Abstract

The optimum processing conditions for PEDOT:PSS and PEDOT:PSS/Tween 80 cast films were investigated by considering film quality and resistivity. The thermal stabilities of these materials were found to strongly influence the accessible annealing temperatures, especially in the presence of the conductivity-enhancing agent Tween 80. The resistivities of PEDOT:PSS films with and without Tween 80 decreased by up to 85% with increases in both annealing temperature and time until a plateau was reached. In addition, thermal structural rearrangements of these polymers were the key driving factors that reduced resistivity, with water removal alone insufficient. Finally, the optimum processing conditions for PEDOT:PSS and PEDOT:PSS/Tween 80 films are detailed.

Similar content being viewed by others

Introduction

There has been a great deal of interest in the intrinsically conducting polymer poly(3,4-ethylenedioythiophene):poly(styrenesulfonate) (PEDOT:PSS) in the last 25 years because it can replace indium tin oxide (ITO) in optoelectric devices. PEDOT:PSS has the added advantages of improved flexibility and ease of processing in roll-to-roll manufacturing. However, the conductivity of pristine PEDOT:PSS is much lower than that of ITO (1 compared to 4500 Scm−1) [1, 2]. While most research has been focused on the use of chemical treatments to improve resistivity and conductivity, there is little published work on optimization through control of the processing parameters.

Annealing of PEDOT:PSS films is an important parameter because it increases conductivity [3, 4]. For instance, Friedel et al. found that the resistivity decreased with annealing temperature from approximately 1.3 MΩcm after annealing for 30 min at 120 °C to 0.15 MΩcm at 250 °C [5]. It is widely accepted that this conductivity enhancement was generated by the removal of excess, or bound, water, which resulted in shrinkage of the insulating hydrophilic PSS regions [3, 5]. There have also been reports that annealing at elevated temperatures causes structural rearrangement through the softening of the PSS region and PEDOT re-alignment [6, 7].

In most reports in the literature, an annealing temperature and time are provided with little to no indication as to why those conditions were selected. Furthermore, conditioning parameters can vary greatly, such as 110 °C for 2 h [8], 140 °C for 20 s [3], 150 °C for 10 min [9] and 200 °C for 2 min [10]. There seems to be little consistency in annealing conditions other than higher temperatures are employed for shorter times. Annealing is generally performed over 100 °C to ensure removal of water, although temperatures as high as 150 °C could be required to fully remove bound moisture, as inferred from thermal gravimetric data [11, 12]. There have been exceptions in which a low temperature of 40 °C has been used to anneal samples for several days in a vacuum oven [13]. However, there was no direct comparison to high-temperature annealing, and while moisture will be removed, structural rearrangements are unlikely to occur at low temperatures.

The literature shows similar inconsistencies with respect to annealing time. As seen above, times can vary from 20 s to 2 h for temperatures ranging between 110 and 200 °C [3, 8,9,10]. To the authors’ knowledge, no report has evaluated annealing time in isolation.

A number of studies that examined the effects of longer annealing times highlighted the risks of prolonged exposure. Vitoratos et al. reported a reduction in the room temperature conductivity from 1.85 to 0.90 Scm−1 when PEDOT:PSS was held at 120 °C for 55 h [14]. This was attributed to breakdown of the ionic bonds between PEDOT and PSS, which led to an increase in the insulating barrier between conductive PEDOT sites, and contradicts reports that PEDOT:PSS is thermally stable to 200 °C [12].

More recently, additives have been used in films to enhance conductivity [15, 16]. In the majority of cases, the same processing conditions applied to pristine PEDOT:PSS have been used with little or no reported consideration of the effects of the additive. The most notable of these is the use of solvents whose evaporation rates are highly dependent on temperature and surfactants, which can be degraded close to the annealing conditions.

In this study, we assess the moisture absorption and stability of PEDOT:PSS and utilize this information to determine the optimum processing conditions for PEDOT:PSS films by considering film quality and resistivity. The effect of the anionic surfactant Tween 80 on the thermal stability of PEDOT:PSS is then assessed for the first time, and the optimum processing conditions are chosen accordingly.

Materials and methods

Materials

A high conductivity, surfactant-free, aqueous dispersion of PEDOT:PSS (1.2 wt%) and polysorbate 80 (Tween 80) were obtained from Sigma‒Aldrich (Gillingham, UK). All materials were used as received.

