Abstract

Developing highly efficient catalyst for selective oxidation of benzene to phenol (SOBP) with low H2O2 consumption is highly desirable for practical application, but challenge remains. Herein, we report unique single-atom Cu1-N1O2 coordination-structure on N/C material (Cu-N1O2 SA/CN), prepared by water molecule-mediated pre-assembly-pyrolysis method, can efficiently boost SOBP reaction at a 2:1 of low H2O2/benzene molar ratio, showing 83.7% of high benzene conversion with 98.1% of phenol selectivity. The Cu1-N1O2 sites can provide a preponderant reaction pathway for SOBP reaction with less steps and lower energy barrier. As a result, it shows an unexpectedly higher turnover frequency (435 h−1) than that of Cu1-N2 (190 h−1), Cu1-N3 (90 h−1) and Cu nanoparticle (58 h−1) catalysts, respectively. This work provides a facile and efficient method for regulating the electron configuration of single-atom catalyst and generates a highly active and selective non-precious metal catalyst for industrial production of phenol through selective oxidation of benzene.

Similar content being viewed by others

Introduction

Selective oxidation of benzene to phenol (SOBP) with H2O2 as oxidant is deemed to be a highly efficientand environmental-benign alternative phenol production craft to the conventional cumene process1,2,3,4,5,6. But the general catalytic processes with metallic nanoparticle or complex show unsatisfied results with low activity or phenol selectivity3,4,5,6. Single-atom catalyst (SAC) is an emerging domain for heterogeneous catalysis7. Besides the maximum atom utilization, the SAC can also present catalytic active sites with unique electron structure, thus producing excellent catalytic performance towards diverse reactions7,8,9,10,11. Fe, Co, Cu-based SACs have been applied in the SOBP reaction and show considerable catalytic performance12,13,14,15,16,17,18. However, the results show that the catalytic activity is very low at a low molar ratio of H2O2/benzene, and a 10:1 or even up to 48:1 of molar ratio of H2O2/benzene was used to obtain a high benzene conversion12,13,14,15,16,17,18. If more than 10:1 of H2O2/benzene molar ratio is used for this reaction, the cost of H2O2 is far beyond the value of the produced phenol, which leads to this SOBP process not practical application. Therefore, to develop a practical catalyst for SOBP reaction process, the low H2O2/benzenemolar ratio is essential.

Regulating the electron configuration of single-atom sites through local coordination states adjustment can efficiently modulate the catalytic performance of SACs19,20,21,22,23,24,25,26. By changing the coordination number of M-Nx site, researchers found that the coordinatively unsaturated single-atom site features lowered barrier of intermediates formation and products desorption, resulting in improved catalytic performance19,20,21,22. Besides, heteroatom doping coordination is another efficient strategy for electron configuration regulation23,24,25,26. For example, with greater electrophilic O coordination, the partially oxidized centralmetal atom possesses more unpaired d-electrons which are ready to be excited, resulting in elevated catalytic performance26. In our previous work concerning single-atom Cu1-Nx catalyst for SOBP27,28, the local coordination state of center Cu atom is increased by one Cu-O coordination after reaction, and the recovered catalyst displays stable or improved catalytic performance for SOBP reaction. Moreover, a recent reseach theoretically predicts N,O-coordinated Cu single-site is efficient for C-H activation, but lack of practical trials29. Therefore, we envision that single Cu sites with unsaturated N,O-coordination might efficiently boost the SOBP reaction at low H2O2 addition.

Herein, with the purpose of developing an efficient catalyst to boost SOBP reaction at low H2O2/benzenemolar ratio, we successfully prepare a single-atom Cu catalyst on N/C material with isolated Cu1-N1O2 sites by a preassembly in aqueous solution followed by a pyrolysis process, confirmed by XAFS, high angle annular dark-field scanning transmission electron microscope (HAADF-STEM), X-ray photoelectron spectroscopy (XPS), and DFT calculation. More interestingly, the as-prepared single-atom catalyst (Cu-N1O2 SA/CN) shows 83.7% of benzene conversion with 98.1% of phenol selectivity at 2:1 of a quite low H2O2/benzene molar ratio. Furthermore, owing to the unique N,O-coordiantion, the Cu-N1O2 SA/CN catalyst shows 4.8 and 2.3 times higher turnover frequency (TOF) value of the previously reported Cu-N3 SA/CN and Cu-N2 SA/CN catalysts, respectively. We present a practical Cu catalyst for phenol production from selective oxidation of benzene since the excellent catalytic performance can be realized at a quite low H2O2 addition.

