Abstract

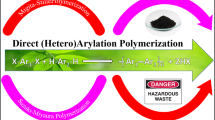

Direct arylation polycondensation has been investigated to develop efficient methods for the preparation of conjugated polymeric materials for use in optoelectronic applications. The reaction conditions have been examined to achieve high molecular weights and minimal structural defects in the recurring structures. Under optimal conditions, the direct arylation method has several advantages over conventional methods, e.g., it has fewer synthetic steps and yields a high-molecular-weight and high-purity polymer. The high-quality polymeric materials that were obtained exhibited superior performance to those obtained using a conventional method when used in optoelectronic devices such as organic photovoltaics and field-effect transistors. Recent developments in C–H/C–H coupling polycondensation are also described.

Similar content being viewed by others

Introduction

Conjugated polymers are expected to serve as the main materials in optoelectronic devices such as organic photovoltaics (OPVs) [1], organic light-emitting diodes (OLEDs) [2], and organic field-effect transistors (OFETs) [3,4,5]. High-performance polymers have been developed by logical molecular designs [6, 7] and the development of conjugated polymeric materials will allow practical applications in organic optoelectronic devices. For use in wide practical applications, mass production of conjugated polymeric materials is required, while also satisfying demands concerning cost and environmental issues [8, 9]. As a practical method for the production of conjugated polymeric materials, polycondensation using C–H direct arylation [10,11,12] is a promising candidate, because this method does not require the use of organometallic monomers that are essential in polycondensation methods that use conventional cross-coupling reactions. The elimination of organometallic monomers reduces the number of synthetic steps for monomer preparation and undesirable metal-containing waste after polymerization. Having fewer synthetic steps, the process is less expensive and the reduction in waste reduces the environmental burden and increases the purity of the product [8, 9]. To take advantage of this approach in material production, direct arylation polycondensation must fulfill the following three requirements [13]:

1. High molecular weight: A synthetic method should afford a high-molecular-weight polymer that, in general, exhibits better performance regarding carrier mobility and photoelectric conversion [14,15,16,17]. To achieve a high molecular weight, the conversion of the coupling reaction must be high.

2. High selectivity: Selectivity in bond formation must be nearly perfect, because structural defects in polymers cannot be removed, even by purification. The structural defects act as carrier trapping sites, thereby lowering device performance [18, 19].

3. High purity: Impurities from metal catalysts or byproducts should be easily removed from the polymeric materials, because impurities lower the initial performance of the polymer and long-term stability [20, 21]. A reduced amount of catalyst and easily separable byproducts are required for obtaining high-purity materials through simple purification processes. Incorporation of decomposed phosphine ligands at chain ends [22] should be avoided, because the terminal defect may act as an impurity, which cannot be removed in purification steps.

In addition to satisfying these demands, the synthetic method must be broadly applicable for preparation of state-of-the-art polymeric materials. As several review papers on direct arylation polycondensation have been published in recent years [23,24,25], this review describes the recent results of the author and the author’s collaborators.

Initial development of direct arylation polycondensation

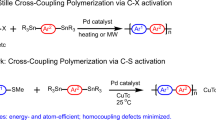

Direct arylation polycondensation of alkylthiophenes was reported in 1999 [26]. Although the idea was quite innovative, the polymerization results did not satisfy the demands mentioned above; the molecular weight and selectivity of the bond formation (head-to-tail content) were somewhat lower than those obtained using conventional methods. In 2010, Ozawa and colleagues [27] reported the successful synthesis of poly(3-hexylthiophene) (P3HT) via Pd-catalyzed direct arylation (Scheme 1). This method afforded high-molecular-weight P3HT and a high head-to-tail content, as well as a good yield. Mori and colleagues [28, 29] reported on the synthesis of P3HT using the same monomer and a Knochel–Hauser base by formation of a Grignard reagent, which afforded high head-to-tail content, a controlled molecular weight, and a narrow molecular weight distribution.

Shortly after Ozawa and Mori’s report, we reported on the direct arylation polycondensation of tetrafluorobenzene with a dibromofluorene derivative (Scheme 2) [30]. The reaction with Pd(OAc)2 and PtBu2Me·HBF4 produced the corresponding polymer with a high molecular weight in a good yield. The molecular weight and the yield were higher than those obtained for the polymer prepared by polycondensation using the conventional Suzuki–Miyaura coupling reaction (Mn = 16500, 74% yield) [31]. In addition, the high purity of the obtained polymer was confirmed by elemental analysis. The high purity was presumably due to the easily separable byproducts (H2O, CO2, and KBr) in the direct arylation polycondensation reaction. In addition, the pure polymer acted as a hole-blocking material in OLEDs [32]. These initial examples demonstrate the high potential of direct arylation polycondensation for the preparation of optoelectronic materials [33].