Methods

Thermal gravimetric analysis (TGA)

TGA was performed with a Netzsch STA 449 C TGA controlled by Proteus analysis software (Berlin, Germany). Analyses were performed on PEDOT:PSS/Tween 80 films (5–15 mg) with heating from 25 to 450 °C at a rate of 10 °C min−1. For all samples (except pure Tween 80), the films were produced by repeatedly filling the crucible with solution and heating at 100 °C for 1 h. Samples were then left in atmospheric conditions to equilibrate for a minimum of 12 h prior to analysis. For the sample of Tween 80 alone, the crucible was filled, and the liquid was tested without a setting or equilibration stage.

PEDOT:PSS film production

All films were produced by drop casting a pristine PEDOT:PSS aqueous solution (2 mL) into Petri dishes. Unless otherwise specified, the solutions were treated at either 20, 40 and 60 °C for 4 h and annealed at temperatures between 25–160 °C over 10–120 min in either a Memmert Universal Digital oven (Schwaback, Germany) or a 30 L S/S Gallenkamp vacuum oven (London, UK) evacuated using an Edwards nXDS-10iR scroll pump (Crawley, UK). The samples were left to equilibrate in atmospheric conditions for 12 h prior to analysis.

PEDOT:PSS/Tween 80 film production

PEDOT:PSS solutions containing various Tween concentrations were produced by pipetting the required mass of Tween 80 into vials of aqueous PEDOT:PSS. The solutions were magnetically stirred and sonicated for 10 min to ensure sufficient mixing and the breakdown of any agglomerates. Films were then drop cast into Petri dishes as specified for pristine PEDOT:PSS.

Sheet resistivity

Sheet resistivity measurements were performed on a Jandel Model RM3000 4-point probe (Leighton Buzzard, UK) that was calibrated using an ITO standard. Ten measurements with a current of 10 µA were taken at various locations across each sample.

Visual analysis of Tween 80 degradation

Samples of Tween 80 (2 mL) were heated in Petri dishes to between 60 and 220 °C in a Memmert Universal Digital Oven (Schwabach, Germany) for 1 h. Images of the samples were taken with a Sony IMX 519, 16-megapixel camera to observe any color changes caused by degradation.

Fourier transform infrared spectroscopy (FTIR)

A ThermoFisher Scientific Nicolet 8700 FTIR (Massachusetts, US) was utilized to probe thermal degradation of Tween 80 during annealing. Samples were produced by mixing dried KBr (200 mg) with Tween 80 (3 drops) and annealed as required in a Memmert Universal Digital Oven (Schwabach, Germany). The mixture was then ground and pressed into 8 mm diameter discs. FTIR studies were performed in transmission mode using 100 scans and a resolution of 4 cm−1 with two level zero infilling. A ‘blank’ KBr disc was run as a background and subtracted from the sample spectra.

Statistical analyses

Where appropriate, a one-way ANOVA with Tukey post hoc analysis was performed on the results using IBM SPSS Statistics for Windows version 27 (IBM Corp, USA) to determine statistical significance within a 95% confidence interval. The results were considered significant if the calculated p value was less than 0.05.

Results and discussion

Moisture uptake of PEDOT:PSS films

PEDOT:PSS is strongly hydroscopic due to the presence of sulfonic groups. Reports have shown that this moisture causes swelling of the insulating PSS regions, and as a result, the conductivity is reduced [3, 5]. It is therefore important to understand the sorption behaviors of these polymeric films.

PEDOT:PSS films were created and dried at 200 °C for 12 h. These films were then subjected to a controlled humidity environment (22 °C and 54% humidity using a saturated salt solution of magnesium nitrate) to determine the mass increase resulting from moisture absorption. Initially, water uptake was rapid before it plateaued after only 160 min (Fig. 1). The results were found to be consistent across the three repeated analyses. These results implied that as little as 3 h was required to fully equilibrate the PEDOT:PSS film under atmospheric conditions following drying.

Thermal stability of PEDOT:PSS

The thermal stability of PEDOT:PSS is of great importance since degradation has been shown to have a negative impact on conductivity [5]. TGA was performed with films of PEDOT:PSS that were dried at 100 °C for 1 h and then allowed to equilibrate in atmospheric conditions for over 12 h.

