Abstract

The radical chemistry of ynamides has recently drawn the attention of synthetic organic chemists to the construction of various N-heterocyclic compounds. Nevertheless, the ynamide-radical chemistry remains a long-standing challenge for chemists due to its high reactivity, undesirable byproducts, severe inherent regio- and chemoselective problems. Importantly, the ynamide C(sp)-N bond fission remains an unsolved challenge. In this paper, we observe Photoinduced radical trigger regio- and chemoselective ynamide bond fission, structural reshuffling and functionalization of 2-alkynyl-ynamides to prepare synthetically inaccessible/challenging chalcogen-substituted indole derivatives with excellent step/atom economy. The key breakthroughs of this work includes, ynamide bond cleavage, divergent radical precursors, broad scope, easy to handle, larger-scale reactions, generation of multiple bonds (N-C(sp2), C(sp2)-C(sp2), C(sp2)-SO2R/C-SR, and C-I/C-Se/C-H) in a few minutes without photocatalysts, metals, oxidants, additives. Control experiments and 13C-labeling experiments supporting the conclusion that sulfone radicals contribute to ynamide structural reshuffling processes via a radical pathway.

Similar content being viewed by others

Introduction

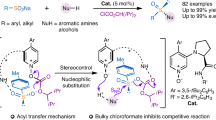

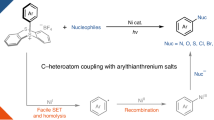

Ynamides are privileged alkyne precursors that bind to nitrogen atoms with an electron-withdrawing group, notably enhancing their stability. In addition, the electron-pushing ability of nitrogen atoms can easily polarize alkyne groups and activate triple bonds, thus realizing high regio- and chemoselectivity in organic transformations1,2,3,4,5,6,7,8. Well-established strategies for ynamides include transition-metal-catalyzed1,2,3,4,5,6,7,8 (metal carbene)/Bronsted acid-mediated1,2,3,4,5,6,7,8,9,10,11,12,13,14 (keteniminium ion) intermediates, which are then trapped by various nucleophiles/electrophiles to yield various difunctionalization products14,15 or N-heterocyclic compounds; these intermediates have been studied by various research groups (Liu, Hashmi, Ye, Sahoo, Gandon, and numerous other groups)1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24 (Fig. 1a). In addition, metal/oxidant/photocatalyst-induced radical addition to the α/β-carbons of ynamides leads to a mixture of E/Z isomers in the products (Fig. 1b)25,26,27,28. Recently, professors Gandon, Sahoo and coworkers observed an intermolecular radical-triggered reactivity of alkynes vs. ynamides in yne‐tethered ynamides with sulfur radicals under traditional reaction conditions (Fig. 1c)29,30. In 2020, Ye and coworkers reported intramolecular photoredox-catalyzed regioselective ketyl radical addition on the α-carbon of ynamide in ketyl-ynamide and radical Smiles rearrangement31. Despite their advantages, these limited existing radical strategies require expensive metals/photocatalysts, oxidants, longer reaction times, harmful waste production, and a lack of atom economy. Importantly, selective intermolecular radical-triggered ynamide bond fission and structural reshuffling have remained unanswered challenges in ynamide chemistry until now.

a Simple ynamide in a metal/Lewis acid. b Regioselective radical addition on α,β-carbons. c Radical chalcogen-triggered cascade reactions on yne-tethered ynamides. d Intramolecular ynamide structural reshuffling with lithium diisopropylamine (LDA) via an ionic pathway. e Intramolecular ynamide structural reshuffling with gold-catalyst. f Well-known ionic pi-bond activator with a metal/Lewis acid in a skeletal rearrangement of o‐alkynylanilines. g Our initial hypothesis and the observed ynamide bond fission, structural reshuffling and functionalization processes on 2-alkynyl-ynamides. h Photoinduced radical diversification strategy for inaccessible/challenging highly substituted indoles.

Structural reshuffling is a process involving multiple-bond fission and new bond formation for molecular skeleton reassembly21,32,33,34,35,36. However, ynamide structural reshuffling has scarcely been reported21,33,36. In 2020, Cui and coworkers reported unusual, ionic divergent intramolecular structural reshuffling of ynamides aided by lithium diisopropylamine (LDA) to produce thiete sulfones, while the additional use of 1,3-dimethyl-tetrahydropyrimidin-2(1H)-one (DMPU) altered the process to produce propargyl sulfonamides (Fig. 1d)35. Very recently, Li and coworkers reported intramolecular ionic gold-catalyzed, 1,2-N-migration of ynamides via 1,1-carboalkoxylation in an atom-economical synthesis of tetrahydrofuran-fused 1,4-dihydroquinolines (Fig. 1e)10. In addition to ynamides, other types of well-known intramolecular ionic path structural rearrangements of substituted 2-alkynylanilines have been reported through the utilization of transition metal/Lewis acid-catalyzed cyclization/migration. In this strategy, an alkyne with metal (Pd, Pt, Rh, Ir, Au, Cu, Co)/Lewis acids first activated to induce the reaction, and simultaneous 1,3-migration occurs to produce straightforward indole derivatives (Fig. 1f)37,38,39,40. Nevertheless, despite the corresponding advances, the above process requires metal/Lewis acids and harsh reaction conditions and follows an intramolecular ionic path, no regio- or chemoselectivity issues are solved, and the reactions are restricted in terms of further functionalization of the migrating group under mild reaction conditions.

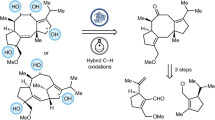

Indoles are favorable structural motifs that appear in numerous marketed drugs, the pharmaceutical industry, drug discovery, material chemistry and numerous other fields, including recent therapeutic leads37,38,39,40,41,42,43. Thus, the construction of inaccessible/challenging indole ring system was a goal for altering the native indole cores, thus enabling access to chalcogen-substituted indoles as potential building blocks for drug discovery in the future. Most importantly, the available active C–I bonds in the products can be used to achieve structural modification of bioactive compounds, drugs and drug leads, as well as natural products44,45,46.

We considered the aforementioned challenges and our ongoing research interest in photoinduced radical cascade reactions under mild reaction conditions47. Photoinduced organic transformations have potential economic and operational benefits due to their efficacy, commercial availability at a low cost and complementary radical generation compared to traditional metal/oxidants, additives and crucial requirements in chemical transformations48,49,50,51,52,53. We postulated that the generated chalcogen radical triggers either the alkyne or ynamide on 2-alkynyl-ynamides to produce possible regio- and chemoselective products based on the exo/endo cyclization mode (Fig. 1g (paths 1–4)).

In this work, we observe radical trigger regio- and chemoselective intermolecular ynamide C(sp)–N bond fission, structural reshuffling and functionalization producing synthetically inaccessible/challenging substituted indole derivatives (Fig. 1g, path 5). We are utilizing 2-alkynyl-ynamides with divergent radical precursors to prepare chalcogen-substituted indoles derivatives via the formation of multiple bonds (N–C(sp2), C(sp2)–C(sp2), C(sp2)–SO2R/C–SR, and C–I/C–Se/C–H) in a rapid transformation that occurs under mild reaction conditions with excellent step/atom economy (Fig. 1h).

