Abstract

Poly(L-lactide-co-glycolide)-b-poly(ɛ-caprolactone) multiblock copolymers (PLGA-PCL MBCs) were synthesized via the self-polycondensation of PLGA-PCL diblock copolymers (PLGA-PCL DBCs) in the presence of condensation agents. PLGA-PCL DBCs were synthesized via the ring-opening copolymerization of lactide and glycolide initiated by benzyl-protected PCL in the presence of tin 2-ethylhexanoate (Sn(Oct)2) or organic catalysts (N-cyclohexyl-N’-[3,5-(trifluoromethyl)phenyl]thiourea (TU) and Tris[2-(dimethylamino)ethyl]amine (Me6TREN)). The introduction of glycolide segments hampered the formation of poly(L-lactide) (PLLA) crystals in PLGA-PCL MBCs, which was confirmed by wide-angle X-ray diffraction (WAXD) measurements. Despite the loss of crystallinity, PLGA-PCL MBCs showed better tensile strength and modulus than the PLLA-PCL random copolymer. The phase-segregated PLGA domains observed by small-angle X-ray scattering (SAXS) measurements acted as hard domains improving the tensile properties. The hydrolytic degradation of PLGA-PCL MBC in phosphate-buffered saline (PBS: pH=7.4) proceeded much faster than that of PLLA-PCL MBC. Both the loss of PLLA crystallinity and the presence of glycolide–glycolide and glycolide–lactide bonds contributed to the enhanced hydrolysis behavior of PLGA-PCL MBCs. The good tensile properties and degradation behavior in PBS expand the applicability of PLGA-PCL MBCs in biomedical applications, particularly for elastic implanting materials.

Similar content being viewed by others

Introduction

Poly(L-lactide) (PLLA) is one of the most intensively investigated biodegradable polymers.1, 2, 3, 4, 5, 6, 7 Bioabsorbable surgical sutures composed of PLLA and poly(glycolide) copolymer are good examples of the biomedical applications of PLLA. Because PLLA itself is a hard and brittle material, modifications to enhance the softness and elasticity of PLLA can broaden the applicability of biodegradable polymers in biomedical applications, particularly for implanting materials.8, 9 The introduction of soft segments such as poly(ɛ-caprolactone) (PCL) is effective at making PLLA more soft and elastic. PLLA-PCL random copolymers are commercially available and show soft and flexible properties. However, the films made from the random copolymers are extremely soft, and additional elasticity is often required for biomedical applications. The coupling of PLLA and PCL segments using coupling agents such as diisocyanates has been investigated to form multiblock copolymers of PLLA and PCL (PLLA-PCL MBCs). PLLA-PCL MBCs, in which the segregated PLLA domains act as hard segments, show good flexibility and elasticity.10, 11, 12, 13

The use of coupling agents might be harmful, limiting biomedical applications. In Jeon et al.14 first reported the synthesis of PLLA-PCL MBC without the use of any coupling agents. Dicarboxylated PLLA and PCL diols were coupled to form PLLA-PCL MBC. Recently, we reported another synthetic route to PLLA-PCL MBCs via the self-polycondensation of PLLA-PCL diblock copolymers (PLLA-PCL DBCs).15 PLLA-PCL DBC contains one carboxy group and one hydroxy group; therefore, the molar ratio of functional groups is automatically controlled to be 1:1, which is advantageous for the formation of high-molecular-weight PLLA-PCL MBCs. PLLA-PCL MBCs were used as an adhesion barrier film in rats in a preliminary study; the results suggested that the porous PLLA-PCL MBC effectively prevents adhesion. However, we also noticed that the degradation of the PLLA-PCL MBC film in rats occurs extremely slowly. The slow hydrolytic degradation of PLLA-PCL MBC has motivated us to investigate new bioabsorbable and elastic materials. One example is a bioabsorbable surgical suture composed of random copolymer of PLLA and poly(glycolide). The introduction of glycolide components enhances hydrolytic degradability in comparison with PLLA homopolymer. The ratio of lactide to glycolide was reported to affect the degradation behavior.16

Here, poly(L-lactide-co-glycolide)(PLGA)-PCL MBCs were synthesized by the self-polycondensation of PLGA-PCL DBCs in the presence of condensation agents. PLGA-PCL DBCs were synthesized using tin 2-ethylhexanoate (Sn(Oct)2) or organic catalysts. The effects of the introduction of glycolide segments on the properties of the poly(L-lactide-co-glycolide)-b-poly(ɛ-caprolactone) multiblock copolymers (PLGA-PCL MBCs) were investigated.