Direct arylation polycondensation of bithiophenes

We have investigated the direct arylation polycondensation of thiophene, bithiophene, and their analogs, because thiophene is the most promising unit for preparing excellent semiconducting materials. An initial assessment of catalytic systems revealed that a Pd precatalyst (Pd(OAc)2) with no phosphine ligand is the most effective catalyst for the direct arylation polycondensation of alkylated bithiophenes (Scheme 3). This highly active catalytic system allows the preparation of the corresponding polymer with a high molecular weight (Mn = 31800) in 3 h [34]. In addition to bithiophene derivatives, this reaction system can be used for the polycondensation of bithiazole, thienothiophene, monothiophene derivatives, and naphthalene diimide-based monomers (Scheme 3, Table S1 in Supplementary Information) [35,36,37,38,39,40,41,42,43]. This simple catalytic system has been used for the preparation of a variety of conjugated polymers by other groups [44,45,46,47], presumably because of its high reactivity and ease of use. It is important to note that this highly reactive system can induce side reactions that cause structural defects; a direct arylation reaction can occur at undesired C–H bonds [34, 35, 45]. An appropriate choice of monomers and the optimization of reaction conditions are essential in order to avoid side reactions [43, 48].

Evaluation of polymers prepared by direct arylation polycondensation

For the further development of direct arylation polycondensation, the reaction conditions were investigated in a model reaction using 3,4-ethylenedioxythiophene (EDOT) [49], which possesses highly reactive C–H bonds for direct arylation (Scheme 4) [37, 50, 51]. The target polymer can be prepared using a conventional cross-coupling method (Scheme 4a, S-PEDOTF) [51]. An investigation of the reaction conditions for the direct arylation polycondensation of EDOT revealed that 1-adamantanecarboxylic acid (1-AdCOOH) is an effective additive that assists the C–H bond cleavage process. The reaction with 1-AdCOOH afforded the corresponding polymer (Scheme 4b, L-PEDOTF) in the presence of only 1 mol% of the Pd precatalyst [37]. The molecular weight of L-PEDOTF (Mn = 47500) is higher than that of S-PEDOTF (Mn = 17100), which was prepared using the conventional method. In addition, direct arylation polycondensation under microwave heating produced the corresponding polymer with an extraordinarily high molecular weight (Scheme 4c, H-PEDOTF) [50]. It is possible that the uniform heating produced under microwave irradiation promoted efficient coupling. These results demonstrate that optimized direct arylation polycondensation can produce higher molecular weight polymers than those obtained using conventional methods. One reason for the high molecular weights of L- and H-PEDOTF is the high tolerance of the C–H bonds to the reaction conditions. The lack of degradation of the reactive point is advantageous, especially compared with the monomers used in the conventional method. For example, the C-Br moiety in the brominated EDOT in Scheme 4a is known to be unstable [52] and the boronate ester moiety can be decomposed via protodeboronation [53].

