Abstract

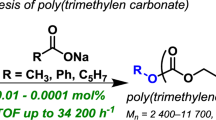

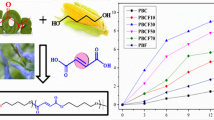

Ester-free trimethylene carbonate derivatives bearing bulky aromatic groups were designed and synthesized, including those with one or two benzyl groups, diphenylmethyl groups, and triphenylmethyl groups. The polymerization reactions of these monomers were investigated with several initiators. The mechanical properties of the polymers were determined with compressive tests, resulting in approximately 0.3 MPa at most. The degradation behaviors were also evaluated in lipase solutions and aqueous 0.01 M NaOH for several weeks, which revealed that the substituents impeded degradation in most cases. The degradation processes were slow, and they were analyzed with weight loss, SEM, SEC, TGA, and DSC studies.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The Supporting Information is available free of charge on the website at DOI: all of the experimental conditions.

References

Schneiderman DK, Hillmyer MA. 50th Anniversary perspective: there is a great future in sustainable polymers. Macromolecules. 2017;50:3733–49.

Rhodes CJ. Plastic pollution and potential solutions. Sci Prog. 2018;101:207–60.

Collignon A, Hecq J-H, Galgani F, Collard F, Goffart A. Annual variation in neustonic micro- and meso-plastic particles and zooplankton in the Bay of Calvi (Mediterranean–Corsica). Mar Pollut Bull. 2014;79:293–8.

Maoa R, Langa M, Yua X, Wub R, Yanga X, Guoa X. Aging mechanism of microplastics with UV irradiation and its effects on the adsorption of heavy metals. J Hazard Mater. 2020;393:122515.

Gijsman P, Meijers G, Vitarelli G. Comparison of the UV-degradation chemistry of polypropylene, polyethylene, polyamide 6 and polybutylene terephthalate. Polym Degrad Stab. 1999;65:433–41.

Driedger AGJ, Dürr HH, Mitchell K, Cappellen PV. Plastic debris in the Laurentian Great Lakes: a review. J Great Lakes Res. 2015;41:9–19.

Schmidt C, Krauth T, Wagner S. Export of plastic debris by rivers into the sea. Environ Sci Technol. 2017;51:12246–53.

Thompson RC, Olsen Y, Mitchell RP, Davis A, Rowland SJ, John AWG, et al. Lost at sea: where is all the plastic. Science. 2004;304:5672–838.

He L, Wu D, Rong H, Li M, Tong M, Kim H. Influence of nano- and microplastic particles on the transport and deposition behaviors of bacteria in quartz sand. Environ Sci Technol. 2018;52:11555–63.

Lin VS. Research highlights: impacts of microplastics on plankton. Environ Sci Processes Impacts. 2016;18:160–3.

Ivleva NP, Wiesheu AC, Niessner R. Microplastic in aquatic ecosystems. Angew Chem Int Ed. 2017;56:1720–39.

Barboza LGA, Vieira LR, Branco V, Carvalho C, Guilhermino L. Microplastics increase mercury bioconcentration in gills and bioaccumulation in the liver, and cause oxidative stress and damage in Dicentrarchus labrax juveniles. Sci Rep. 2018;8:15655.

Raamsdonk LWDV, Zande MVD, Koelmans AA, Hoogenboom RLAP, Peters RJB, Groot MJ, et al. Current insights into monitoring, bioaccumulation, and potential health effects of microplastics present in the food chain. Foods. 2020;9(9):72.

Iwata T. Biodegradable and bio-based polymers: future prospects of eco-friendly plastics. Angew Chem Int Ed. 2015;54:3210–5.

Haider TP, Vçlker C, Kramm J, Landfester K, Wurm FR. Plastics of the future? The impact of biodegradable polymers on the environment and on society. Angew Chem Int Ed. 2019;58:50–62.

Jamshidian M, Tehrany EA, Imran M, Jacquot M, Desobry S. Poly‐lactic acid: production, applications, nanocomposites, and release studies. Compr Rev Food Sci Food Saf. 2010;9:552–71.

Tan GYA, Chen CL, Li L, Ge L, Wang L, Razaad IMN, et al. Start a research on biopolymer polyhydroxyalkanoate (PHA): a review. Polymers. 2014;6:706–54.

Li H, Chang J, Cao A, Wang J. in vitro evaluation of biodegradable poly(butylene succinate) as a novel biomaterial. Macromol Biosci. 2005;5:433–40.

Jem KJ, Tan B. The development and challenges of poly (lactic acid) and poly (glycolic acid). Adv Ind Eng Polym. Res. 2020;3:60–70.

Yamane K, Sato H, Ichikawa Y, Sunagawa K, Shigaki Y. Development of an industrial production technology for high-molecular-weight polyglycolic acid. Polym J. 2014;46:769–75.