Experimental procedure

Materials

L-Lactide was purchased from Musashino Chemical Laboratory (Tokyo, Japan) and was purified by sublimation before use. Glycolide was purchased from Sigma-Aldrich Japan (Tokyo, Japan) and was purified by sublimation before use. ɛ-Caprolactone, benzyl alcohol, benzene, tetrahydrofuran, toluene and dichloromethane were purchased from Kanto Chemical (Tokyo, Japan) and purified by distillation. Molecular sieves 3A were purchased from Kanto Chemical and dried under vacuum at 150 °C before use. Scandium triflate (Sc(OTf)3) was purchased from Sigma-Aldrich Japan and used without further purification. Tin 2-ethylhexanoate (Sn(Oct)2) was purchased from Sigma-Aldrich Japan and purified by distillation. 1,8-Diazabicyclo[5.4.0]undec-7-ene (DBU) was purchased from Watanabe Chemical Industries (Hiroshima, Japan) and purified by distillation. N-Cyclohexyl-N’-[3,5-(trifluoromethyl)phenyl]thiourea (TU) was prepared according to a previously described procedure.17 Tris[2-(dimethylamino)ethyl]amine (Me6TREN) was purchased from Tokyo Chemical Industry (Tokyo, Japan) and purified by distillation. Palladium on activated carbon (10 wt%) was purchased from Merck Millipore (Tokyo, Japan) and used as received. 4-(Dimethylamino)pyridine (DMAP) was purchased from Kanto Chemical and used as received. N,N′-Diisopropylcarbodiimide (DIPCI) was purchased from Kokusan Chemical (Tokyo, Japan) and was used as received. 4-Dimethylaminopyridine 4-toluenesulfonate (DPTS) was prepared according to a previously described procedure.18 PCL oligomers catalyzed by Sc(OTf)3 were prepared according to a previously described procedure.15 PLLA-PCL MBC was synthesized according to a previously described procedure.15 The weight-averaged molecular weight (Mw) and molecular weight distribution (Mw/Mn) were 201 000 (mol g−1) and 2.32, respectively. The degrees of polymerization of PLLA and PCL segments in PLLA-PCL MBC were 26.8 and 27.8, respectively. PLLA-PCL MBC used for the hydrolysis test in PBS had the degrees of polymerization of PLLA and PCL segments of 31.3 and 27.1, respectively. Commercially available PLLA (Fuji Chemical, Osaka, Japan) was used as a reference polymer. The Mw and Mw/Mn were 179 000 (mol g−1) and 4.09, respectively. A random copolymer of poly(L-lactide)-co-poly(ɛ-caprolactone) was kindly donated by BMG (Kyoto Japan); the Mw and Mw/Mn were 400 000 (mol g−1) and 1.75, respectively. The molar ratio of lactide to caprolactone was 52:48. All other materials were purchased from Kanto Chemical and used as received.

Synthesis of PLGA-PCL DBC catalyzed by Sn(Oct)2

PCL oligomer (n=27.8, 1.5 g), L-lactide (1.48 g) and glycolide (0.133 g) were charged into a heat-dried Schlenk flask equipped with a nitrogen inlet. The Schlenk flask was evacuated under vacuum and purged with nitrogen. Sn(Oct)2 (5.3 μl) was added to the flask, and the mixture was stirred and heated at 100 °C for 30 min and then at 130 °C for 6 h. After the mixture cooled to room temperature, chloroform (4 ml) and five drops of acetic acid were added to the mixture. The mixture was poured into cold methanol to precipitate the product. The precipitate was recovered by filtration and dried under vacuum at room temperature. The yield of the benzyl-protected PLGA-PCL DBC (DBC-M1) was 2.47 g (79%).

DBC-M1 (2.5 g), palladium on activated carbon (0.25 g), and tetrahydrofuran (100 ml) were added to a flask equipped with a three-way stopcock. The flask was evacuated two times under vacuum and purged with nitrogen. The flask was finally evacuated and purged with hydrogen, and the mixture was stirred at room temperature for 24 h. After filtration with Celite to remove the palladium on activated carbon, the tetrahydrofuran solution was concentrated using a rotary evaporator. The concentrated tetrahydrofuran solution was poured into cold methanol. The precipitate was recovered by filtration and dried under vacuum at room temperature. The yield of deprotected DBC-M1 was 2.08 g (90%).