Results

Screening of the reaction conditions

We commenced our photoinduced radical-triggered regio- and chemoselective strategy on ynamides by using 4-methyl-N-(phenylethynyl)-N-(2-(phenylethynyl)phenyl)benzenesulfonamide (1a) with 4-methylbenzenesulfonyl iodide (2a) as a model substrate in an acetone solvent under 40 W blue light-emitting diode (LED) light irradiation (Supplementary Figs. 1 and 7). To our delight, we observed radical-triggered ynamide bond fission, structural reshuffling and functionalization to produce a selective single isomer, (E)-3-(1-iodo-2-phenyl-2-tosylvinyl)-2-phenyl-1-tosylindole (3), in 60% yield and trace amounts of (E)-2-phenyl-1-(2-phenyl-1-tosylindol-3-yl)-2-tosylvinyl 4-methylbenzenesulfonate (4) (Table 1, entry 1). An extensive solvent-screening process led to these optimized reaction conditions (Table 1, entries 1–10). Such conditions enabled the production of the desired product at maximum yields (85%) with dichloromethane (DCM) solvent within 3 min, without the formation of the compound (E)-2-phenyl-1-(2-phenyl-1-tosylindol-3-yl)-2-tosylvinyl 4-methylbenzenesulfonate (4). Encouraged by this finding, we altered the solvent molarity ratio from 0.05 to 0.1 M, but the subsequent reaction failed to improve the yields (Table 1, entry 11). Then, the equivalence of compound 2a was altered, but this failed to improve the yield (Table 1, entry 12). The reported methods revealed the high reactivation of sulfonyl iodides; thus, we carried out the reaction in the absence of a light source, but this reaction did not yield the desired product in a few minutes (Table 1, entry 13). The same reaction continued for 24 h, and compounds 3 and 4 were observed in 61/<15 yields (Table 1, entry 14). Next, we performed the reaction under a N2 atmosphere (Supplementary Figs. 2 and 3), which afforded the expected desired product in 81% yield (Table 1, entry 15). From these findings, we believe there is no oxygen role in the reaction. The probable reason could be the spontaneous decomposition ability of the weak –SO2–I bond in 4-methylbenzenesulfonyl iodide to generate an arylsulfonyl radical and iodine radical at room temperature in the absence of light irradiation or any additives54,55,56,57,58,59. The reaction tested with traditional heating at 28 °C (Supplementary Figs. 5 and 6) failed to produce product 3 (Table 1, entry 16) (both starting material visible on TLC).

Next, a blue LED light source which has no second emission peak <400 nm also produced product 3 in 80% yield (Table 1, entry 17) (Supplementary Figs. 4 and 8). According to our observations, the reaction speed and conversion is greatly enhanced by irradiation with visible light; an added advantage is that the reaction also gives a higher final conversion in a shorter reaction time55,60,61,62,63,64. Additionally, reaction time monitoring, solvent molarity, and the use of freshly prepared sulfonyl iodide are vital to inhibit compound 4 formation in this rapid transformation. The molecular structures of the products E isomers (Fig. 2), 3 (Fig. 2a), and 4 (Fig. 2b) were unambiguously confirmed by X-ray crystallography (CCDC numbers: 3 (2084458), 4 (2084457)).

Substrate scope

With the optimized standard reaction conditions in hand, we focused on the feasibility of the reaction substrate scope as depicted in Fig. 3, a broad range of substituted 2-alkynyl-ynamides (1) were compatible with this transformation to produce the corresponding (E)-3-(1-iodo-2-phenyl-2-tosylvinyl)-2-phenyl-1-tosylindole 3–26 with yields ranging from 29% to 88%. Various 2-alkynyl-ynamides 1 (R = Ar) were initially screened, and the reaction produced the desired inaccessible chalcogen-substituted indole derivatives 3–9 in high yields (64–85%) in a few minutes. Long-chain aliphatic and electron-withdrawing groups in the para position smoothly tolerated the reaction and produced the desired products. Moreover, this reaction was also carried out with 2-alkynyl-ynamides 1 (R1 = aromatic) with electron-donating groups p-Me–Ph, p-OMe–Ph, and 3,4-di–OMe–Ph, smoothly producing the desired products (10–12) in efficiently high yields without affecting the functionality. Similarly, 2-alkynyl-ynamides 1 (R1 = aliphatic) with an n-butyl group compatible under standard reaction conditions produced the desired product (13) in good yields (74%). In addition, we were surprised to find that a highly strained cyclopropane ring was readily converted to the desired product in an excellent yield of 82%. This supports the importance of the mild reaction of our divergent radical strategy on the 2-alkynyl-ynamides because cyclopropane is very delicate in the radical homolytic bond fission process. The molecular structure of product 14 was unambiguously confirmed by X-ray crystallography (CCDC number: 14 (2084459)). Importantly, unprotected propan-1-ol gave the desired product (15), albeit in low yield (29%) due to the freely available –OH group in the radical reaction under photoirradiation. Next, various 2-alkynyl-ynamides 1 (R2 = Ar) were studied, and the reactions gave the desired products in moderate to excellent yields of 35–83%. Initially, the electron-donating groups p-Me–Ph (16), p-ethyl–Ph (17), m-OMe–Ph (18) and p-OMe–Ph (19) were found to be compatible with the preparation of the desired products in excellent yields (63–83%) without affecting the substituents in the reaction transformation. To our surprise, highly substituted 3,4-5-OMe–Ph (20) produced the desired product with a moderate yield of 47%. Importantly, 2-alkynyl-ynamides 1 (R2 = Ar) with electron-withdrawing substituents m-NO2-Ph (21), p-COOMe-Ph (22), and p-COMe-Ph (23) were compatible with the preparation of the desired products in good yields (42–64%). Additionally, 2,4-di-Cl-Ph (24) substitutes were also compatible for the preparation of the desired product, which was isolated with a mixture of E/Z isomers (52:48) in moderate yield (43%). The reaction with the product having naphthyl functionality (25) gave a mixture of E/Z isomers (81:19) in moderate yield (55%). Notably, the heterocyclic moiety was smoothly converted to the desired product (26) in low yield (35%) with a mixture of E/Z isomers (76:24), and the probable reason might be the deactivation of the alkyne in ynamide. Next, the R2 = –CH2CH2Ph group was introduced and treated under standard reaction conditions, and the desired product (27) was obtained in moderate yield (59%). This result shows that electronic factors have no effect on the product regioselectivity and chemoselectivity in 2-alkynyl-ynamides. Next, the scope of radical precursor reagents sulfonyl iodides/sulfonyl hydrazides (2) was tested with 2-alkynyl-ynamides 1 to equip the corresponding inaccessible chalcogen-substituted indole derivatives 28–42 with yields ranging from 40% to 90%. Benzene sulfonyl iodide smoothly produced the desired product (28) with an excellent yield of 88%. Due to difficulties in the synthesis/isolation of sulfonyl iodides, a slight modification of the radical precursors was used for the photoinduced radical transformations (sulfonyl iodides were replaced by sulfonyl hydrazides in the presence of oxidizing agents). The reaction proceeded smoothly to give the desired product in the presence of sulfonyl halogens/sulfonyl hydrazide with a series of substituents on the aryl moiety containing electron-donating/drawing groups, such as p-OMe–Ph (29) and p-tert-butyl (30), to give chalcogen-substituted indole derivatives in 71–82% yield. A series of aryl groups with electron-withdrawing groups, p-F–Ph (31), p-Cl–Ph (32), p-Br–Ph (33), p-I–Ph (34), o-NO2–Ph (35), and p-CF3–Ph (36), produced the desired products in good yields of 53–78%. Our reactions were compatible with highly substituted 2,4,5-tri–Cl–Ph sulfonylhydrazine to give desired product 37 in 40% yield. In addition, a series of aliphatic functionalities (methyl (38), ethyl (39)) in compound 2 smoothly generated the desired products in good yields (54–60%). The strained cyclopropane ring was also compatible with the preparation of the corresponding product (40) in excellent yield (77%). The bulky naphthyl (41) moiety smoothly delivered the substituted indole derivatives in excellent yield (90%). Most importantly, the heterocyclic moiety (42) smoothly produced the desired product with a moderate yield of 63%. For all of the above products (except R1 = an aliphatic group), we observe a very broad signal and no sharp peaks (in the case of R1 = an aromatic group, a broad peak is observed at ~7.8 ppm) in the 1H NMR spectra. We hypothesized that bulky iodine could affect the neighboring aromatic protons so that the orthoprotons may broaden (Supplementary Fig. 9).

