Abstract

The lower material and manufacturing costs of conductive polymers, particularly PEDOT:PSS, compared to indium tin oxide have led to significant research into their use in optoelectric devices. In this study, improvements of the electrical properties of PEDOT:PSS and PEDOT:PSS/Tween 80 via the production of multilayered films were investigated. A single layer of pristine PEDOT:PSS was found to give a sheet resistance of 1639 Ω□–1. The application of an additional three layers reduced this value to 29 Ω□-1, corresponding to an increase in conductivity from 2.6 to 18.3 Scm–1. A similar trend was also found with formulations containing Tween 80. X-ray diffraction and Raman spectroscopy showed that the additional layers increased the crystalline order and induced a slight benzoid to quinoid shift. Surface profiling showed progressive increases in surface roughness with each additional layer of pristine PEDOT:PSS; however, this was mitigated by the presence of Tween 80 in the formulations.

Similar content being viewed by others

Introduction

Conductive polymers are attractive replacements for indium tin oxide (ITO) as a result of their flexibilities, reduced material and processing costs and ease of bulk manufacture. However, the conductivities of these polymers are still significantly inferior to those of their ITO counterparts. The most promising material to date is poly(3,4–ethylenedioxythiophene):poly(styrenesulfonate) (PEDOT:PSS) with a conductivity of 1 Scm–1 and sheet resistance of 1800 Ω□–1 [1, 2]. Current work has been focused on improving the electrical properties of PEDOT:PSS through the use of secondary conductivity enhancing agents, such as solvents, surfactants, and/or postprocessing solvent washes [3, 4]. In particular, Tween 80 has recently been shown to reduce the sheet resistance of PEDOT:PSS to 76 Ω□–1 and increase the conductivity to 20 Scm-1 when added prior to dip casting [5].

Thickening by casting of multiple layers of PEDOT:PSS has also been shown to reduce the sheet resistance [6,7,8]. Alemu et al. [6] reported a decrease in the sheet resistance of methanol-washed spin cast PEDOT:PSS films from 140 to 70 Ω□-1 with increasing thickness from 50 (1 layer) to 90 nm (2 layers), with a minimum of 25 Ω□–1 at 300 nm (6 layers). Mengistie et al. [7] observed a similar decrease in formic acid-washed PEDOT:PSS films from 145 to 68 Ω□–1 for 35 nm (1 layer) and 75 nm (2 layers) thick films, respectively, with a minimum of 23 Ω□–1 seen at 225 nm (6 layers). In both cases, annealing and solvent washes were performed after casting of each layer. A similar trend was also observed when different film thicknesses were generated by varying the speed during spin casting of a single layer [8].

To date, little explanation has been given for the relationship between the number of layers/thickness and sheet resistance. In each case, the degree of sheet resistance reduction diminishes as the films become thicker, with one paper reporting an inversely proportional relationship between sheet resistance and thickness [7]. The sheet resistance reduction was also found to be independent of how the thickness was generated, i.e., through multiple layers or changing spin speeds. One theory for the reduction in sheet resistance is that thicker films allow increased electron hopping perpendicular to the applied voltage, and therefore, a more efficient conducting pathway is developed [9]. However, to the authors’ knowledge, no investigations have been performed to assess how additional layers interact with the previous layers. In this study, a range of analytical techniques was used to assess changes to the chemical structure of PEDOT:PSS following the addition of further layers both in the presence and absence Tween 80 as a secondary conductivity enhancing agent.

Experimental

Materials

A high conductivity, surfactant-free, aqueous dispersion of PEDOT:PSS (1.2 wt%) (Clevios PH1000) and Tween 80 (Polysorbate 80) was obtained from Sigma‒Aldrich (Gillingham, UK). All materials were used as received.

Film Casting

PEDOT:PSS solutions were created with a range of Tween 80 concentrations (approximately 0, 0.5 and 1.4 wt%). Each solution was mixed via magnetic stirring for 10 minutes to guarantee thorough homogenization, followed by 10 minutes of sonication to remove any agglomerates. Prior to casting, glass slides (1 × 2 cm) were cleaned with hot water and detergent, rinsed with acetone, and finally rinsed with distilled water, after which they were dried. Dip casting was performed with the method detailed by Carter, et al. [5] Briefly, the glass slides were half submerged in the PEDOT:PSS/Tween 80 solutions for 30 seconds before annealing at 140 °C for 1 h. This process was repeated numerous times to give the needed number of layers and therefore varied thicknesses, with annealing and cooling taking place between each cast. The resultant films were left to equilibrate for 12 h in ambient conditions prior to further analysis.