Bhattacharjee P, Naskar D, Kim HW, Maiti TK, Bhattacharya D, Kundu SC. Non-mulberry silk fibroin grafted PCL nanofibrous scaffold: Promising ECM for bone tissue engineering. Eur Polym J. 2015;71:490–509.

Someya Y, Sugahara Y, Shibata M. Nanocomposites based on poly(butylene adipate-co-terephthalate) and montmorillonite. J Appl Polym Sci. 2005;95:386–92.

Mitsuki T, Tanaka C., Nemoto T. Japan Patent, JP2023-110831A.

Song J, Dou Y, Niu Y, He N. Properties of HA/PBS biodegradable film and evaluation of its influence on the growth of vegetables. Polym Test. 2021;95:107137.

Towata R. Japan Patent, JP2020-127410A.

Xu X, Zhang J, Filion TM, Akalin A, Song J. Modulating mechanical and shape-memory properties while mitigating degradation-induced inflammation of polylactides by pendant aspirin incorporation. ACS Appl Mater Interfaces. 2021;13:22271–81.

Shen Y, Tu T, Yi B, Wang X, Tang H, Liu W, et al. Electrospun acid-neutralizing fibers for the amelioration of inflammatory response. Acta Biomater. 2019;97:200–15.

Zhanga Z, Kuijer R, Bulstrab SK, Grijpma DW, Feijen J. The in vivo and in vitro degradation behavior of poly(trimethylene carbonate. Biomaterials. 2006;27:1741–8.

Pêgo AP, Grijpma DW, Feijen J. Enhanced mechanical properties of 1,3-trimethylene carbonate polymers and networks. Polymer. 2003;44:6495–504.

Yang L, Li J, Zhang W, Jin Y, Zhang J, Liu Y, et al. The degradation of poly(trimethylene carbonate) implants: the role of molecular weight and enzymes. Polym Degrad Stab. 2015;122:77–87.

Tempelaar S, Mespouille L, Coulembier O, Duboisb P, Dove AP. Synthesis and post-polymerization modifications of aliphatic poly(carbonate)s prepared by ring-opening polymerisation. Chem Soc Rev. 2013;42:1312–36.

Yang J, Tian W, Li Q, Li Y, Cao A. Novel biodegradable aliphatic poly(butylene succinate-co-cyclic carbonate)s bearing functionalizable carbonate building blocks: II. Enzymatic biodegradation and in vitro biocompatibility assay. Biomacromolecules. 2004;5:2258–68.

Albertsson AC, Eklund M. Influence of molecular structure on the degradation mechanism of degradable polymers: In vitro degradation of poly(trimethylene carbonate), poly(trimethylene carbonate-co-caprolactone), and poly(adipic anhydride). J Appl Polym Sci. 1995;57:87–103.

Song Y, Kamphuis MMJ, Zhang Z, et al. Flexible and elastic porous poly(trimethylene carbonate) structures for use in vascular tissue engineering. Acta Biomater. 2010;6:1269–77.

Papenburg BJ, Schüller-Ravoo S, Bolhuis-Versteeg LA, Hartsuiker L, Grijpma DW, Feijen J, et al. Designing porosity and topography of poly(1,3-trimethylene carbonate) scaffolds. Acta Biomater. 2009;5:3281–94.

Riahinezhad H, Kerr-Dini N, Amsden BG. Degradation of poly(vinyl sulfone carbonate) in aqueous media. Polym Degrad Stab. 2023;216:110472.

Zhang W, Hou Z, Chen S, Guo J, Hu J, Yang L. et al. Aspergillus oryzae lipase-mediated in vitro enzymatic degradation of poly (2,2′-dimethyltrimethylene carbonate-co-ε-caprolactone). Polym Degrad Stab. 2023;211:110340.

Fukushima K, Watanabe Y, Ueda T, Nakai S, Kato T. Organocatalytic depolymerization of poly(trimethylene carbonate). J Polym Sci. 2022;60:3489–3500.

Yu W, Maynard E, Chiaradia V, Arno MC, Dove AP. Aliphatic polycarbonates from cyclic carbonate monomers and their application as biomaterials. Chem Rev. 2021;121:10865–907.

Ansari I, Singh P, Mittal A, Mahato RI, Chitkara D. 2,2-Bis(hydroxymethyl) propionic acid based cyclic carbonate monomers and their (co)polymers as advanced materials for biomedical applications. Biomaterials. 2021;275:120953.

Fukushima K. Poly(trimethylene carbonate)-based polymers engineered for biodegradable functional biomaterials. Biomater Sci. 2016;4:9–24.

Chanthaset N, Ajiro H. Preparation of thermosensitive biodegradable hydrogel using poly(5-[2-{2-(2-methoxyethoxy)ethyoxy}-ethoxymethyl]-5-methyl-1,3-dioxa-2-one) derivatives. Materialia. 2019;5:100178.

