Commun. 11, 4789 (2020).

Wang, M. et al. Alloying nickel with molybdenum significantly accelerates alkaline hydrogen electrocatalysis. Angew. Chem. Int. Ed. 60, 5771–5777 (2021).

Kabir, S. et al. Platinum group metal-free NiMo hydrogen oxidation catalysts: high performance and durability in alkaline exchange membrane fuel cells. J. Mater. Chem. A 5, 24433–24443 (2017).

Setzler, B. P., Zhuang, Z., Wittkopf, J. A. & Yan, Y. Activity targets for nanostructured platinum group-metal-free catalysts in hydroxide exchange membrane fuel cells. Nat. Nanotechnol. 11, 1020–1025 (2016).

Reiser, C. A. et al. A reverse-current decay mechanism for fuel cells. Electrochem. Solid State Lett. 8, A273–A276 (2005).

Gao, F. Y. et al. Nickel-molybdenum-niobium metallic glass for efficient hydrogen oxidation in hydroxide exchange membrane fuel cells. Nat. Catal. 5, 993–1005 (2022).

Beden, B., Floner, D., Leger, J. M. & Lamy, C. A voltammetric study of the formation of hydroxides and oxyhydroxides on nickel single-crystal electrode in contant with an alkaline-solution. Surf. Sci. 162, 822–829 (1985).

Medway, S. L. et al. In situ studies of the oxidation of nickel electrodes in alkaline solution. J. Electroanalytical Chem. 587, 172–181 (2006).

Oshchepkov, A. G. et al. Recent advances in the understanding of nickel-based catalysts for the oxidation of hydrogen-containing fuels in alkaline media. ACS Catal. 10, 7043–7068 (2020).

Qin, S. et al. Ternary nickel-tungsten-copper alloy rivals platinum for catalyzing alkaline hydrogen oxidation. Nat. Commun. 12, 2686 (2021).

Song, J. et al. Phase-separated Mo-Ni alloy for hydrogen oxidation and evolution reactions with high activity and enhanced stability. Adv. Energy Mater. 11, 2003511 (2021).

Gao, L. et al. A nickel nanocatalyst within a h-BN shell for enhanced hydrogen oxidation reactions. Chem. Sci. 8, 5728–5734 (2017).

Ni, W. et al. Ni3N as an active hydrogen oxidation reaction catalyst in alkaline medium. Angew. Chem. Int. Ed. 58, 7445–7449 (2019).

Stuehmeier, B. M. et al. Highly selective Pt/TiOx catalysts for the hydrogen oxidation reaction. ACS Appl. Energy Mater. 2, 5534–5539 (2019).

Zhou, Y. et al. Lattice-confined Ru clusters with high CO tolerance and activity for the hydrogen oxidation reaction. Nat. Catal. 3, 454–462 (2020).

Linsebigler, A. L., Lu, G. Q. & Yates, J. T. Photocatalysis on TiO2 surfaces-principles, mechanisms, and selected results. Chem. Rev. 95, 735–758 (1995).

Zhuang, Z. et al. Nickel supported on nitrogen-doped carbon nanotubes as hydrogen oxidation reaction catalyst in alkaline electrolyte. Nat. Commun. 7, 10141 (2016).

Oshchepkov, A. G., Bonnefont, A., Parmon, V. N. & Savinova, E. R. On the effect of temperature and surface oxidation on the kinetics of hydrogen electrode reactions on nickel in alkaline media. Electrochim. Acta 269, 111–118 (2018).

Gao, Y. et al. A completely precious metal-free alkaline fuel cell with enhanced performance using a carbon-coated nickel anode. Proc. Natl Acad. Sci. USA 119, e2119883119 (2022).

Ohsaka, T., Izumi, F. & Fujiki, Y. Raman-spectrum of anatase, TiO2. J. Raman Spectrosc. 7, 321–324 (1978).

Parker, J. C. & Siegel, R. W. Calibration of the Raman-spectrum to the oxygen stoichiometry of nanophase TiO2. Appl. Phys. Lett. 57, 943–945 (1990).

Zhang, W. F. et al. Raman scattering study on anatase TiO2 nanocrystals. J. Phys. D. Appl. Phys. 33, 912–916 (2000).

Patra, K. K. & Gopinath, C. S. Bimetallic and plasmonic Ag-Au on TiO2 for solar water splitting: an active nanocomposite for entire visible-light-region absorption. Chemcatchem 8, 3294–3301 (2016).

