Abstract

Given the abundance and the ready availability of anilines, the selective insertion of atoms into the aryl carbon–nitrogen bonds will be an appealing route for the synthesis of nitrogen-containing aromatic molecules. However, because aryl carbon–nitrogen bonds are particularly inert, anilines are normally activated by conversion to more reactive intermediates such as aryldiazonium salts to achieve functionalization of the aryl carbon–nitrogen bonds, but the nitrogen atom is usually not incorporated into products, instead being discarded. The selective insertion of groups into aryl carbon–nitrogen bonds remains an elusive challenge and an unmet need in reaction design. Here we show an aromaticity destruction-reconstruction process that selectively inserts a trimethylenemethane (TMM) group into the aromatic carbon–nitrogen bond of anilines concomitant with a benzylic carbon–hydrogen bond functionalization. This process provides a transformative mode for anilines, and the insertion products are versatile precursor to various nitrogen-containing aromatic molecules through simple conversions.

Similar content being viewed by others

Introduction

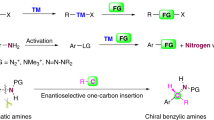

In view of the demand for high atom economy, insertion of functional groups into chemical bonds is of significant interest to synthetic chemists. This comes not only from the perspective of fundamental scientific research but also from its potential use in synthetic chemistry. Recently, transition-metal-catalyzed group insertion into unreactive aryl chemical bonds such as carbon–carbon1,2,3, carbon–cyanide4,5,6, or carbon–halogen7,8,9 bonds has drawn particular attention since aromatic molecular complexity can be rapidly built without the generation of stoichiometric amounts of waste products (Fig. 1a). In this context, given the abundance and the ready availability of anilines and their derivatives, the selective insertion of atoms into the aryl carbon–nitrogen bonds will be an appealing route for the synthesis of nitrogen-containing aromatic molecules. However, compared with the cleavage and functionalization of aliphatic carbon–nitrogen bonds10,11,12,13,14,15,16,17,18, because aryl carbon–nitrogen bonds are particularly inert, the direct cleavage of these bonds is very difficult19,20,21,22,23. Anilines are normally activated by conversion to more reactive intermediates such as aryldiazonium salts24,25,26,27, arylammonium salts28,29,30, triazenes31,32, or amides33, which serve as electrophiles in various reactions thus forming carbon–heteroatom or carbon–carbon bonds (Fig. 1b). Although these elegant methods have enabled the synthesis of a variety of functionalized aromatic molecules using anilines as the aryl source, the nitrogen atom in substrates is usually not incorporated into products, instead it is being discarded. The selective insertion of groups into aryl carbon–nitrogen bonds remains an elusive challenge and an unmet need in reaction design (Fig. 1c).

Functionalization of aryl C–Y bonds: cross-coupling vs group insertion. a functionalization of aromatic C–Y bonds; b conventional functionalization of aryl C–N bonds (nitrogen lost); c functional group insertion into aryl C–N bonds (nitrogen kept). FG functional group, TM transition metal, Ar aryl group. FG in pink and in a cyan rectangle, TM in blue, and Y, N, nitrogen, NH2, amines in purple mean emphasis. The different colors used here is for the convenience of reading

Dearomatization of aromatic compounds has been recognized as a fundamental chemical transformation, especially in the synthesis of complex alicyclic molecules34,35,36,37,38,39,40. The intrinsic functionality and reactivity associated with the aromatic system of anilines may be liberated once the conjugated system is successfully broken up, thus offering a possibility to circumvent the reactivity and the selectivity of anilines41,42,43,44,45,46,47,48,49. In this paper, we report an aromaticity destruction–reconstruction process that selectively inserts a trimethylenemethane (TMM) group into the aryl carbon–nitrogen bond in anilines concomitant with a functionalization of the benzylic carbon–hydrogen bond. This group insertion process provides a transformative mode for anilines and the TMM insertion products are versatile precursors to a variety of nitrogen-containing aromatic molecules through simple conversions.

