Abstract

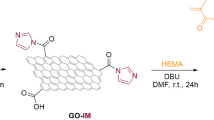

Piezoelectric poly-L-lactide (PLLA) is a biodegradable polymer used in various biomedical applications. However, tailoring and controlling the structure of PLLA to enhance its piezoelectric response remains a challenge. In this work, extensive characterization was performed to reveal the effect of the reduced graphene oxide (rGO) content (0.2, 0.7, and 1.0 wt%) on the morphology, structure, thermal and piezoelectric behavior of PLLA scaffolds. Randomly oriented homogeneous fibers and a quasi-amorphous structure for pure PLLA and hybrid PLLA-rGO scaffolds were revealed. The addition of rGO affected the molecular structure of the PLLA scaffolds: for example, the number of polar C=O functional groups was increased. Increasing the content of rGO to 1 wt% resulted in decreased glass transition and melting temperatures and increased the degree of crystallinity of the scaffolds. The addition of 0.2 wt% rGO enhanced the effective local vertical and lateral piezoresponses by 2.3 and 15.4 times, respectively, in comparison with pure PLLA fibers. The presence of the shear piezoelectric α-phase (P212121) in uniaxially oriented PLLA fibers and C=O bond rotation in the polymer chains explained the observed piezoresponse. Thus, this study revealed routes to prepare hybrid biodegradable scaffolds with enhanced piezoresponse for tissue engineering applications.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Alam MK, Koomson E, Zou H, Yi C, Li C-W, Xu T, et al. Recent advances in microfluidic technology for manipulation and analysis of biological cells (2007–2017). Anal Chim Acta. 2018;1044:29–65. https://doi.org/10.1016/j.aca.2018.06.054

Alvarez K, Nakajima H. Metallic scaffolds for bone regeneration. Materials. 2009;2:790–832. https://doi.org/10.3390/ma2030790

Alkayyali T, Cameron T, Haltli B, Kerr RG, Ahmadi A. Microfluidic and cross-linking methods for encapsulation of living cells and bacteria—a review. Anal Chim Acta. 2019;1053:1–21. https://doi.org/10.1016/j.aca.2018.12.056

Rourke JP, Pandey PA, Moore JJ, Bates M, Kinloch IA, Young RJ, et al. The real graphene oxide revealed: stripping the oxidative debris from the graphene-like sheets. Angew Chem Int Ed. 2011;50:3173–7. https://doi.org/10.1002/anie.201007520

Schultz O, Sittinger M, Haeupl T, Burmester GR. Emerging strategies of bone and joint repair. Arthritis Res. 2000;2:433. https://doi.org/10.1186/ar123

An Y, wei W, Jing H, Ming L, Liu S, Jin Y. Bone marrow mesenchymal stem cell aggregate: an optimal cell therapy for full-layer cutaneous wound vascularization and regeneration. Sci Rep. 2015;5:17036. https://doi.org/10.1038/srep17036

Lopes MS, Jardini A, Filho RM. Synthesis and characterizations of poly (lactic acid) by ring-opening polymerization for biomedical applications. Chem Eng Trans. 2014;38:331–6. https://doi.org/10.3303/CET1438056

Pourjavadi A, Mazaheri Tehrani Z, Jokar S. Chitosan-based supramolecular polypseudorotaxane as a pH-responsive polymer and their hybridization with mesoporous silica-coated magnetic graphene oxide for triggered anticancer drug delivery. Polymer. 2015;76:52–61. https://doi.org/10.1016/j.polymer.2015.08.050

Song J, Yang X, Jacobson O, Lin L, Huang P, Niu G, et al. Sequential drug release and enhanced photothermal and photoacoustic effect of hybrid reduced graphene oxide-loaded ultrasmall gold nanorod vesicles for cancer therapy. ACS Nano. 2015;9:9199–209. https://doi.org/10.1021/acsnano.5b03804

Guo-Qiang C. Plastics from bacteria: natural functions and applications. 2010. https://doi.org/10.1007/978-3-642-03287-5

Wang ZL, Wu W. Piezotronics and piezo-phototronics: fundamentals and applications. Natl Sci Rev. 2014;1:62–90. https://doi.org/10.1093/nsr/nwt002

Shin D-M, Hong SW, Hwang Y-H. Recent advances in organic piezoelectric biomaterials for energy and biomedical applications. Nanomaterials. 2020;10:123. https://doi.org/10.3390/nano10010123

Jacob J, More N, Kalia K, Kapusetti G. Piezoelectric smart biomaterials for bone and cartilage tissue engineering. Inflamm Regen. 2018;38:2. https://doi.org/10.1186/s41232-018-0059-8

Marques L, Holgado LA, Simões RD, Pereira JDAS, Floriano JF, Mota LSLS, et al. Subcutaneous tissue reaction and cytotoxicity of polyvinylidene fluoride and polyvinylidene fluoride-trifluoroethylene blends associated with natural polymers: tissue reaction and cytotoxicity of PVDF and P(VDF-TrFE). J Biomed Mater Res Part B Appl Biomater. 2013;101:1284–93. https://doi.org/10.1002/jbm.b.32941