Synthesis of the PCL oligomer catalyzed by TU and DBU

The typical procedure for synthesizing the PCL oligomer (the target degree of polymerization of the caprolactone segment (n) was 25) catalyzed by TU and DBU is described as follows.19 ɛ-Caprolactone (5 ml), benzyl alcohol (190 μl), TU (0.9 g), benzene (20 ml) and molecular sieves 3A (ca. 30 vol%) were charged into a heat-dried Schlenk flask equipped with a nitrogen inlet. The benzene solution was shaken overnight. DBU (360 μl) in benzene (5 ml) was added to the Schlenk flask, and the mixture was shaken at room temperature. After 40 h, benzoic acid (0.56 g) was added to quench the reaction. The reaction mixture was poured into hexane, and the precipitate was collected by filtration. The crude product was dissolved in acetone and poured into NaCl aqueous solution (0.1 mol l−1). The precipitate was collected by filtration, washed with water, and dried under vacuum at 40 °C for 5 h; the yield was 5.15 g (100%). The degree of polymerization of the caprolactone segment (n), as determined by 1H NMR spectrometry, was 25.1.

Synthesis of PLGA-PCL DBC catalyzed by TU and Me6TREN

PCL oligomer (n=25.1, 2.5 g) catalyzed by TU and DBU, L-lactide (2.73 g), and glycolide (0.24 g), TU (0.39 g), dichloromethane (25 ml), and molecular sieves 3 A (~30 vol%) were charged into a heat-dried Schlenk flask equipped with a nitrogen inlet. The dichloromethane solution was shaken overnight. Me6TREN (270 μl) was added to the Schlenk flask, and the mixture was shaken at room temperature. After 6 h, the reaction mixture was poured into methanol. The precipitate was collected by filtration and dried under vacuum at room temperature overnight; the yield was 4.06 g (74%) (DBC-O1). The degree of polymerization and the ratio of lactide to glycolide are listed in Table 1.

The benzyl-protected PLGA-PCL DBCs catalyzed by organic catalysts (DBC-O1 and DBC-O2) were deprotected in the same manner as that described for DBC-M1. The yields of PLGA-PCL DBC were 3.71 g (94%) and 2.36 g (87%), respectively.

Synthesis of PLGA-PCL MBC

The typical experimental procedure for the synthesis of PLGA-PCL MBC from PLGA-PCL DBC is described as follows. In a heat-dried Schlenk flask equipped with a nitrogen inlet, DBC-M1 (2.0 g) was dissolved in dichloromethane (6 ml). DPTS (17 mg), DMAP (5 mg) and DIPCI (90 μl) were added to the solution. The reaction mixture was stirred at room temperature for 24 h. After being diluted with dichloromethane (5 ml), the reaction mixture was poured into cold methanol (150 ml). The precipitate was collected by filtration and dried under vacuum at 40 °C for 12 h; the yield was 1.97 g (97%).

Preparation and hydrolysis tests of MBC films

The MBC films were prepared on a glass plate by casting the chloroform solution of MBCs. After drying at room temperature and atmospheric pressure, the film on the glass plate was dried under vacuum at room temperature for 12 h. The film was removed from the glass plate by immersing the plate in water. The removed film was wiped and dried under vacuum at 40 °C for 12 h. The films were subjected to hydrolysis testing by immersing the films in aqueous NaOH solution (1.0 mol l−1) or PBS (pH=7.4) at 37 °C. The residual weights and contact angles of the films were averaged for two samples.

Measurements

1H and 13C NMR spectra were recorded using a JEOL JNM-ECX 500 NMR spectrometer (Tokyo, Japan). Inverse-gated decoupling 13C NMR measurements for DBCs were conducted in dimethyl sulfoxide-d6 at 30 °C. The delay time between the pulses was set to 15 s. The inherent viscosity was measured in chloroform at 30 °C at a concentration of 0.5 g dl−1. Gel permeation chromatography (GPC) measurements (Shodex KF802.5 and KF806M columns, Tokyo, Japan) were conducted using chloroform as the solvent, and the molecular weight was calculated on the basis of polystyrene standards. Wide-angle X-ray diffraction (WAXD) measurements were conducted using a RIGAKU Ultima IV X-ray diffractometer (Tokyo, Japan). Small-angle X-ray scattering (SAXS) measurements were conducted using a RIGAKU Micromax-007HF. Tensile tests were performed using a Shimadzu EZ TEST EX-LX 50N (Kyoto, Japan) with a gauge length of 30 mm and a crosshead speed of 20 mm min−1. The tensile modulus was determined by the initial maximum slope of the stress–strain curve. The thickness of the PLLA-PCL MBC and PLGA-PCL MBC films for tensile tests ranged from 30 to 50 μm. The thickness of the PLLA-PCL random copolymer film for tensile tests was approximately 60 μm. Each film was cut into test pieces (50 × 5 mm), and 10 test pieces were measured to determine the mechanical properties of each film.