Results

Initial test

In connection with our recent research on the functionalization of the aryl carbon–nitrogen bonds by using the dearomatization strategy50, we investigated the reaction of anilines with palladium–TMM (Pd–TMM) complexes under oxidative dearomatization conditions. Pd–TMM complexes in situ generated from 3-acetoxy-2-trimethylsilylmethyl-1-propene and palladium(0) catalysts has served as useful synthons in dipolar cycloaddition with unsaturated bonds in the construction of various cyclic compounds since the first report by Trost in 197951,52,53,54,55,56,57,58,59,60,61,62,63. To our delight, in an initial test, we observed the formation of a TMM-containing spiro intermediate and its conversion into compound 3 in which the aryl carbon–nitrogen bond was inserted by the TMM group and the para-benzylic carbon–hydrogen bond was functionalized by methoxylation under acidic conditions.

Optimization of reaction conditions

Encouraged by these initial results, a set of variables, including palladium catalysts, acidic catalysts, solvents, the ratio of reagents, and temperatures, were screened to establish the optimum reaction conditions (for details, see Supplementary Table 1 in the Supplementary Information). The reaction can be conducted in a one-pot three-step manner. Pd(PPh3)4 and Bi(OTf)3 proved to be the best catalysts for the formation and the conversion of the spiro intermediate, respectively. Moreover, changing the nature of nitrogen protecting group in substrate has a large effect on the transformation. The reaction works with sulfamide groups but not with benzamide or acetamide. Under the optimized conditions, the one-pot reaction of N-tosyl protected p-toluidine provided the TMM insertion product 3 in 68% yield (Fig. 2).

TMM insertion into aryl carbon–nitrogen bond in p-toluidine concomitant with benzylic methoxylation. Ts tosyl, Ac acetyl, TMS thrimethylsilyl. Trimethylenemethane in pink, which is consistent with the color of FG in Fig.1 means that is insertion group. N in purple is consistent with the color of N in Fig.1. Methoxyl group in cornflower blue means that it is a newly incorporated group

Substrate scope

Substrate scope investigation revealed that the TMM insertion reaction displays broad substrate compatibility (Fig. 3). Under the optimized conditions, the reaction is tolerant of a range of functional groups on the aromatic ring or on the substituents. For example, halogen groups remain unaffected in the palladium-catalyzed reaction leading to the formation of compounds 4 and 5. Compounds 6 and 7 bearing an allylic or a 1-phenylethyl group were formed in good yields. Reaction of 2-aryl- or 2-alkynyl-substituted anilines proceeds smoothly regardless of the different electronic demands on the aryl or the alkynyl substituents. The oxidative dearomatization of substrate bearing an ethynyl group was complex owing to the sensitive of the ethynyl group to the used oxidant. It is noteworthy that, even in the presence of multiple methyl groups at the ortho or the meta position of the substrate, methoxylation occurs exclusively at the para-benzylic positions. For example, reaction of 2,4-dimethylaniline provided the 4-methoxymethyl-substituted TMM insertion product 23 in 71% yield. Steric hindrance in the TMM insertion reaction was observed, consistent with our hypothesis. For example, compound 25 bearing two ortho-ethyl groups was formed in a lower yield than compound 24, bearing two methyl groups since the ortho-ethyl substituents, sterically or otherwise, decrease the reactivity of the ketimino group in the dearomatized intermediate. In addition to a methyl group, ethyl, n-butyl, or isopropyl groups can be the para-substituent of anilines. Tetrahydronaphthalen-2-amine or 2,3-dihydro-1H-inden-5-amine are also suitable substrates. Moreover, the TMM insertion process can be extended to substrates lacking a para-benzylic C–H bond, and methoxylation takes place in the ortho-benzylic position, as in the reaction of 4-(tert-butyl)-2,6-dimethylaniline that produces compound 33 in 71% yield. When phenylamine was employed as substrate, the reaction failed to afford the TMM insertion product but gave rise to the corresponding spiro intermediate as the major product.

