Abstract

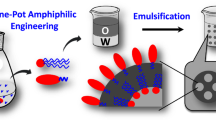

Nanoemulsions are useful as drug carriers. Conjugating targeting molecules to nanoemulsions would expand their application to the cell-specific delivery of drugs. Click reactions, such as the Cu (I)-catalyzed azide-alkyne 1,3-dipolar cycloaddition (CuAAC) reaction, are a convenient tool for such functionalization as the conjugation of label or targeting molecules. In this study, we sought to synthesize siloxane-based amphiphilic polymers containing alkyne moieties to form nanoemulsions capable of conjugating azide-functionalized labels by the CuAAC reaction. The siloxane-based homopolymer (P1) and copolymer with polydimethylsiloxane (P2) containing chloropropyl groups were reacted with an imidazole derivative that had an ethynyl group at the 1-position to generate PIm1 and PIm2, respectively. PIm1 and PIm2 exhibited good solubility in polar solvents such as methanol, dimethylformamide, dimethyl sulfoxide and H2O. Further, PIm2 exhibited solubility in chloroform and dichloromethane. Azide-functionalized fluorescent dyes and green fluorescent proteins were conjugated with PIm1 and PIm2 by the CuAAC reaction. The labeled polymer emulsified soybean oil in water to form emulsions. The average emulsion size was 150 nm. The fluorescent labels on the emulsions were successfully observed with a fluorescent microscope. Conjugation of PIm1 and PIm2 with targeting molecules by the click reaction would be useful for cell-specific drug delivery.

Similar content being viewed by others

Introduction

Nanoemulsions, which are submicron-sized emulsions formed by dispersing an oil phase with amphiphilic molecules such as surfactants in an aqueous phase, have gained increasing attention as drug carriers for medical and pharmaceutical fields for application as parenteral, oral or topical formulations.1 Particularly, nanoemulsions are advantageous for delivery of lipophilic anticancer drugs because the oil phase of the emulsions solubilizes lipophilic drugs, significantly enhancing solubility of the drugs over that in an aqueous solution.1

For medical applications, emulsions must be physically stable. However, emulsions are a thermodynamically unstable system that may lead to aggregation, flocculation, coalescence and eventual phase separation with time.2 Thus, physical stability is an important requisite in formulating emulsions. Many factors are known to affect the stability of emulsions, such as particle size, surface charge and surface tension.3

Poly(dimethylsiloxane) is by far the most common silicone polymer in both medical and nonmedical fields because of its high thermal and oxidative stability, biological compatibility and chemical inactivity.4, 5 For example, poly(dimethylsiloxane) is therapeutically used as an antifoaming agent6 and antiflatulent.7 Amphiphilic polysiloxane copolymers consisting of hydrophobic and hydrophilic siloxane derivatives have been widely used as surfactants.8 In particular, polysiloxanes modified with quaternary ammonium groups, which have great capacity for lower surface tension, have been synthesized.9, 10, 11 The formation of nanoaggregates by amphiphilic polysiloxanes has also been reported.12, 13 Photosensitive micelles have also been developed using amphiphilic azo-polysiloxanes.14, 15 The capability of micelle formation has been attributed to the flexibility of the polysiloxane main chain that permits the arrangement of hydrophilic and hydrophobic groups on both sides of the polymeric chain. Further, polymersomes based on poly-(dimethylsiloxane)-poly(2-methyloxazoline) block copolymers have been demonstrated as efficient drug delivery vehicles to cells.16, 17, 18