Sheet resistance

An Ossila 4-point probe (Sheffield, UK) was used to measure the sheet resistance at a maximum of 1 V. Ten readings were acquired at 6 locations on each film to avoid potential orientation bias. The conductivity was calculated from the sheet resistance with Eq. (1).

where \({\sigma }_{s}\) is the conductivity (Scm-1), \({R}_{s}\) is the sheet resistance (Ω□-1) and \(t\) is the film thickness (cm).

Surface profiling

Film thicknesses and roughnesses were measured with an Ambios XP200 Stylus Profilometer (Ambios Technology, Santa Cruz, USA). Five measurements were performed on each sample, 2 mm apart, with a scan length of 10 mm. The thickness was taken as the average height displacement from the three central runs and between 5 and 10 mm where the films were found to be more consistent.

The surface roughness average (Ra) was calculated as a measure of film quality with Eq. (2).

where \(n\) is the number of data points, \({Z}_{i}\) is the measured height displacement and \({Z}_{{mean}}\) is the mean height displacement. To accommodate the curvature of the film, \({Z}_{{mean}}\) was calculated from a moving average across 500 data points.

X-ray diffraction (XRD)

XRD analyses were conducted with a 3rd generation Malvern Panalytical Empyrean XRD (Malvern, UK) equipped with multicore (iCore/dCore) optics and a Pixel3D detector operated in 1D scanning mode. Scans were performed with Cu Kα1/2 radiation (1.5419 Å) spanning a 2θ range from 1.5 to 50°, employing a step size of 0.0263° and a count time of approximately 147 s/step.

Raman spectroscopy

A Renishaw inVia Raman microscope (Wotton-under-Edge, UK) was used to obtain the Raman spectra in this study. A wavelength of 532 nm was utilized, and the spectra were normalized to the largest peak height to allow for comparison between samples.

Results and discussion

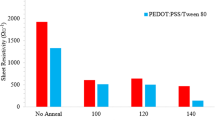

Previous research has shown that the addition of small quantities of Tween 80 improved the conductivity of PEDOT:PSS, with the properties improving further as the concentration was increased [5]. Evidence of this is provided in Fig. 1 for a single layer sample, in which a sheet resistivity of approximately 1100 Ω□–1 was reported for pristine PEDOT:PSS; this was reduced to 100 Ω□–1 for samples containing 1.40 wt% surfactant. This was attributed to increased chain orientation and separation of the conductive/nonconductive regions caused by disruption of the ionic interaction between PEDOT and PSS [5]. Therefore, the effect of increasing the thickness by applying additional layers on the electrical properties and film quality was investigated for pristine PEDOT:PSS and formulations containing approximately 0.5 and 1.4 wt% Tween 80.

Sheet resistance (Ω□–1) of PEDOT:PSS/Tween 80 films with increasing layers. Data were plotted for films containing surfactant concentrations of 0.00 (green circle), 0.48 (blue square) and 1.40 (red triangle) wt%. Error bars show ±1 standard deviation for 6 locations across each film. p < 0.001 for each formulation

Electrical properties

The sheet resistances of the PEDOT:PSS/Tween 80 films were found to decrease significantly (p < 0.001 for all formulations) with the number of layers applied (Fig. 1). This was most noticeable for pristine PEDOT:PSS, with a reduction of 98% observed between layers 1 and 4 compared to a 64% drop for the formulation containing 1.40 wt% Tween 80.

As expected, the film thickness increased for each formulation as more layers were applied, and therefore, more material was deposited onto the slides (Fig. 2). In each case, the thickness increased by more than that of the initial layer, highlighting preferential binding of PEDOT:PSS to itself rather than the glass slide. This was more apparent with the pristine PEDOT:PSS film, as the presence of Tween 80 was likely to hinder the interaction between the PEDOT:PSS solution and the previously deposited layer.

When the sheet resistance was factored in relation to thickness, a significant reduction in sheet resistance was observed as the sample thickness increased for each formulation (Fig. 3). This effect was particularly pronounced for samples containing 0 or 0.49 wt% Tween 80, where a distinct curve in the trend was evident. In contrast, the sample containing 1.40 wt% surfactant also exhibited a notable decrease in the sheet resistivity, but this followed a more linear trend with a comparatively lower initial sheet resistance.