Szewczyk PK, Gradys A, Kim SK, Persano L, Marzec M, Kryshtal A, et al. Enhanced piezoelectricity of electrospun polyvinylidene fluoride fibers for energy harvesting. ACS Appl Mater Interfaces. 2020;12:13575–83. https://doi.org/10.1021/acsami.0c02578

Klee D, Ademovic Z, Bosserhoff A, Hoecker H, Maziolis G, Erli H-J. Surface modification of poly(vinylidenefluoride) to improve the osteoblast adhesion. Biomaterials. 2003;24:3663–70. https://doi.org/10.1016/S0142-9612(03)00235-7

Pinheiro E, Deivarajan T. A concise review encircling lead-free porous piezoelectric ceramics. Acta Phys Pol, A. 2019;136:555–65. https://doi.org/10.12693/APhysPolA.136.555

Naga Kumar C, Prabhakar MN, Song J-I. Synthesis of vinyl ester resin-carrying PVDF green nanofibers for self-healing applications. Sci Rep. 2021;11:908. https://doi.org/10.1038/s41598-020-78706-3

Das R, Curry EJ, Le TT, Awale G, Liu Y, Li S, et al. Biodegradable nanofiber bone-tissue scaffold as remotely-controlled and self-powering electrical stimulator. Nano Energy. 2020;76:105028. https://doi.org/10.1016/j.nanoen.2020.105028

Garlotta D. A literature review of poly(lactic acid). J Polym Environ. 2001;9:63–84. https://doi.org/10.1023/A:1020200822435

Nijenhuis AJ, Grijpma DW, Pennings AJ. Lewis acid catalyzed polymerization of L-lactide. Kinetics and mechanism of the bulk polymerization. Macromolecules. 1992;25:6419–24. https://doi.org/10.1021/ma00050a006

Ochiai T, Fukada E. Electromechanical properties of poly-L-lactic acid. Jpn J Appl Phys. 1998;37:3374–6. https://doi.org/10.1143/JJAP.37.3374

Weng W, Song S, Cao L, Chen X, Cai Y, Li H, et al. A comparative study of bioartificial bone tissue poly-L-lactic acid/polycaprolactone and PLLA scaffolds applied in bone regeneration. J Nanomater. 2014;2014:1–7. https://doi.org/10.1155/2014/935149

Hu Y, Kang W, Fang Y, Xie L, Qiu L, Jin T. Piezoelectric poly(vinylidene fluoride) (PVDF) polymer-based sensor for wrist motion signal detection. Appl Sci. 2018;8:836. https://doi.org/10.3390/app8050836

Surmenev RA, Orlova T, Chernozem RV, Ivanova AA, Bartasyte A, Mathur S, et al. Hybrid lead-free polymer-based nanocomposites with improved piezoelectric response for biomedical energy-harvesting applications: a review. Nano Energy. 2019;62:475–506. https://doi.org/10.1016/j.nanoen.2019.04.090

Shin SR, Li Y-C, Jang HL, Khoshakhlagh P, Akbari M, Nasajpour A, et al. Graphene-based materials for tissue engineering. Adv Drug Del Rev. 2016;105:255–74. https://doi.org/10.1016/j.addr.2016.03.007

Zeyrek Ongun M, Oguzlar S, Doluel EC, Kartal U, Yurddaskal M. Enhancement of piezoelectric energy-harvesting capacity of electrospun β-PVDF nanogenerators by adding GO and rGO. J Mater Sci Mater Electron. 2020;31:1960–8. https://doi.org/10.1007/s10854-019-02715-w

Cai Z, Xiong P, He S, Zhu C. Improved piezoelectric performances of highly orientated poly (β-hydroxybutyrate) electrospun nanofiber membrane scaffold blended with multiwalled carbon nanotubes. Mater Lett. 2019;240:213–6.

Chung C, Kim Y-K, Shin D, Ryoo S-R, Hong BH, Min D-H. Biomedical applications of graphene and graphene oxide. Acc Chem Res. 2013;46:2211–24. https://doi.org/10.1021/ar300159f

Sandhya P, Jose J, Sreekala M, Padmanabhan M, Kalarikkal N, Thomas S. Reduced graphene oxide and ZnO decorated graphene for biomedical applications. Ceram Int. 2018;44:15092–8.