Reaction conditions: 1 (0.10 mmol), 2 (sulfonyl iodides (0.11 mmol)), and DCM (0.05 M) were stirred at 28 °C under irradiation with a 40 W Kessil blue LED lamp (Kessil A160WE Tuna Blue, λmax = 462 nm flanked by a second peak at λ = 382 nm) and cooled with a fan, and reaction vessels were placed ~8.5 cm from the LED light for 2–10 min; isolated yields, a major E isomer was formed. aMixtures of E/Z isomers were formed (E/Z ratios were determined based on indole 4-position aromatic C–H protons in 1HNMR. Notes: (1) Freshly prepared sulfonyl iodide was used, and the reaction was carefully monitored. (2) Most of the sulfonyl iodides were unstable during synthesis (or) at room temperature. b1 (0.10 mmol), 2 (sulfonyl hydrazide) (1.5 equiv), I2 (0.5 equiv), aq. 70% tert-butyl hydroperoxide (TBHP) (3.0 equiv), and DCM (0.05 M) were stirred at 28 °C under irradiation with a 40 W Kessil blue LED lamp (Kessil A160WE Tuna Blue, λmax = 462 nm flanked by a second peak at λ = 382 nm) and cooled with a fan, and reaction vessels were placed ~8.5 cm from the LED light for irradiation with a 40 W Kessil blue LED lamp for 10–30 min; isolated yields. c4-(tert-butyl)benzenesulfonyl iodide was used. dNaphthalene-1-sulfonyl iodide was used.

To demonstrate the scope and usefulness of our method, we chose to study different starting materials of 2-alkynyl-ynamides (1) and sulfonyl halogens (2), as shown in Fig. 4a. Various N-protecting groups (N-SO2Ph (1w), 4-chloro-N-(phenylethynyl)-N-(2-(phenylethynyl)phenyl)benzenesulfonamide (1x), and N-SO2Et (1y)) with 4-methylbenzenesulfonyl iodide (2a) smoothly afforded desired products 43-45 in 72–77% yield. Next, sulfonyl bromides (2ca) gave the desired products (46 and 47) in 20–52% yield under standard reaction conditions. However, 4-toluenesulfonyl chloride (S17) failed to give the desired product under optimized reaction conditions. The reason for the low reactivity of the sulfonyl bromides/chlorides is due to the relative strength of the sulfone–halogen bond54,55,56,57,58,59,60,61,62,63,64. The UV–vis absorption spectra of sulfonyl iodide 2a in various solvents (DCM, MeCN, and THF in 10−2–10−5 M) were measured (Supplementary Figs. 13–24). In more concentrated solutions better absorption in each of these solvents was observed in the blue LED area (our actual reaction condition is even more concentrated than the samples used for UV–vis measurement). In case of sulfonyl bromide 2ca, marginal absorption in the blue LED area in various concentrations (10−2–10−5 M in DCM) was observed (Supplementary Figs. 25–28). Next, we changed the reaction time from minutes to hours under the optimized reaction conditions in Fig. 4b. Sulfonyl iodides (2b and 2c) and sulfonyl hydrazides (2.5 equiv) (2bc and 2be) produced desired products 28 and 30 in a short time under both reaction conditions. In parallel, we performed the same reactions with extended reaction times and observed undesired products 48 and 49 in low yields in addition to the expected major products (28 and 30). We hypothesized that the formation of the side products was due to the in situ formation of sulfonic acid from sulfonyl iodides or sulfonyl hydrazides65. To validate our hypothesis, we used compound 3 as a starting material and treated it with p-toluenesulfonic acid monohydride under optimized reaction conditions. To our surprise, the iodine product (3) replaced by the –OTs product (4) was formed in moderate yield. Note that when we used 4-toluenesulfonyl bromide as a radical source, product 4 did not form in the reaction due to the bond energy (Csp2–Br) in compound 46 being higher than the Csp2–I bond energy in compound 3 (Supplementary Fig. 10). Next, we extended our methodology by using propargyl-linked ynamide (1aa) under optimized reaction conditions (Fig. 4c) and produced 2-(iodo(phenyl)methylene)-3-phenyl-1,4-ditosyl-2,5-dihydropyrrole as product (50) in 23% yield. The molecular structure of product 50 was unambiguously confirmed by X-ray crystallography (CCDC number: 50 (2107787)). However, we did not observe cleavage of the C(sp)–N bond of ynamide because propargylamide alkyne is more reactive than ynamide29,30. The reaction of homopropargyl tethered ynamide (1ab) in thin layer chromatography (TLC) showed multiple spots, probably due to the lower stability of starting material 1ab (spontaneous decomposition in the presence of water (trace amount) within 2–3 days yielded hydration products with ynamide alkynes), and the formed product can easily isomerize into various products66. In accordance with these reactions, the aromatic ring between the alkyne and ynamide in compound 1 is necessary for stability via electron delocalization.

Next, we diversified the radical precursor selenosulfonates based on our previous work47. We focused on the substrate scope of the reaction, as depicted in Fig. 5. A broad range of substituted 2-alkynyl-ynamides 1 were compatible in the transformation to equip the corresponding (E)-2-phenyl-3-(2-phenyl-1-(phenylselanyl)-2-tosylvinyl)-1-tosylindole derivatives (51–75) with yields ranging from 18% to 74%. 2-Alkynyl-ynamides 1 (R = Ar) with electron-donating/withdrawing groups –Ph (51), p-Me–Ph (52), p-ethyl–Ph (53), p-Cl–Ph (54), and p-Br–Ph (55) were investigated first, and the reaction produced the desired inaccessible selenosulfonate-substituted indole derivatives in good yields of 55–68% in a few minutes. The molecular structure of product 51 was unambiguously confirmed by X-ray crystallography (CCDC number: 51 (2084460)). Next, the reaction was used to—test 2-alkynyl-ynamide 1 (R1 = aromatic) with electron donating groups p-Me–Ph (56), p-OMe–Ph (57), and 3,4-di-OMe–Ph (58), and the desired products were produced in efficiently good yields (40–70%) without affecting the functionality. Notably, the n-butyl group (59) and strained cyclopropane (60) smoothly produced the desired products in moderate yields of 38–74%. Next, we tested various 2-alkynyl-ynamides 1 (R2 = Ar) with electron-donating and electron-withdrawing groups, such as p-Me–Ph (61), p-ethyl–Ph (62), m-OMe–Ph (63), m-NO2–Ph (64), p-COOMe–Ph (65), and p-COMe–Ph (66), which produced the desired products in low to moderate yields (25–69%). Next, we used various selenosulfonate radical precursors with electron-donating/withdrawing groups –Ph (67), p-OMe–Ph (68), p-Cl–Ph (69), p-F–Ph (70) and heterocyclic groups (71) compatible with the sulfone moiety to produce the desired products in moderate yields (20–69%). Modifications of the selenium moiety with groups such as p-Me–Ph (72), p-F–Ph (73), m-Cl–Ph (74), and n-pentyl (75) groups smoothly produced the desired products in 18–59% yield.