An initial mass loss of 10% was observed as the sample was heated to 250 °C, and the greatest weight loss rate was observed at 100 °C (Fig. 2). This mass reduction was attributed to the loss of excess and bound water from the sample.

A second mass loss was initiated above 300 °C, and a 25% loss occurred up to 450 °C. This mass loss was attributed to degradation caused by the breakdown of the PSS sulfonate groups within the PEDOT:PSS structure followed by carbon oxidation at higher temperatures [5, 12].

These results show that the temperature used for processing PEDOT:PSS must be kept below 250 °C to avoid significant degradation.

Processing optimization

Setting temperature

After drop casting liquid PEDOT:PSS on a substrate, a setting stage is required to create the film through evaporation of water. The effects of the setting temperature on the quality and sheet resistivities of the films were investigated.

Although elevated temperatures were found to increase the rate of evaporation and therefore accelerate film production, bubbles were found on the surface with setting temperatures of 80 °C and above. These results also confirmed the need for a setting stage prior to any annealing. No significant change in sheet resistivity was observed with setting temperature (Fig. 3), as shown by one-way ANOVA with Tukey post hoc analysis (p = 0.085),

Annealing conditions

Annealing PEDOT:PSS films has been shown to greatly improve the resistivity. As seen by TGA, temperatures above 100 °C are required to fully remove bound water from PEDOT:PSS; however, the polymer begins to degrade at 250 °C. As a result, the range for annealing temperatures was limited to 80–160 °C.

In general, sheet resistivity was found to decrease significantly with annealing temperature (p = 0.000 for each setting temperature) (Fig. 4) (Supplementary information SI1). Annealing removed bound and excess water from the PEDOT:PSS films, and higher temperatures were most effective. This led to shrinkage of the hydrophilic, insulating PSS regions and reduced the resistivity [3, 5]. It has also been reported that higher temperatures can induce structural rearrangements within the film and PEDOT realignment [6].

Graph representing the effect of annealing temperature (°C) on the sheet resistivity (Ω▫−1) of PEDOT:PSS after setting at temperatures of 25 °C (blue square), 40 °C (green circle) and 60 °C (red triangle). Error bars show ±1 SD for 10 measurements across each film. Statistical analyses of the effects of sheet resistivity with annealing temperature gave p values of 0.000 for all three setting temperatures

Although the effect of setting temperature on the annealing results was found to be significant (p = 0.000, 0.000, 0.000, 0.000 and 0.010 for annealing temperatures of 80, 100, 120, 140 and 160 °C, respectively), no discernible trends were revealed (Supplementary information SI2).

The results showed that heating above 140 °C had little effect with any preset temperature. ANOVA performed on the two conditions that produced the lowest resistivity, set at 25 °C, annealed at 140 °C and set at 60 °C, annealed at 160 °C, revealed no significant differences in the means (p = 0.827). As a result, setting at 25 °C followed by annealing at 140 °C was deemed most appropriate for PEDOT:PSS films, since less energy was required than setting at 60 °C.

To isolate the roles of water removal and high temperatures in annealing, a set of samples were subjected to 140 °C (high) and 25 °C (low) temperatures in a vacuum oven following setting at 25 °C for 12 h. These were compared to annealing in a conventional oven at 140 °C and a combination of low temperature in the vacuum oven followed by high temperature in the conventional oven. Prior to annealing, the sheet resistivities of the cast films were relatively comparable (Fig. 5). Following annealing, all conditions generated significant reductions in sheet resistivity; however, the effect was noticeably less when the low-temperature vacuum oven was used in isolation.

Effects of differing annealing conditions with either a conventional or vacuum oven on sheet resistivity (Ω▫−1). The conditions were as follows: vacuum oven, low temperature (black circle); vacuum oven, high temperature (red square); conventional oven, high temperature (green cross); vacuum oven, low temperature then conventional oven, high temperature (blue triangle). Error bars show ±1 SD of 10 measurements across each film

Mass losses from the PEDOT:PSS films during annealing were found to be comparable across the majority of conditions, but the high-temperature vacuum oven removed slightly more moisture (Supplementary information SI3). These results showed that a high temperature was required to significantly reduce the PEDOT:PSS sheet resistivity. This confirms the theory that reorganization occurs at elevated temperatures, which has previously been linked to softening of the PSS phase and improved alignment of PEDOT, producing better conductivity pathways [6, 7]. Heat is therefore required to fully optimize PEDOT:PSS resistivity, and removal of water alone is insufficient.