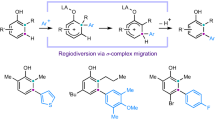

Plausible reaction pathway

Although the precise mechanism of the TMM insertion reaction is not clear at this stage, a plausible pathway could involve the dearomatization of anilines converting the electron-rich aromatic system into an electron-deficient cyclohexadienimine system to permit an aza-TMM cycloaddition of the ketimino group with the Pd–TMM complexes (Fig. 4). This dearomatizing transformation would introduce the TMM group by forming a spiro intermediate. Rearomatizing rearrangement would release the tension of the spiro structure and trapping the benzylic carbon cation by nucleophilic attack would deliver the TMM insertion and benzylic methoxylation products.

Plausible reaction pathway. The transformation might proceed via a dearomatization of anilines, an aza-TMM cycloaddition, followed by a subsequent rearomatizing rearrangement and trapping the benzylic carbon cation by nucleophilic attack. PG protecting group. Green scissors mean the bonds there will be cut

Variable benzylic functionalization

This assumption led us to investigate the possibility of introducing different functional group into the benzylic position just by varying the solvent in the rearrangement step (Fig. 5). We are delighted to observe the formation of 4-hydroxymethyl-substituted TMM insertion products 34 and 35 when acetone and water was used as a mixed solvent. Moreover, the use of nitriles as solvents instead of methanol led to the formation of the 4-acetamido-substituted products 40–43.

Synthetic applications

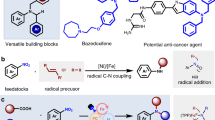

To demonstrate the synthetic utility of this TMM insertion process, we explored a number of selective transformations of the insertion products with a view to the synthesis of functionalized nitrogen-containing aromatic molecules (Fig. 6). The representative product 3a is readily converted to the epoxide 44 by epoxidation to the aziridine 45 by iodocyclization or to the tetrahydroquinoline 46 by reduction and radical amination. The condensation of compound 3a with allyl bromide followed by an olefin metathesis gave rise to 2,5-dihydro-1H-pyrrole 4764. Compound 3a is also well suited to the construction of 3-azabicyclo[4.1.0]hept-4-ene 48 by reaction with propargyl bromide and subsequent platinum-catalyzed cyclization65. The 4-methoxymethyl group in compound 3a can be oxidized to a formyl group by treatment with DDQ. The insertion product 24 bearing two ortho-methyl groups undergoes reduction and a radical sp3 C–H amination reaction to form 2,3,4,5-tetrahydro-1H-benzo[c]azepine 5066. The reactivity of the alkynyl functional group in the insertion products can also be exploited. For example, a gold(I)-catalyzed cyclization of product 13 in the presence of 5 equivalents of H2O delivers multi-functional benzocycloheptene 51 in 63% yield67.

Synthetic applications of the TMM insertion products. a) m-CPBA (6 equiv), CH2Cl2, 25 °C, 58%; b) NaI (1.2 equiv), t-BuOCl (1.2 equiv), MeCN, 25 °C, 50%; c) i. H2 (1 atm), Pd/C, MeOH, 25 °C, 95%, ii. 1,3-diiodo-5,5-dimethylimidazolidine-2,4-dione (1.8 equiv), Na2SO3 (2 equiv), ClCH2CH2Cl, 60 °C, 83%; d) i. 3-bromoprop-1-ene (1.2 equiv), K2CO3 (2 equiv), MeCN, 80 °C, 76%, ii. Grubbs catalyst II (4 mol%), CH2Cl2, rt, 80%; e) i. 3-bromoprop-1-yne (1.2 equiv), K2CO3 (2 equiv), MeCN, 80 °C, 80%, ii. PtCl2 (4 mol%), toluene, 80 °C, 67%; f) DDQ (6 equiv), CH2Cl2:H2O = 10:1, 25 °C, 78%. The pink part in the structures mean that it is an insertion group