Reaction conditions: 2-alkynyl-ynamides 1 (0.1 mmol), areneselenosulfonates (0.11 mmol), and DCM (0.05 M) were stirred at 28 °C under irradiation with a 40 W Kessil blue LED lamp (Kessil A160WE Tuna Blue, λmax = 462 nm flanked by a second peak at λ = 382 nm) and cooled with a fan, and reaction vessels were placed ~8.5 cm from the LED light for 10–30 min; isolated yields, a major E isomer was formed. Note: The reaction was monitored carefully.

Following our previous work47, we treated 2-alkynyl-ynamides (1) under visible-light irradiation with thiols acting as a radical precursor (Supplementary Table 1). We focused on the feasibility of the substrate scope of the reaction, as depicted in Fig. 6. In this transformation, a series of substituted 2-alkynyl-ynamides (1) were compatible with equipping the corresponding mixture of (E/Z)-2-phenyl-3-(2-phenyl-2-(phenylthio)vinyl)-1-tosylindole derivatives in low to moderate yields with electron-donating/withdrawing groups –Ph (76), p-Cl–Ph (77), and p-Br–Ph (78). The ratio of the E and Z mixture in the products changes with the substituents. In the case of compound 1 (R = Cl or Br), we exclusively observed the Z isomer in product 77 or the major Z isomer in product 78 (E/Z, 10:90). We believe that the radical intermediate (E) formed in the mechanism affects the formation of the single isomer (Supplementary Fig. 54)67. The molecular structure of product 76 was unambiguously confirmed by X-ray crystallography (CCDC number: 76 (2084461)). Next, the reaction was also applied to 2-alkynyl-ynamides 1 (R1 and R2 = aromatic), where the electron-donating groups p-Me–Ph (79) and p-Me–Ph (80) produced the desired products in moderate yields of 44–50% with a mixture of E/Z ratios (47:53 and 17:83). Most importantly, various aromatic thiols containing electron-donating/electron-withdrawing groups P-Me–Ph (81), m-OMe–Ph (82), p-OMe–Ph (83), o-Br–Ph (84), and p-Br–Ph (85) produced the desired products in moderate yields of 38–53%. In all cases, we observed the formation of a mixture of E/Z isomers. According to our experimental observations, the electron-withdrawing group at R gave good selectivity (Z) compared to other substitutes, either in ynamide or thiol moieties.

Reaction conditions: 2-alkynyl-ynamides 1 (0.1 mmol), aromatic thiol (0.25 mmol), and MeCN (0.1 M) were stirred at 28 °C under irradiation with a 40 W Kessil blue LED for 4–7 h in air; isolated yields of the mixture of E and Z isomers were reported, and E/Z ratios were determined based on alkene protons in 1HNMR. aZ isomer was formed.

Larger scale synthesis and product synthetic transformations

To demonstrate the robustness of our diversified radical strategy (Fig. 7), we performed larger-scale reactions of 4-methyl-N-(phenylethynyl)-N-(2-(phenylethynyl)phenyl)benzenesulfonamide 1a (1.0 g of TsI (2a), 0.25 g of Se-phenyl 4-methylbenzenesulfonoselenoate (2da), and 0.25 g of benzenethiol (2ae)) that underwent smooth transformations to produce the desired products in good yields (3 (74%), 51 (60%), and 76 (46%)) without affecting the quantity of the starting material (Fig. 7a). The active C–I bond in the synthesized products was further transformed into the respective derivatives, such as p-tolylboronic acid (S26) (Suzuki reaction), producing the expected product in a good yield of 61% (86) (eq 1, Fig. 7b). Most importantly, under basic reaction conditions, the elimination of sulfone and iodine produced indole 3-substituted alkynes (87) in 58% yield (eq 2, Fig. 7b). Next, a deiodination product (88) was obtained through palladium catalysis at a moderate yield (54%) (eq 3, Fig. 7b). The products are very interesting but difficult to synthesize in the known protocols reported in the literature, and this synthetic route will be more attractive to chemists working with simple reaction conditions.