Annealing time

The resistivity was found to decrease significantly following annealing at 140 °C for as little as 10 min (p = 0.000) (Fig. 6). Literature findings have suggested that times as short as 20 s could be utilized at this temperature [3]; however, this was not compared to longer time periods to determine whether the sample was fully annealed. The resistivity continued to decrease with annealing time until a plateau was reached at 40 min (Supplementary Information SI4). Vitoratos et al. previously reported a continual decrease in conductivity following annealing for more than 3 h at 120 °C [14]; therefore, prolonged annealing is not recommended. These data showed that the optimum annealing time is 40 min.

Based on the above work, the optimum processing conditions for PEDOT:PSS have been found to be setting at 25 °C for 4 h followed by annealing at 140 °C for 40 min. At least 3 h is then required to allow the film to equilibrate under atmospheric conditions.

Processing optimization with Tween 80

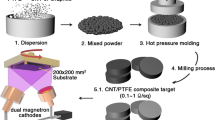

The optimum processing conditions for PEDOT:PSS films have been determined. However, it is possible that when conductivity enhancing agents are added, these settings have to be adapted. Here, we illustrate this with the surfactant Tween 80 (Fig. 7). Surfactants are believed to enhance conductivity by simultaneously interacting with both hydrophobic PEDOT and hydrophilic PSS. This leads to phase separation of the components and therefore better conductive pathways [17].

Thermal stability of PEDOT:PSS/Tween 80 formulations

The degradation profiles of PEDOT:PSS films were altered in the presence of Tween 80 (Fig. 8). PEDOT:PSS displayed an initial mass loss of approximately 10% due to water removal, followed by degradation above 250 °C. While there was a comparable mass loss attributable to moisture removal, addition of the surfactant caused the onset of degradation to appear at approximately 160 °C, a much lower temperature than that for pristine PEDOT:PSS. This effect became more pronounced with higher Tween 80 concentrations. Tween 80 also showed a second mass reduction, which coincided with degradation of the pristine PEDOT:PSS at 250 °C.

It is clear that the earlier degradation seen in the PEDOT:PSS/Tween 80 samples was caused by addition of the surfactant; however, Tween 80 alone did not display significant degradation until 220 °C (Fig. 8). It is therefore likely that addition of the surfactant to PEDOT:PSS altered the properties of the system in such a way that degradation occurred earlier. Addition of a range of cationic and anionic surfactants has been reported to reduce the onset of degradation by up to 50 °C [18]. However, these reported changes were significantly smaller than those observed here.

To provide further insight, Tween 80 was heated in air to search for signs of degradation at lower temperatures, which may not produce a significant mass loss. Visual inspection of the surfactant showed a color change as the temperature was increased above 160 °C (Fig. 9).

Reports have shown that Tween 80 undergoes autooxidation between 150 and 240 °C, which likely explains the amber color seen here [19, 20]. As Tween 80 degrades, free radicals are initially formed, followed by insertion of oxygen as peroxide and chain cleavage [19, 20]. These degradation products have been shown to cause denaturing of proteins and are therefore likely to react with PEDOT:PSS and cause premature degradation [19].

Infrared spectroscopic analyses were performed to assess the stability of Tween 80 at 140 °C, the optimum annealing temperature reported for PEDOT:PSS films (Fig. 10). The spectrum of Tween 80 was characterized by strong peaks at 3428, 1735 and 1107 cm−1 attributed to O-H, C = O and C-O vibrations, respectively. In addition, peaks were observed at 2923, 2864, 948 and 842 cm−1 resulting from the CH2 and CH3 absorptions [21]. There was no discernible difference between the spectrum of untreated Tween 80 and that of the sample heated to 140 °C, confirming that no degradation occurred at this temperature (Fig. 10).

The TGA data showed that addition of Tween 80 into PEDOT:PSS reduced the degradation temperature, thereby impacting the maximum annealing temperature that can be used. Whereas pristine PEDOT:PSS could feasibly be annealed up to 200 °C, the PEDOT:PSS/Tween 80 samples are limited to 140 °C to ensure that no degradation occurs, which could negatively impact the conductivities of the films.