Sheet resistance (Ω□-1) as a function of average PEDOT:PSS/Tween 80 film thickness (µm) for Tween 80 concentrations (wt%) of 0.00 (green circle), 0.49 (blue square) and 1.40 wt% (red triangle). Error bars show ±1 standard deviation of 6 locations across each film. Dotted guidelines show the trend of the data

Similar decreases in the sheet resistances of PEDOT:PSS films with increasing thickness have been previously reported in the literature. In each case, the thickness was increased via the application of additional layers with solvent washes, and annealing was performed before each subsequent layer [6,7,8]. Kim et al. reported an inversely proportional relationship between the sheet resistance and thickness [8]. This was consistent with Thévenin’s theorem, which states that the resistances within a circuit can be replaced at the terminals by an equivalent combination of a voltage source in series with a single resistance. This resistance is calculated through the following two equations:

where RTh is the Thévenin resistance and R1 and R2 are resistances within the circuit.

As the thickness of the conductive film is increased by adding more layers, the number of ‘resistances’ in parallel also increases, leading to an overall reduction in the Thévenin resistance and therefore the sheet resistance.

Application of this relationship to the data published by Alemu et al. [6] and Mengistie et al. [7] also generated the same proportionality; however, it was not found to be representative when modeling the data reported here. This suggested that something else, in addition to the thickness effect, was responsible for the reductions in sheet resistance observed.

Considering that the multiple dip method entails submerging an existing film into the PEDOT:PSS solution, it is plausible that this process could function as a solvent wash. Solvent washes are commonly used to remove excess PSS from a film and improve the conductivity, typically employing solvents such as methanol [4, 6, 10, 11]. While water is not a common solvent for such washes, prior research has demonstrated its utility as a posttreatment method to enhance the conductivity from 3 to 10 Scm–1 [12, 13]. This observation may partially explain the less substantial decreases seen in the sheet resistance when Tween 80 was present, potentially because the surfactant acted as a barrier to PSS removal. An alternative hypothesis is that the PEDOT:PSS solution interacted with the existing PEDOT:PSS film, as opposed to the glass, when a new layer was applied. The differing surface energy of the PEDOT:PSS film may lead to preferential deposition of PEDOT-rich regions, while excess PSS may not be as readily deposited. Additionally, the presence of the PEDOT:PSS film beneath the newly applied solution might induce phase separation between the PEDOT and PSS, creating more effective conductive pathways.

Calculations of the film conductivities showed that those of both pristine PEDOT:PSS and the formulation containing 0.49 wt% Tween 80 improved as the number of layers, and therefore the thickness, increased (Fig. 4). However, the conductivity with 1.40 wt% surfactant decreased when two layers were applied, and there were no further changes as the thickness was increased further.

If the application requires pure PEDOT:PSS alone, this work shows that the deposition of multiple layers increased the conductivity from 2.64 Scm–1 to as high as 18.25 Scm–1 for 4 layers. However, the optimum solution is to use a formulation containing 1.40 wt% as a single layer, as this gives the highest overall conductivity (26.86 Scm–1). Moreover, the complexity of adding multiple layers, along with the associated increases in time and material requirements, is not conducive to efficient bulk manufacture. Additionally, although not explored in this study, increasing thicknesses could diminish light transmission through the film [1, 6, 7]. This poses a significant problem in the context of optoelectronic devices, where optimal performance relies on high light transmission.

Structural analyses

X-ray diffraction (XRD)

The XRD pattern for PEDOT:PSS typically exhibits three primary peaks at 2θ values of approximately 3.4, 17.4 and 26.9° [5, 14, 15]. These values are consistent with the results obtained in this study for pristine PEDOT:PSS after dip casting once onto a glass slide (Fig. 5). The first peak, situated at 2θ = 3.5°, was attributed to the spacing for lamellar stacking (d100) of the PEDOT and PSS chains. Through Bragg’s Law, 2d sinθ = λ, this distance was calculated as 25.2 Å for 1-dip pristine PEDOT:PSS. Similarly, the distance for π-π stacking (d010) of the PEDOT chains was calculated as 3.4 Å from the peak at 2θ = 26.4°. The amorphous halo of PSS was observed at 2θ = 17.2°, corresponding to a d spacing of 5.2 Å for a single layer of pristine PEDOT:PSS.