Mechanistic studies

To gain insights into this reaction mechanism, we conducted several control experiments to form products 3, 51 in Fig. 8 and 76 in Supplementary Figs. 52–54. First, we conducted radical-trapping experiments using (2,2,6,6-tetramethylpiperidin-1-yl)oxidanyl 89 (TEMPO), ethene-1,1-diyldibenzene (90), and butylated hydroxytoluene 91 (BHT) as radical scavengers under standard conditions (Fig. 8a). The TEMPO and ethene-1,1-diyldibenzene radical scavengers completely shut down the desired product formation in the reaction. When we used ethene-1,1-diyldibenzene, sulfone radical-trapping product 92 was observed in 15% yield. The product was confirmed by 1H nuclear magnetic resonance (NMR), 13C NMR, and high-resolution mass spectrometry (HRMS) (Supplementary Fig. 49). The above reactions suggest that radical operation is involved in this transformation. However, in the case of the radical scavenger BHT, the desired product was observed in 55% yields with extended reaction times. The probable reason for this result could be the low reactivity of BHT compared to that of 4-methyl-N-(phenylethynyl)-N-(2-(phenylethynyl)phenyl)benzenesulfonamide (1a). To determine the importance of the alkynyl group in 2-alkynyl-ynamides (1), we performed a reaction with simple ynamide 93 (Fig. 8b). Surprisingly, this reaction did not produce the expected ynamide bond-fission product (94); instead, a regioselective α,β-addition product (94a) was observed in 58% yield. The molecular structure of product 94a was unambiguously confirmed by X-ray crystallography (CCDC number: 94a (2084462)); this reveals the importance of the 2-alkynyl moiety in 2-alkynyl-ynamides (1) for successful transformations. Next, experiments were conducted by using simple ynamide (93) and 4-methyl-N-(phenylethynyl)-N-(2-(phenylethynyl)phenyl)benzenesulfonamide (1a) to compare the reactivities (ynamide 1a is more reactive than ynamide 93) and produce the particular desired product (3) at 64% yields (Fig. 8c). We speculated that the 2-alkynyl moiety in 4-methyl-N-(phenylethynyl)-N-(2-(phenylethynyl)phenyl)benzenesulfonamide (1a) acts as a directing group in this regio- and chemoselective radical cascade process. Most importantly, to identify the in situ reshuffling groups in these transformations (Ph, alkyne or sulfone), we synthesized 13C-labeled 4-methyl-N-(phenylethynyl-2-13C)-N-(2-(phenylethynyl)phenyl)benzenesulfonamide (1a′) and treated it under standard reaction conditions to produce the 13C-labeled desired products (3′) at a higher yield (79%) (Fig. 8d) (Supplementary Fig. 178). This synthesis realizes the first sulfone radical addition to the α-carbon of ynamide and then intramolecular alkyne migration via the expulsion of sulfone radicals and the simultaneous addition of available sulfone radicals to the β 13C-labeled alkyne. To determine the importance of the electron-withdrawing group in the 2-alkynyl-ynamides (1), we replaced –Ts (aromatic) with the –Ms (aliphatic) group (1z) and treated it under standard reaction conditions to produce the desired product (95) at an excellent yield (80%) (Fig. 8e). The molecular structure of product 95 was unambiguously confirmed by X-ray crystallography (CCDC number: 95 (2084463)). These results suggest that sulfone derivatives (aliphatic or aromatic) may not be involved in the alkyne migration process, but they will exert a strong influence on ynamide stabilization and isomerization1,2,3,4,5,6,7,8. Despite our attempts, we were not able to synthesize other protection groups in compound 1. The nature of the alkyne migration step was investigated via a crossover experiment with ynamides 1k and 1n (eq 1, Fig. 8f). No new crossover products were observed, selectively giving desired products 16 (65%) and 19 (55%). Furthermore, a detailed crossover experiment was performed with ynamides 1k and 1y′ (eq 2, Fig. 8f), but no crossover products were formed (16a and 96a), selectively giving desired products 16 (69%) and 96 (58%). This step is consistent with previously reported intramolecular migration processes on o‐alkynylanilines37,38,39,40. The carbon-linker length effect was tested by using compounds S22 and 2a. To our disappointment, the expected product (97) was not observed, and a selective 1,2-addition on propargylamine was observed to produce product 97a in 55% yield (Supplementary Fig. 181). These results indicate the possibility of isomerization in the 2-alkynyl-ynamides (1) (Fig. 8g). The molecular structure of product 97a was unambiguously confirmed by X-ray crystallography (CCDC number: 97a (2084593)). In the absence of a radical precursor under standard reaction conditions (Supplementary Fig. 50a), the expected product (87) was not formed, which means that light does not induce compound 1a via cyclization in the first step without a radical source. The sulfone/thiol radical precursor is vital for this successful transformation. Furthermore, to find the crucial reaction intermediates, under standard conditions, the compounds 4-methyl-N-(2-(phenylethynyl)phenyl)benzenesulfonamide (S8), phenylacetylene (S2), and TsI (2a) were treated under standard reaction conditions and expected to yield the desired product (3), but the 1,2-addition product 98 ((E)-1-((2-iodo-2-phenylvinyl)sulfonyl)-4-methylbenzene) was observed in 61% yield with phenylacetylene (Supplementary Fig. 50b). Based on this transformation, 4- methyl-N-(2-(phenylethynyl)phenyl)benzenesulfonamide (S8) and phenylacetylene (S2) are not the crucial reaction intermediates in the reaction. Next, we utilized 4-methyl-N-(2-(phenylethynyl)phenyl)benzenesulfonamide (S8) under light irradiation, but the expected 2-phenyl-1-tosylindole product (99) did not form, confirming that the indole forms via radical addition and ynamide bond fission with a light source (Supplementary Fig. 50c). Ynamide (1a) was treated with I2 under standard conditions (Supplementary Fig. 50d), and the expected (E)-3-(1,2-diiodo-2-phenylvinyl)-2-phenyl-1-tosyl-1H-indole product (100) was not observed. Based on this result, iodine does not play a key role in this transformation. Next, we hypothesized that radical addition-ynamide bond fission can produce products S8 and 1-methyl-4-((phenylethynyl)sulfonyl)benzene (101) and promote further recombination of these two fragments, which may provide compound 87 (Supplementary Fig. 50e). Unfortunately, our concept failed due to the absence of radical intermediates (see mechanism intermediates C and D). To prove homolytic bond cleavage in Ts-C(sp) (101), we chose 2-phenyl-1-tosylindole (99) and 101 as starting materials and performed the reaction, but we failed to obtain the expected product (Supplementary Fig. 50f). In addition, we selected the protocol from the literature to prove our hypothesis with 101 ethers as a radical precursor (Supplementary Fig. 50g) under light irradiation68, delivering expected products (S)-2-(phenylethynyl)tetrahydrofuran (102) in 19% yield. Now, this reaction gives a clear idea of homolytic bond fission in Ts-C(sp). Finally, a key reaction intermediate, 2-phenyl-3-(phenylethynyl)-1-tosylindole (87), was synthesized and treated with 2a under standard reaction conditions (Fig. 8h). Surprisingly, the key intermediate produced the desired product (3) at a good yield of 72%. In addition, we also obtained blue LED emission spectra and UV–vis absorption spectra of various radical precursors (2a, 2c, 2da, 4-methylbenzenesulfonohydrazide (2bd) and 2ea) (Supplementary Figs. 11–44). The UV–vis absorption spectra show marginal absorption of blue light, which suggests that blue LED light activates the radical precursors by absorption of light. In case of compound 4-methyl-N-(phenylethynyl)-N-(2-(phenylethynyl)phenyl)benzenesulfonamide (1a), UV–vis absorption was not observed (Supplementary Figs. 45–48), which suggests that blue LED light only activate the radical precursors but not ynamides (1).

a Radical inhibition experiments with TEMPO, ethene-1,1-diyldibenzene and BHT. b To determine the importance of the alkynyl group in 2-alkynyl-ynamides (1), we performed a reaction with simple ynamide 93. c One-pot strategy for the reactivity comparison of 2-alkynyl-ynamides 1a and simple ynamide with 2a. d 13C-labeled experiment to identify the in situ reshuffling groups in the transformations with help of 1a′ with 2a. e Importance of the electron-withdrawing group in the 2-alkynyl-ynamides by replacing N-Ts with N-Ms in ynamide. f Intermolecular or intramolecular alkyne migration was investigated via a crossover experiments. g The carbon-linker length effect was tested by using compounds S22 and 2a. h Reaction tested by using intermediate 2-phenyl-3-(phenylethynyl)-1-tosylindole (87) with 2a under standard condition.

Based on the results of the above control experiment, previous1,2,3,4,5,6,7,8,9,10,11,37,38,39,40,47,54,55,56,57,58,59,60,61,62,63,64,69,70 reports and our own research experience41, a plausible mechanism is depicted in Fig. 9 for compounds 3′, 51 and 76 (Supplementary Fig. 55). Blue LED light activate the radical precursor 2a (TsI) to the excited state 2a′. Then homolytic bond fission of excited state 2a′ to generate sulfone (a) and iodine (b) radicals57. The generated reactive sulfone radical (a) triggers regio- and chemoselectively on the α-carbon of isomerized ynamide intermediate A, producing nitrogen-center radical-cation intermediate B and then inducing selective 5-endo-dig cyclization with an alkyne to generate key reactive intermediate C. The nucleophilic β-carbon of ynamide pushes electrons toward nitrogen cations via C(sp)–N bond fission to generate key intermediate D. Simultaneously, intramolecular migration and insertion of 1-methyl-4-((phenylethynyl-2-13C)sulfonyl)benzene (99′) by discharging sulfone radicals via Ts–C(sp) homolytic bond fission68,71,72 generates another key intermediate E. Finally, liberated radical sulfone addition to the β-carbon of the alkyne produces vinyl radical intermediate F. The available second radical source (iodine radical/selenium) binds with intermediate F to produce the final product (3′/51).