Liu Y, Zhou H, Zhou W, Meng S, Qi C, Liu Z, et al. Biocompatible, high‐performance, wet‐adhesive, stretchable all‐hydrogel supercapacitor implant based on PANI@rGO/Mxenes electrode and hydrogel electrolyte. Adv Energy Mater. 2021;11:2101329. https://doi.org/10.1002/aenm.202101329

Cao L, Lu C, Wang Q, Li F. Biocompatibility and fabrication of RGO/chitosan film for cartilage tissue recovery. Environ Toxicol Pharm. 2017;54:199–203. https://doi.org/10.1016/j.etap.2017.07.006

Defteralı Ç, Verdejo R, Peponi L, Martín ED, Martínez-Murillo R, López-Manchado MÁ, et al. Thermally reduced graphene is a permissive material for neurons and astrocytes and de novo neurogenesis in the adult olfactory bulb in vivo. Biomaterials. 2016;82:84–93. https://doi.org/10.1016/j.biomaterials.2015.12.010

Pariy IO, Ivanova AA, Shvartsman VV, Lupascu DC, Sukhorukov GB, Ludwig T, et al. Piezoelectric response in hybrid micropillar arrays of poly(vinylidene fluoride) and reduced graphene oxide. Polymers. 2019;11:1065. https://doi.org/10.3390/polym11061065

Díaz E, Iglesias N, Ribeiro S, Lanceros-Méndez S. Cytocompatible scaffolds of poly(L-lactide)/reduced graphene oxide for tissue engineering. J Biomater Sci Polym. Ed. 2021;1–14. https://doi.org/10.1080/09205063.2021.1922023.

Chieng B, Ibrahim N, Yunus W, Hussein M, Then Y, Loo Y. Effects of graphene nanoplatelets and reduced graphene oxide on poly(lactic acid) and plasticized poly(lactic acid): a comparative study. Polymers. 2014;6:2232–46. https://doi.org/10.3390/polym6082232

Li B, Xiong F, Yao B, Du Q, Cao J, Qu J, et al. Preparation and characterization of antibacterial dopamine-functionalized reduced graphene oxide/PLLA composite nanofibers. RSC Adv. 2020;10:18614–23. https://doi.org/10.1039/D0RA03224G

Ahmad AF, Aziz SA, Abbas Z, Obaiys SJ, Matori KA, Zaid MHM, et al. Chemically reduced graphene oxide-reinforced poly(lactic acid)/poly(ethylene glycol) nanocomposites: preparation, characterization, and applications in electromagnetic interference shielding. Polymers. 2019;11:661. https://doi.org/10.3390/polym11040661

Mishra S, Unnikrishnan L, Nayak SK, Mohanty S. Advances in piezoelectric polymer composites for energy harvesting applications: a systematic review. Macromol Mater Eng. 2019;304:1800463. https://doi.org/10.1002/mame.201800463

Choi YS, Kim SK, Williams F, Calahorra Y, Elliott JA, Kar-Narayan S. The effect of crystal structure on the electromechanical properties of piezoelectric Nylon-11 nanowires. Chem Commun. 2018;54:6863–6. https://doi.org/10.1039/C8CC02530D

Guzhova AA, Galikhanov MF, Kuznetsova NV, Petrov VA, Khairullin RZ. Effect of polylactic acid crystallinity on its electret properties, physics, technologies and innovation (PTI-2016): In Proceedings of the III international young researchers’ conference, 2016, p. 020009.

Fukada E. History and recent progress in piezoelectric polymers. IEEE Trans Ultrason, Ferroelectr Freq Control. 2000;47:1277–90. https://doi.org/10.1109/58.883516

Fukada E. Recent developments of polar piezoelectric polymers. IEEE Trans Dielectr Electr Insul. 2006;13:1110–9. https://doi.org/10.1109/TDEI.2006.247839

Lai Y-H, Chen Y-H, Pal A, Chou S-H, Chang S-J, Huang E-W, et al. Regulation of cell differentiation via synergistic self-powered stimulation and degradation behavior of a biodegradable composite piezoelectric scaffold for cartilage tissue. Nano Energy. 2021;90:106545. https://doi.org/10.1016/j.nanoen.2021.106545

Katsouras I, Asadi K, Li M, van Driel TB, Kjær KS, Zhao D, et al. The negative piezoelectric effect of the ferroelectric polymer poly(vinylidene fluoride). Nat Mater. 2016;15:78–84. https://doi.org/10.1038/nmat4423

Leyva-Porras C, Cruz-Alcantar P, Espinosa-Solís V, Martínez-Guerra E, Piñón-Balderrama CI, Compean Martínez I, et al. Application of differential scanning calorimetry (DSC) and modulated differential scanning calorimetry (MDSC) in food and drug industries. Polymers. 2019;12:5. https://doi.org/10.3390/polym12010005

Jia S, Yu D, Zhu Y, Wang Z, Chen L, Fu L. Morphology, crystallization and thermal behaviors of PLA-based composites: wonderful effects of hybrid GO/PEG via dynamic impregnating. Polymers. 2017;9:528. https://doi.org/10.3390/polym9100528

Rodriguez BJ, Callahan C, Kalinin SV, Proksch R. Dual-frequency resonance-tracking atomic force microscopy. Nanotechnology. 2007;18. https://doi.org/10.1088/0957-4484/18/47/475504.

Gowda B, Gowda H. Simulation of an adaptive fluid-membrane piezoelectric lens. Micromachines. 2019;10. https://doi.org/10.3390/mi10120797.