After further dip casting to produce 2- and 5-layer samples, no change was observed in the positions of the latter two peaks (Fig. 5). This showed that multiple dip casting did not affect the amorphous regions of PSS or π-π stacking of the PEDOT chains. Increased intensities were observed for these peaks; however, this was likely due to the increased concentration of polymer present. In contrast, the relative size and position of the lamella stacking peak was found to deviate with the number of layers. This peak shifted from approximately 2θ = 3.5° to 3.8 and 3.9° as more layers were added, resulting in a decrease in the d spacing of lamellar stacking from 25.2 to 23.3 and 22.7 Å, respectively. In addition, the relative intensity decreased on going from 2 to 5 layers, indicative of a reduction in the crystallinity. However, this was compensated by the appearance of two new ordering peaks in the 5-layered sample at approximately 2θ = 7.3 and 9.7°.

The presence of Tween 80 in PEDOT:PSS films has previously been reported to enhance the PEDOT:PSS order, as observed by the appearance of additional sharp peaks in the XRD diffraction pattern [5]. A similar trace was observed here for the 1-layer sample (Fig. 6). As seen with pristine PEDOT:PSS, the addition of further dip cast layers increased the position of the lamellar stacking peak from 2θ = 3.3 to 4.7 and 4.8° with 1, 2 and 5 layers, respectively. This equated to a reduction in the d spacing from 26.8 to 18.8 and 18.4°, respectively, indicative of closer packing of the PEDOT and PSS lamella. Additionally, the extra peaks observed in the presence of Tween 80 at 2θ = 2.3, 4.6, 6,8 and 11.3°, corresponding to d spacings of 38.4, 19.2, 13.0 and 7.8 Å, respectively, increased in intensity as more layers were applied. New peaks were also observed with 5 layers at 2θ = 9.0 and 15.7°, equating to d spacings of 8.8 and 5.6 Å.

These results show that the application of additional layers decreased the lamellar stacking of alternating PEDOT and PSS chains while increasing the overall number of crystalline orderings. The effect was more pronounced in the presence of Tween 80. A similar reduction in the d spacing of the lamella stacking peak has been observed following washing with trifluoromethane sulfonic acid in methanol [14]. It was postulated that the acid reacted with the insulating PSS regions, which were then removed by methanol, leaving behind a more aligned PEDOT:PSS system with a higher conductivity. Others have also demonstrated an increase in conductivity following washing with methanol and ethanol, which was attributed to the ability of these polar solvents to dissolve and therefore remove excess PSS from PEDOT:PSS films [11, 16, 17]. Based on these observations, it is therefore possible that the application of the additional layers also served as a solvent wash to remove some of the excess PSS from the proceeding layer, leaving a more oriented material. This was especially prevalent in those samples containing Tween 80, as previous work has shown distinct phase separation with excess Tween 80, possibly along with PSS [5]. Limited studies have been performed on the use of water in solvent washes; however, Takano et al. reported a marginal increase in conductivity along with improved crystallinity, as determined by wide angle X-ray spectroscopy (WAXS) [13].

Another theory proposed is that the free PSS molecules in the solution repelled those in the preceding layer of the film, leading to preferential PEDOT:PSS deposition. Alternatively, the initial film may act as a template for ordering of additional layers, which would also result in the observed changes to the XRD pattern. A final hypothesis is that the addition of a new layer did not create a continuous structure; therefore, the presence of new peaks was due to the separated layers.

Raman spectroscopy

Raman spectroscopy is a useful tool for determining the orientations of the double bonds in PEDOT and thereby detecting benzoid to quinoid transitions. The spectra of pristine PEDOT:PSS consisted of three main peaks (Fig. 7). The Cβ-Cβ and Cα = Cβ stretching vibrations for the 5-membered ring within PEDOT generated peaks at approximately 1372 and 1429 cm–1, whereas the peak at approximately 1586 cm–1 was created by the PSS component [3, 18].

Benzoid to quinoid shifts have been reported in the literature as a redshift of the Cα = Cβ peak, as the bond length increases to that of a single bond, and a blueshift of the Cβ-Cβ peak, as it contracts to a double bond [17, 18]. In some cases, these shifts are not obvious without deconvolution of the peaks and instead appear as a narrowing from one side [3]. In the current work, the broadness of the peaks and proximity to each other prevented deconvolution for the multiple dip samples; however, merging of the two peaks at 1372 and 1429 was apparent when two layers were applied. This suggested that a conformational change occurred from a coiled, benzoid form to the expanded coil or linear, quinoid form.