Results

Synthesis and structural characterizations

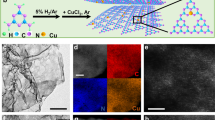

The single-atom Cu-N1O2 SA/CN catalyst was fabricated by a modified preassembly pyrolysis method as early reported27,28, in which the dimethyl sulfoxide (DMSO) was replaced by deionized water for the supramolecular pre-assembly process, making this procedure environmentally friendly. As shown in Fig. 1a, the melamine aqueous solution with copper nitrate was directly mixed with cyanuric acid aqueous solution, resulting in the Cu containing supermolecule precursor. Owing to the weak basicity of melamine aqueous solution, the –O− of cyanuric acid molecule was supposed to coordinate with cupric ions, forming Cu-O coordination, besides the coordination of melamine ring with cupric ions. However, in DMSO solvent, the cyanuric acid molecule cannot coordinate with cupric ions owing to the very weak coordinating ability of –OH of the cyanuric acid molecule. Fourier Transform Infrared (FTIR) spectroscopy (Supplementary Fig. 1) shows that the C = O stretching bands (νC=O) located at 1781 and 1741 cm−1, which is higher than the reported νC=O of cyanuric acid (1739 and 1695 cm−1)30, indicating the formation of hydrogen-bonded supramolecular aggregates via hydrogen bonding of N–H…O and N–H…N linkages between melamine and cyanuric acid31. Moreover, the Cu containing Cu-N1O2 SA/CN precursor shows similar FTIR spectrum to that of CN precursor, demonstrating that the presence of Cu2+ does not affect the formation of hydrogen-bonded supramolecular aggregates. Followed by pyrolysis under N2 atmosphere at 600 °C for 2 h, the single-atom Cu-N1O2 SA/CN catalyst was obtained. FTIR spectrum of Cu-N1O2 SA/CN (Supplementary Fig. 1) shows that the characteristic peaks of C = O disappear and new peaks centred at 3500–3000, 1800–1100, and 800 cm−1 attributed to tri-s-triazine arise, proving the presence of a heterocyclic ringstructure32. For comparison, bare CN was fabricated without copper nitrate, and supported Cu nanoparticle (Cu NP/CN) catalyst with 0.78 wt% Cu was also fabricated (details see Supplementary)33.

X-ray diffraction (XRD) patterns (Supplementary Fig. 2) display the characterization diffraction peak at 27.4°, which is related to the stacking of N/C layers, with decreased diffraction intensity for Cu-N1O2 SA/CN contrast to CN and Cu NP/CN, implying the insertion of Cu species into the N/C material (CN) matrix34,35,36. N2-physisorption results (Supplementary Fig. 3 and Supplementary Table 1) show the similar textural properties of as-prepared samples, but larger VBJH value for Cu-N1O2 SA/CN than both CN and Cu NP/CN (0.72 vs 0.35/0.39 cm3 g−1), which is attributed to the implanting of Cu species in CN matrix37. Scanning electron microscopy (SEM) image (Fig. 1b) demonstrates the similar surface topography of Cu-N1O2 SA/CN to CN and Cu NP/CN with flake and nanotube morphology (Supplementary Fig. 4a, b). Moreover, no nanoparticles or clusters on Cu-N1O2 SA/CN were observed in transmission electron microscopy (TEM) image (Fig. 1c), while Cu nanoparticles on the Cu NP/CN can be clearly detected on local Energy-Dispersive X-ray (EDX) spectroscopy and TEM images (Supplementary Fig. 4c–e). The Cu atoms are isolated dispersed on CN matrix, which is directly monitored by the atomic-resolution HAADF-STEM image (Fig. 1d, the dense bright dots). Meanwhile, EDX elemental mapping (Fig. 1e) display the uniform C, N, O, Cu distribution on CN matrix of Cu-N1O2 SA/CN. The Cu content of Cu-N1O2 SA/CN was 0.16 wt%, determined by inductively coupled plasma atomic emission spectroscopy (ICP-AES). KSCN titration (Supplementary Fig. 5 and Supplementary Table 2) was carried out to determine the dispersity of Cu atoms. The results demonstrate that most of Cu atoms are readily accessible.

To explore the electronic properties of catalysts, XPS was conducted and the binding energy (BE) was calibrated by graphitic C at 284.6 eV as internal standard38,39.The survey XPS spectra (Supplementary Fig. 6) indicate the essential surface elements of C, N, Oand similar composition of as-prepared samples (Supplementary Table 3). Deconvoluted C 1 s XPS spectra (Fig. 2a) reveal the dominant component of graphitic C (284.6 eV), C-N (285.7 eV) and N-C=N(288.3 eV) species on Cu-N1O2 SA/CN, which is consistent with CN and Cu NP/CN (Supplementary Fig. 7a)40,41. Deconvoluted N 1 s XPS spectrum of Cu-N1O2 SA/CN (Fig. 2b) certifies the Cu-N coordination besides C=N-C (398.7 eV), N-(C)3 (400.3 eV), -NHx (401.3 eV) and π excitations (404.5 eV) compared with CN and Cu NP/CN (Supplementary Fig. 8a)42,43,44. Moreover, the deconvoluted O 1 s XPS spetrum of Cu-N1O2 SA/CN (Fig. 2c) features the Cu-O peak (529.6 eV) compared with Cu-N3 SA/CN and CN matrix (Supplementary Fig. 9a), indcating the Cu-O coordination. Notably, the Cu-O BE value in Cu-N1O2 SA/CN is higher than that in Cu NP/CN (529.6 vs 529.1 eV, Supplementary Fig. 9b), indicating the discrepancy in local coordination environment. The Cu 2p XPS spectra of Cu-N1O2 SA/CN (Fig. 2d) and Cu NP/CN (Supplemntary Fig. 8b) show the BE value of ~932.6 eV (between 932.4 eV (Cu+ 2p) and 933.6 eV (Cu2+ 2p)), implying the low valance state of Cu species (+1<δ < +2)45,46. Ar etching treatment on Cu-N1O2 SA/CN was carried out (Fig. 2d) and the result shows the increased intensity of Cu 2p signal. Moreover, the Cu 2p signal slightly shift to higher BE value, which might be attributed to the decomposition of CN matrix under Ar etching (Supplementary Fig. 7b).