Liva R, Janis V, Roberts J, Andrejs P. Nonlinear behavior of PLA and lignin-based flax composites subjected to tensile loading. J Thermoplast Compos Mater. 2011;26:476–96. https://doi.org/10.1177/0892705711425846

Naoshi H, Hiroto I, Yoshimichi O. Electrical conduction properties of several biodegradable polymers. 2007 annual report—conference on electrical insulation and dielectric phenomena. 2007. https://doi.org/10.1109/CEIDP.2007.4451542

Svyntkivska M, Makowski T, Piorkowska E, Brzezinski M, Herc A, Kowalewska A. Modification of polylactide nonwovens with carbon nanotubes and ladder poly(silsesquioxane). Molecules. 2021;26:1353. https://doi.org/10.3390/molecules26051353

Nazir F, Iqbal M, Khan AN, Mazhar M, Hussain Z. Fabrication of robust poly l-lactic acid/cyclic olefinic copolymer (PLLA/COC) blends: study of physical properties, structure, and cytocompatibility for bone tissue engineering. J Mater Res Technol. 2021;13:1732–51. https://doi.org/10.1016/j.jmrt.2021.05.073

Leroy A, Ribeiro S, Grossiord C, Alves A, Vestberg RH, Salles V, et al. FTIR microscopy contribution for comprehension of degradation mechanisms in PLA-based implantable medical devices. J Mater Sci Mater Med. 2017;28:87. https://doi.org/10.1007/s10856-017-5894-7

Xue B, Xie L, Zhang J. Detailed molecular movements during poly(l -lactic acid) cold-crystallization investigated by FTIR spectroscopy combined with two-dimensional correlation analysis. RSC Adv. 2017;7:47017–28. https://doi.org/10.1039/C7RA08921J

Tretinnikov ON, Kato K, Iwata H. Adsorption of enantiomeric poly(lactide)s on surface-grafted poly(l -lactide). Langmuir. 2004;20:6748–53. https://doi.org/10.1021/la049277t

Dubinenko G, Zinoviev A, Bolbasov E, Kozelskaya A, Shesterikov E, Novikov V, et al. Highly filled poly(l‐lactic acid)/hydroxyapatite composite for 3D printing of personalized bone tissue engineering scaffolds. J Appl Polym Sci. 2021;138:49662 https://doi.org/10.1002/app.49662

El-Hadi AM. Effect of processing conditions on the development of morphological features of banded or nonbanded spherulites of poly(3-hydroxybutyrate) (PHB) and polylactic acid (PLLA) blends. Polym Eng Sci. 2011;51:2191–202. https://doi.org/10.1002/pen.21991

Wang X, Gao Y, Li X, Xu Y, Jiang J, Hou J, et al. Selective localization of graphene oxide in electrospun polylactic acid/poly(ε-caprolactone) blended nanofibers. Polym Test. 2017;59:396–403. https://doi.org/10.1016/j.polymertesting.2017.02.022

Ribeiro C, Sencadas V, Costa CM, Gómez Ribelles JL, Lanceros-Méndez S. Tailoring the morphology and crystallinity of poly(L-lactide acid) electrospun membranes. Sci Technol Adv Mater. 2011;12:015001. https://doi.org/10.1088/1468-6996/12/1/015001

Porwal V, Singh M, Chaturvedi D, Tandon P, Dayal, Gupta V. Vibrational dynamics and heat capacity in poly(L -lactic acid): vibrational dynamics and heat capacity in PLLA. J Polym Sci Part B: Polym Phys. 2010;48:175–82. https://doi.org/10.1002/polb.21886

Polak-Kraśna K, Abaei AR, Shirazi RN, Parle E, Carroll O, Ronan W, et al. Physical and mechanical degradation behaviour of semi-crystalline PLLA for bioresorbable stent applications. J Mech Behav Biomed Mater. 2021;118:104409. https://doi.org/10.1016/j.jmbbm.2021.104409

Suzuki T, Ei A, Takada Y, Uehara H, Yamanobe T, Takahashi K. Modification of physical properties of poly(L-lactic acid) by addition of methyl-β-cyclodextrin. Beilstein J Org Chem. 2014;10:2997–3006. https://doi.org/10.3762/bjoc.10.318

Furukawa T, Sato H, Murakami R, Zhang J, Noda I, Ochiai S, et al. Raman microspectroscopy study of structure, dispersibility, and crystallinity of poly(hydroxybutyrate)/poly(l-lactic acid) blends. Polymer. 2006;47:3132–40. https://doi.org/10.1016/j.polymer.2006.03.010

Wang G, He C, Yang W, Qi F, Qian G, Peng S, et al. Surface-modified graphene oxide with compatible interface enhances poly-l-lactic acid bone scaffold. J Nanomater. 2020;2020:1–11. https://doi.org/10.1155/2020/5634096