Ferrara, M. A. et al. Study of strain and wetting phenomena in porous silicon by Raman scattering. J. Raman Spectrosc. 39, 199–204 (2008).

Cerdeira, F., Buchenauer, C. J., Pollak, F. H. & Cardona, M. Stress-induced shifts of first-order Raman frequencies of diamond- and zinc-blende-type semiconductors. Phys. Rev. B 5, 580–593 (1972).

Grosvenor, A. P., Biesinger, M. C., Smart, R. S. C. & McIntyre, N. S. New interpretations of XPS spectra of nickel metal and oxides. Surf. Sci. 600, 1771–1779 (2006).

Arfelli, M., Ingo, G. M., Mattogno, G. & Beccaria, A. M. XPS investigation on the corrosion behavior of nickel in sea-water. Surf. Interface Anal. 16, 299–303 (1990).

Luo, P. F. F., Kuwana, T., Paul, D. K. & Sherwood, P. M. A. Electrochemical and XPS study of the nickel-titanium electrode surface. Anal. Chem. 68, 3330–3337 (1996).

Lisowski, W., Vandenberg, A. H. J., Hanekamp, L. J. & Vansilfhout, A. Composition and thickness of surface-layer on molybdenum tips forscanning tunneling microscopy (STM) studied by SEM/AES/(AR)XPS. Surf. Interface Anal. 19, 93–99 (1992).

Cimino, A. & Angelis, B. A. D. The application of X-ray photoelectron spectroscopy to the study of molybdenum oxides and supported molybdenum oxide catalysts. J. Catal. 36, 11–22 (1975).

Grim, S. O. & Matienzo, L. J. X-Ray photoelectron spectroscopy of inorganic and organometallic compounds of molybdenum. Inorg. Chem. 14, 1014–1018 (1975).

Sanjines, R. et al. Electronic-structure of anatase TiO2 oxide. J. Appl. Phys. 75, 2945–2951 (1994).

Berlich, A., Liu, Y. C. & Morgner, H. Evaporation of Ni and carbon containing species onto NiO/Ni as case study for metal support catalysts investigated by metastable induced electron spectroscopy (MIES). Radiat. Phys. Chem. 74, 201–209 (2005).

Himpsel, F. J., Knapp, J. A. & Eastman, D. E. Experimental energy-band dispersions and exchange splitting for Ni. Phys. Rev. B 19, 2919–2927 (1979).

Starnberg, H. I. & Nilsson, P. O. Experimental self-energy corrections to the Ni valence band. J. Phys. F. Met. Phys. 18, L247–L250 (1988).

Mun, B. S. et al. A study of electronic structures of Pt3M (M=Ti,V,Cr,Fe,Co,Ni) polycrystalline alloys with valence-band photoemission spectroscopy. J. Chem. Phys. 123, 204717 (2005).

Vojvodic, A., Norskov, J. K. & Abild-Pedersen, F. Electronic structure effects in transition metal surface chemistry. Top. Catal. 57, 25–32 (2014).

Passens, M. et al. Tuning the surface electronic structure of a Pt3Ti(111) electro catalyst. Nanoscale 8, 13924–13933 (2016).

Davydova, E. S. et al. Stability limits of Ni-based hydrogen oxidation electrocatalysts for anion exchange membrane fuel cells. ACS Catal. 9, 6837–6845 (2019).

Du, W. et al. Unveiling the in situ dissolution and polymerization of Mo in Ni4Mo alloy for promoting the hydrogen evolution reaction. Angew. Chem. Int. Ed. 60, 7051–7055 (2021).

Schalenbach, M. et al. Nickel-molybdenum alloy catalysts for the hydrogen evolution reaction: Activity and stability revised. Electrochim. Acta 259, 1154–1161 (2018).

Oshchepkov, A. G. et al. Bimetallic NiM/C (M = Cu and Mo) catalysts for the hydrogen oxidation reaction: deciphering the role of unintentional surface oxides in the activity enhancement. ACS Catal. 12, 15341–15351 (2022).

Hammer, B. & Norskov, J. K. Theoretical surface science and catalysis-calculations and concepts. Adv. Catal. 45, 71–129 (2000).

Xu, M. et al. TiO2-x-modified Ni nanocatalyst with tunable metal-support interaction for water-gas shift reaction. ACS Catal. 7, 7600–7609 (2017).

Aso, R. et al. Direct identification of the charge state in a single platinum nanoparticle on titanium oxide. Science 378, 202–206 (2022).