Target cell-specific binding and delivery are desired for drug carriers. In targeted delivery, targeting ligands should be easily and specifically attached to the surface of drug carriers. Click ligation is ideal for this purpose because the reaction can effectively proceed under physiological conditions without interfering with native functional groups on the targeting molecules. The copper-catalyzed azide-alkyne cycloaddition (CuAAC) reaction has most frequently been utilized for click ligation.19, 20 ‘Clickable’ micelles have been developed by introducing azide or alkyne groups through cross-linking after micelle formation.21, 22 Amphiphilic polymers at the end of which an azide or alkyne group is introduced have been synthesized to form ‘clickable’ polymersomes.23, 24 Alkyne-functionalized polymersomes based on poly-(dimethylsiloxane)-poly(2-methyloxazoline) block copolymers have also been developed, conjugated with a polyguanylic acid ligand by click ligation and successfully delivered to macrophage cells overexpressing a scavenger receptor.18 In these polymers, the alkyne groups were introduced at the ends of their hydrophilic blocks. Compared with such end-functionalized block copolymers, functionalization in the side chains of a polymer backbone enables conjugation of targeting molecules in high density, thereby enhancing interaction with target cells. Quaternization reactions have been employed to introduce hydrophilic parts to polysiloxanes,9, 10, 11, 14, 15 which inspired us to also utilize these reactions to introduce alkyne functionality to the polymer backbone. In addition, imidazolium-based polymerized ionic liquids have been shown to possess high binding ability to DNA suitable for gene delivery.25 Similarly, polysiloxanes modified with imidazolium salts should also be useful as a gene delivery vector. Therefore, we employed an imidazole derivative for a quaternization reaction to produce imidazolium salts.

In this study, we synthesized amphiphilic polysiloxane copolymers with alkyne-functionalized and quaternized imidazolium salts. Azide-functionalized fluorescent dyes and green fluorescent proteins were attached to the polymers by the CuAAC reaction. The labeled polymers emulsified soybean oil to form emulsions with a diameter of 150 nm. The fluorescence of the labels was successfully observed with a fluorescent microscope.

Experimental Procedure

Materials

N-(4-Bromobenzyl)imidazole and 4-bromobenzylbromide were prepared as previously reported.26 Tetrahydrofuran, diethyl ether and toluene (Kanto Chemical, Tokyo, Japan) were used after distillation over sodium. Dimethyl sulfoxide (Kanto Chemical) was used after distillation over calcium hydride. Imidazole (Nacalai Tesque, Kyoto, Japan), potassium hydroxide, triphenylphosphine, triethylamine, sodium hydroxide (Kanto Chemical), 1-butyn-3-methyl-3-ol, copper (I) iodide, soybean oil, Nile red (Wako Pure Chemical Industries, Osaka, Japan), 4-bromobenzylbromide, bis(triphenylphosphine)palladium (II) dichloride, 3-chloropropylmethyldichlorosilane, tetramethylammonium hydroxide solution in methanol and dichlorodimethylsilane (Tokyo Chemical Industry, Tokyo, Japan), tris[(1-benzyl-1-H-1,2,3-triazol-4-yl)methyl]amine, tetrakis(acetonitrile)copper (I) hexafluorophosphate (TACH, Sigma-Aldrich Japan, Tokyo, Japan), Alexa Fluor 488 azide, Cy3 azide and 3-(azidotetra(ethyleneoxy))propionic acid succinimidyl ester (Life Technologies, Carlsbad, CA, USA) were commercially available and used as received.

Preparation of azide-functionalized green fluorescent protein

A cysteine-free green fluorescent protein variant (cfSGFP2) was expressed in Escherichia coli DH5α cells and purified as previously reported.27 The expression plasmid for cfSGFP2 was a generous gift from Professor Ikuo Wada (Fukushima Medical University). An azide group was introduced to the N-terminal amino group of cfSGFP2 by incubating 0.4 mM cfSGFP2 and 10 mM 3-(azidotetra(ethyleneoxy))propionic acid succinimidyl ester in 100 mM sodium phosphate buffer (pH 7.2) containing 0.15 M NaCl (phosphate-buffered saline) for 1 h at ambient temperature. The unreacted succinimidyl ester was removed by dialysis against phosphate-buffered saline overnight.