Results and discussion

Synthesis of PLGA-PCL MBC

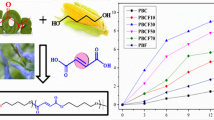

PLGA-PCL MBCs were synthesized by the self-polycondensation of PLGA-PCL DBCs, as described in Scheme 1. Benzyl-protected PLGA-PCL DBC with lactide-to-glycolide feed ratios of 9:1 was prepared via the ring-opening copolymerization of L-lactide (LA) and glycolide (GA), which was initiated by benzyl-protected PCL, in the presence of Sn(Oct)2 at 130 °C. Figure 1a shows the 1H NMR spectrum of benzyl-protected PLGA-PCL DBC (DBC-M1). The peaks from 4.9 to 4.7 p.p.m. marked with j are attributed to methylene protons originating from glycolide units. The peaks j′ and h′ are attributed to terminal units of methylene and methine protons, respectively. Other peaks are assigned to the proposed structure. The degrees of polymerization of LA and GA were calculated on the basis of the integration ratio of peak a to peak h or j, as summarized in Table 1. The composition of DBC-M1 is almost consistent with the feed molar ratio of LA to GA. The sublimation of lactide during the copolymerization was observed, which might cause the slight difference between the feed composition and the final composition.

In addition to the abovementioned method using Sn(Oct)2, PLGA-PCL DBCs were also synthesized using organic catalysts. Intensive efforts have been aimed at developing organic catalysts for the synthesis of biodegradable polymers.20, 21, 22, 23, 24, 25 The use of organic catalysts can eliminate the risk of contamination from hazardous heavy metals, which is potentially advantageous for the use of the resulting polymers in biomedical applications. In this study, benzyl-protected PCL was prepared via the ring-opening polymerization of ɛ-caprolactone in the presence of TU and DBU.19 Benzyl-protected PLGA-PCL DBCs (DBC-O1 and DBC-O2) were then prepared by the ring-opening copolymerization of LA and GA, which was initiated by benzyl-protected PCL in the presence of TU and Me6TREN.19 The degree of polymerization and the composition ratio of LA and GA were calculated on the basis of the integration ratio of the 1H NMR spectrum, similar to the case for DBC-M1. As shown in Table 1, the lactide units were more incorporated in DBC-O1 (0.94) although the feed molar ratio of lactide was 0.90. During the initial stage of copolymerization, the reaction mixture became cloudy just after the addition of Me6TREN. The cloudy solution might be attributed to the precipitation of ring-opened glycolide or its dimer, which could be eliminated during the DBC purification step. The low solubility of the glycolide components could result in the deviation between the feed ratio and the final ratio of lactide to glycolide in the DBC. Benzyl-protected PLGA-PCL DBC in the ratio of LA (0.90) and GA (0.10) (DBC-O2) was obtained when the feed ratio of LA and GA was set to be 0.85:0.15.

The microstructures of DBC-M1 and DBC-O2 were characterized by NMR measurements. The 1H NMR spectra of DBC-M1 and DBC-O2 in the region of glycolide methylene units are compared in Figure 2. The peaks at 4.75 p.p.m. (Figures 2a and b) were attributed to the methylene unit connected with caprolactone segments.26 The peaks at 4.91 p.p.m. were attributed to methylene units connected with glycolide units on both sides (G- G -G), which was a major peak in the spectrum of DBC-O2.27 In contrast to DBC-O2, many resonance peaks were observed from 4.78 to 4.95 p.p.m. in the spectrum of DBC-M1. Figure 3 shows inverse-gated 13C NMR spectra of DBC-M1 and DBC-O2 in the region of carbonyl carbons. The peaks at 172.72, 169.19 and 166.69 p.p.m. were attributed to carbonyl carbons of caprolactone (Cap- Cap -Cap), lactide (L- L -L) and glycolide (G- G -G) segments. The peak at 166.56 p.p.m. was attributed to the carbonyl carbons of glycolide units connected with lactide units (G -L).27 The peak intensity for G -L units in Figure 3a was stronger than that in Figure 3b. Both 1H and 13C NMR spectra suggest that the glycolide units in DBC-M1 are randomly connected with glycolide and lactide units. The small peak intensity for G -L units in DBC-O2 suggests that DBC-O2 contains more block-like glycolide segments in comparison with DBC-M1. The small peaks at 174.01 and 169.69 p.p.m. were attributed to carbonyl carbons of the terminal lactide unit and the lactide unit connected with caprolactone units. No peaks attributed to carbonyl carbons generated by ester exchange reactions were observed in Figures 3a and b. 13C NMR spectra of DBC-M1 and DBC-O2 in full range are provided in the Supplementary Figures 1S and 2S.