To further confirm the local coordination structure of atomically dispersed Cu, X-ray absorption near edge structure (XANES) spectra and corresponding fourier transformation of extended X-ray absorption fine structure (FT-EXAFS) spectra were conducted (Fig. 3, Supplementary Figs. 10, 11, Supplementary Table 4). As shown innormalized Cu K-edge XAENS profiles (Fig. 3a), same like the single-atom Cu-N2 SA/CN and Cu-N3 SA/CN, the absorption threshold of Cu-N1O2 SA/CN located beween Cu foil and CuO (highlighted by dotted), demonstrating the low valance state of Cu47,48,49,50, which is consistent with the XPS result (Fig. 2d). The k3-weighted FT-EXAFS (Fig. 3b) profiles show the single-atom catalysts (Cu-N2 SA/CN, Cu-N3 SA/CN and Cu-N1O2 SA/CN) feature the main peak at ~1.40 Å, corresponding to the first coordination shell of Cu-N(O). No Cu-Cu (Cu foil) and Cu-O-Cu (CuO) coordination at 2.23 Å and 2.54 Å were observed, demonstrating the atomic Cu on CN matrix. Furthermore, wavelet transform (WT) was performed for the discrimination of backscattering atoms (Fig. 3c and Supplementary Fig. 10c)51. Cu-N1O2 SA/CN features no Cu-Cu coordination (7.2 Å−1) of Cu foil, further demonstrating the isolated dispersion of Cu atoms. And Cu-N1O2 SA/CN displays only one intensity maximum at 4.6 Å−1, which is between the Cu-O (4.9 Å−1) and Cu-N (4.2 Å−1) coordination in CuO and CuPc (Supplementary Fig. 10). In contrast, the N coordinated Cu-N3 SA/CN and Cu-N2 SA/CNshow intensity maximun at 4.3 and 4.4 Å−1, respectively. Together with the concomitance of Cu-O and Cu-N bonds demonstrated by XPS results (Fig. 2b, c), the Cu atom was presumed to be coordinated by a mixed structure of Cu-O and Cu-N52,53,54. The quantitative FT-EXAFS fitting analysis (Fig. 3d and Supplementary Table 4) further demonstrates the Cu-N(O) first shell coordination, which is distinctly different from that of Cu foil (Supplementary Fig. 11). The Cu atom was coordinated by 3 neighbouring atoms with the average distance of 1.95 Å. The structure model of single Cu site was constructed by DFT calculations (Supplementary Fig. 12 and Supplementary Table 5), the results show Cu1-N1O2 configuration features lower energy and similar parameters to EXAFS fitting results, which is the most possible coordination structure (insert in Fig. 3d).

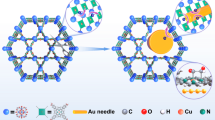

Selective oxidation of benzene to phenol

SACs have been proved to be efficient for selective oxidation of benzene to phenol (SOBP), which is deemed to be the atomic economy and clean pathway for phenol production1,2,3,12,13,14,15,16,17,18. However, it generally needs large amount of H2O2 for high benzene conversion (H2O2/Benzene molar ratio > 10) (SupplementaryTable 6)12,13,14,15,16,17,18, which makes it not practical in industry. Figure 4a and Supplementary Figs. 13, 14, Supplementary Table 7 display the catalytic performance over various catalysts for SOBPat 2:1 of H2O2/Benzene molar ratio. As presented, only trace of benzene is consumed without catalyst (blank) or with CN. The Cu NP/CN shows 13.5% benzene conversion with poor phenol selectivity of 74.6% and carbon balance of 85.4%, indicating its strong oxidation ability for organics degradation. Interestingly, the developed single-atom Cu-N1O2 SA/CN catalyst shows increased benzene conversion of 28.6% with excellent phenol selectivity of 98.0%. It event higher than the single-atom Cu-N3 SA/CN (19.5%, 98.5%) and Cu-N2 SA/CN (18.2%, 98.7%). And the benzene conversion gradually increased with the reaction time prolonged, while the phenol selectivity stabilized at ~98% (Supplementary Fig. 14). Moreover, by extending reaction time and increasing catalyst mass, the benzene conversion reached to 83.7% with 98.1% phenol selectivity, demonstrating the superiority of Cu-N1O2 SA/CN. Furthermore, the turnover frequency (TOF) results in Fig. 4b show that the Cu-N1O2 SA/CN shows 2.3 times TOF of Cu-N2 SA/CN (435 vs 190 h−1) and 4.8 times of Cu-N3 SA/CN (435 vs 90 h−1), respectively, while the phenol selectivity are similar (~98%). The extrordinary catalytic performance of single-atom Cu-N1O2 SA/CN should be attributed to the unique Cu1-N1O2 sites (Supplementary Tables 8–11 and Supplementary Fig. 15). It can be concluded that the N,O-coordinated singe-atom Cu shows much superior activity to the single-site Cu with Cu-N coordination. Besides the remarkable activity, the Cu-N1O2 SA/CN also shows high phenol selectivity than Cu NP/CN. Phenol oxidation to benzoquinone over Cu-N1O2 SA/CN and Cu NP/CN (Supplementary Fig. 16a) demonstrate the weak oxidation ability of Cu-N1O2 SA/CN for phenol with H2O2, and the apparent activation energy (Ea) of benzene oxidation is lower than that of phenol oxidation over Cu-N1O2 SA/CN obtained from kinetic study (Supplementary Fig. 16b), which can explain its high selectivity in benzene selective oxidation for phenol.This is the first example for realizing the highly efficient transformation of benzene to phenol through selective oxidation reaction at a 2:1 of low H2O2/benzene molar ratio, which may promote the industrial production of phenol from benzene selective oxidation.

a Catalytic performance over various catalysts for SOBP. Reaction conditions: 30 mg catalyst, 0.4 mL benzene, 2:1 H2O2/benzene molar ratio, 2.0 mL CH3CN as solvent, 60 °C, 5 h. *50 mg catalyst, 72 h, other conditions are same as above. b The comparison of benzene TOF over various catalysts. Reaction conditions: 30 mg catalyst, 0.4 mL benzene, 2:1 H2O2/benzene molar ratio, 2.0 mL CH3CN, 60 °C, 5 h.