Wang G, Qi F, Yang W, Yang Y, He C, Peng S, et al. Crystallinity and reinforcement in poly-l-lactic acid scaffold induced by carbon nanotubes. Adv Polym Tech. 2019;2019:1–10. https://doi.org/10.1155/2019/8625325

Sharma N, Sharma V, Jain Y, Kumari M, Gupta R, Sharma SK, et al. Synthesis and characterization of graphene oxide (GO) and reduced graphene oxide (rGO) for gas sensing application. Macromol Symp. 2017;376:1700006. https://doi.org/10.1002/masy.201700006

Hu C, Li Z, Wang Y, Gao J, Dai K, Zheng G, et al. Comparative assessment of the strain-sensing behaviors of polylactic acid nanocomposites: reduced graphene oxide or carbon nanotubes. J Mater Chem C. 2017;5:2318–28. https://doi.org/10.1039/C6TC05261D

Lech A, Butruk-Raszeja BA, Ciach T, Lawniczak-Jablonska K, Kuzmiuk P, Bartnik A, et al. Surface modification of PLLA, PTFE and PVDF with extreme ultraviolet (EUV) to enhance cell adhesion. Int J Mol Sci. 2020;21:9679. https://doi.org/10.3390/ijms21249679

Patel DI, Noack S, Vacogne CD, Schlaad H, Bahr S, Dietrich P, et al. Poly(l -lactic acid), by near-ambient pressure XPS. Surf Sci Spectra. 2019;26:024004. https://doi.org/10.1116/1.5110309

Majeed MH, Shayesteh P, Persson AR, Wallenberg LR, Schnadt J, Wendt OF. A Pd II carbene complex with anthracene side-arms for π-stacking on reduced graphene oxide (rGO): activity towards undirected C-H oxygenation of arenes: A Pd II carbene complex with anthracene side-arms for π-stacking on reduced graphene oxide (rGO): activity towards undirected C-H oxygenation of arenes. Eur J Inorg Chem. 2018;2018:4742–6. https://doi.org/10.1002/ejic.201800978

Renò F, D’Angelo D, Gottardi G, Rizzi M, Aragno D, Piacenza G, et al. Atmospheric pressure plasma surface modification of poly(D,L-lactic acid) increases fibroblast, osteoblast and keratinocyte adhesion and proliferation. Plasma Process Polym. 2012;9:491–502. https://doi.org/10.1002/ppap.201100139

Wang DH, Hu Y, Zhao JJ, Zeng LL, Tao XM, Chen W. Holey reduced graphene oxide nanosheets for high performance room temperature gas sensing. J Mater Chem A. 2014;2:17415–20. https://doi.org/10.1039/C4TA03740E

Stloukal P, Novák I, Mičušík M, Procházka M, Kucharczyk P, Chodák I, et al. Effect of plasma treatment on the release kinetics of a chemotherapy drug from biodegradable polyester films and polyester urethane films. Int J Polym Mater. 2018;67:161–73. https://doi.org/10.1080/00914037.2017.1309543

Guerrouani N, Baldo A, Bouffin A, Drakides C, Guimon M-F, Mas A. Allylamine plasma-polymerization on PLLA surface evaluation of the biodegradation. J Appl Polym Sci. 2007;105:1978–86. https://doi.org/10.1002/app.26388

Chernozem RV, Romanyuk KN, Grubova I, Chernozem PV, Surmeneva MA, Mukhortova YR, et al. Enhanced piezoresponse and surface electric potential of hybrid biodegradable polyhydroxybutyrate scaffolds functionalized with reduced graphene oxide for tissue engineering. Nano Energy. 2021;89:106473. https://doi.org/10.1016/j.nanoen.2021.106473

De Giglio E, Ditaranto N, Sabbatini L. Polymer surface chemistry: characterization by XPS. in: L. Sabbatini (Ed.). Polymer surface characterization. De Gruyter. 2014. p. 73–112.

Gupta B, Kumar N, Panda K, Kanan V, Joshi S, Visoly-Fisher I. Role of oxygen functional groups in reduced graphene oxide for lubrication. Sci Rep. 2017;7:45030. https://doi.org/10.1038/srep45030

Pluta M, Galeski A, Alexandre M, Paul M-A, Dubois P. Polylactide/montmorillonite nanocomposites and microcomposites prepared by melt blending: Structure and some physical properties. J Appl Polym Sci. 2002;86:1497–506. https://doi.org/10.1002/app.11309

Fukushima K, Tabuani D, Camino G. Nanocomposites of PLA and PCL based on montmorillonite and sepiolite. Mater Sci Eng C. 2009;29:1433–41. https://doi.org/10.1016/j.msec.2008.11.005

Rodriguez-Garcia ME, Londoño-Restrepo SM, Ramirez-Gutierrez CF, Millan-Malo B. Effect of the crystal size on the X-ray diffraction patterns of isolated orthorhombic starches: A-type. Mater Sci. 2018;18;1973–82.