Measurements

1H and 13C nuclear magnetic resonance (NMR) spectra were recorded on a Bruker AVANCE 400F spectrometer (Ettlingen, Germany) in deuterated chloroform (CDCl3) or dimethyl sulfoxide ((CD3)2SO) at ambient temperature. Infrared (IR) spectra were measured on a Perkin-Elmer Spectrum One Fourier transform-IR spectrometer (Waltham, MA, USA). The melting temperature and glass transition temperature (Tg) were determined by differential scanning calorimetry (DSC) on a Rigaku ThermoPlus DSC 8230 (Tokyo, Japan) at a heating rate of 10 °C min−1 under a nitrogen flow rate of 10 ml min−1. Number-average and weight-average molecular weights were estimated by size-exclusion chromatography on a Showa Denko Shodex GPC-101 system (Tokyo, Japan) with polystyrene gel columns (a pair of Shodex GPC LF-804) using tetrahydrofuran as a mobile phase and polystyrene as molecular weight standards. Gas chromatography–mass spectroscopy was conducted using an Agilent 6890/5973 instrument (Santa Clara, CA, USA). The fluorescent behavior of the emulsions was visualized with an Olympus Inverted microscope IX71 (Tokyo, Japan) with excitation at 488 nm (Alexa Fluor 488 and cfSGFP2) or 550 nm (Cy3 and Nile red).

Synthesis of N-(4-[3-hydroxy-3-methyl-1-butynyl]benzyl)imidazole (2)

Under a dry argon atmosphere, N-(4-bromobenzyl)imidazole (1) (1.8 g, 7.6 mmol), bis(triphenylphosphine)palladium dichloride (270 mg, 0.38 mmol), triphenylphosphine (50 mg, 1.9 mmol), 1-butyn-3-methyl-3-ol (1.2 ml, 12 mmol) and triethylamine (1.6 ml) in 50 ml of tetrahydrofuran were stirred at ambient temperature for 20 min.28 In addition, copper (I) iodide (18 mg, 97 μmol) was added to the reaction mixture, and the resulting mixture was stirred for 24 h at 70 °C. The reaction mixture was filtered through celite and the filtrate was evaporated under reduced pressure. The residue was dissolved in chloroform. The resulting chloroform solution was washed with a saturated sodium chloride aqueous solution several times, dried over anhydrous sodium sulfate and filtered. The filtrate was concentrated under reduced pressure and purified by silica gel chromatography eluted with a mixed solvent of chloroform/methanol (v/v=16:1). The collected fraction (Rf value of 0.46) was concentrated under reduced pressure, and the residue was recrystallized from a mixed solvent of chloroform and hexane to afford 2 as white crystals with an yield of 1.20 g (66%). 1H NMR (CDCl3, 400 MHz): δ(p.p.m.)=7.55 (s, 1H, imidazole proton), 7.36 (d, J=8.3, 2H, phenyl protons), 7.10 (s, 1H, imidazole proton), 7.04 (d, J=8.4, 2H, phenyl protons), 6.87 (s, 1H, imidazole proton), 5.09 (s, 2H, Ph-CH2-imidazole), 3.33 (br s, 1H, -OH), 1.62 (s, 6H, -CH3). 13C NMR (CDCl3, 100 MHz): δ(p.p.m.)=137.4, 136.0, 132.2, 129.8, 127.1, 123.0, 119.3, 95.0, 81.1, 65.3, 50.5, 31.5. IR (KBr, cm−1): 3350 (-OH).

Synthesis of N-(4-ethynylbenzyl)imidazole (3)

Under a dry argon atmosphere, a solution of compound 2 (1.2 g, 5.0 mmol) in 25 ml of toluene was added to sodium hydroxide (0.19 g, 4.8 mmol) and the suspension was refluxed for 20 h. The reaction mixture was poured into water and extracted with chloroform. The combined organic layer was washed with brine several times, dried over anhydrous sodium sulfate and filtered. The filtrate was concentrated under reduced pressure and purified by silica gel chromatography eluted with a mixed solvent of chloroform/methanol (v/v=16:1). The collected fraction (Rf value of 0.57) was concentrated under reduced pressure, and the residue was recrystallized from a mixed solvent of chloroform and hexane to afford 3 as white crystals with an yield of 0.74 g (82%). 1H NMR (CDCl3, 400 MHz): δ(p.p.m.)=7.56 (s, 1H, imidazole proton), 7.48 (d, J=8.2, 2H, phenyl protons), 7.10 (d, J=8.2, 2H, phenyl protons), 7.06 (s, 1H, imidazole proton), 6.89 (s, 1H, imidazole proton), 5.12 (s, 2H, Ph-CH2-imidazole), 3.09 (s, 1H, -CH). 13C NMR (CDCl3, 100 MHz): δ(p.p.m.)=137.0, 136.3, 132.2, 129.5, 126.6, 121.6, 116.7, 82.3, 77.5, 49.9. IR (KBr, cm−1): 3200 (alkyne C-H), 2100 (alkyne C-C).