Insight into the origin of high catalytic performance

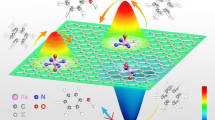

To understand the origin of the remarkable performance over Cu-N1O2 SA/CN for SOBP, the H2O2 activation over as-prepared catalysts were eveluated (Supplementary Fig. 17). The single-atom Cu-N1O2 SA/CN catalyst shows the highest H2O2 activation ability, which provides large amount ofactive O* species. Although the Cu NP/CN also shows higher H2O2 conversion than Cu-N2 SA/CN and Cu-N3 SA/CN, the benzene TOF over Cu NP/CN is the lowest. The severely bubbling in practical operation indicating Cu NP/CN tends to catalyze H2O2 self-decompostion rather than contributing to hydroxylation. DFT calculations were further performed to study the electronic properties and reaction machenism of various single-atom Cu coordination configurations for the in-depth investigation. Figure 5a displays the differential charge density of Cu1-N2, Cu1-N3 and Cu1-N1O2 coordination configurations. Owing to the greater electrophilicity of the O atom relative to the N atom, the Cu1-N1O2 site is more conductive to charge distribution than Cu1-N2 and Cu1-N3 sites, resulting in faster electron transfer between CN support and Cu atoms55,56. Furthermore, Bader charge analysis shows that the Cu atom in Cu1-N1O2 site transfers 0.966 |e| to the neighboring atoms, much higher than Cu1-N2 (0.741 |e|) and Cu1-N3 (0.664 |e|) sites, indicating the better charge transfer capability of Cu1-N1O2 site. Figure 5b–d display the density of state (DOS) of Cu1-N1O2, Cu1-N3 and Cu1-N2 coordination configurations. As revealed, the conduction band of Cu1-N1O2 site is muchcloser to the Fermi level than that of Cu1-N3 site, further demonstrating the better charge transfer capability of Cu1-N1O2 site57. Moreover, owing to the enhanced charge transfer capability and greater electrophilicity of O atom, the Cu1-N1O2 site featuring less Cu-3d electron, meaning more 3d orbitals were unoccupied, which is beneficial to the adsorption of reactant58,59.

a Differential charge density of Cu1-N2, Cu1-N3 and Cu1-N1O2 coordination configuration. b–d The density of states of Cu1-N1O2 coordination configurations. e, f Free energy diagram of H2O2 activation e and benzene oxidation to phenol f on various sites. g Arrhenius plots for benzene oxidation over various catalysts. TS: transient state.

Figure 5e, f and Supplementary Fig. 18 display the relative energy profiles of the reaction pathway in the presence of CH3CN solvent over the Cu1-N1O2, Cu1-N2 and Cu1-N3 sites. In this study, the solvent effect is considered, and the COSMO (conductor-like solvent model) of Dmol3 is applied to simulate the solvent effects of CH3CN60,61, and the value of CH3CN solvent dielectric constant Ɛ is 37.5 in COSMO. As shown in Fig. 5e, the process of H2O2 from gaseous state to the adsorbed state is an strongly exothermic over Cu1-N1O2, Cu1-N2 and Cu1-N3 sites; then, H2O2* activation to produce O* needs to overcome the activation barrier of 1.15, 0.54, and 1.17 eV over Cu1-N1O2, Cu1-N2 and Cu1-N3 sites, respectively. However, the strongly exothermic process of H2O2 from gaseous state to theadsorbed state provide the adequate energy for H2O2* activation over Cu1-N1O2 and Cu1-N2 sites, which results in O* production from H2O2 in gaseous state is a spontaneous process. Over Cu1-N3 site, O* production from H2O2 in gaseous state requires to overcome the overall barrier of 0.50 eV. In the subsequent benzene oxidation process, the absorbed benzene (absorption energy see Supplementary Table 12) prefer to spontaneously react with active O* species to form C6H6O* intermediate and one-step produces phenol with an activation barrier of 0.36 eV over Cu1-N1O2 site (Fig. 5f, phenol desorption energy see Supplementary Table 12). But for the single Cu1-N2 and Cu1-N3 site, before reacting with the absorbed benzene molecule, the O* species at the stable C-Cu bridge and C-top sites firstly migrate to the Cu center overcoming the higher activation barriers of 1.75 eV and 2.04 eV over single-atom Cu1-N2 and Cu1-N3 site, respectively, then the absorbed benzene molecule is oxidized to phenol overcoming the activation barriers of 0.74 eV and 0.54 eV, respectively (Fig. 5f). Above analysis shows that the overall barrier of benzene oxidation to phenol over Cu1-N2 and Cu1-N3 sites is much higher than that over Cu-N1O2 site (1.75 and 2.04 eV vs. 0.36 eV), as a result, the single-atom Cu-N1O2 SA/CN catalyst shows superior catalytic performance than the other twotypesof single-atom samples. Moreover, the Ea over various catalysts obtained from kinetic study (Fig. 5g) demonstrate the lowest Ea value over single-atom Cu-N1O2 SA/CN catalyst for benzene oxidation.