All benzyl-protected PLGA-PCL DBCs were deprotected by catalytic hydrogenation in the presence of palladium on activated charcoal.15 The PLGA-PCL DBCs were quantitatively recovered, and the removal of the benzyl group was confirmed by 1H NMR measurements.

The self-polycondensation of PLGA-PCL DBCs in the presence of condensation agents was conducted to form PLGA-PCL MBCs in the same manner as in our previous report.15 The 1H NMR spectrum of PLGA-PCL MBC synthesized from DBC-M1 (MBC-1) is shown in Figure 1b. The peak attributed to terminal lactide units (peak h′ in Figure 1a) disappeared after the self-polycondensation. The results of the synthesis of PLGA-PCL MBCs are summarized in Table 2. Both the inherent viscosities and weight-averaged molecular weights suggest the formation of high-molecular-weight multiblock copolymers. The self-polycondensation of PLGA-PCL DBCs prepared in the presence of organic catalysts (DBC-O1 and DBC-O2) also successfully proceeded to form PLGA-PCL MBCs (MBC-2 and MBC-3). The metal-free PLGA-PCL MBC prepared using organic catalysts might be advantageous for biomedical applications.

Properties of PLGA-PCL MBCs

The multiblock copolymers were examined by WAXD, as shown in Figure 4. The PLLA-PCL random copolymer showed no diffraction peaks, which implies that the random copolymer is amorphous. As previously reported, PLLA-PCL MBC primarily contains PLLA crystals.15 The diffraction peaks of the PLLA crystals disappeared for PLGA-PCL MBCs. The introduction of glycolide segments clearly hampered the formation of PLLA crystals. No noticeable difference was observed in MBC1, MBC2 and MBC3. The multiblock copolymers were also examined by SAXS, as shown in Figure 5. PLLA-PCL MBC and PLGA-PCL MBCs showed clear reflection peaks, indicating the formation of regularly ordered structures in the multiblock copolymers. PLLA-PCL MBC showed two reflection peaks, whereas PLGA-PCL MBCs showed one reflection. PLLA-PCL triblock and multiblock copolymers were previously reported to show reflections at 30.95 and 15.053 nm, respectively.14 The difference in reflection was attributed to a difference in crystalline packing. Here, the WAXD measurements clearly indicated that PLLA-PCL MBC contained PLLA crystals, while PLGA-PCL MBCs were amorphous. Therefore, the major peak at 18.397 nm in the pattern of PLLA-PCL MBC is attributed to the lamellar structure originating from the PLLA crystals. The peak at 12.042 nm in the MBC1 pattern is attributed to the ordered structure formed by the phase separation of PLGA and PCL segments. The shoulder peak observed in the pattern of PLLA-PCL MBC is also originated by the phase separated PLLA and PCL segments. The pattern of MBC2 was slightly different from the patterns of MBC1 and MBC3 in the lamellar structural region. The high content of PLLA segments and the microstructure of MBC2 could contribute the difference. No reflections were observed for the PLLA-PCL random copolymer, which implies the absence of a regularly ordered structure. The DSC measurement of MBC1 also suggested the phase separation of the PLGA and PCL domains (Supplementary Figure 3S). The glass transition temperatures of the PCL and PLLA homopolymers are −60 and 60 °C, respectively. The DSC curve of MBC1 showed two glass transition at −46 and 60 °C. Small exothermic and endothermic peaks attributed to the crystallization of the PLLA segments in MBC1 were also observed during the heating scan. Therefore, these two glass transitions suggested phase separation in MBC1.