Discussion

In summary, we report an aromaticity destruction–reconstruction process that selectively inserts a TMM group into the aromatic carbon–nitrogen bond in anilines concomitant with a benzylic carbon–hydrogen bond functionalization. The process involves a dearomatization, destroying the aromaticity of anilines, a palladium-catalyzed aza-TMM cycloaddition to introduce the functional group, and a Lewis acid-catalyzed rearrangement to complete the group insertion and restore the aromaticity. The process provides a transformative mode of anilines since the group insertion products are versatile precursors through simple conversions to a range of nitrogen-containing aromatic molecules. Development of an extension of this strategy to other aromatic systems is in progress.

Methods

General method for TMM insertion of anilines

PhIO (0.11 mmol) was added to a solution of compound 1 (0.1 mmol) in MeOH (2.0 mL) at 25 °C. After 5 min, the reaction mixture was concentrated in vacuo, then was passed through a short silica gel column to remove PhI. The resulting product was mixed with a solution of 2 (0.11 mmol) and Pd(PPh3)4 (0.01 mmol) in anhydrous EtOAc (2.0 mL), and the resulting mixture was stirred at 80 °C for 1 h. Then the reaction mixture was concentrated in vacuo. The resulting crude product was mixed with a solution of Bi(OTf)3 (0.012 mmol) in MeOH (2.0 mL) and stirred at 25 °C for 12 h. After the substrate was consumed completely (monitored by thin-layer chromatographic analysis), the mixture was passed through a short silica gel column and then concentrated under reduced pressure. The residue was purified by flash column chromatography on silica gel (petroleum ether/ethyl acetate = 5/1) to furnish the product 3. (0.023 mg, 68%). White solid; mp: 80–81 °C; 1H NMR (400 MHz, CDCl3): δ 7.70 (d, J = 8.2 Hz, 2 H), 7.28 (d, J = 8.1 Hz, 2 H), 7.22 (d, J = 7.9 Hz, 2 H), 7.06 (d, J = 7.9 Hz, 2 H), 4.99 (s, 1 H), 4.85 (s, 1 H), 4.65 (t, J = 6.3 Hz, 1 H), 4.41 (s, 2 H), 3.45 (d, J = 6.4 Hz, 2 H), 3.38 (s, 3 H), 3.30 (s, 2 H), 2.42 (s, 3 H); 13C NMR (100 MHz, CDCl3) δ 143.8, 143.4, 137.8, 136.8, 136.3, 129.6, 128.9, 127.9, 127.1, 114.2, 74.4, 58.1, 47.2, 40.0, 21.5; HRMS (m/z): [M + H]+ calcd. for C19H23NO3S, 346.1471; found, 346.1478.

Data availability

All data that support the findings of this study are available within this article and its Supplementary Information (including experimental procedures, compound characterization data). Data are also available from the corresponding author upon reasonable request.

References

Chen, P., Billett, B. A., Tsukamoto, T. & Dong, G. “Cut and sew” transformations via transition-metal-catalyzed carbon−carbon bond activation. ACS Catal. 7, 1340–1360 (2017).

Fumagalli, G., Stanton, S. & Bower, J. F. Recent methodologies that exploit C−C single-bond cleavage of strained ring systems by transition metal complexes. Chem. Rev. 117, 9404–9432 (2017).

Souillart, L. & Cramer, N. Catalytic C−C bond activations via oxidative addition to transition metals. Chem. Rev. 115, 9410–9464 (2015).

Chen, F., Wang, T. & Jiao, N. Recent advances in transition-metal-catalyzed functionalization of unstrained carbon−carbon bonds. Chem. Rev. 114, 8613–8661 (2014).