Chung, Y. W., Lo, W. J. & Somorjai, G. A. Low energy electron diffraction and electron spectroscopy studies of the clean (110) and (100) titanium dioxide (rutile) crystal surfaces. Surf. Sci. 64, 588–602 (1977).

Tian, H. J., Roberts, C. A. & Wachs, I. E. Molecular structural determination of molybdena in different environments: aqueous solutions, bulk mixed oxides, and supported MoO3 catalysts. J. Phys. Chem. C. 114, 14110–14120 (2010).

Desilvestro, J., Corrigan, D. A. & Weaver, M. J. Spectroelectrochemistry of thin nickel hydroxide films on gold using surface-enhanced Raman spectroscopy. J. Phys. Chem. 90, 6408–6411 (1986).

Desilvestro, J., Corrigan, D. A. & Weaver, M. J. Characterization of redox states of nickel hydroxide film electrodes by in situ surface Raman spectroscopy. J. Electrochem. Soc. 135, 885–892 (1988).

Hall, D. S., Bock, C. & MacDougall, B. R. The electrochemistry of metallic nickel: oxides, hydroxides, hydrides and alkaline hydrogen evolution. J. Electrochem. Soc. 160, F235–F243 (2013).

Melendres, C. A. & Pankuch, M. On the composition of the passive film on nickel-a surface-enhanced Raman spectroelectrochemical study. J. Electroanalytical Chem. 333, 103–113 (1992).

Hardcastle, F. D. & Wachs, I. E. Determination of molybdenum oxygen bond distances and bond orders by Raman-spectroscopy. J. Raman Spectrosc. 21, 683–691 (1990).

Sheng, W. et al. Correlating hydrogen oxidation and evolution activity on platinum at different pH with measured hydrogen binding energy. Nat. Commun. 6, 5848 (2015).

Ravel, B. & Newville, M. ATHENA, ARTEMIS, HEPHAESTUS: data analysis for X-ray absorption spectroscopy using IFEFFIT. J. Synchrotron Radiat. 12, 537–541 (2005).

Braun, S., Salaneck, W. R. & Fahlman, M. Energy-level alignment at organic/metal and organic/organic interfaces. Adv. Mater. 21, 1450–1472 (2009).

Bard, A. & Faulkner, L. Methods involving forced convection-hydrodynamic methods. In Electrochemical Methods: Fundamentals and Applications (Wiley, New York, 2001), chap. 9, pp. 341.

Bard, A. & Faulkner, L. Kinetics of electrode reactions. In Electrochemical Methods: Fundamentals and Applications. (Wiley, New York, 2001), chap. 3, pp. 99.

Peng, H. et al. Alkaline polymer electrolyte fuel cells stably working at 80 degrees C. J. Power Sources 390, 165–167 (2018).

Kresse, G. & Furthmuller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Kresse, G. & Furthmuller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Blochl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 78, 1396–1396 (1997).

Grimme, S., Antony, J., Ehrlich, S. & Krieg, H. A consistent and accurate ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H-Pu. J. Chem. Phys. 132, 154104 (2010).

Grimme, S., Ehrlich, S. & Goerigk, L. Effect of the damping function in dispersion corrected density functional theory. J. Comput. Chem. 32, 1456–1465 (2011).

Wang, V. et al. VASPKIT: A user-friendly interface facilitating high-throughput computing and analysis using VASP code. Comput. Phys. Commun. 267, 108033 (2021).

Zhao, X. et al. Nitrogen-inserted nickel nanosheets with controlled orbital hybridization and strain fields for boosted hydrogen oxidation in alkaline electrolytes. Energy Environ. Sci. 15, 1234–1242 (2022).

Acknowledgements

The authors would like to thank the financial support from the National Natural Science Foundation of China. Grant numbers: 22172112 and 21773171 (S.W.C.); 21991150 and 21991154 (Z.L.). S.W.C. also thanks the financial support from the Fundamental Research Funds for the Central Universities.

Author information

Authors and Affiliations

Contributions

T.X.Y. and R.R.J.: experiments, data collection and analysis, writing the original draft; W.F.Y.: DFT calculations; P.J.J. and Z.Z.B.: XAFS experiment and analysis; Z.L. and S.W.C: conceptualization, supervision, funding acquisition and editing the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Alexandr Oshchepkov, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tian, X., Ren, R., Wei, F. et al. Metal-support interaction boosts the stability of Ni-based electrocatalysts for alkaline hydrogen oxidation. Nat Commun 15, 76 (2024). https://doi.org/10.1038/s41467-023-44320-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-023-44320-w

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.