Abstract

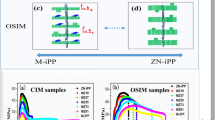

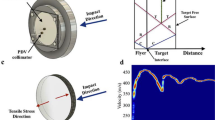

Here, the nano-scale elastic modulus of a phase-separated polyolefin blend consisting of isotactic polypropylene (iPP) and ethylene-co-octene rubber (EO) was investigated using atomic force microscopy (AFM). We investigated the elastic modulus of the EO domain for the injection-molded specimens with three different annealing temperatures: without further annealing (“as-is”), 100 °C annealing (“100 °C”), and 155 °C annealing (“155 °C”). The shapes of the EO domains of those specimens were observed as fibrous and highly oriented along the flow direction. However, the elastic moduli of the EO domains were distributed differently depending upon their annealing temperatures. The elastic modulus in the “as-is” sample was distributed from 2 to >50 MPa, with higher modulus EO domains (>10–50 MPa) than the inherent elastic modulus of the EO. These domains were supposed to be derived from the high-stress EO domain based on the negative pressure accumulated inside the fibrous EO domain, which is attributed to the elongated and tense EO molecules. The 100 °C specimen, with an annealing temperature that was much higher than the melting point of the EO, still contained many higher elastic modulus EO domains, demonstrating that the 100 °C annealing temperature was still insufficient to remove the stress inside these EO domains. Finally, the 155 °C sample did not show any higher modulus EO domains, and its elastic modulus distribution became closer to that of the inherent EO.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Moore Jr EP. Polypropylene Handbook. Car Hanser Verlag, Münich, Germany, 1996.

Grein C, Bernreitner K, Hauer A, Gahleitner M, Neißl W. Impact modified isotatic polypropylene with controlled rubber intrinsic viscosities: some new aspects about morphology and fracture. J Appl Polym Sci. 2003;87:1702–12.

JSR Co., Ltd., Japanese Patent JP2001-172335A.

Ono M, Washiyama J, Nakajima K, Nishi T. Polymer. Anisotropic thermal expansion in polypropylene/poly(ethylene-co-octene) binary blends: influence of arrays of elastomer domains. Polymer. 2005;46:4899–908.

Yasuda T. Automotive and plastics. JETI 2002;50:35–9.

Levinson R, Pan H, Ban Weiss G, Rosado P, Paolini R, Akbari H. Potential benefits of solar reflective car shells: cooler cabins, fuel savings and emission reductions. Appl Energy. 2011;88:4343–57.

Li X, Wu H, Han L, Hunag T, Wang Y, Bai H, et al. Annealing induced microstructure and fracture resistance changes in isotactic polypropylene/ethylene-octene copolymer blends with and without β-phase nucleating agent. J Polym Sci Part B Polym Phys. 2010;48:2108–20.

Poussin L, Bertin YA, Parisot J, Brassy C. Influence of thermal treatment on the structure of an isotactic polypropylene. Polymer 1998;39:4261–5.

Yu B, Geng C, Zhou M, bai H, Fu Q, He B. Impact toughness of polypropylene/glass fiber composites: Interplay between intrinsic toughening and extrinsic toughening. Compos Part B: Eng. 2016;92:413–9.

Hikosaka M, Seto T. The order of the molecular chains in isotactic polypropylene crystals. Polym J. 1973;5:111–27.

Craig J, Carriere H, Craig S. The effects of short-chain branching and comonomer type on the interfacial tension of polypropylene-polyolefin elastomer blends. J Appl Polym Sci. 1997;66:1175–81.

Charfeddine I, Majesté JC, Carrot C, Lhost O. Surface tension and interfacial tension of polyolefins and polyolefin blends. J Appl Polym Sci. 2022;139:51885.

Freger V. Swelling and morphology of the skin layer of polyamide composite membranes: an atomic force microscopy study. Environ Sci Technol. 2004;38:3168–75.

Coffey DC, Reid OG, Rodovsky DB, Bartholomew GP, Ginger DS. Mapping local photocurrents in polymer/fullerene solar cells with photoconductive atomic force microscopy. Nano Lett. 2007;7:738–44.

Liu H, Liang X, Nakajima K. Nanoscale strain–stress mapping for a thermoplastic elastomer revealed using a combination of in situ atomic force microscopy nanomechanics and Delaunay triangulation. Nanorheological analysis of polymer surfaces by atomic force microscopy. J Polym Sci. 2022;20:3134–40.

Liang X, Miyafuji K, Hara K, Mogi K, Nishida R, Liu H, et al. Direct visualization of stretch-induced phase separation in methoxy silyl-terminated polypropylene oxide/epoxy resin-type polymer alloys via AFM nanomechanics: a toughening mechanism. Polymer 2022;259:125343.

Nguyen HK, Aoki M, Liang X, Yamamoto S, Tanaka K, Nakajima K. Local mechanical properties of heterogeneous nanostructures developed in a cured epoxy network: implications for innovative adhesion technology. ACS Appl Nano Mater. 2021;4:12188–96.