Wen, Q., Lu, P. & Wang, Y. Recent advances in transition-metal-catalyzed C–CN bond activations. RSC Adv. 4, 47806–47826 (2014).

Nakao, Y. Catalytic C–CN bond activation. Top. Curr. Chem. 346, 33–58 (2014).

Petrone, D. A., Ye, J. & Lautens, M. Modern transition-metal-catalyzed carbon−halogen bond formation. Chem. Rev. 116, 8003–8104 (2016).

Petrone, D. A., Yoon, H., Weinstabl, H. & Lautens, M. Additive effects in the palladium-catalyzed carboiodination of chiral N-allyl carboxamides. Angew. Chem. Int. Ed. 53, 7908–7912 (2014).

Hao, W., Wei, J., Geng, W., Zhang, W.-X. & Xi, Z. Transfer of aryl halide to alkyl halide: reductive elimination of alkylhalide from alkylpalladium halides containing syn-β-hydrogen atoms. Angew. Chem. Int. Ed. 53, 14533–14537 (2014).

Geng, W., Zhang, W.-X., Hao, W. & Xi, Z. Cyclopentadiene-phosphine/palladium catalyzed cleavage of C-N bonds in secondary amines: synthesis of pyrrole and indole derivatives from secondary amines and alkenyl or aryldibromides. J. Am. Chem. Soc. 134, 20230–20233 (2012).

Wang, Y., Zhao, F., Chi, Y., Zhang, W.-X. & Xi, Z. Substituent-controlled selective synthesis of N-acyl 2-aminothiazoles by intramolecular zwitterion-mediated C–N bond cleavage. J. Org. Chem. 79, 11146–11154 (2014).

Yu, H., Gao, B., Hu, B. & Huang, H. Charge-transfer complex promoted C−N bond activation for Ni-catalyzed carbonylation. Org. Lett. 19, 3520–3523 (2017).

Yu, H., Zhang, G., Liu, Z.-J. & Huang, H. Palladium-catalyzed carbonylation of allylamines via C–N bond activation leading to β,γ-unsaturated amides. RSC Adv. 4, 64235–54237 (2014).

Herzon, S. B. & Hartwig, J. F. Direct, catalytic hydroaminoalkylation of unactivated olefins with N-alkyl arylamines. J. Am. Chem. Soc. 129, 6690–6691 (2007).

Miyazaki, Y., Ohta, N., Semba, K. & Nakao, Y. Intramolecular aminocyanation of alkenes by cooperative palladium/boron catalysis. J. Am. Chem. Soc. 136, 3732–3735 (2014).

Hu, J., Xie, Y. & Huang, H. Palladium-catalyzed insertion of an allene into an aminal: aminomethylamination of allenes by C−N bond activation. Angew. Chem. Int. Ed. 53, 7272–7276 (2014).

Qin, G., Li, L., Li, J. & Huang, H. Palladium-catalyzed formal insertion of carbenoids into aminals via C–N bond activation. J. Am. Chem. Soc. 137, 12490–12493 (2015).

Harada, S. et al. General approach to nitrogen-bridged bicyclic frameworks by Rh-catalyzed formal carbenoid insertion into an amide C−N bond. J. Org. Chem. 80, 10317–10333 (2015).

Wang, Q., Su, Y., Lia, L. & Huang, H. Transition-metal catalysed C–N bond activation. Chem. Soc. Rev. 45, 1257–1272 (2016).

Ouyang, K., Hao, W., Zhang, W.-X. & Xi, Z. Transition-metal-catalyzed cleavage of C−N single bonds. Chem. Rev. 115, 12045–12090 (2015).

Koreeda, T., Kochi, T. & Kakiuchi, F. Substituent effects on stoichiometric and catalytic cleavage of carbon–nitrogen bonds in aniline derivatives by ruthenium–phosphine complexes. Organometallics 32, 682–690 (2013).

