Abstract

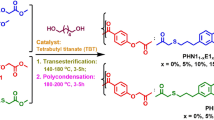

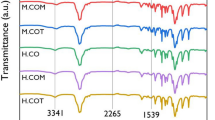

In this study, poly(vinyl alcohol) (PVA) was crosslinked via catalyst-free solid-state esterification at 120 °C with 2,5-furandicarboxylic acid (FDCA) at concentrations ranging from 1 to 10%. The structural characterization of the obtained products was carried out by attenuated total reflection Fourier transform infrared spectroscopy. The effects of ester crosslinks on the water absorption properties of the modified products were investigated through swelling degree analysis. The improvement in thermal properties of the obtained products was confirmed by thermal gravimetric analysis/differential thermal analysis, which showed that thermal stability was optimal for low concentrations of FDCA, i.e., 1 and 5%, where degradation maximums occurred at 354 and 371 °C, respectively, compared to 267 °C for unmodified PVA. The mechanical properties of the products were also studied via tensile testing, where the tensile strength of the crosslinked PVA using 5% FDCA (48.2 ± 2.6 MPa), doubled when compared to untreated PVA (25.5 ± 1.2 MPa).

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Muthuraj R, Misra M, Mohanty AK. Biodegradable compatibilized polymer blends for packaging applications: a literature review. J Appl Polym Sci. 2018;135:45726.

Scaffaro R, Maio A, Sutera F, Gulino EF, Morreale M. Degradation and recycling of films based on biodegradable polymers: a short review. Polymers. 2019;11:651.

Jayanth D, Kumar PS, Nayak GC, Kumar JS, Pal SK, Rajasekar R. A review on biodegradable polymeric materials striving towards the attainment of green environment. J Polym Environ. 2018;26:838–65.

Narancic T, O’Connor KE. Plastic waste as a global challenge: are biodegradable plastics the answer to the plastic waste problem? Microbiology. 2019;165:129–37.

Shen M, Song B, Zeng G, Zhang Y, Huang W, Wen X, et al. Are biodegradable plastics a promising solution to solve the global plastic pollution? Environ Pollut. 2020;263:114469.

Manfra L, Marengo V, Libralato G, Costantini M, De Falco F, Cocca M, et al. Biodegradable polymers: a real opportunity to solve marine plastic pollution? J Hazard Mater. 2021;416:125763.

Halima NB. Poly (vinyl alcohol): review of its promising applications and insights into biodegradation. RSC Adv. 2016;6:39823–32.

Aslam M, Kalyar MA, Raza ZA. Polyvinyl alcohol: a review of research status and use of polyvinyl alcohol based nanocomposites. Polym Eng Sci. 2018;58:2119–32.

Feldman D. Poly (vinyl alcohol) recent contributions to engineering and medicine. J Compos Sci. 2020;4:175.

Shimao M. Biodegradation of plastics. Curr Opin Biotechnol. 2001;12:242–7.

Kawai F, Hu X. Biochemistry of microbial polyvinyl alcohol degradation. Appl Microbiol Biotechnol. 2009;84:227–37.

Sonker AK, Tiwari N, Nagarale RK, Verma V. Synergistic effect of cellulose nanowhiskers reinforcement and dicarboxylic acids crosslinking towards polyvinyl alcohol properties. J Polym Sci Part A: Polym Chem. 2016;54:2515–25.

Falqi FH, Bin-Dahman OA, Hussain M, Al-Harthi MA. Preparation of miscible PVA/PEG blends and effect of graphene concentration on thermal, crystallization, morphological, and mechanical properties of PVA/PEG (10 wt%) blend. Int J Polym Sci. 2018;2018:8527693.

Sonker AK, Rathore K, Nagarale RK, Verma V. Crosslinking of polyvinyl alcohol (PVA) and effect of crosslinker shape (aliphatic and aromatic) thereof. J Polym Environ. 2018;26:1782–94.

Kim K-J, Lee S-B, Han N-W. Kinetics of crosslinking reaction of PVA membrane with glutaraldehyde. Korean J Chem Eng. 1994;11:41–47.

Figueiredo KCS, Alves TLM, Borges CP. Poly (vinyl alcohol) films crosslinked by glutaraldehyde under mild conditions. J Appl Polym Sci. 2009;111:3074–80.

Liu L, Kentish SE. Pervaporation performance of crosslinked PVA membranes in the vicinity of the glass transition temperature. J Membr Sci. 2018;553:63–69.

