Abstract

A novel filler for rubber was prepared by deep processing of coal gasification fine slag (CGFS) using an airflow sorter. Five processed CGFS samples with different sizes and carbon contents were obtained. The effects of particle size, unburned carbon, and surface properties of CGFS on the comprehensive properties of filled styrene butadiene rubber (SBR) were investigated. The mechanical properties were improved with decreasing CGFS size, and the curing and mechanical properties exhibited better performance owing to the unburned carbon. Unburned carbon can improve the dispersion properties of the filler and the compatibility between the matrix and filler. The best values for the curing characteristics and mechanical properties of SBR appeared when CGFS-S2 and CGFS-S3 were used as the fillers, respectively. Heavy calcium carbonate (CaCO3) particles were used as a comparative filler, and the results demonstrated that CGFS particles have the potential to replace CaCO3 in rubber.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Ahmed K, Kawakami M, Khosla A, Furukawa H. Soft, conductive nanocomposites based on ionic liquids/carbon nanotubes for 3D printing of flexible electronic devices. Polym J. 2019;51:511–21.

Mostafa A, Lucyshyn T, Holzer C, Flachberger H, Oefner W, Riess G, Fritz B. Influence of filler treatment on the behavior of blast furnace slag filled polypropylene compounds. J Appl Polym Sci. 2019;135:46535.

Chen T, Lin H, Zhao H, Chen X, Wu T, Li G, Ji H, Sha J, Ma Y, Xie L. Agglomerate size evolution in modular twin-screw extruder: Modeling and validation with CaCO3/LLDPE compounding experiments. J Appl Polym Sci. 2017;134:45535.

Aly K, Younis O, Mahross M, Tsutsumi O, Mohamed MG, Sayed M. Novel conducting polymeric nanocomposites embedded with nanoclay: synthesis, photoluminescence, and corrosion protection performance. Polym J. 2019;51:71–90.

Watanabe R, Hagihara H, Sato H. Structure-property relationships of polypropylene-based nanocomposites obtained by dispersing mesoporous silica into hydroxyl-functionalized polypropylene. Part 2: Matrix-filler interactions and pore filling of mesoporous silica characterized by evolved gas analysis. Polym J. 2018;50:1067–77.

da Rocha EBD, Linhares FN, Gabriel CFS, Sousa AMF, Furtado CRG. Stress relaxation of nitrile rubber composites filled with a hybrid metakaolin/carbon black filler under tensile and compressive forces. Appl Clay Sci. 2018;151:181–8.

Mi X, Zhong L, Wei F, Zeng L, Zhang J, Zhang D, Xu T. Fabrication of halloysite nanotubes/reduced graphene oxide hybrids for epoxy composites with improved thermal and mechanical properties. Polym Test. 2019;76:473–80.

Watanabe R, Hagihara H, Sato H. Structure-property relationships of polypropylene-based nanocomposites obtained by dispersing mesoporous silica into hydroxyl-functionalized polypropylene. Part 1: toughness, stiffness and transparency. Polym J. 2018;50:1057–65.

Xue G, Zhang B, Xing J, Sun M, Zhang X, Li J, Wang L, Liu C. A facile approach to synthesize in situ functionalized graphene oxide/epoxy resin nanocomposites: mechanical and thermal properties. J Mater Sci. 2019;54:13973–89.

Piekarska K, Piorkowska E, Bojda J. The influence of matrix crystallinity, filler grain size and modification on properties of PLA/calcium carbonate composites. Polym Test. 2017;62:203–9.

Srivabut C, Ratanawilai T, Hiziroglu S. Effect of nanoclay, talcum, and calcium carbonate as filler on properties of composites manufactured from recycled polypropylene and rubberwood fiber. Constr Build Mater. 2018;162:450–8.

Çoban O, Bora MÖ, Kutluk T. Comparative study of volcanic particle and calcium carbonate filler materials in HDPE for thermal and mechanical properties. Polym Compos. 2018;39:E1900–07.