The good recyclability is important for a heterogeneous catalyst. Supplementary Fig. 19 displays no obvious decrease in benzene conversion over Cu-N1O2 SA/CN after five cycles, demonstrating its high recycling stability and reusability. XPS and HAADF-STEM concerning the used catalyst (Supplementary Figs. 20 and 21) also reveal that the single Cu atoms remains without agglomeration and the surface properties shows no significant change. And the Cu content in Cu-N1O2 SA/CN-used shows no obvious erosion (0.14 wt%, determined by ICP-AES).

Discussion

In summary, we successfully prepared a single-atom Cu catalyst with a unique Cu1-N1O2 local coordination structure through the preassembly of melamine, cyanuric acid, and copper nitrate in an aqueous solution. The developed catalyst shows 83.7% of benzene conversion with 98.1% of phenol selectivity at 2:1 of a quite low molar ratio of H2O2/benzene, while more than 10:1 of molar ratio of H2O2/benzene was generally used to obtain a good reaction result. Owing to the combination of high catalytic performance with the 2:1 of a quite low molar ratio of H2O2/benzene, this work can boost the practical industrial process for the phenol production through selective oxidation of benzene. DFT calculations reveal the greater electrophilicity of the O atom in Cu1-N1O2 site endowing single-tom Cu-N1O2 SA/CN catalyst enhanced charge transfer capability and more unoccupied Cu-3d orbital. As a result, the unique Cu1-N1O2 moieties provides a preponderant reaction pathway with less steps and lower barrier for SOBP, resulting in the much high TOF value than those on Cu1-N2 and Cu1-N3 sites. We realize highly-efficient benzene-to-phenol transformation at a quite low H2O2 addition, which promotes the industrial production of phenol through selective oxidation of benzene. For another, this work also opens a new window for designing other single-atom catalysts with unique coordiantion structures towards diverse reactions.

Methods

Synthesis of single-atom Cu-N1O2 SA/CN catalyst

The general procedure of fabricating isolated single Cu atoms anchored in N/C material (CN) catalyst was as follow: a certain amount of Cu(NO3)2·3H2O was dissolved in deionized water together with melamine by heating, the obtained solution was marked as solution A. A certain amount of cyanuric acid was dissolved in deionized water by heating, the resulted solution was marked as solution B. Then, solution B was decanted tardily into solution A under stirring condition. The mixture was kept with magnetic stirring. A light green powder precursor was obtained by filtration. The precursor was dried for 12 h after being washed with deionized water and ethanol, respectively. As follows, the as-dried light green powder was acquired. Finally, the powdered precursor was pyrolyzed under N2 atmosphere for 2 h in a tube furnace. The resulted sample was named as Cu-N1O2 SA/CN. The content of Cu is 0.16 wt% determined by ICP-AES.

Synthesis of single-atom Cu-N2 SA/CN catalyst

The single-atom Cu-N2 SA/CN was prepared according our former work28. Typically, 0.14 g of CN support was dispersed into a copper nitrate containing aqueous sultion in a round-bottom glass flask under magnetic stirring for 40 min. Subsequently, 1 mL of NaBH4 aqueous solution was injected into the flask and kept on stirring for 4 h. After that, solid catalyst was recovered by centrifugation, washed with the deionized water for 3 times and ethanol for 1 time, respectively, and dried at 60 °C overnight. Then, the obtained solid was immersed in 10 mL of dilute HNO3 solution and magnetic stirred for 4 h in a glass flask at room temperature. Then the solid was centrifuged, washed with deionized water to neutral and dried. The finally acquired solid catalyst was named as Cu-N2 SA/CN. The Cu content is 0.20 wt% determined by ICP-AES.

Synthesis of single-atom Cu-N3 SA/CN catalyst

The single-atom Cu-N3 SA/CN was prepared according our previous work27. Generally, a certain amount of Cu(NO3)2·3H2O was dissolved in 20 mL DMSO with 0.50 g melamine by ultrasonic for 10 min, the as-obtained green clarified solution was marked as solution A. 0.51 g cyanuric acid was dissolved in 10 mL DMSO through ultrasonic for 10 min, the resulted solution was marked as solution B. Then, solution B was decanted tardily into solution A. The green solution momentarily became blue as solution B was added, and white precipitate was formed subsequently. The mixture was kept on magnetic stirring for 10 min. Light green powder precursor was obtained by filtration. The precursor was dried off at 60 °C for 12 h after washed with deionized water and ethanol. Light green dried powder was acquired. Finally, the powdered precursor was pyrolyzed under N2 atmosphere for 4 h in a tube furnace at a ramp rate of 2.3 °C min−1. The resulted sample was named as Cu-N3 SA/HCNS. The content of Cu is 0.85 wt% determined by ICP-AES.

Synthesis of CN support

The procedure of CN synthesis is similar to Cu-N1O2 SA/CN except that without the addition of Cu(NO3)2·3H2O.

Synthesis of nanoparticle Cu NP/CN catalyst

The Cu NP/CN catalyst was fabricated as former report27. Typically, a certain amount of Cu(OAc)2·H2O was dissolved in 18 mL deionized water with 0.43 g PVP-K30 under ultrasonic in a 50 mL round-bottom flask. Then an aqueous solution (2 mL) of 1.2 mmol NaBH4 and 1.0 mmol NaOH was injected into the flask at room temperature and kept stirring for 1 h. Then, 0.5 g CN support was added to the flask and kept on stirring for another 12 h. The solid was centrifuged and washed with water for 3 times and ethanol for 2 times, respectively. The final Cu NP/CN catalyst was obtained after dried off for 12 h at 60 °C. The content of Cu is 0.78 wt% determined by ICP-AES.