Ji W, Afsar NU, Wu B, Sheng F, Shehzad MA, Ge L, et al. In-situ crosslinked SPPO/PVA composite membranes for alkali recovery via diffusion dialysis. J Membr Sci. 2019;590:117267.

Zhang Y, Zhu PC, Edgren D. Crosslinking reaction of poly (vinyl alcohol) with glyoxal. J Polym Res. 2010;17:725–30.

Leone G, Consumi M, Pepi S, Pardini A, Bonechi C, Tamasi G, et al. Poly-vinyl alcohol (PVA) crosslinked by trisodium trimetaphosphate (STMP) and sodium hexametaphosphate (SHMP): effect of molecular weight, pH and phosphorylating agent on length of spacing arms, crosslinking density and water interaction. J Mol Struct. 2020;1202:127264.

Miyazaki T, Takeda Y, Akane S, Itou T, Hoshiko A, En K. Role of boric acid for a poly (vinyl alcohol) film as a cross-linking agent: Melting behaviors of the films with boric acid. Polymer. 2010;51:5539–49.

Bolto B, Tran T, Hoang M, Xie Z. Crosslinked poly (vinyl alcohol) membranes. Prog Polym Sci. 2009;34:969–81.

Heydari M, Moheb A, Ghiaci M, Masoomi M. Effect of cross‐linking time on the thermal and mechanical properties and pervaporation performance of poly (vinyl alcohol) membrane cross‐linked with fumaric acid used for dehydration of isopropanol. J Appl Polym Sci. 2013;128:1640–51.

Jose J, Al-Harthi MA. Citric acid crosslinking of poly (vinyl alcohol)/starch/graphene nanocomposites for superior properties. Iran Polym J. 2017;26:579–87.

Sonker AK, Teotia AK, Kumar A, Nagarale RK, Verma V. Development of polyvinyl alcohol based high strength biocompatible composite films. Macromol Chem Phys. 2017;218:1700130.

Sonker AK, Rathore K, Teotia AK, Kumar A, Verma V. Rapid synthesis of high strength cellulose–poly (vinyl alcohol)(PVA) biocompatible composite films via microwave crosslinking. J Appl Polym Sci. 2019;136:47393.

Sonker AK, Verma V. Influence of crosslinking methods toward poly (vinyl alcohol) properties: microwave irradiation and conventional heating. J Appl Polym Sci. 2018;135:46125.

Kudoh Y, Kojima T, Abe M, Oota M, Yamamoto T. Proton conducting membranes consisting of poly (vinyl alcohol) and poly (styrene sulfonic acid): crosslinking of poly (vinyl alcohol) with and without succinic acid. Solid State Ion. 2013;253:189–94.

Dlamini DS, Wang J, Mishra AK, Mamba BB, Hoek EMV. Effect of cross-linking agent chemistry and coating conditions on physical, chemical, and separation properties of PVA-Psf composite membranes. Sep Sci Technol. 2014;49:22–29.

Salgado‐Chavarría D, Palacios‐Alquisira J. Poly (vinyl alcohol) membranes cross‐linked with maleic anhydride and 2, 5‐furandicarboxylic acid: conventional heating and microwave irradiation. ChemistrySelect. 2020;5:4826–38.

Sajid M, Zhao X, Liu D. Production of 2, 5-furandicarboxylic acid (FDCA) from 5-hydroxymethylfurfural (HMF): recent progress focusing on the chemical-catalytic routes. Green Chem. 2018;20:5427–53.

Liguori F, Barbaro P, Calisi N. Continuous‐flow oxidation of HMF to FDCA by resin‐supported platinum catalysts in neat water. ChemSusChem. 2019;12:2558–63.

Liu X, Zhang M, Li Z. CoO x-MC (MC= mesoporous carbon) for highly efficient oxidation of 5-hydroxymethylfurfural (5-HMF) to 2,5-furandicarboxylic acid (FDCA). ACS Sustain Chem Eng. 2020;8:4801–8.

Guan W, Zhang Y, Chen Y, Wu J, Cao Y, Wei Y, et al. Hierarchical porous bowl-like nitrogen-doped carbon supported bimetallic AuPd nanoparticles as nanoreactors for high efficient catalytic oxidation of HMF to FDCA. J Catal. 2021;396:40–53.

Menegazzo F, Ghedini E, Signoretto M. 5-Hydroxymethylfurfural (HMF) production from real biomasses. Molecules. 2018;23:2201.

