Abstract

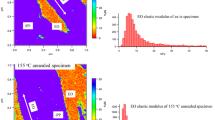

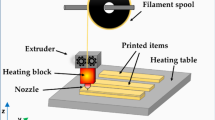

Ziegler-Natta isotactic polypropylenes (ZN-iPP) were melt blended with metallocene-based isotactic polypropylenes (M-iPP) to regulate and strengthen their mechanical properties systematically. Quantitatively, the hierarchical structure was characterized by synchrotron wide-angle X-ray diffraction, small-angle X-ray scattering, and differential scanning calorimetry. Without specific catalysts, the iPP samples exhibited a continuous change in the tensile strength (26.9–49.5 MPa) and impact strength (4.7–23.2 KJ/m2). With variable composition, the iPP blends exhibited mechanical properties that were related to the complex lamellar morphology, which is characterized by a gradually changing ratio of γ- to α-crystals and a continuous change in lamellar thickness. Compared to conventional injection molding samples, the oscillatory shear injection molding samples were simultaneously reinforced and toughened at a given blend composition, which was attributed to the shish-kebab structure (containing the α-parent crystal, α-daughter crystal, γ-crystals) and the relatively thicker lamellar thickness throughout the samples. The regulatory capacity of strength, ductility, and toughness of the iPP blends in this work is outstanding, providing an avenue to use iPP more efficiently, which should be valuable in industrial applications.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Jasinska-Walc L, Bouyahyi M, Duchateau R. Potential of functionalized polyolefins in a sustainable polymer economy: synthetic strategies and applications. Acc Chem Res. 2022;55:1985–96.

Garcia JM, Robertson ML. The future of plastics recycling. Science. 2017;358:870–2.

Zhang Z, Lei J, Chen Y, Chen J, Ji X, Tang J, et al. Tailored structure and properties of injection-molded atactic polypropylene/isotactic polypropylene blend. ACS Sustain Chem Eng. 2013;1:937–49.

Zhou M, Mi D, Hou F, Zhang J. Tailored crystalline structure and mechanical properties of isotactic polypropylene/high molecular weight polyethylene blend. Ind Eng Chem Res. 2017;56:8385–92.

Graziano A, Jaffer S, Sain M. Review on modification strategies of polyethylene/polypropylene immiscible thermoplastic polymer blends for enhancing their mechanical behavior. J Elastomers Plast. 2019;51:291–336.

Auriemma F, Ballesteros ORD, Rosa CD, Invigorito C. Tailoring the mechanical properties of isotactic polypropylene by blending samples with different stereoregularity. Macromolecules. 2011;44:6026–38.

Auriemma F, Ruiz de Ballesteros O, De Rosa C. Theoretical investigation of nano-scale organization in blends of semicrystalline/semicrystalline polymers by small angle X-ray scattering. Macromolecules. 2010;43:9787–801.

Seyedi M, Savchak M, Tiiara A, Luzinov I. Toward mechanical recycling of polystyrene/polypropylene blends with bottlebrush-modified graphene oxide as a compatibilizer. ACS Appl Mater Interfaces. 2022;14:35074–86.

Su Y, Huang P, Zhao Y, Zheng W, Lan X, Luo H, et al. Lightweight polypropylene/polylactic acid composite foams with controllable hollow radially gradient porous structures for oil/water separation. Ind Eng Chem Res. 2022;61:10982–9.

Schrauwen BAG, Breemen LCAV, Spoelstra AB, Govaert LE, Peters GWM, Meijer HEH. Structure, deformation, and failure of flow-oriented semicrystalline polymers. Macromolecules. 2004;37:8618–33.

Wang K, Chen F, Li Z, Fu Q. Control of the hierarchical structure of polymer articles via “structuring” processing. Prog Polym Sci. 2014;39:891–920.

Chen YH, Zhong GJ, Wang Y, Li ZM, Li L. Unusual tuning of mechanical properties of isotactic polypropylene using counteraction of shear flow and β-nucleating agent on β-form nucleation. Macromolecules. 2009;42:4343–8.

Lezak E, Bartczak Z, Galeski A. Plastic deformation of the γ phase in isotactic polypropylene in plane-strain compression. Macromolecules. 2006;40:4933–41.

Rosa CD, Auriemma F, Spera C, Talarico G, Tarallo O. Comparison between polymorphic behaviors of ZieglerNatta and Metallocene-made isotactic polypropylene: the role of the distribution of defects in the polymer chains. Macromolecules. 2004;37:1441–54.

Caelers HJM, Govaert LE, Peters GWM. The prediction of mechanical performance of isotactic polypropylene on the basis of processing conditions. Polymer. 2016;83:116–28.

Wang Y, Pan J-L, Mao Y, Li Z-M, Li L, Hsiao BS. Spatial distribution of γ-crystals in metallocene-made isotactic polypropylene crystallized under combined thermal and flow fields. J Phys Chem B. 2010;114:6806–16.

Picken SJ, Aerts J, Visser R, Northolt MG. Structure and rheology of aramid solutions: x-ray scattering measurements. Macromolecules. 1990;23:3849–54.

Natta G, Corradini P. Structure and properties of isotactic polypropylene. Nuovo Cimento Suppl. 1960;15:40–51.

Brückner S, Meille SV. Non-parallel chains in crystalline -isotactic polypropylene. Nature. 1989;340:455–7.

Yang SG, Chen YH, Deng BW, Lei J, Li L, Li ZM. Window of pressure and flow to produce β-crystals in isotactic polypropylene mixed with β-nucleating agent. Macromolecules. 2017;50:4807–16. acs.macromol.7b00041.