Kumar PN, Nagappan V, Karthikeyan C. Effects of fly ash, calcium carbonate fillers on mechanical, moisture absorption properties in poly vinyl chloride resin. Mater Today: Proc. 2019;16:1219–25.

da Costa HM, Visconte LLY, RCR Nunes RCR, Furtado CRG. Rice-husk-ash-filled natural rubber. II. Partial replacement of commercial fillers and the effect on the vulcanization process. J Appl Polym Sci. 2003;87:1405–13.

da Costa HM, Visconte LLY, Nunes RCR, Furtado CRG. Rice husk ash filled natural rubber. III. Role of metal oxides in kinetics of sulfur vulcanization. J Appl Polym Sci. 2003;90:1519–31.

Mahmood N, Khan MS, Khan AU, Stöckelhuber KW, Heinrich G. Purification, surface modification of coal ash silica and its potential application in rubber composites. J Appl Polym Sci. 2010;117:1493–501.

Nillawong M, Sombatsompop N, Sirisinha C. Viscoelastic properties of nitrile rubber filled with lignite fly ash. J Appl Polym Sci. 2010;116:3497–502.

Liu S, Chen X, Ai W, Wei C. A new method to prepare mesoporous silica from coal gasification fine slag and its application in methylene blue adsorption. J Clean Prod. 2019;212:1062–71.

Zhu D, Miao S, Xue B, Jiang Y, Wei C. Effect of coal gasification fine slag on the physicochemical properties of soil. Water Air Soil Pollut. 2019;230:155.

Gu Y, Qiao X. A carbon silica composite prepared from water slurry coal gasification slag. Microporous Mesoporous Mater. 2019;276:303–07.

Ai W, Xue B, Wei C, Dou K, Miao S. Mechanical and thermal properties of coal gasification fine slag reinforced low density polyethylene composites. J Appl Polym Sci. 2018;135:46203.

Ai W, Liu S, Zhang J, Miao S, Wei C. Mechanical and nonisothermal crystallization properties of coal gasification fine slag glass bead-filled polypropylene composites. J Appl Polym Sci. 2019;136:47803.

Lin OH, Md Akil H, Ishak ZAM. Characterization and properties of activated nanosilica/polypropylene composites with coupling agents. Polym Compos. 2009;30:1693–700.

Luo F, Wang S, Xue B, Jiang Y, Wei C. Utilization of fly ash acid residue as a reinforcing filler in ethylene propylene diene monomer rubber. J Appl Polym Sci. 2013;129:1053–9.

Thongsang S, Sombatsompop N, Ansarifar A. Effect of fly ash silica and precipitated silica fillers on the viscosity, cure, and viscoelastic properties of natural rubber. Polym Advan Technol. 2008;19:1296–304.

Ansarifar A, Shiah SF, Bennett M. Optimising the chemical bonding between silanised silica nanofiller and natural rubber and assessing its effects on the properties of the rubber. Int J Adhes Adhes. 2006;26:454–63.

Xu F, Lu Y, Xie Y, Liu Y. Controllable morphology evolution of electrodeposited ZnO nano/micro-scale structures in aqueous solution. Mater Des. 2009;30:1704–11.

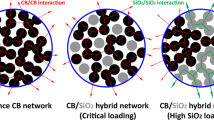

Zhao S, Xie S, Sun P, Zhao Z, Li L, Shao X, Liu X, Xin Z. Synergistic effect of graphene and silicon dioxide hybrids through hydrogen bonding self-assembly in elastomer composites. RSC Adv. 2018;8:17813–25.

Lin Y, Liu S, Peng J, Liu L. The filler–rubber interface and reinforcement in styrene butadiene rubber composites with graphene/silica hybrids: a quantitative correlation with the constrained region. Compos Part A: Appl Surf Manuf. 2016;86:19–30.

Meier JG, Klüppel M. Carbon black networking in elastomers monitored by dynamic mechanical and dielectric spectroscopy. Macromol Mater Eng. 2008;293:12–38.

Wang MJ. Effect of filler-elastomer interaction on tire tread performance part I. Kgk-Kaut Gummi Kunst. 2007;60:438–43.

Acknowledgements

This research was financially supported by the National Natural Science Foundation of China (grant number 51874145).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ai, W., Zhang, J., Miao, S. et al. A low-cost and high-value reinforcing filler for styrene butadiene rubber fabricated by a pneumatic separation technique from coal gasification fine slag. Polym J 52, 493–503 (2020). https://doi.org/10.1038/s41428-019-0300-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-019-0300-6