Processing optimization for PEDOT:PSS/Tween 80 films

A series of experiments was carried out to assess the optimum processing conditions for PEDOT:PSS/Tween 80 films. It has already been shown that the maximum annealing temperature was limited due to earlier onset of degradation caused by the addition of Tween 80, which brought into question whether other processing parameters should be changed. Optimization was performed by determining the resistivities of the films and was considered optimal when the lowest value was obtained.

Annealing temperature

Sheet resistivity was measured after equilibration under atmospheric conditions for 12 h to analyze the effects of annealing temperatures on PEDOT:PSS/Tween 80 films containing approximately 0.52 wt% surfactant (Fig. 11). As seen with pristine PEDOT/PSS, the sheet resistivity decreased significantly (p = 0.000) (Supplementary information SI5) as the annealing temperature was increased to 140 °C; this was again attributed to removal of more water and greater structural rearrangements at elevated temperatures [3, 5, 6]. These effects were also more significant here, as the presence of surfactants disrupted the PEDOT and PSS ionic interactions and allowed for increased chain mobility during high-temperature annealing [17].

Annealing Time

The optimum time for annealing at 140 °C was analyzed with PEDOT:PSS/Tween 80 films containing surfactant concentrations of approximately 0.52 wt%. A large reduction in resistivity was observed after annealing for only 20 min (p = 0.000) (Fig. 12). The resistivity continued to decrease significantly until 60 min, at which point a plateau was observed (Supplementary information SI6). A comparison with pristine PEDOT:PSS films showed slight increases in the annealing time required to produce the lowest resistivity when Tween 80 was present. This was thought to result from Tween 80 having a high affinity for water; therefore, evaporation occurred at a slower rate.

Analyses of PEDOT:PSS/Tween 80 films showed that the optimum processing conditions were setting at 25 °C for 4 h followed by annealing at 140 °C for 60 min. Under these conditions, a sheet resistivity of 202 Ω▫−1 was obtained compared with 395 Ω▫−1 under the optimum processing conditions for pristine PEDOT:PSS. This highlighted the ability of Tween 80 to reduce the resistivity of PEDOT:PSS. A similar resistivity of approximately 195 Ω▫−1 has been previously reported with 1 vol% polyethylene glycol 200 (PEG 200), which then decreased further to 115 Ω▫−1 at a PEG 200 concentration of 4 vol% [15].

Conclusion

Overall, it can be seen that the conditions under which pristine PEDOT:PSS and PEDOT:PSS/Tween 80 films are processed are important. The parameters selected are limited by water evaporation and the thermal stabilities of the polymers. High-temperature annealing has been established as the key driving factor reducing resistivity, with water removal alone insufficient to optimize sample processing. This has been linked to chain mobility at temperatures above 140 °C, which creates improved alignment and better conducting pathways.

The optimum processing conditions for pristine PEDOT:PSS films were determined to involve setting at 25 °C for 4 h followed by annealing at 140 °C for 40 min. Equilibration for 3 h under atmospheric conditions is then required. Similar processing conditions were found for PEDOT:PSS/Tween 80 films, except that 60 min was required to anneal the material completely.

References

Crawford GP. Flexible flat panel displays. Chichester: John Wiley & Sons, Ltd; 2005.

Ouyang J, Chu CW, Chen FC, Xu Q, Yang Y. High‐conductivity poly(3,4‐ethylenedioxythiophene):poly(styrene sulfonate) film and its application in polymer optoelectronic devices. Adv Funct Mater. 2005;15:203–8.

Koidis C, Logothetidis S, Kapnopoulos C, Karagiannidis PG, Laskarakis A, Hastas NA. Substrate treatment and drying conditions effect on the properties of roll-to-roll gravure printed PEDOT:PSS thin films. Mater Sci Eng B. 2011;176:1556–61.

Lombardo V, Apos, Urso L, Mannino G, Scalese S, Spucches D, et al. Transparent conductive polymer obtained by in-solution doping of PEDOT:PSS. Polymer. 2018;155:199–207.