The purity and semiconducting properties of PEDOTFs were investigated to confirm the advantages of the direct arylation method (Table 1). The results of the elemental analysis of H-PEDOTF matched well to the values calculated from the formula of the repeating unit. Bromine was not detected by elemental analysis, even though the fluorene terminal units may, in principle, possess a Br moiety. The absence of Br termini may be attributed to the small number of the terminal units as well as minor debromination reactions in the later stage of polymerization. In contrast, the analytical results indicate that L- and S-PEDOTF contain impurities and Br termini. Inductively coupled plasma atomic emission spectrometry (ICP-AES) measurements reveal that direct arylation polycondensation achieved lower levels of Pd residues in the polymers than the conventional method, which is due to the low loading of Pd (1 mol%) in the direct arylation method. It should be noted that high-molecular-weight and high-purity H-PEDOTF was obtained through simple purification steps, requiring only washing with several solvents and re-precipitation. Soxhlet extraction and high-performance liquid chromatography purification were not required. H-PEDOTF exhibited better semiconducting properties in OPVs and OFETs than did the other samples that were evaluated (Table 1) [51]. Bulk heterojunction (BHJ) solar cells with H-PEDOTF and PC70BM reached 4% power conversion efficiency (PCE), although that with S-PEDOTF was only 0.48%. As the PCE correlates with hole mobility in the polymers in OFETs, the better performance of H-PEDOTF in the OPV may be due to the high hole mobility in the polymer. As H-PEDOT has a higher molecular weight and purity than the other samples, the dominant factor responsible for the improvement is unknown. Therefore, the effects on terminal structure, the residual amount of Pd, and the molecular weight were investigated for the model polymers. Thus, PEDOTF samples with different terminal structures (Br or H), the amount of residual Pd, and the molecular weights were tabulated for comparison (Table 2) [54]. P1 is the same sample as L-PEDOTF. P2 has very little Br termini because of the treatment of the C-Br moiety at the end of polymerization. The amount of Pd residue was reduced to 3 p.p.m. in P3 by washing the polymer with an aqueous solution of sodium N,N-diethyldithiocarbamate. P4 has a purity that is similar to P3, but with a higher molecular weight. Regarding both the PCE and hole mobility, P1 has lower values than those of P2–P4, indicating that the terminal structure is the most dominant factor in this case. The Br terminals may act as hole-trapping sites [55]. In contrast, the Pd residue and molecular weight had a negligible effect on the initial performance of the OPVs and OFETs. The stability tests of the OPV devices showed that Pd residue and the molecular weight of the polymer affect the lifetime of the device; the device containing P4 has the longest lifetime among the P2–P4 group, although the initial performances were very similar [54].

Synthesis of donor–acceptor polymer

Direct arylation polycondensation for the synthesis of donor–acceptor (D–A) polymers was investigated after the establishment of the model reactions because D–A polymers often exhibit high levels of performance in OPVs; the D–A structure possesses a narrow highest energy occupied molecular orbital/lowest unoccupied molecular orbital gap, enabling wide light absorption and high hole mobility because of the strong interchain interactions [1]. For the synthesis of D–A polymers, a new reaction system was required, because the conditions mentioned above are not applicable to C–H bonds in the acceptor monomers, although donor monomers, such as EDOT, can be readily polymerized. An investigation of the reaction conditions for acceptor C–H monomers revealed that the addition of PCy3 ligands and the selection of a low polar solvent (toluene) are effective for the smooth polycondensation of acceptor monomers [56] such as thienopyrroledione derivatives [57, 58]. In addition, a Pd(0) precatalyst (Pd(PCy3)2) has been found to be a suitable precatalyst by mechanistic studies of direct arylation, thereby avoiding side reactions, such as the homocoupling reaction [42, 59]. Based on these findings, the polycondensation of thienopyrroledione and dibromocyclopentadithiophene derivatives was conducted using Pd(PCy3)2 as the catalyst and toluene as the solvent (Scheme 5) [60]. The reaction produced the corresponding D–A polymer with a molecular weight of 25,000 in 82% yield, which was higher than previously reported values for the Migita–Kosugi–Stille coupling polycondensation [61]. Nuclear magnetic resonance and mass spectrometry analyses indicated that the polymer possessed no structural defects and no Br termini, which might be due to a minor debromination reaction that occurred during the polycondensation reaction. Elemental analysis demonstrated the high purity of the polymer. This D–A polymer served as the p-type semiconducting material in BHJ solar cells with PC70BM. The maximum PCE of the solar cell was 6.8% after optimization of the device’s structure. The PCEs of the devices were comparable to those of the polymer obtained from the Migita–Kosugi–Stille coupling polycondensation [61], thus confirming that the direct arylation polycondensation yields high-performance semiconducting materials.

In-depth studies by other groups have also enabled the synthesis of high-performance polymers without structural defects [62,63,64]. Further development of this method will enable the synthesis of state-of-the-art materials that can lead to practical applications.

Polycondensation using C–H/C–H coupling reactions has been investigated to develop next-generation methods [65,66,67,68]. One example is the aerobic oxidation polycondensation of thiazole monomers (Scheme 6) [69]. This polymerization proceeds with a catalytic amount of Cu(OAc)2 and oxygen from the air and yields a bithiazole-based conjugated polymer along with the formation of H2O, which is a green by-product. The thiophene-thiazole polymer served as a semiconducting material in OFETs. As the monomer is synthesized by direct arylation of thiazole at the 5-position, this strategy skips the preparation of an organometallic reagent and reduces the overall number of reaction steps.