The mechanical properties of the multiblock copolymers were evaluated via the tensile testing of thin films. Typical stress–strain curves are shown in Figure 6, and the tensile properties are summarized in Table 3. All copolymers showed much larger elongation at break than PLLA due to the introduction of the PCL segments. The multiblock copolymers showed larger tensile strengths and moduli than the PLLA-PCL random copolymer. The PLLA-PCL MBCs exhibited higher tensile moduli than PLGA-PCL MBCs. The crystalline segments in PLLA-PCL MBC contributed to the high tensile modulus values. Despite their amorphous nature, the tensile strengths and moduli of PLGA-PCL MBCs were better than those of PLLA-PCL random copolymers. The tensile properties of MBC1, MBC2, and MBC3 were quite similar. Similar to thermoplastic elastomers, the PLGA domains formed via the phase separation of PLGA and PCL segments, which acted as the hard domains, likely contributed to the enhanced tensile properties.

We previously reported that the rate of hydrolytic degradation in aqueous NaOH (1.0 mol l−1) is qualitatively ordered as PLLA-PCL MBC<PLLA-PCL random<PLLA.15 The introduction of hydrophobic PCL segments and PLLA crystals in PLLA-PCL MBC can retard the hydrolysis. Hydrolysis tests of PLGA-PCL MBCs in aqueous NaOH (1.0 mol l−1) and in PBS (pH=7.4) were conducted to evaluate the effect of the introduction of glycolide segments on the degradability of multiblock copolymers. Figure 7 shows the degradation behavior of MBC1, MBC2, MBC3 and PLLA-PCL MBC films in aqueous NaOH (1.0 mol l−1). All MBC films exhibited decreases in contact angle within the first few hours. The PLGA-PCL MBC films showed rapid decreases in contact angle compared with the PLLA-PCL MBC films. After the initial decrease in contact angle, the surface-hydrolyzed MBC films showed contact angles between 20° and 30°. The hydrolytic degradation in PBS (pH=7.4) was also examined for PLLA, PLLA-PCL MBC, PLGA-PCL MBC (LA:GA=0.93:0.07) and PLLA-PCL random copolymers (Figure 8). After gradual weight loss, the PLGA-PCL MBC and PLLA-PCL random copolymer films broke into small pieces after 11 (PLGA-PCL MBC) and 6 (random) weeks, whereas the PLLA-PCL MBC and PLLA films retained their original shapes after 12 weeks of hydrolysis. The PLLA-PCL MBC film did not exhibit a weight loss or decrease in contact angle, which implies that the hydrolysis of the PLLA-PCL MBC film in PBS was extremely slow. PLLA showed a weight loss in the early stage but no change in contact angle during the hydrolysis, although the PLLA film was initially amorphous under the experimental conditions. As observed for PLLA-PCL MBC films in aqueous NaOH,15 the contact angle of the PLGA-PCL MBC film gradually decreased during hydrolysis in PBS. The results indicate that the hydrolytic degradation of PLGA-PCL MBC proceeded much faster than that of PLLA-PCL MBC in PBS. Both the loss of PLLA crystallinity and the presence of glycolide–glycolide and glycolide–lactide bonds contributed to the enhanced hydrolysis behavior of PLGA-PCL MBC. It was reported that the crystallization of PLLA segments occurs during the hydrolysis in PBS.28, 29 The crystallization of PLLA segments during the hydrolysis was also reported for poly(D,L-lactic-co-glycolic acid).30 Therefore, the possibility of crystallization of PLLA segments in PLGA-PCL MBC cannot be excluded, although PLGA-PCL MBC is amorphous at the beginning of the hydrolysis test. We also preliminarily observed that the low-molecular-weight PLGA-PCL MBC showed more enhanced hydrolysis behavior. The crystallization behavior and the effect of the molecular weight of PLGA-PCL MBC on hydrolysis in PBS will be reported in the near future.

It should be noted that no noticeable differences in tensile properties and hydrolytic degradation behavior were observed for MBC1 and MBC3, although the difference in microstructure was observed for the corresponding DBCs. The small amount of glycolide units in PLGA-PCL MBCs simply hampered the formation of PLLA crystals, which resulted in the lower tensile modulus and faster hydrolysis in comparison with PLLA-PCL MBC. The difference in microstructure could influence the properties if more glycolide units are introduced to the DBC.