Koreeda, T., Kochi, T. & Kakiuchi, F. Cleavage of C−N bonds in aniline derivatives on a ruthenium center and its relevance to catalytic C−C bond formation. J. Am. Chem. Soc. 131, 7238–7239 (2009).

Ueno, S., Chatani, N. & Kakiuchi, F. Ruthenium-catalyzed carbon-carbon bond formation via the cleavage of an unreactive aryl carbon-nitrogen bond in aniline derivatives with organoboronates. J. Am. Chem. Soc. 129, 6098–6099 (2007).

Oger, N., d’Halluin, M., Le Grognec, E. & Felpin, F.-X. Using aryl diazonium salts in palladium-catalyzed reactions under safer conditions. Org. Process Res. Dev. 18, 1786–1801 (2014).

Schmidt, B. & Wolf, F. Synthesis of phenylpropanoids via Matsuda−Heck coupling of arene diazonium salts. J. Org. Chem. 82, 4386–4395 (2017).

Qin, H.-L., Zheng, Q., Bare, G. A. L., Wu, P. & Sharpless, K. B. A Heck–Matsuda process for the synthesis of b-arylethenesulfonyl fluorides: selectively addressable Bis-electrophiles for SuFEx click chemistry. Angew. Chem. Int. Ed. 55, 14155–14158 (2016).

Nelson, H. M., Williams, B. D., Miro, J. & Toste, F. D. Enantioselective 1,1-arylborylation of alkenes: merging chiral anion phase transfer with Pd catalysis. J. Am. Chem. Soc. 137, 3213–3216 (2015).

Zhang, X.-Q. & Wang, Z.-X. Nickel-catalyzed cross-coupling of aryltrimethylammonium triflates and amines. Org. Biomol. Chem. 12, 1448–1453 (2014).

Xie, L.-G. & Wang, Z.-X. Nickel-catalyzed cross-coupling of aryltrimethylammonium iodides with organozinc reagents. Angew. Chem. Int. Ed. 50, 4901–4904 (2011).

Blakey, S. B. & MacMillan, D. W. C. The first Suzuki cross-couplings of aryltrimethylammonium salts. J. Am. Chem. Soc. 125, 6046–6047 (2003).

Li, W. & Wu, X.-F. N2 extrusion and CO insertion: a novel palladium-catalyzed carbonylative transformation of aryltriazenes. Org. Lett. 17, 1910–1913 (2015).

Saeki, T., Son, E.-C. & Tamao, K. Boron trifluoride induced palladium-catalyzed cross-coupling reaction of 1-aryltriazenes with areneboronic acids. Org. Lett. 6, 617–619 (2004).

Tobisu, M., Nakamura, K. & Chatani, N. Nickel-catalyzed reductive and borylative cleavage of aromatic carbon−nitrogen bonds in N-aryl amides and carbamates. J. Am. Chem. Soc. 136, 5587–5590 (2014).

Zheng, C. & You, S.-L. Catalytic asymmetric dearomatization by transition-metal catalysis: a method for transformations of aromatic compounds. Chem 1, 830–857 (2016).

Zi, W., Zuo, Z. & Ma, D. Intramolecular dearomative oxidative coupling of indoles: a unified strategy for the total synthesis of indoline alkaloids. Acc. Chem. Res. 48, 702–711 (2015).

Zhuo, C.-X., Zheng, C. & You, S.-L. Transition-metal-catalyzed asymmetric allylic dearomatization reactions. Acc. Chem. Res. 47, 2558–2573 (2014).

Zhuo, C.-X., Zhang, W. & You, S.-L. Catalytic asymmetric dearomatization reactions. Angew. Chem. Int. Ed. 51, 12662–12686 (2012).

Roche, S. P. & Porco, J. A. Jr. Dearomatization strategies in the synthesis of complex natural products. Angew. Chem. Int. Ed. 50, 4068–4093 (2011).