Rixman MA, Dean D, Macias C, Ortiz C. Nanoscale intermolecular interactions between human serum albumin and alkanethiol self-assembled monolayers. Langmuir 2003;19:6202–18.

Ortiz C, Hadziioannou G. Entropic elasticity of single polymer chains of poly(methacrylic acid) measured by atomic force microscopy. Macromolecules 1999;32:780–7.

Al-Mawaali S, Bemis J, Akhremitchev BB, Janesko B, Walker GC. Study of the polydispersity of grafted poly(dimethylsiloxane) surfaces using single-molecule atomic force microscopy. J Phys Chem B. 2001;105:3965–71.

Pavoor PV, Bellare A, Storm A, Yang D, Cohen RE. Mechanical characterization of polyelectrolyte multilayers using quasi-static nanoindentation. Macromolecules. 2004;37:4865–71.

Vanlandingham MR, Mcknight SH, Plamese GR, Elings JR, Huang X, Bagetti TA, et al. Nanoscale indentation of polymer systems using the atomic force microscope. J Adhes. 1997;64:31–59.

Akhremitchev BB, Walker GC. Finite sample thickness effects on elasticity determination using atomic force microscopy. Langmuir. 1999;15:5630–4.

Nakajima K, Fujinami S, Nukaga H, Watabe H, Kitano H, Ohno N, et al. Nanorheology mapping by atomic force microscopy. Kobunshi Ronbunshu. 2005;62:476–87.

Cappella B, Kaliappan SK, Sturm H. Using AFM force-distance curves to study the glass-to-rubber transition of amorphous polymers and their elastic-plastic properties as a function of temperature. Macromolecules. 2005;36:1874–81.

Tomasetti E, Legras R, Nysten B. Quantitative approach towards the measurement of polypropylene/(ethylene-propylene) copolymer blends surface elastic properties by AFM. Nanotechnology. 1998;9:305–15.

Hertz H. Uber die beruhrung fester elastischer. J Reine Angew Math. 1882;92:156–71.

Johnson KL, Kendall K, Roberts AD. Surface energy and the contact of elastic solids. Proc R Soc Lond Ser A. 1971;324:301–13.

Liu H, Chen N, Fujinami S, Louzguine-Luzgin D, Nakajima K, Toshio N. Quantitative nanomechanical investigation on deformation of poly(lactic acid). Macromolecules .2012;45:8770–9.

Sun Y, Akhremitchev BB, Walker GL. Using the adhesive interaction between atomic force microscopy tips and polymer surfaces to measure the elastic modulus of compliant samples. Langmuir .2004;20:5837–45.

Liang X, Nakajima K. Study of the Mullins effect in carbon black-filled styrene-butadiene rubber by atomic force microscopy nanomechanics. Macromolecules 2022;55:6023–30.

Wang D, Liang X, Russell TP, Nakajima K. Visualization and quantification of the chemical and physical properties of a diffusion-induced interface using AFM nanomechanical mapping. Macromolecules .2014;47:3761–5.

Nukaga H, Fujinami S, Watabe H, Nakajima K, Nishi T. Nanorheological analysis of polymer surfaces by atomic force microscopy. Jpn J Appl Phys. 2005;44:5425–9.

Nakajima K, Ito M, Wang D, Liu H, Nguyen HK, Liang X, et al. Nano-palpation AFM and its quantitative mechanical property mapping. Microscopy .2014;63:193–208.

Ono M, Washiyama J, Nakajima K, Nishi T. Anisotripic thermal expansion in polypropylene/poly(ethylene-co-octene) binary blends : influenece of arrays of elastomer domains. Polymer .2005;46:4899–908.

Atsumi T, Nishitsuji S, Inoue T, Kobayashi S. Structure-proerties of a super ductile nylon alloy. Kobunshi Ronbunshu. 2011;68:616–22.

Moffitt M, Rharbi Y, Chen W, Tong JD, Winnik MA, Thurman DW, et al. Stratified morphology of a polypropylene/elastomer blend following channel flow. J Polym Sci : Polym Phys Ed. 2002;40:2842–59.

Chang YW, Lee Y. Preparation and properties of polyethylene-octene elastomer (POE)/organoclay nanocomposites. Polym Bull. 2012;68:483–92.

Lim JY, Hassan A, Rahmat AR, Wahit MU. Morphology, thermal and mechanical behavior of polypropylene nanocomposites toughened with poly(ethylene-co-octene). Polym Int. 2006;55:204–15.

Acknowledgements

The authors wish to thank SunAllomer Ltd. for supplying iPP samples and for supporting the blend sample and plaque preparation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ono, M., Nakajima, K. Influence of thermal treatment on the elastic modulus of a nano-dispersed elastomer domain in an injection-molded isotactic polypropylene/thermoplastic elastomer binary blend. Polym J 56, 87–96 (2024). https://doi.org/10.1038/s41428-023-00844-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-023-00844-y