Conclusions

PLGA-PCL DBCs were synthesized via the ring-opening copolymerization of lactide and glycolide initiated by benzyl-protected PCL in the presence of Sn(Oct)2 or organic catalysts (TU and Me6TREN). The introduction and microstructure of MBCs were confirmed by 1H and 13C NMR measurements. Both 1H and 13C NMR spectra suggest that DBC-O2 synthesized using organic catalysts contains more block-like glycolide segments than DBC-M1 synthesized using Sn(Oct)2. PLGA-PCL MBCs were successfully synthesized via the self-polycondensation of PLGA-PCL DBC in the presence of condensation agents. The introduction of glycolide segments hampered the formation of PLLA crystals in PLGA-PCL MBCs, which was confirmed by WAXD measurements. Despite the loss of crystallinity, PLGA-PCL MBCs showed better tensile properties than the PLLA-PCL random copolymer. The phase-segregated PLGA domains observed by SAXS measurements acted as hard domains, improving the tensile properties. Hydrolytic degradation in alkaline NaOH solution was improved by the introduction of glycolide segments. Moreover, PLGA-PCL MBC was hydrolytically degraded in PBS (pH=7.4). Both the loss of PLLA crystallinity and the presence of glycolide–glycolide and glycolide–lactide bonds contributed to the enhanced hydrolysis behavior of PLGA-PCL MBC. The good tensile properties and degradation behavior in PBS broaden the applicability of PLGA-PCL MBCs for biomedical applications, especially as elastic implanting materials.

Synthesis of PLGA-PCL multiblock copolymer.

References

Dorgan, J. R., Braun, B., Wegner, J. R. & Knauss, D. M. Poly(lactic acids): a brief review. ACS Symp. Ser. 939, 102–125 (2006).

Drumright, R. E., Gruber, P. R. & Henton, D. E. Polylactic acid technology. Adv. Mater. 12, 1841–1846 (2000).

Madhavan Nampoothiri, K., Nair, N. R. & John, R. P. An overview of the recent developments in polylactide (pla) research. Bioresour. Technol. 101, 8493–8501 (2010).

Gunatillake, P.A. & Adhikari, R. Biodegradable synthetic polymers for tissue engineering. Eur. Cells Mater. 5, 1–16 (2003).

Garlotta, D. A literature review of poly(lactic acid). J. Polym. Environ. 9, 63–84 (2002).

Tsuji, H. Poly(lactide) stereocomplexes: formation, structure, properties, degradation, and applications. Macromol. Biosci. 5, 569–597 (2005).

Ikada, Y. & Tsuji, H. Biodegradable polyesters for medical and ecological applications. Macromol. Rapid Commun. 21, 117–132 (2000).

Shi, R., Chen, D., Liu, Q., Wu, Y., Xu, X., Zhang, L. & Tian, W. Recent advances in synthetic bioelastomers. Int. J. Mol. Sci. 10, 4223–4256 (2009).

Li, Y., Thouas, G. A. & Chen, Q.-Z. Biodegradable soft elastomers: synthesis/properties of materials and fabrication of scaffolds. RSC Adv. 2, 8229–8242 (2012).

Zhang, J., Xu, J., Wang, H., Jin, W. & Li, J. Synthesis of multiblock thermoplastic elastomers based on biodegradable poly (lactic acid) and polycaprolactone. Mater. Sci. Eng. C 29, 889–893 (2009).

Nakayama, Y., Okuda, S., Yasuda, H. & Shiono, T. Synthesis of multiblock poly(l-lactide)-co-poly(ɛ-caprolactone) from hydroxy-telechelic prepolymers prepared by using neodymium tetrahydroborate. React. Funct. Polym. 67, 798–806 (2007).

Nagata, M. & Sato, Y. Synthesis and properties of photocurable biodegradable multiblock copolymers based on poly(ɛ-caprolactone) and poly(l-lactide) segments. J. Polym. Sci. A Polym. Chem. 43, 2426–2439 (2005).

Cohn, D. & Salomon, A. H. Designing biodegradable multiblock PCL/PLA thermoplastic elastomers. Biomaterials 26, 2297–2305 (2005).

Jeon, O., Lee, S.-H., Kim, S. H., Lee, Y. M. & Kim, Y. H. Synthesis and characterization of poly(l-lactide)−poly(ɛ-caprolactone) multiblock copolymers. Macromolecules 36, 5585–5592 (2003).

Jikei, M., Takeyama, Y., Yamadoi, Y., Shinbo, N., Matsumoto, K., Motokawa, M., Ishibashi, K. & Yamamoto, F. Synthesis and properties of poly(l-lactide)-poly(εcaprolactone) multiblock copolymers by the self-polycondensation of diblock macromonomers. Polym. J. 47, 657–665 (2015).