López Ortiz, F., Iglesias, M. J., Fernández, I., Andújar Sánchez, C. M. & Gómez, G. R. Nucleophilic dearomatizing (DNAr) reactions of aromatic C,H-systems. a mature paradigm in organic synthesis. Chem. Rev. 107, 1580–1691 (2007).

Magdziak, D., Meek, S. J. & Pettus, T. R. R. Cyclohexadienone ketals and quinols: four building blocks potentially useful for enantioselective synthesis. Chem. Rev. 104, 1383–1429 (2004).

Zhang, Y.-C., Zhao, J.-J., Jiang, F., Sun, S.-B. & Shi, F. Organocatalytic asymmetric arylative dearomatization of 2,3-disubstituted indoles enabled by tandem reactions. Angew. Chem. Int. Ed. 53, 13912–13915 (2014).

Hashimoto, T., Nakatsu, H., Takiguchi, Y. & Maruoka, K. Axially chiral dicarboxylic acid catalyzed activation of quinone imine ketals: enantioselective arylation of enecarbamates. J. Am. Chem. Soc. 135, 16010–16013 (2013).

Ito, M. et al. Organocatalytic C-H/C-H’ cross-biaryl coupling: C-selective arylation of sulfonanilides with aromatic hydrocarbons. J. Am. Chem. Soc. 135, 14078–14081 (2013).

GirouxM.-A., Guérard, K. C., BeaulieuM.-A., SabotC. & CanesiS. Alternative coupling reaction with unactivated furan derivatives. Eur. J. Org. Chem. 2009, 3871–3874 (2009).

Lebold, T. P. & Kerr, M. A. Total syntheses of clausamines A-C and clausevatine D. Org. Lett. 10, 997–1000 (2008).

Jean, A., Cantat, J., Bérard, D., Bouchu, D. & Canesi, S. Novel method of aromatic coupling between N-aryl methanesulfonamide and thiophene derivatives. Org. Lett. 9, 2553–2556 (2007).

Nair, V., Dhanya, R., Rajesh, C., Bhadbhade, M. M. & Manoj, K. Lewis acid-promoted annulation of o-quinonediimines by allylstannane: a facile synthesis of quinoxaline derivatives. Org. Lett. 6, 4743–4745 (2004).

Tichenor, M. S., Kastrinsky, D. B. & Boger, D. L. Total synthesis, structure revision, and absolute configuration of (+)-yatakemycin. J. Am. Chem. Soc. 126, 8396–8398 (2004).

Zawada, P. V., Banfield, S. C. & Kerr, M. A. Diels-alder reactions of 4-alkoxy-4-alkylcyclohexa-2,5-dienimines: synthesis of 5-alkylindoles. Synlett https://doi.org/10.1055/s-2003-39306 (2003).

Wang, S.-E., Wang, L., He, Q. & Fan, R. Destruction and construction: application of dearomatization strategy in aromatic carbon–nitrogen bond functionalization. Angew. Chem. Int. Ed. 54, 13655–13658 (2015).

Trost, B. M. & Chan, D. M. T. New conjunctive reagents. 2-acetoxymethyl-3-allyltrimethylsilane for methylenecyclopentane annulations catalyzed by palladium(0). J. Am. Chem. Soc. 101, 6429–6432 (1979).

Huisgen, R. 1,3-Dipolar cycloadditions past and future. Angew. Chem. Int. Ed. 2, 565–632 (1963).

Nakamura, E. & Yamago, S. Thermal reactions of dipolar trimethylenemethane species. Acc. Chem. Res. 35, 867–877 (2002).

Yamago, S. & Nakamura, E. Use of methylenecyclopropanone ketals for cyclopentane synthesis. a new efficient thermal [3+2] cycloaddition. J. Am. Chem. Soc. 111, 7285–7286 (1989).