Sonsiam C, Kaewchada A, Jaree A. Synthesis of 5-hydroxymethylfurfural (5-HMF) from fructose over cation exchange resin in a continuous flow reactor. Chem Eng Process. 2019;138:65–72.

Zhang Y, Li B, Guan W, Wei Y, Yan C, Meng M, et al. One-pot synthesis of HMF from carbohydrates over acid-base bi-functional carbonaceous catalyst supported on halloysite nanotubes. Cellulose. 2020;27:3037–54.

El Fergani M, Candu N, Tudorache M, Bucur C, Djelal N, Granger P, et al. From useless humins by-product to Nb@graphite-like carbon catalysts highly efficient in HMF synthesis. Appl Catal A: Gen. 2021;618:118130.

Fei X, Wang J, Zhu J, Wang X, Liu X. Biobased poly (ethylene 2, 5-furancoate): No longer an alternative, but an irreplaceable polyester in the polymer industry. ACS Sustain Chem Eng. 2020;8:8471–85.

Terzopoulou Z, Papadopoulos L, Zamboulis A, Papageorgiou DG, Papageorgiou GZ, Bikiaris DN. Tuning the properties of furandicarboxylic acid-based polyesters with copolymerization: a review. Polymers. 2020;12:1209.

Trung NV, Nguyen MN, Ngoc ANT, Thi NP, Quang TT, Thi TT. Synthesis and characterizations of biobased copolymer poly (ethylene-co-butylene 2, 5-furandicarboxylate). Int J Polym Sci. 2021;2021:9104546.

Zhang D, Dumont MJ. Advances in polymer precursors and bio‐based polymers synthesized from 5‐hydroxymethylfurfural. J Polym Sci Part A: Polym Chem. 2017;55:1478–92.

Burgess SK, Karvan O, Johnson JR, Kriegel RM, Koros WJ. Oxygen sorption and transport in amorphous poly (ethylene furanoate). Polymer. 2014;55:4748–56.

Burgess SK, Mikkilineni DS, Daniel BY, Kim DJ, Mubarak CR, Kriegel RM, et al. Water sorption in poly (ethylene furanoate) compared to poly (ethylene terephthalate). Part 1: equilibrium sorption. Polymer. 2014;55:6861–9.

Burgess SK, Mikkilineni DS, Daniel BY, Kim DJ, Mubarak CR, Kriegel RM, et al. Water sorption in poly (ethylene furanoate) compared to poly (ethylene terephthalate). Part 2: kinetic sorption. Polymer. 2014;55:6870–82.

Rimdusit N, Jubsilp C, Mora P, Hemvichian K, Thuy TT, Karagiannidis P, et al. Radiation graft-copolymerization of ultrafine fully vulcanized powdered natural rubber: effects of styrene and acrylonitrile contents on thermal stability. Polymers. 2021;13:3447.

Yang M-H, Chu T-J. The determination of interaction parameter χ1 for polyvinyl alcohol and water from the diffusion data. Polym Test. 1993;12:57–64.

Peng Z, Kong LX. A thermal degradation mechanism of polyvinyl alcohol/silica nanocomposites. Polym Degrad Stab. 2007;92:1061–71.

Gilman JW, VanderHart Dl, Kashiwagi T. Thermal decomposition chemistry of poly(vinyl alcohol). In Fire and polymers II, 599. ACS Symposium Series. American Chemical Society; 1995. p. 161–85.

Tsanaktsis V, Vouvoudi E, Papageorgiou GZ, Papageorgiou DG, Chrissafis K, Bikiaris DN. Thermal degradation kinetics and decomposition mechanism of polyesters based on 2,5-furandicarboxylic acid and low molecular weight aliphatic diols. J Anal Appl Pyrolysis. 2015;112:369–78.

Acknowledgements

This research is funded by the Vietnam National Foundation for Science and Technology Development (NAFOSTED) under grant number 104.02-2019.12. The authors are grateful to Nigel Van de Velde for the valuable comments and corrections during the revision of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vu Trung, N., Pham Thi, N., Nguyen, T.H. et al. Tuning the thermal and mechanical properties of poly(vinyl alcohol) with 2,5-furandicarboxylic acid acting as a biobased crosslinking agent. Polym J 54, 335–343 (2022). https://doi.org/10.1038/s41428-021-00583-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-021-00583-y

This article is cited by

-

Antibacterial Activity and Drug Release of Ciprofloxacin Loaded PVA-nHAp Nanocomposite Coating on Ti-6Al-4 V

Journal of Inorganic and Organometallic Polymers and Materials (2022)