In summary, we developed a robust approach for photoinduced divergent radical-triggered regio- and chemoselective ynamide bond fission, skeletal reshuffling, and functionalization of 2-alkynyl-ynamides under mild reaction conditions. These photoinduced radical transformations on ynamides include the ynamide C(sp)–N bond fission, featuring divergent radical precursors and a very short reaction time. Such transformations are atom economic, have mild reaction conditions and are easy to handle, and their reaction procedures are simple. E-isomers are observed in the products of the iodine and selenium derivatives, a mixture of E/Z isomers are observed in the thio derivatives, and a broad substrate scope is achieved. Additionally, there is no need for expensive photocatalysts/metals, oxidants, or additives, and there is high scalability for the synthesis of inaccessible/highly challenging indole derivatives. Moreover, the control experiments and 13C-labeled studies provide further support regarding the viability of the proposed mechanism. The 13C-labeled studies revealed that the reaction presumably proceeds in situ with sulfone reshuffling from the α-carbon to the β-carbon in ynamides. Moreover, the products bearing active C–I bonds can be easily converted to essential derivatives, which cannot be achieved through known synthetic methods.

Methods

General procedure for the synthesis of (E)-3-(1-iodo/bromo-2-phenyl-2-tosylvinyl)-2-phenyl-1-tosylindole derivatives (3, 5-27, 28, 30, 41, 43–47 and 98)

An oven-dried screw-capped, 8 mL vial equipped with a magnetic stir bar was charged with ynamide 1 (0.10 mmol, 1.0 equiv), sulfonyl iodide/sulfonyl bromide (0.11 mmol, 1.1 equiv), and DCM (0.05 M) solvent was added. The resulting solution was stirred up to starting material completion (2–10 min) at 28 °C under a blue LED light (the reaction mixture vial cooled with a fan, and the reaction mixtures were placed ~8.5 cm from the blue LED light). After that, the crude reaction mixture was diluted with water and extracted with DCM. The organic layer was dried over Na2SO4, filtered, and concentrated. The crude material was purified by flash column chromatography to give the corresponding product.

General procedure for synthesis of (E)-3-(1-iodo-2-((4-methoxyphenyl)sulfonyl)-2-phenylvinyl)-2-phenyl-1-tosylindole derivatives (29, 31–40 and 42)

An oven-dried screw-capped 8 mL vial equipped with a magnetic stir bar was charged with ynamide 1 (0.10 mmol, 1.0 equiv) sulfonyl hydrazides (0.15 mmol, 1.5 equiv) in DCM (0.05 M), I2 (0.05 mmol, 0.5 equiv), aq. 70% TBHP (0.30 mmol, 3.0 equiv) was added. The resulting solution was stirred up to starting material completion (30 min) at 28 °C under a blue LED light (the reaction mixture vial was placed ~8.5 cm away from the LED light with a clip fan for cooling). After that, the crude reaction mixture was diluted with water and extracted DCM. The crude material was purified by flash column chromatography to give the corresponding product.

General procedure for synthesis of (E)-2-phenyl-3-(2-phenyl-1-(phenylselanyl)-2-tosylvinyl)-1-tosylindole derivatives (51–75)

An oven-dried screw-capped, 8 mL vial equipped with a magnetic stir bar was charged with ynamide (0.10 mmol, 1.0 equiv), selenosulfonates (0.11 mmol, 1.1 equiv), and DCM (0.05 M) solvent was added. The resulting solution was stirred up to starting material completion (10–30 min) at 28 °C under a blue LED light (the reaction mixture vial cooled with a fan, and the reaction mixtures were placed ~8.5 cm from the blue LED light). After that, the crude reaction mixture was diluted water and extracted with DCM. The organic layer was dried over Na2SO4, filtered, and concentrated. The crude material was purified by flash column chromatography to give the corresponding product.

General procedure for synthesis of (E/Z)-2-phenyl-3-(2-phenyl-2-(phenylthio)vinyl)-1-tosylindole derivatives (76-85)

An oven-dried screw-capped, 8 mL vial equipped with a magnetic stir bar was charged with ynamide (0.10 mmol, 1.0 equiv) aromatic thiols (0.25 mmol, 2.5 equiv), MeCN (0.1 M) was added. The resulting solution was stirred under a blue LED light (the reaction mixture vial cooled with a fan, and the reaction mixtures were placed ~8.5 cm from the blue LED light) up to starting material completion at 28 °C. After that, the crude reaction mixture was diluted with water and extracted with ethyl acetate. The organic layer was dried over Na2SO4, filtered, and concentrated. The crude material was purified by flash column chromatography to give the corresponding product.

Data availability

All data generated and analyzed during this study are included in this article and its Supplementary Information, and also available from the corresponding author. The X-ray crystallographic coordinates for structures reported in this study have been deposited at the Cambridge Crystallographic Data Center (CCDC), under deposition numbers CCDC numbers: 3 (2084458), 4 (2084457), 14 (2084459), 50 (2107787), 51 (2084460), 76 (2084461), 94a (2084462), 95 (2084463), 97a (2084593). These data can be obtained free of charge from The Cambridge Crystallographic Data Center via www.ccdc.cam.ac.uk/data_request/cif.

References

Hu, Y.-C., Zhao, Y., Wan, B. & Chen, Q.-A. Reactivity of ynamides in catalytic intermolecular annulations. Chem. Soc. Rev. 50, 2582–2625 (2021).

Chen, Y.-B., Qian, P.-C. & Ye, L.-W. Bronsted acid-mediated reactions of ynamides. Chem. Soc. Rev. 49, 8897–8909 (2020).

Hong, F.-L. & Ye, L.-W. Transition metal-catalyzed tandem reactions of ynamides for divergent N-heterocycle synthesis. Acc. Chem. Res. 53, 2003–2019 (2020).

Luo, J. et al. Exploiting remarkable reactivities of ynamides: opportunities in designing catalytic enantioselective reactions. ACS Catal. 10, 13978–13992 (2020).

Lynch, C. C., Sripada, A. & Wolf, C. Asymmetric synthesis with ynamides: unique reaction control, chemical diversity and applications. Chem. Soc. Rev. 49, 8543–8583 (2020).

Zhou, B., Tan, T.-D., Zhu, X.-Q., Shang, M. & Ye, L.-W. Reversal of regioselectivity in ynamide chemistry. ACS Catal. 9, 6393–6406 (2019).

Wang, X. -N. et al. Ynamides in ring forming transformations. Acc. Chem. Res. 47, 560–578 (2014).

Ye, L.-W. et al. Nitrene transfer and carbene transfer in gold catalysis. Chem. Rev. 121, 9039–9112 (2021).

Ito, T. et al. Asymmetric intramolecular dearomatization of nonactivated arenes with ynamides for rapid assembly of fused ring system under silver catalysis. J. Am. Chem. Soc. 143, 604–611 (2021).

Qi, L.-J. et al. Gold-catalyzed 1,1-carboalkoxylation of oxetane-ynamides via exocyclic metal carbenes: divergent and atom-economical synthesis of tricyclic N-heterocycles. ACS Catal. 11, 3679–3686 (2021).

Zhu, B.-H. et al. Regio- and stereoselective synthesis of diverse 3,4-dihydro-2-quinolones through catalytic hydrative cyclization of imine- and carbonyl-ynamides with water. ACS Catal. 11, 1706–1713 (2021).