Trost, B. M. & Debien, L. Palladium-catalyzed trimethylenemethane cycloaddition of olefins activated by the σ‑electron-withdrawing trifluoromethyl group. J. Am. Chem. Soc. 137, 11606–11609 (2015).

Trost, B. M. & Bringley, D. A. Enantioselective synthesis of 2,2-disubstituted tetrahydrofurans: palladium-catalyzed [3+2] cycloadditions of trimethylenemethane with ketones. Angew. Chem. Int. Ed. 52, 4466–4469 (2013).

Procopiou, G., Lewis, W., Harbottle, G. & Stockman, R. A. Cycloaddition of chiral tert-butanesulfinimines with trimethylenemethane. Org. Lett. 15, 2030–2033 (2013).

Trost, B. M. & Silverman, S. M. Enantioselective construction of pyrrolidines by palladium-catalyzed asymmetric [3+2] cycloaddition of trimethylenemethane with imines. J. Am. Chem. Soc. 134, 4941–4954 (2012).

Trost, B. M. & McDougall, P. J. Access to a welwitindolinone core using sequential cycloadditions. Org. Lett. 11, 3782–3785 (2009).

Trost, B. M., McDougall, P. J., Hartmann, O. & Wathen, P. T. Asymmetric synthesis of bicyclo[4.3.1]decadienes and bicyclo[3.3.2]-decadienes via [6+3] trimethylenemethane cycloaddition with tropones. J. Am. Chem. Soc. 130, 14960–14961 (2008).

Shintani, R., Park, S., Duan, W.-L. & Hayashi, T. Palladium-catalyzed asymmetric [3+3] cycloaddition of trimethylenemethane derivatives with nitrones. Angew. Chem. Int. Ed. 46, 5901–5903 (2007).

Shintani, R. & Hayashi, T. Palladium-catalyzed [3+3] cycloaddition of trimethylenemethane with azomethine imines. J. Am. Chem. Soc. 128, 6330–6331 (2006).

Trost, B. M. & Marrs, C. M. A [3+2] and [4+3] cycloaddition approach to N-heterocycles via Pd-catalyzed TMM reactions with imines. J. Am. Chem. Soc. 115, 6636–6645 (1993).

Verendel, J. J. et al. Highly flexible synthesis of chiral azacycles via iridium-catalyzed hydrogenation. J. Am. Chem. Soc. 132, 8880–8881 (2010).

Fürstner, A., Szillat, H. & Stelzer, F. Novel rearrangements of enynes catalyzed by PtCl2. J. Am. Chem. Soc. 122, 6785–6786 (2000).

Lindsay, V. N. G., Viart, H. M.-F. & Sarpong, R. Stereodivergent intramolecular C(sp3)−H functionalization of azavinyl carbenes: synthesis of saturated heterocycles and fused N‑heterotricycles. J. Am. Chem. Soc. 137, 8368–8371 (2015).

Nieto-Oberhuber, C. et al. Gold(I)-catalyzed intramolecular [4+2] cycloadditions of arylalkynes or 1,3-enynes with alkenes. J. Am. Chem. Soc. 130, 269–279 (2008).

Acknowledgements

Financial support from the National Natural Science Foundation of China (21332009, 21572033) is greatly appreciated.

Author information

Authors and Affiliations

Contributions

R.F. directed the research and developed the concept of the reaction with D.H., who also performed the experiments and prepared the Supplementary Methods. Q.H. checked the experimental data. R.F. wrote the manuscript with contributions from the other authors.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Han, D., He, Q. & Fan, R. Formal group insertion into aryl C‒N bonds through an aromaticity destruction-reconstruction process. Nat Commun 9, 3423 (2018). https://doi.org/10.1038/s41467-018-05637-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-018-05637-z

This article is cited by

-

Bifunctional reagents in organic synthesis

Nature Reviews Chemistry (2021)

-

Conversion of anilines to chiral benzylic amines via formal one-carbon insertion into aromatic C–N bonds

Nature Communications (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.