References

Liu C, Wang K, Gong X, Heeger AJ. Low bandgap semiconducting polymers for polymeric photovoltaics. Chem Soc Rev. 2016;45:4825–46.

Grimsdale AC, Chan KL, Martin RE, Jokisz PG, Holmes AB. Synthesis of light-emitting conjugated polymers for applications in electroluminescent devices. Chem Rev. 2009;109:897–1091.

Beaujuge PM, Fréchet JMJ. Molecular design and ordering effects in π-functional materials for transistor and solar cell applications. J Am Chem Soc. 2011;133:20009–29.

Takimiya K, Nakano M. Thiophene-fused naphthalene diimides: New building blocks for electron deficient p-functional materials. Bull Chem Soc Jpn. 2018;91:121–40.

Iino H, Hanna JI. Liquid crystalline organic semiconductors for organic transistor applications. Polym J. 2017;49:23–30.

Osaka I, Takimiya K. Naphthobischalcogenadiazole conjugated polymers: emerging materials for organic electronics. Adv Mater. 2017;29:1605218.

Ie Y, Aso Y. Development of donor-acceptor copolymers based on dioxocycloalkene-annelated thiophenes as acceptor units for organic photovoltaic materials. Polym J. 2017;49:13–22.

Osedach TP, Andrew TL, Bulović V. Effect of synthetic accessibility on the commercial viability of organic photovoltaics. Energy Environ Sci. 2013;6:711–8.

Burke DJ, Lipomi DJ. Green chemistry for organic solar cells. Energy Environ Sci. 2013;6:2053–66.

Satoh T, Miura M. Catalytic direct arylation of heteroaromatic compounds. Chem Lett. 2007;36:200–5.

Rossi R, Bellina F, Lessi M, Manzini C. Cross-coupling of heteroarenes by C-H functionalization: recent progress towards direct arylation and heteroarylation reactions involving heteroarenes containing one heteroatom. Adv Synth Catal. 2014;356:17–117.

Segawa Y, Maekawa T, Itami K. Synthesis of extended π-systems through C-H activation. Angew Chem Int Ed. 2015;54:66–81.

Henson ZB, Müllen K, Bazan GC. Design strategies for organic semiconductors beyond the molecular formula. Nat Chem. 2012;4:699–704.

Schilinsky P, Asawapirom U, Scherf U, Biele M, Brabec CJ. Influence of the molecular weight of poly(3-hexylthiophene) on the performance of bulk heterojunction solar cells. Chem Mater. 2005;17:2175–80.

Tong M, Cho S, Rogers JT, Schmidt K, Hsu BBY, Moses D, Coffin RC, Kramer EJ, Bazan GC, Heeger AJ. Higher molecular weight leads to improved photoresponsivity, charge transport and interfacial ordering in a narrow bandgap semiconducting polymer. Adv Funct Mater. 2010;20:3959–65.

Osaka I, Saito M, Mori H, Koganezawa T, Takimiya K. Drastic change of molecular orientation in a thiazolothiazole copolymer by molecular-weight control and blending with PC61BM leads to high efficiencies in solar cells. Adv Mater. 2012;24:425–30.

Yasuda T, Meguro H, Okamoto S, Han L. Bulk-heterojunction organic photovoltaic cells fabricated using a high-viscosity solution of poly(3-hexylthiophene) with extremely high molecular weight. Polym J. 2013;45:129–32.

Sirringhaus H, Brown PJ, Friend RH, Nielsen MM, Bechgaard K, Langeveld-Voss BMW, Spiering AJH, Janssen RAJ, Meijer EW, Herwig P, De Leeuw DM. Two-dimensional charge transport in self-organized, high-mobility conjugated polymers. Nature. 1999;401:685–8.

Hendriks KH, Li W, Heintges GHL, Van Pruissen GWP, Wienk MM, Janssen RAJ. Homocoupling defects in diketopyrrolopyrrole-based copolymers and their effect on photovoltaic performance. J Am Chem Soc. 2014;136:11128–33.

Krebs FC, Nyberg RB, Jørgensen M. Influence of residual catalyst on the properties of conjugated polyphenylenevinylene materials: palladium nanoparticles and poor electrical performance. Chem Mater. 2004;16:1313–8.