Zhou, L. et al. Gold and carbene relay catalytic enantioselective cycloisomerization/cyclization reactions of ynamides and enals. Angew. Chem., Int. Ed. 59, 1557–1561 (2020).

Liu, X. et al. Copper-catalyzed azide-ynamide cyclization to generate α-Imino copper carbenes: divergent and enantioselective access to polycyclic N-heterocycles. Angew. Chem. Int. Ed. 59, 17984–17990 (2020).

Dutta, S. et al. Keteniminium-driven umpolung difunctionalization of ynamides. Angew. Chem. Int. Ed. 59, 10785–10790 (2020).

Gogoi, M. P. et al. Yb(III)-catalysed syn-thioallylation of ynamides. Chem. Commun. 57, 7521–7524 (2021).

Hong, F.-L. et al. Copper-catalyzed asymmetric reaction of alkenyl diynes with styrenes by formal [3 + 2] cycloaddition via Cu-containing all-carbon 1,3-dipoles: access to chiral pyrrole-fused bridged [2.2.1] skeletons. J. Am. Chem. Soc. 142, 7618–7626 (2020).

Kaldre, D., Klose, I. & Maulide, N. Stereodivergent synthesis of 1,4-dicarbonyls by traceless charge-accelerated sulfonium rearrangement. Science 361, 664–667 (2018).

Kim, Y., Dateer, R. B. & Chang, S. Borane-catalyzed selective hydrosilylation of internal ynamides leading to β-silyl (Z)-enamides. Org. Lett. 19, 190–193 (2017).

Chen, C.-N. et al. Gold-catalyzed [3+2]-annulations of α-aryl diazoketones with the tetrasubstituted alkenes of cyclopentadienes: high stereoselectivity and enantioselectivity. Angew. Chem. Int. Ed. 60, 4479–4484 (2021).

Hong, F.-L. et al. Copper-catalyzed asymmetric reaction of alkenyl diynes with styrenes by formal [3+2] cycloaddition via Cu-containing all-carbon 1,3-dipoles: access to chiral pyrrole-fused bridged [2.2.1] skeletons. J. Am. Chem. Soc. 142, 7618–7762 (2020).

Prabagar, B., Mallick, R. K., Prasad, R., Gandon, V. & Sahoo, A. K. Umpolung reactivity of ynamides: an unconventional [1,3]-sulfonyl and [1,5]-sulfinyl migration cascade. Angew. Chem. Int. Ed. 58, 2365–2370 (2019).

Tian, X. et al. Acyl migration versus epoxidation in gold catalysis: facile, switchable, and atom-economic synthesis of acylindoles and quinoline derivatives. Angew. Chem. Int. Ed. 59, 471–478 (2020).

Zhou, B. et al. Stereoselective synthesis of medium lactams enabled by metal-free hydroalkoxylation/stereospecific [1,3]-rearrangement. Nat. Commun. 10, 1–11 (2019).

Romain, E. et al. Trans-selective radical silylzincation of ynamides. Angew. Chem., Int. Ed. 53, 11333–11337 (2014).

Mahe, C. & Cariou, K. Ynamides in free radical reactions. Adv. Synth. Catal. 362, 4820–4832 (2020).

Wang, L., Lu, C., Yue, Y. & Feng, C. Visible-light-promoted oxo-sulfonylation of ynamides with sulfonic acids. Org. Lett. 21, 3514–3517 (2019).

Tan, T.-D., Wang, Z.-S., Qian, P.-C. & Ye, L.-W. Radical reactions of ynamides. Small Methods 5, 2000673 (2021).

Deng, Y., Zhang, J., Bankhead, B., Markham, J. P. & Zeller, M. Photoinduced oxidative cyclopropanation of ene-ynamides: synthesis of 3-aza[n.1.0]bicycles via vinyl radicals. Chem. Commun. 57, 5254–5257 (2021).

Dutta, S., Mallick, R. K., Prasad, R., Gandon, V. & Sahoo, A. K. Alkyne versus ynamide reactivity: regioselective radical cyclization of Yne-ynamides. Angew. Chem. Int. Ed. 58, 2289–2294 (2019).

Dutta, S., Prabagar, B., Vanjari, R., Gandon, V. & Sahoo, A. K. An unconventional sulfur-to-selenium-to-carbon radical transfer: chemo-and regioselective cyclization of yne-ynamides. Green Chem. 22, 1113–1118 (2020).

Wang, Z.-S. et al. Ynamide smiles rearrangement triggered by visible-light-mediated regioselective ketyl–ynamide coupling: rapid access to functionalized indoles and isoquinolines. J. Am. Chem. Soc. 142, 3636–3644 (2020).

Li, L., Li, Z.-L., Gu, Q.-S., Wang, N. & Liu, X.-Y. A remote C–C bond cleavage-enabled skeletal reorganization: access to medium-/large-sized cyclic alkenes. Sci. Adv. 3, e1701487/1–e1701487/8 (2017).

Vanjari, R., Dutta, S., Prabagar, B., Gandon, V. & Sahoo, A. K. Ring expansion and 1,2-migration cascade of benzisoxazoles with ynamides: experimental and theoretical studies. Chem.—Asian J. 14, 4828–4836 (2019).

Liu, J. et al. Gold-catalyzed atom-economic synthesis of sulfone-containing pyrrolo[2,1-a]isoquinolines from diynamides: evidence for consecutive sulfonyl migration. ACS Catal. 9, 2610–2617 (2019).

Zeng, L. et al. Skeletal reorganization divergence of N-sulfonyl ynamides. Nat. Commun. 11, 5639 (2020).

Oh, C. H., Karmakar, S., Park, H. S., Ahn, Y. C. & Kim, J. W. Domino process in silver-catalyzed reactions of N-arylformimidates and active methylene compounds involving cycloisomerization and 1,3-alkenyl shift. J. Am. Chem. Soc. 132, 1792–1793 (2010).

Chong, E. & Blum, S. A. Aminoboration: addition of B–N σ bonds across C–C π bonds. J. Am. Chem. Soc. 137, 10144–10147 (2015).

Tambe, S. D., Iqbal, N. & Cho, E. J. Nickel-catalyzed trans-carboamination across internal alkynes to access multifunctionalized indoles. Org. Lett. 22, 8550–8554 (2020).

Flynn, A. J., Ford, A. & Maguire, A. R. Synthetic and mechanistic aspects of sulfonyl migrations. Org. Biomol. Chem. 18, 2549–2610 (2020).

Kulandai Raj, A. S., Narode, A. S. & Liu, R.-S. Gold(I)-catalyzed reactions between N-(o-alkynylphenyl)imines and vinyldiazo ketones to form 3-(furan-2-ylmethyl)-1H-indoles via postulated azallyl gold and allylic cation intermediates. Org. Lett. 23, 1378–1382 (2021).

Shonberg, J. et al. Structure–activity study of N-((trans)-4-(2-(7-cyano-3,4-dihydroisoquinolin-2(1H)-yl)ethyl)cyclohexyl)-1H-indole-2-carboxamide (SB269652), a bitopic ligand that acts as a negative allosteric modulator of the dopamine D2 receptor. J. Med. Chem. 58, 5287–5307 (2015).