Ajiro H, Takahashi Y, Akashi M. Thermosensitive biodegradable homopolymer of trimethylene carbonate derivative at body temperature. Macromolecules. 2012;45:2668–74.

Haramiishi Y, Chanthaset N, Kan K, Akashi M, Ajiro H. Contrast effect on hydrolysis of poly(trimethylene carbonate) depending on accelerated species due to the hydrophilic oligo(ethylene glycol) units at side groups. Polym Degrad Stab. 2016;130:78–82.

Nobuoka H, Ajiro H. Nobuoka H, Ajiro H. Biodegradable and biocompatible crosslinked film with trimethylene carbonate bearing oligo(ethylene glycol). Chem Lett. 2019;48:245–8.

Nobuoka H, Ajiro H. Novel synthesis method of ester free trimethylene carbonate derivatives. Tetrahedron Lett. 2019;60:164–70.

Miyake R, Maehara A, Chanthaset N, Ajiro H. Thermal property control by copolymerization of trimethylene carbonate and its derivative bearing triphenylmethyl group. ChemistrySelect. 2022;7:e202104326.

Nobuoka H, Ajiro H. Development of ester free type poly(trimethylene carbonate) derivatives with pendant fluoroaromatic groups. Macromol Chem Phys. 2019;220:1900051.

Ouchi M, Inoue Y, Wada K, Iketani S, Kakushi T, Weber E. Molecular design of crown ethers. 4. Syntheses and selective cation binding of 16-crown-5 and 19-crown-6 lariats. J Org Chem. 1987;52:2420–7.

Weber E. Polytopic cation receptors. 2. Synthesis and selective complex formation of spiro-linked "multiloop crown compounds. J Org Chem. 1982;47:3478–86.

Nederberg F, Lohmeijer BGG, Leibfarth F, Pratt RC, Choi J, Dove AP, et al. Organocatalytic ring opening polymerization of trimethylene carbonate. Biomacromolecules. 2007;8:153–60.

Kricheldorf HR, Stricker A. Polymers of carbonic acid, 28. SnOct2-initiated polymerizations of trimethylene carbonate (TMC, 1,3-dioxanone-2. Macromol Chem Phys. 2000;201:2557–65.

Kricheldorf HR, Stricker A. Polymers of carbonic acid 29. Bu 2 SnOct 2 —initiated polymerizations of trimethylene carbonate (TMC, 1,3-dioxanone-2. Polymer. 2000;41:7311–20.

Albertsson AC, Sjöling M. Homopolymerization of 1,3-dioxan-2-one to high-molecular-weight poly(trimethylene carbonate). J Macromol Sci Pure Appl Chem. 1992;A29:43–54.

Nakazono K, Yamashita C, Ogawa T, Iguchi H, Takata T. Synthesis and properties of pendant fluorene moiety-tethered aliphatic polycarbonates. Polym J. 2015;47:355–61.

Matsuo J, Aoki K, Sanda F, Endo T. Substituent effect on the anionic equilibrium polymerization of six-membered cyclic carbonates. Macromolecules. 1998;31:4432–8.

Brissenden AJ, Amsden BG. Insights into the polymerization kinetics of thermoresponsive polytrimethylene carbonate bearing a methoxyethoxy side group. J Polym Sci. 2020;58:2697–707.

Prinse M, Qi R, Amsden BG. Polymer micelles for the protection and delivery of specialized pro-resolving mediators. Eur J Pharm Biopharm. 2023;184:159–69.

Hong M, Chen EYX. Completely recyclable biopolymers with linear and cyclic topologies via ring-opening polymerization of γ-butyrolactone. Nat Chem. 2016;8:42–9.

Aris MH, Annuar MSM, Ling TC. Lipase-mediated degradation of poly-ε-caprolactone in toluene: behavior and its action mechanism. Polym Degrad Stab. 2016;133:182–91.

Yamamoto T, Tezuka I. Topological polymer chemistry: new synthesis of cyclic and multicyclic polymers and topology effects thereby. Kobunshi Ronbunshu. 2011;68:782–94.

Acknowledgements

This work was supported by JSPS KAKENHI: Grant-in-Aid for Scientific Research on Innovative Areas (JP22H04547), Grant-in-Aid for Scientific Research (B) (JP20H02799) and Fostering Joint International Research (B) (JP19KK0277). The research was partly supported by The Mazda Foundation (21KK-134). The authors thank Ms. Nishikawa for performing the MALDI-TOF/MS experiments. The authors also appreciate fruitful discussions with Dr. T. Ando, Dr. N. Chanthaset, and H. Yoshida.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Miyake, R., Ajiro, H. Investigation of the mechanical properties and degradation of ester-free poly(trimethylene carbonate) derivatives bearing various bulky aromatic groups. Polym J 56, 319–333 (2024). https://doi.org/10.1038/s41428-023-00848-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-023-00848-8