Park JK, Jo J, Seo JH, Moon JS, Park YD, Lee K, Heeger AJ, Bazan GC. End-capping effect of a narrow bandgap conjugated polymer on bulk heterojunction solar cells. Adv Mater. 2011;23:2430–5.

Goodson FE, Hauck SI, Hartwig JF. Palladium-catalyzed synthesis of pure, regiodefined polymeric triarylamines. J Am Chem Soc. 1999;121:7527–39.

Okamoto K, Zhang J, Housekeeper JB, Marder SR, Luscombe CK. C-H arylation reaction: atom efficient and greener syntheses of π-conjugated small molecules and macromolecules for organic electronic materials. Macromolecules. 2013;46:8059–78.

Rudenko AE, Thompson BC. Optimization of direct arylation polymerization (DArP) through the identification and control of defects in polymer structure. J Polym Sci Part A Polym Chem. 2015;53:135–47.

Pouliot J-R, Grenier F, Blaskovits JT, Beaupré S, Leclerc M. Direct (hetero)arylation polymerization: simplicity for conjugated polymer synthesis. Chem Rev. 2016;116:14225–74.

Sévignon M, Papillon J, Schulz E, Lemaire M. New synthetic method for the polymerization of alkylthiophenes. Tetrahedron Lett. 1999;40:5873–6.

Wang Q, Takita R, Kikuzaki Y, Ozawa F. Palladium-catalyzed dehydrohalogenative polycondensation of 2-bromo-3-hexylthiophene: an efficient approach to head-to-tail poly(3-hexylthiophene). J Am Chem Soc. 2010;132:11420–1.

Tamba S, Tanaka S, Okubo Y, Meguro H, Okamoto S, Mori A. Nickel-catalyzed dehydrobrominative polycondensation for the practical preparation of regioregular poly(3-substituted thiophene)s. Chem Lett. 2011;40:398–9.

Tamba S, Shono K, Sugie A, Mori A. C-H functionalization polycondensation of chlorothiophenes in the presence of nickel catalyst with stoichiometric or catalytically generated magnesium amide. J Am Chem Soc. 2011;133:9700–3.

Lu W, Kuwabara J, Kanbara T. Polycondensation of dibromofluorene analogues with tetrafluorobenzene via direct arylation. Macromolecules. 2011;44:1252–5.

Giovanella U, Botta C, Galeotti F, Vercelli B, Battiato S, Pasini M. Perfluorinated polymer with unexpectedly efficient deep blue electroluminescence for full-colour OLED displays and light therapy applications. J Mater Chem C. 2013;1:5322–9.

Lu W, Kuwabara J, Iijima T, Higashimura H, Hayashi H, Kanbara T. Synthesis of π-conjugated polymers containing fluorinated arylene units via direct arylation: efficient synthetic method of materials for oleds. Macromolecules. 2012;45:4128–33.

Kuwabara J, Kanbara T. Development of synthetic method for π conjugated polymers via direct arylation polycondensation. J Synth Org Chem, Jpn. 2014;72:1271–8.

Fujinami Y, Kuwabara J, Lu W, Hayashi H, Kanbara T. Synthesis of thiophene- and bithiophene-based alternating copolymers via Pd-catalyzed direct C-H arylation. ACS Macro Lett. 2012;1:67–70.

Kuwabara J, Nohara Y, Choi SJ, Fujinami Y, Lu W, Yoshimura K, Oguma J, Suenobu K, Kanbara T. Direct arylation polycondensation for the synthesis of bithiophene-based alternating copolymers. Polym Chem. 2013;4:947–53.

Lu W, Kuwabara J, Kanbara T. Synthesis of 4,4′-dinonyl-2,2′-bithiazole-based copolymers via Pd-catalyzed direct C-H arylation. Polym Chem. 2012;3:3217–9.

Yamazaki K, Kuwabara J, Kanbara T. Detailed optimization of polycondensation reaction via direct C-H arylation of ethylenedioxythiophene. Macromol Rapid Commun. 2013;34:69–73.

Nohara Y, Kuwabara J, Yasuda T, Han L, Kanbara T. Two-Step direct arylation for synthesis of naphthalenediimide-based conjugated polymer. J Polym Sci Part A Polym Chem. 2014;52:1401–7.

Kuramochi M, Kuwabara J, Lu W, Kanbara T. Direct arylation polycondensation of bithiazole derivatives with various acceptors. Macromolecules. 2014;47:7378–85.