Catalytic performance evaluation

Selective oxidation of benzene to phenol was performed as the probe evaluation for catalytic performance test. The reaction system includes 30 mg of catalyst, 2 mL of CH3CN, 0.4 mL of benzene and 1 mL of H2O2 (30 wt%). The reaction was carried out at 60 °C in oil bath kettle with magnetic stirring for a period of time. After the reaction was accomplished, the final products were analyzed by Fuli 9790II gas chromatograph (GC) equipped with a 30 m × 0.32 mm × 0.50 μm SE-54 capillary column and a flame ionization detector (FID).

The benzene conversion and phenol selectivity were determined by GC analysis with n-dodecane as internal standard.

The conversion of benzene was calculated as: (mole of consumed benzene)/(mole of initial benzene) × 100%.

The selectivity of phenol was calculated as: (mole of formed phenol)/(mole of consumed benzene) × 100%.

The selectivity of benzoquinone was calculated as: (mole of formed benzoquinone)/(mole of consumed benzene) × 100%.

The yield of phenol was calculated as: (mole of formed phenol)/(mole of initial benzene) × 100%.

The carbon balance was calculated as: (mole of formed phenol + mole of formed benzoquinone + mole of remained benzene)/(mole of initial benzene) × 100%.

Turnover frequency (TOF) of benzene was calculated as: (mole of consumed benzene)/(reaction time (h) × mole of active Cu).

The mole of active Cu is determined by KSCN titration for single-atom Cu catalyst. For Cu NP/HCNS, the mole of active Cu is 50% for the 2 nm Cu nanoparticles.

Data availability

All data generated or analyzed in this study are provided in this Article and Supplementary Information, and are also available from the corresponding authors upon request.

References

Niwa, S.-I. et al. A one-step conversion of benzene to phenol with a palladium membrane. Science 295, 105–107 (2002).

Zhou, Y. et al. Immediate hydroxylation of arenes to phenols via V-containing all-silica ZSM-22 zeolite triggered non-radical mechanism. Nat. Commun. 9, 2931 (2018).

Chen, X. F., Zhang, J. S., Fu, X. Z., Antonietti, M. & Wang, X. C. Fe-g-C3N4-catalyzed oxidation of benzene to phenol using hydrogen peroxide and visible light. J. Am. Chem. Soc. 131, 11658–11659 (2009).

Detoni, C., Carvalho, N. M. F., de Souza, R. O. M. A., Aranda, D. A. G. & Antunes, O. A. C. Oxidation of benzene catalyzed by 2,2′-bipyridine and 1,10-phenantroline Cu(II) complexes. Catal. Lett. 129, 79–84 (2009).

Tsuji, T. et al. Specific enhancement of catalytic activity by a dicopper core: selective hydroxylation of benzene to phenol with hydrogen peroxide. Angew. Chem. Int. Ed. 56, 7779–7782 (2017).

Balducci, L. et al. Direct oxidation of benzene to phenol with hydrogen peroxide over a modified titanium silicalite. Angew. Chem. Int. Ed. 42, 4937–4940 (2003).

Gawande, M. B., Fornasiero, P. & Zbořil, R. Carbon-based single-atom catalysts for advanced applications. ACS Catal. 10, 2231–2259 (2020).

Maiti, K., Maiti, S., Curnan, M. T., Kim, H. J. & Han, J. W. Engineering single atom catalysts to tune properties for electrochemical reduction and evolution reactions. Adv. Energy Mater. 11, 2101670 (2021).

Huang, D. K. et al. Recent advances in tuning the electronic structures of atomically dispersed M–N–C materials for efficient gas-involving electrocatalysis. Mater. Horiz. 7, 970–986 (2020).

Leandro Duarte de AlmeidaSc, M., Wang, H. L., Junge, K., Cui, X. J. & Beller, M. Recent advances in catalytic hydrosilylations: developments beyond traditional platinum catalysts. Angew. Chem. Int. Ed. 60, 550–565 (2021).

Tiwari, J. N., Singh, A. N., Sultan, S. & Kim, K. S. Recent advancement of p- and d-block elements, single atoms, and graphene-based photoelectrochemical electrodes for water splitting. Adv. Energy Mater. 10, 2000280 (2020).

Deng, D. H. et al. A single iron site confined in a graphene matrix for the catalytic oxidation of benzene at room temperature. Sci. Adv. 1, e150046 (2015).

Zhu, Y. Q. et al. A cocoon silk chemistry strategy to ultrathin N-doped carbon nanosheet with metal single-site catalysts. Nat. Commun. 9, 3861 (2018).

Chen, W. M. et al. Dynamic evolution of nitrogen and oxygen dual-coordinated single atomic copper catalyst during partial oxidation of benzene to phenol. Nano Res. 15, 3017–3025 (2021).

Liu, J. et al. Direct observation of metal oxide nanoparticles being transformed into metal single atoms with oxygen-coordinated structure and high-loadings. Angew. Chem. Int. Ed. 60, 15248–15243 (2021).

Zhou, H. et al. Cation-exchange induced precise regulation of single copper site triggers room-temperature oxidation of benzene. J. Am. Chem. Soc. 142, 12643–12650 (2020).