The addition of Tween 80 has previously been reported to cause PEDOT:PSS to remain in the benzoid form [5]. However, as seen with pristine PEDOT:PSS, the addition of additional layers of PEDOT:PSS/Tween 80 resulted in merging of the Cα = Cβ and Cβ-Cβ peaks, indicative of a lengthening and shortening of the respective bonds and therefore a benzoid to quinoid shift (Fig. 8).

Solvent washes with polar solvents, such as methanol, did not cause the observed conformation change from benzoid to quinoid [14, 17]. The XRD and Raman results therefore suggested a combined effect of solvent washing during further dip casting coupled with preferential ordering of the new layer templated by the preceding layer.

Surface roughness

In addition to the electrical properties, it is also important to assess the quality of the film. Surface profiling of pristine PEDOT:PSS showed that a smooth finish was produced when the first layer was applied (Fig. 9). However, as additional layers were added, the roughness increased dramatically, and the overall coverage decreased. The addition of Tween 80 into the formulation significantly mitigated these issues.

Calculation of the average surface roughness (Ra) for these films allowed quantitative comparisons to be drawn. A dramatic increase in the average surface roughness was observed as the number of layers was increased for the pristine PEDOT:PSS films (Fig. 10). The formulations containing Tween 80 showed an initial lower average roughness than pristine PEDOT:PSS, and the impact of the additional layers was significantly reduced. This enhancement in the initial surface roughness with inclusion of the surfactant was ascribed to alterations in the surface energy and wettability of the solution induced by Tween 80 [5]. As a result, the surfactant effectively reduced the surface tension of the PEDOT:PSS solution, thereby enhancing the coating process during casting [5].

Conclusions

The sheet resistance was found to decrease as additional layers of both pristine PEDOT:PSS and formulations containing Tween 80 were applied. These decreases were coupled with increases in film thickness, as expected for the deposition of additional material onto the glass slides. Calculations of the conductivities showed a decrease with increasing layer number/thickness for both pristine PEDOT:PSS and PEDOT:PSS containing 0.49 wt% Tween 80; however, an initial increase followed by a plateau was found for the formulation containing 1.40 wt% Tween 80.

The sheet resistances of the films did not follow the expected inversely proportional relationship with thickness, indicating that other effects, in addition to Thévenin’s theorem, were involved. XRD diffraction showed an increase in crystalline order and a reduction in the d spacing of the lamellae stacking as more layers were applied to the films. In addition, Raman spectroscopy suggested a slight conformational change from the benzoid to quinoid forms. These observations led to a number of theories on the effect of the additional layers. First, the application of each layer is believed to act as a solvent wash for the previous layer, removing some of the insulating PSS. The previous layer is also believed to both hinder the absorption of PSS while acting as a template for ordering of the subsequent layer.

Surface profiling revealed that the surface roughness of pristine PEDOT:PSS increased with each layer added; however, this effect could be mitigated by including Tween 80 in the formulation.

References

Martin BD, Nikolov N, Pollack SK, Saprigin A, Shashidhar R, Zhang F, et al. Hydroxylated secondary dopants for surface resistance enhancement in transparent poly(3,4- ethylenedioxythiophene)– poly(styrenesulfonate) thin films. Synth Met. 2004;142:187–93.

Zotti G, Zecchin S, Schiavon G, Louwet F, Groenendaal L, Crispin X, et al. Electrochemical and XPS studies toward the role of monomeric and polymeric sulfonate counterions in the synthesis, composition, and properties of poly(3,4- ethylenedioxythiophene). Macromolecules. 2003;36:3337–44.

Ouyang J. “Secondary doping” methods to significantly enhance the conductivity of PEDOT:PSS for its application as transparent electrode of optoelectronic devices. Displays. 2013;34:423–36.

Shi H, Liu C, Jiang Q, Xu J. Effective approaches to improve the electrical conductivity of PEDOT:PSS: a review. Adv Electron Mater. 2015;1:1–16.

Carter JL, Kelly CA, Marshall JE, Hammond V, Goodship V, Jenkins MJ. PEDOT:PSS conductivity enhancement through addition of the surfactant Tween 80. Polymers. 2022;14:5072–86.