Lu W, Kuwabara J, Kuramochi M, Kanbara T. Synthesis of bithiazole-based crystalline polymers via palladium-catalyzed direct C-H arylation. J Polym Sci Part A Polym Chem. 2015;53:1396–402.

Kuwabara J, Takase N, Yasuda T, Kanbara T. Synthesis of conjugated polymers possessing diketopyrrolopyrrole units bearing phenyl, pyridyl, and thiazolyl groups by direct arylation polycondensation: effects of aromatic groups in DPP on physical properties. J Polym Sci Part A Polym Chem. 2016;54:2337–45.

Kuwabara J, Kuramochi M, Liu S, Yasuda T, Kanbara T. Direct arylation polycondensation for the synthesis of bithiazole-based conjugated polymers and their physical properties. Polym J. 2017;49:123–31.

Fujie Y, Kuwabara J, Kanbara T. Selectivity of reaction sites for direct arylation polycondensation in bithiophene derivatives. Mol Cryst Liq Cryst. 2015;622:14–18.

Chang SW, Waters H, Kettle J, Kuo ZR, Li CH, Yu CY, Horie M. Pd-catalysed direct arylation polymerisation for synthesis of low-bandgap conjugated polymers and photovoltaic performance. Macromol Rapid Commun. 2012;33:1927–32.

Kowalski S, Allard S, Scherf U. Scope and limitations of a direct arylation polycondensation scheme in the synthesis of PCPDTBT-type copolymers. Macromol Rapid Commun. 2015;36:1061–8.

Hayashi S, Koizumi T. Chloride-promoted Pd-catalyzed direct C–H arylation for highly efficient phosphine-free synthesis of π-conjugated polymers. Polym Chem. 2015;6:5036–9.

Nakabayashi K, Otsuki N, Mori H. Phosphine-free direct arylation synthesis and self-assembled nanostructure analysis of poly(3-hexylselenophene). J Polym Sci Part A Polym Chem. 2017;55:2749–55.

Lu W, Kuwabara J, Kanbara T. Synthesis of π-conjugated polymer consisting of pyrrole and fluorene units by Ru-catalyzed site-selective direct arylation polycondensation. Macromol Rapid Commun. 2013;34:1151–6.

Amaladass P, Clement JA, Mohanakrishnan AK. Pd-mediated C-H arylation of EDOT and synthesis of push-pull systems incorporating EDOT. Tetrahedron. 2007;63:10363–71.

Choi SJ, Kuwabara J, Kanbara T. Microwave-assisted polycondensation via direct arylation of 3,4-ethylenedioxythiophene with 9,9-dioctyl-2,7-dibromofluorene. ACS Sustain Chem Eng. 2013;1:878–82.

Kuwabara J, Yasuda T, Choi SJ, Lu W, Yamazaki K, Kagaya S, Han L, Kanbara T. Direct arylation polycondensation: a promising method for the synthesis of highly pure, high-molecular-weight conjugated polymers needed for improving the performance of organic photovoltaics. Adv Funct Mater. 2014;24:3226–33.

Meng H, Perepichka DF, Bendikov M, Wudl F, Pan GZ, Yu W, Dong W, Brown S. Solid-state synthesis of a conducting polythiophene via an unprecedented heterocyclic coupling reaction. J Am Chem Soc. 2003;125:15151–62.

Lennox AJJ, Lloyd-Jones GC. Selection of boron reagents for Suzuki–Miyaura coupling. Chem Soc Rev. 2014;43:412–43.

Kuwabara J, Yasuda T, Takase N, Kanbara T. Effects of the terminal structure, purity, and molecular weight of an amorphous conjugated polymer on its photovoltaic characteristics. ACS Appl Mater Interfaces. 2016;8:1752–8.

Son D, Kuwabara T, Takahashi K, Marumoto K. Direct observation of UV-induced charge accumulation in inverted-type polymer solar cells with a TiOx layer: microscopic elucidation of the light-soaking phenomenon. Appl Phys Lett. 2016;109:133301–5.

Kuwabara J, Yamazaki K, Yamagata T, Tsuchida W, Kanbara T. The effect of a solvent on direct arylation polycondensation of substituted thiophenes. Polym Chem. 2015;6:891–5.

Berrouard P, Najari A, Pron A, Gendron D, Morin PO, Pouliot JR, Veilleux J, Leclerc M. Synthesis of 5-alkyl[3,4-c]thienopyrrole-4,6-dione-based polymers by direct heteroarylation. Angew Chem Int Ed. 2012;51:2068–71.