Xiao H, Liu F, Jiang T, Yeh J-T. Kinetics and crystal structure of isothermal crystallization of poly(lactic acid) plasticized with triphenyl phosphate. J Appl Polym Sci. 2010. https://doi.org/10.1002/app.32225

De Santis P, Kovacs AJ. Molecular conformation of poly(S-lactic acid). Biopolymers. 1968;6:299–306. https://doi.org/10.1002/bip.1968.360060305

Hoogsteen W, Postema AR, Pennings AJ, Ten Brinke G, Zugenmaier P. Crystal structure, conformation and morphology of solution-spun poly(L-lactide) fibers. Macromolecules. 1990;23:634–42. https://doi.org/10.1021/ma00204a041

Cartier L, Okihara T, Ikada Y, Tsuji H, Puiggali J, Lotz B. Epitaxial crystallization and crystalline polymorphism of polylactides. Polymer. 2000;41:8909–19. https://doi.org/10.1016/S0032-3861(00)00234-2

Zhou H, Green TB, Joo YL. The thermal effects on electrospinning of polylactic acid melts. Polymer. 2006;47:7497–505. https://doi.org/10.1016/j.polymer.2006.08.042

Chrissafis K, Bikiaris DN. Can nanoparticles really enhance thermal stability of polymers? Part I: An overview on thermal decomposition of addition polymers. Thermochim Acta. 2011. https://doi.org/10.1016/j.tca.2011.06.010

Wang S, Chi H, Chen L, Li W, Li Y, Li G, et al. Surface functionalization of graphene oxide with polymer brushes for improving thermal properties of the polymer matrix. Adv Polym Tech. 2021;2021:1–11. https://doi.org/10.1155/2021/5591420

Sandhya PK, Sreekala MS, Padmanabhan M, Jesitha K, Thomas S. Effect of starch reduced graphene oxide on thermal and mechanical properties of phenol formaldehyde resin nanocomposites. Compos B Eng. 2019;167:83–92. https://doi.org/10.1016/j.compositesb.2018.12.009

Fredi G, Karimi Jafari M, Dorigato A, Bikiaris DN, Checchetto R, Favaro M, et al. Multifunctionality of reduced graphene oxide in bioderived polylactide/poly(dodecylene furanoate) nanocomposite films. Molecules. 2021;26:2938. https://doi.org/10.3390/molecules26102938

Qiu Z, Guan W. In situ ring-opening polymerization of poly(l-lactide)-graft-graphene oxide and its effect on the crystallization kinetics and morphology of biodegradable poly(l-lactide) at low loadings. RSC Adv. 2014;4:9463. https://doi.org/10.1039/c3ra46656f

Cuong NT, Barrau S, Dufay M, Tabary N, Da Costa A, Ferri A, et al. On the nanoscale mapping of the mechanical and piezoelectric properties of poly (L-lactic acid) electrospun nanofibers. Appl Sci. 2020;10:652. https://doi.org/10.3390/app10020652

Vadas D, Nagy ZK, Csontos I, Marosi G, Bocz K. Effects of thermal annealing and solvent-induced crystallization on the structure and properties of poly(lactic acid) microfibres produced by high-speed electrospinning. J Therm Anal Calorim. 2020;142:581–94. https://doi.org/10.1007/s10973-019-09191-8

Bĕhálek L, Seidl M, Dobránsky J. Crystallization of polylactic acid composites with banana and hemp fibres by means of DSC and XRD methods. Appl Mech Mater. 2014;616:325–32. 10.4028. https://www.scientific.net/AMM.616.325

Leonés A, Peponi L, Lieblich M, Benavente R, Fiori S. In vitro degradation of plasticized PLA electrospun fiber mats: morphological, thermal and crystalline evolution. Polymers. 2020;12:2975. https://doi.org/10.3390/polym12122975

Yasuniwa M, Tsubakihara S, Ohoshita K, Tokudome SI. X-ray studies on the double melting behavior of poly(butylene terephthalate). J Polym Sci, Part B: Polym Phys. 2001;39:2005–15. https://doi.org/10.1002/polb.1176

Bassett D, Olley R, Alraheil I. On crystallization phenomena in PEEK☆. Polymer. 1988;29:1745–54. https://doi.org/10.1016/0032-3861(88)90386-2

Lee Y, Porter RS, Lin JS. On the double-melting behavior of poly(ether ether ketone). Macromolecules. 1989;22:1756–60. https://doi.org/10.1021/ma00194a043

Jonas AM, Russell TP, Yoon DY. Synchrotron X-ray scattering studies of crystallization of poly(ether-ether-ketone) from the glass and structural changes during subsequent heating-cooling processes. Macromolecules. 1995;28:8491–503. https://doi.org/10.1021/ma00129a005

Sanjeeva Murthy N. X-ray diffraction from polymers. in: Q. Guo (Ed.). Polymer morphology: principles, characterization, and processing. John Wiley & Sons, Inc. 2016. Wiley Online Library. p. 14–36.