Alemu D, Wei HY, Ho KC, Chu CW. Highly conductive PEDOT:PSS electrode by simple film treatment with methanol for ITO-free polymer solar cells. Energy Environ Sci 2012;5:9662–71.

Mengistie DA, Ibrahem MA, Wang PC, Chu CW. Highly conductive PEDOT:PSS treated with formic acid for ITO-free polymer solar cells. ACS Appl Mater interfaces. 2014;6:2292–9.

Kim YH, Sachse C, Machala ML, May C, Müller‐Meskamp L, Leo K. Highly conductive PEDOT:PSS electrode with optimized solvent and thermal post‐treatment for ITO‐free organic solar cells. Adv Funct Mater. 2011;21:1076–81.

Nardes AM, Kemerink M, Janssen RAJ, Bastiaansen JAM, Kiggen NMM, Langeveld BMW, et al. Microscopic understanding of the anisotropic conductivity of PEDOT:PSS thin films. Adv Mater. 2007;19:1196–200.

Kirchmeyer, S, Reuter, K & Simpson, J Poly(3,4-ethylene dioxythiophene) scientific importance, remarkable properties, and applications. In: Skotheim, T & Reynolds, J (eds.) Handbook of conducting polymers. 3rd ed. Boca Raton, London and New York: CRC press. 2007.

Oh JY, Shin M, Lee JB, Ahn JH, Baik HK, Jeong U. Effect of PEDOT nanofibril networks on the conductivity, flexibility, and coatability of PEDOT:PSS films. ACS Appl Mater Interfaces. 2014;6:6954–61.

Yu Z, Xia Y, Du D, Ouyang J. PEDOT:PSS films with metallic conductivity through a treatment with common organic solutions of organic salts and their application as a transparent electrode of polymer solar cells. ACS Appl Mater Interfaces. 2016;8:11629–38.

Takano T, Masunaga H, Fujiwara A, Okuzaki H, Sasaki T. PEDOT nanocrystal in highly conductive PEDOT:PSS polymer films. Macromolecules. 2012;45:3859–65.

Wang X, Kyaw AKK, Yin C, Wang F, Zhu Q, Tang T, et al. Enhancement of thermoelectric performance of PEDOT:PSS films by post-treatment with a superacid. RSC Adv. 2018;8:18334–40.

Kim N, Kee S, Lee SH, Lee BH, Kahng YH, Jo YR, et al. Highly conductive PEDOT:PSS nanofibrils induced by solution‐ processed crystallization. Adv Mater. 2014;26:2268–72.

Kim S, Cho S, Lee SJ, Lee G, Kong M, Moon S, et al. Boosting up the electrical performance of low-grade PEDOT:PSS by optimizing non-ionic surfactants. Nanoscale. 2017;9:16079–85.

Yoon SS, Khang D. Roles of nonionic surfactant additives in PEDOT:PSS thin films. J Phys Chem C. 2016;120:29525–32.

Kanwat A, Jang J. High work function with reduced phase separation of PSS in metal oxide modified PEDOT:PSS Interlayers for organic photovoltaics. RSC Adv. 2016;6:114800.

Acknowledgements

We express their gratitude to Mr. Frank Biddlestone for his valuable technical support. We also gratefully acknowledge Dr. Steven Huband for his technical proficiency and the use of the facilities at the X-ray Diffraction Research Technology Platform at the University of Warwick. Additionally, we would like to thank Ben Breeze for assistance with Raman spectroscopy at the Spectroscopy Research Technology Platform at the University of Warwick.

Funding

This work was supported by the EPSRC and UKRI (Grant number: EP/N509590/1).

Author information

Authors and Affiliations

Contributions

JLC: Conceptualization, Methodology, Formal Analysis, Data Curation, Writing—Original Draft Preparation, Writing—Review & Editing CAK: Conceptualization, Methodology, Formal Analysis, Writing—Original Draft Preparation, Writing—Review & Editing, Supervision JEM: Data Curation, Writing—Review & Editing Mike Jenkins: Conceptualization, Methodology, Writing—Review & Editing, Supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Carter, J.L., Kelly, C.A., Marshall, J.E. et al. Effect of thickness on the electrical properties of PEDOT:PSS/Tween 80 films. Polym J 56, 107–114 (2024). https://doi.org/10.1038/s41428-023-00854-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-023-00854-w