Fulo, H. F. et al. Synthesis, molecular pharmacology, and structure-activity relationships of 3-(indanoyl)indoles as selective cannabinoid type 2 receptor antagonists. J. Med. Chem. 64, 6381–6396 (2021).

He, F. et al. Melatonin- and ferulic acid-based HDAC6 selective inhibitors exhibit pronounced immunomodulatory effects in vitro and neuroprotective effects in a pharmacological Alzheimer’s disease mouse model. J. Med. Chem. 64, 3794–3812 (2021).

Mutra, M. R., Dhandabani, G. K., Li, J. & Wang, J.-J. Regio- and chemoselective synthesis of nitrogen-containing heterocycles via the oxidative cascade cyclization of unactivated 1,n-enynes. Chem. Commun. 56, 2051–2054 (2020).

Wu, W. et al. Involving single-atom silver (0) in selective dehalogenation by AgF under visible-light irradiation. ACS Catal. 9, 6335–6341 (2019).

Knorr, R., Behringer, C., Knittl, M., von Roman, U. & Lattke, E. Doubly diastereoconvergent preparation and microsolvation-controlled properties of (Z)- and (E)-1’-lithio-1’-(2,6-dimethylphenyl)propenes. J. Am. Chem. Soc. 139, 4690–4703 (2017).

Mutra, M. R., Kudale, V. S., Li, J., Tsai, W.-H. & Wang, J.-J. Alkene versus alkyne reactivity in unactivated 1,6-enynes: regio- and chemoselective radical cyclization with chalcogens under metal- and oxidant-free conditions. Green Chem. 22, 2288–2300 (2020).

Mutra, M. R., Dhandabani, G. K. & Wang, J.-J. Mild access to N-formylation of primary amines using ethers as C1 synthons under metal-free conditions. Adv. Synth. Catal. 360, 3960–3968 (2018).

Zheng, D., Ploeger, S., Daniliuc, C. G. & Studer, A. Photo-mediated intermolecular coupling of alkenes with ketones via acyloxy nitroso compounds. Angew. Chem. Int. Ed. 60, 8547–8551 (2021).

Tavakolian, M. & Hosseini-Sarvari, M. Catalyst-free organic transformations under visible-light. ACS Sustain. Chem. Eng. 9, 4296–4323 (2021).

Dadashpour, S. & Emami, S. Indole in the target-based design of anticancer agents: a versatile scaffold with diverse mechanisms. Eur. J. Med. Chem. 150, 9–29 (2018).

Zhou, J., Li, L., Yan, M. & Wei, W. Computational design of an intramolecular photocyclization reaction with state-selective reactivity: a strategy for indole synthesis. Green Chem. 21, 5521–5527 (2019).

Sulthana, S. & Pandian, P. A review on indole and benzothiazole derivatives its importance. J. Drug Deliv. Ther. 9, 505–509 (2019).

Brumwell, J. E., Simpkins, N. S. & Terrett, N. K. Radical cyclization of dienes and enynes using phosphorus- and sulfur-centered radicals. Tetrahedron 50, 13533–13552 (1994).

Da Silva Correa, C. M. M. & Waters, W. A. Reactions of the free p-toluene sulfonyl radical. I. Diagnostic reactions of free radicals. J. Chem. Soc. C. 1874–1879 (1968).

Da Silva Correa, C. M. M. & Oliveira, M. A. B. C. S. Reaction of arenesulfonyl halides with free radicals. Part 3. J. Chem. Soc. Perkin Trans. II, 811–814 (1987).

Ho, H. T., Ito, O., Iino, M. & Matsuda, M. Studies of sulfonyl radicals. 4. Flash photolysis of aromatic sulfones. J. Phys. Chem. 82, 314–319 (1978).

Truce, W. E., Heuring, D. L. & Wolf, G. C. Addition of sulfonyl iodides to allenes. J. Org. Chem. 39, 238–244 (1974).

Hiltunen, J. et al. Process for the preparation of arylsulfonylpropenenitriles by photocatalytic reactions. FI128424B (2020).

Alabugin, I. V. et al. In search of efficient 5-endo-dig cyclization of a carbon-centered radical: 40 years from a prediction to another success for the Baldwin rules. J. Am. Chem. Soc. 130, 10984–10995 (2008).

Truce, W. E. & Wolf, G. C. Adducts of sulfonyl iodides with acetylenes. J. Org. Chem. 36, 1727–1732 (1971).

Aaltonen, T. et al. Process for the preparation of arylsulfonylpropenenitriles by photocatalytic reactions. WO2019043289A1 (2019).

Kostryukov, S. G., Masterova, Y. Y., Burtasov, A. A. & Romanova, E. V. Photochemical selenosulfonation of tricyclo[4.1.0.02,7]heptane derivatives. Russ. J. Org. Chem. 56, 1006–1013 (2020).

Zhang, Y. & Vessally, E. Direct halosulfonylation of alkynes: an overview. RSC Adv. 11, 33447–33460 (2021).

Khodair, A. I., Abdel-Wahab, A. A., El-Khawaga, A. M. & Schank, K. Reactions of organometallic reagents with sulfonyl halides. V. Action of p-toluenesulfonyl iodide on selected diarylcadmium compounds. Phosphorus Sulfur 21, 321–325 (1985).

Zhu, B.-H., Wang, C.-M., Su, H.-Y. & Ye, L.-W. NaBArF4-Catalyzed Oxidative Cyclization of 1,5- and 1,6-Diynes: Efficient and Divergent Synthesis of Functionalized γ- and δ-Lactams. Chin. J. Chem. 37, 58–62 (2019).

Wille, U. Radical Cascades Initiated by Intermolecular Radical Addition to Alkynes and Related Triple Bond Systems. Chem. Rev. 113, 813–853 (2013).

Paul, S. & Guin, J. Radical C(sp3)-H alkenylation, alkynylation and allylation of ethers and amides enabled by photocatalysis. Green. Chem. 19, 2530–2534 (2017).

Liu, L., Ward, R. M. & Schomaker, J. M. Mechanistic Aspects and synthetic applications of radical additions to allenes. Chem. Rev. 119, 12422–12490 (2019).

Evano, G., Michelet, B. & Zhang, C. The anionic chemistry of ynamides: a review. C. R. Chim. 20, 648–664 (2017).

Ociepa, M., Turkowska, J. & Gryko, D. Amines in C(sp3)–C(sp) and C(sp3)–C(sp2) bond formation redox-activated enabled by metal-free photoredox catalysis. ACS Catal. 8, 11362–11367 (2018).

Zhou, S. et al. Catalytic radical trifluoromethylalkynylation of unactivated alkenes. Org. Lett. 19, 698–701 (2017).

Acknowledgements

The authors gratefully acknowledge funding from the Ministry of Science and Technology (MOST 108-2113-M-037-015-MY3), Taiwan, and the Centre for Research and Development of Kaohsiung Medical University for 400 and 600 MHz NMR, LC–MS.

Author information

Authors and Affiliations

Contributions

M.R.M. conceived, designed the project, performed, analyzed the experimental data and wrote the manuscript. J.J.W. supervised and contributed to the relevant discussions while writing the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Akhila Sahoo and the anonymous reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mutra, M.R., Wang, J. Photoinduced ynamide structural reshuffling and functionalization. Nat Commun 13, 2345 (2022). https://doi.org/10.1038/s41467-022-30001-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-022-30001-7

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.