He Z, Rault F, Lewandowski M, Mohsenzadeh E, Salaün F. Electrospun PVDF nanofibers for piezoelectric applications: a review of the influence of electrospinning parameters on the β phase and crystallinity enhancement. Polymers. 2021. https://doi.org/10.3390/polym13020174

Sharma P, Wu D, Poddar S, Reece TJ, Ducharme S, Gruverman A. Orientational imaging in polar polymers by piezoresponse force microscopy. J Appl Phys. 2011;110:052010. https://doi.org/10.1063/1.3623765

Sharma P, Reece TJ, Ducharme S, Gruverman A. High-resolution studies of domain switching behavior in nanostructured ferroelectric polymers. Nano Lett. 2011;11:1970–5. https://doi.org/10.1021/nl200221z

Kobayashi J, Asahi T, Ichiki M, Oikawa A, Suzuki H, Watanabe T, et al. Structural and optical properties of poly lactic acids. J Appl Phys. 1995;77:2957–73. https://doi.org/10.1063/1.358712

Alemán C, Lotz B, Puiggali J. Crystal structure of the α-form of poly(l -lactide). Macromolecules. 2001;34:4795–801. https://doi.org/10.1021/ma001630o

Tajitsu Y. Piezoelectric poly-L-lactic acid fabric and its application to control of humanoid robot. Ferroelectrics. 2017;515:44–58. https://doi.org/10.1080/00150193.2017.1360107

Tajitsu Y. Basic study of controlling piezoelectric motion of chiral polymeric fiber. Ferroelectrics. 2009;389:83–94. https://doi.org/10.1080/00150190902987871

Shvartsman VV, Kholkin AL. Nanoscale investigation of polycrystalline ferroelectric materials via piezoresponse force microscopy. In: Multifunctional polycrystalline ferroelectric materials. Springer, Dordrecht, the Netherlands; 2011. p. 409–68.

Smith M, Calahorra Y, Jing Q, Kar-Narayan S. Direct observation of shear piezoelectricity in poly-l-lactic acid nanowires. APL Mater. 2017;5. https://doi.org/10.1063/1.4979547.

Sultana A, Ghosh SK, Sencadas V, Zheng T, Higgins MJ, Middya TR, et al. Human skin interactive self-powered wearable piezoelectric bio-e-skin by electrospun poly- l -lactic acid nanofibers for non-invasive physiological signal monitoring. J Mater Chem B. 2017;5:7352–9. https://doi.org/10.1039/C7TB01439B

Zhao G, Huang B, Zhang J, Wang A, Ren K, Wang ZL. Electrospun poly(l-lactic acid) nanofibers for nanogenerator and diagnostic sensor applications. Macromol Mater Eng. 2017;302:1600476. https://doi.org/10.1002/mame.201600476

Nath R, Hong S, Klug JA, Imre A, Bedzyk MJ, Katiyar RS, et al. Effects of cantilever buckling on vector piezoresponse force microscopy imaging of ferroelectric domains in BiFeO3 nanostructures. Appl Phys Lett. 2010;96:163101. https://doi.org/10.1063/1.3327831

Rodrigues GDC, Zelenovskiy P, Romanyuk KN, Luchkin S, Kopelevich Y, Kholkin AL. Strong piezoelectricity in single-layer graphene deposited on SiO2 grating substrates. Nat Commun. 2015;6. https://doi.org/10.1038/ncomms8572.

Kanemaru K, Okubo Y, Hirose K, Iino M. Regulation of neurite growth by spontaneous Ca2+ oscillations in astrocytes. J Neurosci. 2007;27:8957–66. https://doi.org/10.1523/JNEUROSCI.2276-07.2007

Poon KK, Wurm MC, Evans DM, Einarsrud MA, Lutz R, Glaum J. Biocompatibility of (Ba,Ca)(Zr,Ti)O3 piezoelectric ceramics for bone replacement materials. J Biomed Mater Res Part B Appl Biomater. 2020;108:1295–303. https://doi.org/10.1002/jbm.b.34477

Ribeiro C, Correia DM, Rodrigues I, Guardão L, Guimarães S, Soares R, et al. In vivo demonstration of the suitability of piezoelectric stimuli for bone reparation. Mater Lett. 2017;209:118–21. https://doi.org/10.1016/j.matlet.2017.07.099

Guo H-F, Li Z-S, Dong S-W, Chen W-J, Deng L, Wang Y-F, et al. Piezoelectric PU/PVDF electrospun scaffolds for wound healing applications. Colloids Surf B Biointerfaces. 2012;96:29–36. https://doi.org/10.1016/j.colsurfb.2012.03.014

Sencadas V, Ribeiro C, Heredia A, Bdikin IK, Kholkin AL, Lanceros-Mendez S. Local piezoelectric activity of single poly(L-lactic acid) (PLLA) microfibers. Appl Phys A. 2012;109:51–55. https://doi.org/10.1007/s00339-012-7095-z