Wu, K. L. et al. Dopamine polymer derived isolated single-atom site metals/N-doped porous carbon for benzene oxidation. Chem. Commun. 56, 8916–8919 (2020).

Shen, Q. K. et al. Ionic-liquid-assisted synthesis of metal single-atom catalysts for benzene oxidation to phenol. Sci. China Mater. 65, 163–169 (2022).

Wu, H. et al. Highly doped and exposed Cu(I)–N active sites within graphene towards efficient oxygen reduction for zinc–air batteries. Energy Environ. Sci. 9, 3736–3745 (2016).

Yan, C. et al. Coordinatively unsaturated nickel–nitrogen sites towards selective and high-rate CO2 electroreduction. Energy Environ. Sci. 11, 1204–1210 (2018).

Wang, X. et al. Regulation of coordination number over single Co sites: triggering the efficient electroreduction of CO2. Angew. Chem. Int. Ed. 57, 1944–1948 (2018).

Rong, X., Wang, H., Lu, X., Si, R. & Lu, T. Controlled synthesis of a vacancy-defect single-atom catalyst for boosting CO2 electroreduction. Angew. Chem. Int. Ed. 59, 1961–1965 (2020).

Wan, J. et al. In situ phosphatizing of triphenylphosphine encapsulated within metal–organic frameworks to design atomic Co1–P1N3 interfacial structure for promoting catalytic performance. J. Am. Chem. Soc. 142, 8431–8439 (2020).

Zhang, J. et al. Tuning the coordination environment in single-atom catalysts to achieve highly efficient oxygen reduction reactions. J. Am. Chem. Soc. 141, 20118–20126 (2019).

Liu, Y. et al. Atomically dispersed Cu anchored on nitrogen and boron codoped carbon nanosheets for enhancing catalytic performance. ACS Appl. Mater. Interfaces 13, 61047–61054 (2021).

Jin, X. et al. Electron configuration modulation of Ni single-atoms for remarkably elevated photocatalytic hydrogen evolution. Angew. Chem. Int. Ed. 59, 6827–6831 (2020).

Zhang, T. et al. Preassembly strategy to fabricate porous hollow carbonitride spheres inlaid with single Cu–N3 sites for selective oxidation of benzene to phenol. J. Am. Chem. Soc. 140, 16936–16940 (2018).

Zhang, T. et al. Single atomic Cu-N2 catalytic sites for highly active and selective hydroxylation of benzene to phenol. iScience 22, 97–108 (2019).

Wang, S. M., Xin, Y., Yuan, J. Y., Wang, L. B. & Zhang, W. H. Direct conversion of methane to methanol on boron nitride-supported copper single atoms. Nanoscale 14, 5447–5453 (2022).

Arrachart, G., Carcel, C., Trens, P., Moreau, J. & Wong Chi Man, M. Silylated melamine and cyanuric acid as precursors for imprinted and hybrid silica materials with molecular recognition properties. Chem. -Eur. J. 15, 6279–6288 (2009).

Jun, Y. et al. From melamine-cyanuric acid supramolecular aggregates to carbon nitride hollow spheres. Adv. Funct. Mater. 23, 3661–3667 (2013).

Jürgens, B. et al. Melem (2,5,8-Triamino-tri-s-triazine), an important intermediate during condensation of melamine rings to graphitic carbon nitride: synthesis, structure determination by X-ray powder diffractometry, solid-state NMR, and theoretical studies. J. Am. Chem. Soc. 125, 10288 (2003).

Nishimura, S., Takagaki, A., Maenosono, S. & Ebitani, K. In situ time-resolved XAFS study on the formation mechanism of Cu nanoparticles using poly(N-vinyl-2-pyrrolidone) as a capping agent. Langmuir 26, 4473–4479 (2010).

Ma, T. Y., Tang, Y. H., Dai, S. & Qiao, S. Z. Proton-functionalized two-dimensional graphitic carbon nitride nanosheet: an excellent metal-/label-free biosensing platform. Small 10, 2382–2389 (2014).

Sun, L. L. et al. Synergistic effect of single-atom Ag and hierarchical tremella-like g-C3N4: electronic structure regulation and multi-channel carriers transport for boosting photocatalytic performance. Appl. Catal. B Environ. 306, 121106 (2022).

Cao, H. B. et al. Different roles of Fe atoms and nanoparticles on g-C3N4 in regulating the reductive activation of ozone under visible light. Appl. Catal. B Environ. 296, 120362 (2021).

Han, Q. et al. Atomically thin mesoporous nanomesh of graphitic C3N4 for high-efficiency photocatalytic hydrogen evolution. ACS Nano 10, 2745–2751 (2016).

Zhao, Z. K., Yang, H. L., Li, Y. & Guo, X. W. Cobalt-modified molybdenum carbide as an efficient catalyst for chemoselective reduction of aromatic nitro compounds. Green. Chem. 16, 1274–1281 (2014).

Zhou, Q., Ge, G. F., Guo, Z. L., Liu, Y. F. & Zhao, Z. K. Poly(imidazolium-methylene)-assisted grinding strategy to prepare nanocarbon-embedded network monoliths for carbocatalysis. ACS Catal. 10, 14604–14614 (2020).

Huang, Y. et al. Graphitic carbon nitride (g-C3N4): an interface enabler for solid-state lithium metal batteries. Angew. Chem. Int. Ed. 59, 3699 (2020).

Yang, F., Liu, D. Z., Li, Y. X., Cheng, L. J. & Ye, J. H. Salt-template-assisted construction of honeycomb-like structured g-C3N4 with tunable band structure for enhanced photocatalytic H2 production. Appl. Catal. B Environ. 240, 64–71 (2019).