Friedel B, Keivanidis PE, Brenner TJK, Abrusci A, McNeill CR, Friend RH, et al. Effects of layer thickness and annealing of PEDOT:PSS layers in organic photodetectors. Macromolecules. 2009;42:6741–7.

Huang J, Miller PF, de Mello JC, de Mello AJ, Bradley DDC. Influence of thermal treatment on the conductivity and morphology of PEDOT/PSS films. Synth Met. 2003;139:569–72.

Aasmundtveit KE, Samuelsen EJ, Pettersson LAA, Inganäs O, Johansson T, Feidenhans R. Structure of thin films of poly(3,4-ethylenedioxythiophene). Synth Met. 1999;101:561–4.

Yoshioka Y, Jabbour G. Desktop inkjet printer as a tool to print conducting polymers. Synth Met. 2006;156:779–83.

Rutledge SA, Helmy AS. Etch-free patterning of poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonate) for optoelectronics. ACS Appl Mater interfaces. 2015;7:3940–8.

Nardes AM, Kemerink M, de Kok MM, Vinken E, Maturova K, Janssen RAJ. Conductivity, work function, and environmental stability of PEDOT:PSS thin films treated with sorbitol. Org Electron. 2008;9:727–34.

Zhou J, Anjum DH, Chen L, Xu X, Ventura IA, Jiang L, et al. The temperature- dependent microstructure of PEDOT/ PSS films: insights from morphological, mechanical and electrical analyses. J Mater Chem C. 2014;2:9903–10.

Elschner A, Kirchmeyer S, Lövenich W, Merker U, Reuter K. PEDOT; principals and applications of an intrinsically conductive polymer. Boca Raton FL: CRC Press; 2011.

Peters K, Braun J, Schmidt-Hansberg B, Scharfer P, Schabel W. Phase equilibrium of water in different types of PEDOT:PSS. Chem Eng Process: Process Intensif. 2011;50:555–7.

Vitoratos E, Sakkopoulos S, Dalas E, Paliatsas N, Karageorgopoulos D, Petraki F, et al. Thermal degradation mechanisms of PEDOT:PSS. Org Electron Phys Mater Appl. 2009;10:61–66.

Mengistie DA, Wang PC, Chu CW. Effect of molecular weight of additives on the conductivity of PEDOT:PSS and efficiency for ITO-free organic solar cells. J Mater Chem A. 2013;1:9907–15.

Wei Q, Mukaida M, Naitoh Y, Ishida T. Morphological change and mobility enhancement in PEDOT:PSS by adding co‐solvents. Adv Mater. 2013;25:2831–6.

Yoon SS, Khang D. Roles of nonionic surfactant additives in PEDOT:PSS thin films. J Phys Chem C. 2016;120:29525–32.

Romyen N, Thongyai S, Praserthdam P, Wacharawichanant S. Effect of surfactant addition during polymerization on properties of PEDOT:PSS for electronic applications. J Electron Mater. 2017;46:6709–16.

Kerwin BA. Used in the formulation of protein biotherapeutics: structure and degradation pathways. J Pharm Sci. 2008;97:2924–35.

Kishore RSK, Pappenberger A, Dauphin IB, Ross A, Buergi B, Staempfli A, et al. Degradation of polysorbates 20 and 80: studies on thermal autoxidation and hydrolysis. J Pharm Sci. 2011;100:721–31.

Fu X, Kong W, Zhang Y, Jiang L, Wang J, Lei J. Novel solid–solid phase change materials with biodegradable trihydroxy surfactants for thermal energy storage. RSC Adv. 2015;5:68881–9.

Acknowledgements

We would like to thank Mr. Frank Biddlestone for his technical assistance. Funding: This work was supported by the EPSRC and UKRI (Grant number: EP/N509590/1).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Carter, J.L., Kelly, C.A. & Jenkins, M.J. Processing optimization of PEDOT:PSS and PEDOT:PSS/Tween 80 films. Polym J 55, 253–260 (2023). https://doi.org/10.1038/s41428-022-00740-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-022-00740-x

This article is cited by

-

Enhanced adhesion of PEDOT:PSS to substrates using polydopamine as a primer

Polymer Journal (2024)

-

Hydrothermally synthesized MoS2 composites with rGO and PEDOT:PSS for Li-Ion batteries: enhanced capacity reclamation with rGO addition

Journal of Solid State Electrochemistry (2024)