Farahani A, Zarei-Hanzaki A, Abedi HR, Haririan I, Akrami M, Aalipour Z, et al. An investigation into the polylactic acid texturization through thermomechanical processing and the improved d33 piezoelectric outcome of the fabricated scaffolds. J Mater Res Technol. 2021;15:6356–66. https://doi.org/10.1016/j.jmrt.2021.11.048

Li J-W, Huang C-Y, Chen K-Y, Chen J-X, Hsu X-Y, Chen Y-F, et al. Enhanced piezoelectric properties of poly(vinylidenefluoride-co-trifluoroethylene)/carbon-based nanomaterial composite films for pressure sensing applications. Polymers. 2020;12:2999. https://doi.org/10.3390/polym12122999

Paik H, Choi Y-Y, Hong S, No K. Effect of Ag nanoparticle concentration on the electrical and ferroelectric properties of Ag/P(VDF-TrFE) composite films. Sci Rep. 2015;5:13209. https://doi.org/10.1038/srep13209

Tingting L, Xiang-Yang L, Chaobin H. Ab initio elasticity of poly(lactic acid) crystals. J Phys Chem B. 2010;114:3133–9. https://doi.org/10.1021/jp911198p

Nye JF. Physical properties of crystals: their representation by tensors and matrices. 1st published in pbk. with corrections, 1984 ed. Clarendon Press; Oxford University Press. Oxford [Oxfordshire]: New York; 1984.

Ando M, Kawamura H, Kageyama K, Tajitsu Y. Film sensor device fabricated by a piezoelectric poly(L-lactic acid) film. Jpn J Appl Phys. 2012; 51. https://doi.org/10.1143/JJAP.51.09LD14

Xuan L, Sai C, Xianye Z, Jinhao L, Haihui L, Na H, et al. Poly‐l‐lactic acid/graphene electrospun composite nanofibers for wearable sensors. Energy Technol. 2020. https://doi.org/10.1002/ente.201901252

Tai Y, Yang S, Yu S, Banerjee A, Myung NV, Nam J. Modulation of piezoelectric properties in electrospun PLLA nanofibers for application-specific self-powered stem cell culture platforms. Nano Energy. 2021;89:106444. https://doi.org/10.1016/j.nanoen.2021.106444

Li H, Xue F, Bai J, Bai X, Ye W, Zhang L, et al. In vitro degradation of self‐reinforced poly(lactic acid) with beta‐tricalcium phosphate composite prepared by equal channel angular pressing. Polym Compos. 2020;41:4054–63. https://doi.org/10.1002/pc.25692

Arias V, Höglund A, Odelius K, Albertsson A-C. Tuning the degradation profiles of poly(l -lactide)-based materials through miscibility. Biomacromolecules. 2014;15:391–402. https://doi.org/10.1021/bm401667b

Yoshida M, Onogi T, Onishi K, Inagaki T, Tajitsu Y. High piezoelectric performance of poly(lactic acid) film manufactured by solid-state extrusion. Jpn J Appl Phys. 2014;53:09PC02. https://doi.org/10.7567/JJAP.53.09PC02

Acknowledgements

The authors acknowledge the results obtained and their discussion in cooperation with A.M.S. Jekhan (TPU). The research was carried out at Tomsk Polytechnic University within the framework of the Tomsk Polytechnic University Development Program. The authors are thankful to the Central Laboratories of TPU (Analytical Center) for the XPS measurements. Work was conducted with the application of equipment of the Tomsk Regional Core Shared Research Facilities Centre of National Research Tomsk State University. The financial support (PFM study) from the Ministry of Science and Higher Education (grant agreement #075-15-2021-588 from 1.06.2021) and Russian Science Foundation (project # 22-13-20043, materials purchase, SEM and DSC analyses) is acknowledged. The work was also supported by the Special Research Fund (BOF) of Ghent University [grant numbers BOF16/FJD/029 (RVC and AGS)] and the German-Russian Interdisciplinary Science Center (G-RISC) (project number M-2021 a-8_d). The authors strongly condemn all violence and promote peaceful solutions.

Author information

Authors and Affiliations

Contributions

IOP: Investigation, Visualization, Writing—original draft. RVC: Conceptualization, Investigation, Writing—review & editing. PVC: Formal analysis, Visualization. YRM: Investigation. AGS: Conceptualization, Resources. VVS: Supervision, Conceptualization, Resources. DCL: Supervision, Resources. MAS: Conceptualization, Investigation. RAS: Supervision, Conceptualization, Resources, Project management, Writing—review & editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Pariy, I.O., Chernozem, R.V., Chernozem, P.V. et al. Hybrid biodegradable electrospun scaffolds based on poly(l-lactic acid) and reduced graphene oxide with improved piezoelectric response. Polym J 54, 1237–1252 (2022). https://doi.org/10.1038/s41428-022-00669-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-022-00669-1

This article is cited by

-

The role of multi-walled carbon nanotubes in enhancing the hydrolysis and thermal stability of PLA

Scientific Reports (2024)

-

Hybrid Electrospinning Printing for Nanofiber Self-Supporting 3D Microfluidic Devices

Fibers and Polymers (2024)