Wakioka M, Nakamura Y, Hihara Y, Ozawa F, Sakaki S. A highly efficient catalyst for the synthesis of alternating copolymers with thieno[3,4‑c]pyrrole-4,6-dione units via direct arylation polymerization. Macromolecules. 2014;47:626–31.

Kuwabara J, Sakai M, Zhang Q, Kanbara T. Mechanistic studies and optimisation of a Pd-catalysed direct arylation reaction using phosphine-free systems. Org Chem Front. 2015;2:520–5.

Kuwabara J, Fujie Y, Maruyama K, Yasuda T, Kanbara T. Suppression of homocoupling side reactions in direct arylation polycondensation for producing high performance OPV materials. Macromolecules. 2016;49:9388–95.

Jo J, Pron A, Berrouard P, Leong WL, Yuen JD, Moon JS, Leclerc M, Heeger AJ. A new terthiophene-thienopyrrolodione copolymer-based bulk heterojunction solar cell with high open-circuit voltage. Adv Energy Mater. 2012;2:1397–403.

Iizuka E, Wakioka M, Ozawa F. Mixed-ligand approach to palladium-catalyzed direct arylation polymerization: effective prevention of structural defects using diamines. Macromolecules. 2016;49:3310–7.

Matsidik R, Komber H, Luzio A, Caironi M, Sommer M. Defect-free naphthalene diimide bithiophene copolymers with controlled molar mass and high performance via direct arylation polycondensation. J Am Chem Soc. 2015;137:6705–11.

Dudnik AS, Aldrich TJ, Eastham ND, Chang RPH, Facchetti A, Marks TJ. Tin-free direct C–H arylation polymerization for high photovoltaic efficiency conjugated copolymers. J Am Chem Soc. 2016;138:15699–709.

Saito H, Kuwabara J, Kanbara T. Facile synthesis of fluorene-based π-conjugated polymers via sequential bromination/direct arylation polycondensation. J Polym Sci Part A Polym Chem. 2015;53:2198–201.

Saito H, Chen J, Kuwabara J, Yasuda T, Kanbara T. Facile one-pot access to π-conjugated polymers via sequential bromination/direct arylation polycondensation. Polym Chem. 2017;8:3006–12.

Saito H, Kuwabara J, Yasuda T, Kanbara T. Synthesis of pyrrole-based poly(arylenevinylene)s via Rh-catalyzed dehydrogenative direct alkenylation. Polym Chem. 2016;7:2775–9.

Aoki H, Saito H, Shimoyama Y, Kuwabara J, Yasuda T, Kanbara T. Synthesis of conjugated polymers containing octafluorobiphenylene unit via Pd-catalyzed cross-dehydrogenative-coupling reaction. ACS Macro Lett. 2017;7:90–94.

Faradhiyani, A, Zhang, Q, Maruyama, K, Kuwabara, J, Yasuda, T & Kanbara, T Synthesis of bithiazole-based semiconducting polymers via Cu-catalysed aerobic oxidative coupling. Mater Chem Front. 2018. https://doi.org/10.1039/C7QM00584A

Acknowledgements

I am deeply grateful to Professor T Kanbara and the students in the laboratory for their support. I also express thanks to Dr T Yasuda, Professor K Osakada, Professor D Takeuchi, Professor Y Nishihara, Professor H Mori, and Professor S Kagaya for their technical assistance in the evaluation of semiconducting properties, elemental analyses, high-temperature gel permeation chromatography measurements, and microanalyses. This study was supported by Grant-in-Aid for Scientific Research (17K05973) and Scientific Research on Innovative Areas (17H05141).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that he has no conflict of interest.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Kuwabara, J. Direct arylation polycondensation for synthesis of optoelectronic materials. Polym J 50, 1099–1106 (2018). https://doi.org/10.1038/s41428-018-0101-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-018-0101-3

This article is cited by

-

Direct arylation polycondensation for the synthesis of medium-bandgap polymer donors (PBDB-T) for organic photovoltaics

Polymer Journal (2023)

-

Regiocontrolled synthesis of ester-functionalized polythiophenes via direct arylation polycondensation

Polymer Journal (2021)

-

Efficient synthesis of mono- and bis-arylated ethylenedioxy thiophene-based functional π-conjugated molecules via clay-supported palladium-catalysed direct arylation reactions

Research on Chemical Intermediates (2020)