Ran, J. et al. Endowing g-C3N4 membranes with superior permeability and stability by using acid spacers. Angew. Chem. Int. Ed. 58, 16463–16468 (2019).

Zhang, H. G. et al. Single atomic iron catalysts for oxygen reduction in acidic media: particle size control and thermal activation. J. Am. Chem. Soc. 139, 14143–14149 (2017).

Zhang, M. L. et al. Metal (hydr)oxides@polymer core–shell strategy to metal single-atom materials. J. Am. Chem. Soc. 139, 10976–10979 (2017).

Zeng, L. et al. Synergistic effect of Ru-N4 sites and Cu-N3 sites in carbon nitride for highly selective photocatalytic reduction of CO2 to methane. Appl. Catal. B Environ. 307, 121154 (2022).

Wang, Y. F. et al. Single-atomic Cu with multiple oxygen vacancies on ceria for electrocatalytic CO2 reduction to CH4. ACS Catal. 8, 7113–7119 (2018).

Wang, X. et al. Uncoordinated amine groups of metal–organic frameworks to anchor single Ru sites as chemoselective catalysts toward the hydrogenation of quinoline. J. Am. Chem. Soc. 139, 9419–9422 (2017).

Kang, L. Q. et al. Design, identification, and evolution of a surface Ruthenium(II/III) single site for CO activation. Angew. Chem. Int. Ed. 60, 1212 (2021).

Liu, X. H. et al. Identifying the activity origin of a cobalt single-atom catalyst for hydrogen evolution using supervised learning. Adv. Funct. Mater. 31, 2100547 (2021).

Bao, H. H. et al. Isolated copper single sites for high-performance electroreduction of carbon monoxide to multicarbon products. Nat. Commun. 12, 238 (2021).

Shao, C. F. et al. A versatile approach to boost oxygen reduction of Fe-N4 sites by controllably incorporating sulfur functionality. Adv. Funct. Mater. 31, 2100833 (2021).

Zhang, F. F. et al. High-efficiency electrosynthesis of hydrogen peroxide from oxygen reduction enabled by a tungsten single atom catalyst with unique terdentate N1O2 coordination. Adv. Funct. Mater. 32, 2110224 (2021).

Zhang, T. et al. Site-specific axial oxygen coordinated FeN4 active sites for highly selective electroreduction of carbon dioxide. Adv. Funct. Mater. 32, 2111446 (2022).

Ni, W. P. et al. Nonnitrogen coordination environment steering electrochemical CO2-to-CO conversion over single-atom tin catalysts in a wide potential window. ACS Catal. 11, 5212–5221 (2021).

Li, Y. et al. Implementing metal-to-ligand charge transfer in organic semiconductor for improved visible-near-infrared photocatalysis. Adv. Mater. 28, 6959–6965 (2016).

Wang, Y. et al. Increasing solar absorption of atomically thin 2D carbon nitride sheets for enhanced visible-light photocatalysis. Adv. Mater. 31, 1807540 (2019).

Jiang, X. H. et al. Silver single atom in carbon nitride catalyst for highly efficient photocatalytic hydrogen evolution. Angew. Chem. Int. Ed. 59, 23112–23116 (2020).

Joo, S. et al. Enhancing thermocatalytic activities by upshifting the d-band center of exsolved Co-Ni-Fe ternary alloy nanoparticles for the dry reforming of methane. Angew. Chem. Int. Ed. 60, 15912–15919 (2021).

Zhou, Y. et al. Engineering eg orbital occupancy of Pt with Au alloying enables reversible Li−O2 batteries. Angew. Chem. Int. Ed. 61, e202201416 (2022).

Zhang, R. G., Ling, L. X., Wang, B. J. & Huang, W. Solvent effects on adsorption of CO over CuCl(111) surface: a density functional theory study. Appl. Surf. Sci. 256, 6717–6722 (2010).

Zhang, R. G., Ling, L. X., Li, Z. & Wang, B. J. Solvent effects on Cu2O(111) surface properties and CO adsorption on Cu2O(111) surface: a DFT study. Appl. Catal. A: Gen. 400, 142–147 (2011).

Acknowledgements

Z.Z. acknowledges the financial support from the National Natural Science Foundation of China (21978030, 21676046) and the Chinese Ministry of Education via the Program for New Century Excellent Talents in Universities (NCET-12-0079). R.Z. acknowledges the financial support from the National Natural Science Foundation of China (21736007).

Author information

Authors and Affiliations

Contributions

T.Z. conceived and performed the experiments, collected and analyzed data, and wrote the paper. B.W., R.Z., and Z.S. conceived and performed the DFT calculations and wrote the DFT section. S.L. and Y.L. performed the HAADF-STEM measurements. Z.Z. conceived the idea, supervised the project work, and led the data analysis and discussion, and prepared and finalized the paper. All the authors commented on the manuscript and have given approval to the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Ivo F. Teixeira and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, T., Sun, Z., Li, S. et al. Regulating electron configuration of single Cu sites via unsaturated N,O-coordination for selective oxidation of benzene. Nat Commun 13, 6996 (2022). https://doi.org/10.1038/s41467-022-34852-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-022-34852-y

This article is cited by

-

Engineering metal oxide catalyst for volatile organic compounds oxidation

Ionics (2024)

-

Performance Regulation of Single-Atom Catalyst by Modulating the Microenvironment of Metal Sites

Topics in Current Chemistry (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.