Miller, R. A., Brady, J. M. & Cutright, D. E. Degradation rates of oral resorbable implants (polylactates and polyglycolates): Rate modification with changes in PLA/PGA copolymer ratios. J. Biomed. Mater. Res. 11, 711–719 (1977).

Pratt, R. C., Lohmeijer, B. G. G., Long, D. A., Lundberg, P. N. P., Dove, A. P., Li, H., Wade, C. G., Waymouth, R. M. & Hedrick, J. L. Exploration, optimization, and application of supramolecular thiourea-amine catalysts for the synthesis of lactide (co)polymers. Macromolecules 39, 7863–7871 (2006).

Moore, J. S. & Stupp, S. I. Room temperature polyesterification. Macromolecules 23, 65–70 (1990).

Lohmeijer, B. G. G., Pratt, R. C., Leibfarth, F., Logan, J. W., Long, D. A., Dove, A. P., Nederberg, F., Choi, J., Wade, C., Waymouth, R. M. & Hedrick, J. L. Guanidine and amidine organocatalysts for ring-opening polymerization of cyclic esters. Macromolecules 39, 8574–8583 (2006).

Dove, A. P. Organic catalysis for ring-opening polymerization. ACS Macro Lett. 1, 1409–1412 (2012).

Kamber, N. E., Jeong, W., Waymouth, R. M., Pratt, R. C., Lohmeijer, B. G. G. & Hedrick, J. L. Organocatalytic ring-opening polymerization. Chem. Rev. 107, 5813–5840 (2007).

Kadota, J., Pavlovic̀, D. E., Desvergne, J.-P., Bibal, B., Peruch, F. D. R. & Deffieux, A. Ring-opening polymerization ofl-lactide catalyzed by an organocatalytic system combining acidic and basic sites. Macromolecules 43, 8874–8879 (2010).

Kiesewetter, M. K., Shin, E. J., Hedrick, J. L. & Waymouth, R. M. Organocatalysis: opportunities and challenges for polymer synthesis. Macromolecules 43, 2093–2107 (2010).

Makiguchi, K., Ogasawara, Y., Kikuchi, S., Satoh, T. & Kakuchi, T. Diphenyl phosphate as an efficient acidic organocatalyst for controlled/living ring-opening polymerization of trimethylene carbonates leading to block, end-functionalized, and macrocyclic polycarbonates. Macromolecules 46, 1772–1782 (2013).

Ottou, W. N., Sardon, H., Mecerreyes, D., Vignolle, J. & Taton, D. Update and challenges in organo-mediated polymerization reactions. Prog. Polym. Sci. 56, 64–115 (2016).

Kasperczyk, J. Copolymerization of glycolide and ɛ-caprolactone, 1, analysis of the copolymer microstructure by means of 1H and 13C NMR spectroscopy. Macromol. Chem. Phys. 200, 903–910 (1999).

Kasperczyk, J. Microstructural analysis of poly[(l,l-lactide)-co-(glycolide)] by 1H and 13C n.m.r. spectroscopy. Polymer 37, 201–203 (1996).

Cam, D., Hyon, S.-H. & Ikada, Y. Degradation of high molecular weight poly(l-lactide) in alkaline medium. Biomaterials 16, 833–843 (1995).

Malin, M., Hiljanen-Vainio, M., Karjalainen, T. & Seppälä, J. Biodegradable lactone copolymers. Ii. Hydrolytic study of ɛ-caprolactone and lactide copolymers. J. Appl. Polym. Sci. 59, 1289–1295 (1996).

Park, T. G. Degradation of poly(lactic-co-glycolic acid) microspheres: effect of copolymer composition. Biomaterials 16, 1123–1130 (1995).

Acknowledgements

This work is partially supported by the Adaptable and Seamless Technology Transfer Program through target-driven R&D (A-Step), JST Japan. We appreciate Prof Go Matsuba (Yamagata University) for the assistance of SAXS measurements.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Jikei, M., Suga, T., Yamadoi, Y. et al. Synthesis and properties of poly(L-lactide-co-glycolide)-b-Poly(ɛ-caprolactone) multiblock copolymers formed by self-polycondensation of diblock macromonomers. Polym J 49, 369–375 (2017). https://doi.org/10.1038/pj.2016.126

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2016.126