Jones AT, Aizlewood JM, Beckett DR. Crystalline forms of isotactic polypropylene. Macromol Chem Phys. 1964;75:134–58.

Auriemma F, De Rosa C. Crystallization of metallocene-made isotactic polypropylene: disordered modifications intermediate between the α and γ forms. Macromolecules. 2002;35:9057–68.

Foresta T, Piccarolo S, Goldbeck-Wood G. Competition between α and γ phases in isotactic polypropylene: effects of ethylene content and nucleating agents at different cooling rates. Polymer. 2001;42:1167–76.

Xie XL, Yue L, Xu JZ, Zheng Y, Zhong GJ, Li ZM. Largely enhanced mechanical performance of poly(butylene succinate) multiple system via shear stress-induced orientation of the hierarchical structure. J Mater Chem A. 2018;55:1985–96. 10.1039.C8TA03778G-.

Alamo RG, Kim MH, Galante MJ, Isasi JR, Mandelkern L. Structural and kinetic factors governing the formation of the γ polymorph of isotactic polypropylene. Macromolecules. 1999;32:4050–64.

Xie X-L, Li Y, Xu J-Z, Yan Z, Zhong G-J, Li Z-M. Largely enhanced mechanical performance of poly (butylene succinate) multiple system via shear stress-induced orientation of the hierarchical structure. J Mater Chem A. 2018;6:13373–85.

Kumaraswamy G, Verma RK, Kornfield JA, Yeh F, Hsiao BS. Shear-enhanced crystallization in isotactic polypropylene. In-situ synchrotron SAXS and WAXD. Macromolecules. 2004;37:9005–17.

Xie X-L, Li Y, Xu J-Z. Largely enhanced mechanical performance of poly(butylene succinate) multiple system via shear stress-induced orientation of the hierarchical structure. J Mater Chem A. 2018;6:13373–85.

Auriemma F, De Rosa C. Stretching isotactic polypropylene:? From “cross-β” to crosshatches, from γ form to α form. Macromolecules. 2006;39:7635–47.

Kazmierczak T, Galeski A, Argon AS. Plastic deformation of polyethylene crystals as a function of crystal thickness and compression rate. Polymer. 2005;46:8926–36.

Chang B, Schneider K, Xiang F, Vogel R, Roth S, Heinrich G. Critical strains for lamellae deformation and cavitation during uniaxial stretching of annealed isotactic polypropylene. Macromolecules. 2018;51:6276–90.

Lotz B, Wittmann JC. The molecular origin of lamellar branching in the α (monoclinic) form of isotactic polypropylene. J Polym Sci B Polym Phys. 1986;24:1541–1558.

Meille SV, Brückner S. Non-parallel chains in crystalline γ-isotactic polypropylene. Nature. 1989;340:455–7.

Bucknall CB, Soares V, Yang H, & Zhang X. Rubber toughening of plastics: Rubber particle cavitation and its consequences[J]. Macromolecular Symposia. 1996;265–71.

Karnani R, Krishnan M, Narayan R. Biofiber-reinforced polypropylene composites. Polym Eng Sci. 1997;37:476–83.

Thio Y, Argon A, Cohen R, Weinberg M. Toughening of isotactic polypropylene with CaCO3 particles. Polymer. 2002;43:3661–74.

Reddy KR, Tashiro K, Sakurai T, Yamaguchi N. Cocrystallization phenomenon between the H and D species of isotactic polypropylene blends as revealed by thermal and infrared spectroscopic analyses for a series of D/H blend samples. Macromolecules. 2008;41:9807–13.

Reddy KR, Tashiro K, Sakurai T, Yamaguchi N. Isotope effect on the isothermal crystallization behavior of isotactic polypropylene blends between the deuterated and hydrogenated species. Macromolecules. 2009;42:1672–8.

Mandelkern L. Crystallization of polymers. Volume 1. Equilibrium concepts. Cambridge University Press: Cambridge, UK and New York; 2002.

Lotz B, Graff S, Straupe C, Wittmann J. Single crystals of γ phase isotactic polypropylene: combined diffraction and morphological support for a structure with non-parallel chains. Polymer. 1991;32:2902–10.

van Erp TB, Balzano L, Peters GWM. Oriented gamma phase in isotactic polypropylene homopolymer. ACS Macro Lett. 2012;1:618–22.

Yang S-G, Zhang Z, Zhou D, Wang Y, Lei J, Li L, et al. Flow and pressure jointly induced ultrahigh melting temperature spherulites with oriented thick lamellae in isotactic polypropylene. Macromolecules. 2015;48:5834–44.

Kalay G, Bevis MJ. Processing and physical property relationships in injection-molded isotactic polypropylene. 1. Mechanical properties. J Polym Sci B Polym Phys. 1997;35:241–63.

Mi D, Xia C, Jin M, Wang F, Shen K, Zhang J. Quantification of the effect of shish-kebab structure on the mechanical properties of polypropylene samples by controlling shear layer thickness. Macromolecules. 2016;49:4571–8.

Acknowledgements

The authors appreciate the financial support from the National Natural Science Foundation of China (Grant No. 51503023), the Opening Project of State Key Laboratory of Polymer Materials Engineering (Sichuan University) (Grant No. sklpme 2021-05-04), and Foundation of Liaoning Province Education Administration (LJKZ0533). We also thank the Shanghai Synchrotron Radiation Facility (SSRF) for supporting the X-ray measurements.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Y., Wang, Y., Qiu, S. et al. Tailoring the mechanical properties of binary polypropylene blends with polymorphic and oriented hierarchical structures. Polym J 55, 837–848 (2023). https://doi.org/10.1038/s41428-023-00773-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-023-00773-w