Synthesis of cyclic oligomer (CP1)

Under a dry argon atmosphere, 3-chloropropyldichloromethylsilane (6.0 ml, 38 mmol) in 36 ml of diethyl ether was added dropwise to water (36 ml) at 0 °C.29 The mixture was stirred for 24 h at ambient temperature. The reaction mixture was extracted with ethyl acetate. The combined organic layer was washed with a saturated sodium hydrogen carbonate aqueous solution several times, dried over anhydrous sodium sulfate and filtered. The filtrate was concentrated under reduced pressure to form a colorless liquid with an yield of 4.7 g (91%). 1H NMR (CDCl3, 400 MHz): δ(p.p.m.)=3.53 (m, 2H, Si(CH2)2CH2Cl), 1.83 (m, 2H, SiCH2CH2-), 0.72 (m, 2H, SiCH2-), 0.12 (m, 3H, SiCH3). 13C NMR (CDCl3, 100 MHz): δ(p.p.m.)=47.6, 26.4, 14.6, −0.5. IR (NaCl, cm−1): 1080 (Si-O).

Synthesis of homopolymer (P1)

Under a dry argon atmosphere, five drops of tetramethylammonium hydroxide (10% methanol solution) were added to CP1 (5.2 g, 38 mmol) and the mixture was stirred for 4 h at 60 °C. The reaction mixture was dissolved in a small amount of chloroform and poured into methanol (150 ml) to isolate the corresponding polymer as colorless precipitates with an yield of 4.0 g (78%). 1H NMR (CDCl3, 400MH): δ(p.p.m.)=3.51 (m, 2H, Si(CH2)2CH2Cl), 1.78 (m, 2H, SiCH2CH2-), 0.67 (m, 2H, SiCH2-), 0.12 (m, 3H, SiCH3). 13C NMR (CDCl3, 100 MHz): δ(p.p.m.)=47.6, 26.7, 15.0, 0.3. IR (NaCl, cm−1): 1080 (Si-O).

Synthesis of quaternized homopolymer (PIm1)

In a 10-ml recovery flask, P1 (0.15 g, 1.5 mmol) and N-(4-ethynylbenzyl) imidazole (3) (0.44 g, 2.4 mmol) were dissolved in 1.8 ml of dimethyl sulfoxide, and the flask was sealed. After degassing via three freeze-thaw cycles, the mixture was stirred for 4 days at 80 °C under a vacuum. The reaction mixture was dissolved in a small amount of methanol and poured into diethyl ether to isolate the corresponding quaternized polymer as brown precipitates with an yield of 0.33 g (89%). 1H NMR ((CD3)2SO, 400 MHz): δ(p.p.m.)=10.29 (s, 1H, imidazole proton), 8.23 (s, 1H, imidazole proton), 8.04 (s, 1H, imidazole proton), 7.52 (d, J=7.6, 2H, phenyl protons), 7.40 (d, J=7.5, 2H, phenyl protons), 5.60 (s, 2H, benzyl protons), 4.33 (s, 2H, Si(CH2)2CH2-), 4.17 (s, 1H, alkynyl proton), 1.76 (s, 2H, SiCH2CH2-), 0.38 (s, 2H, SiCH2-), 0.10 (s, 3H, SiCH3). 13C NMR (CDCl3, 100 MHz): δ(p.p.m.)=135.8, 132.1, 132.0, 128.7, 122.9, 122.3, 122.0, 82.7, 81.7, 51.1, 41.2, 23.6, 13.3, −0.8. IR (NaCl, cm−1): 3290 (alkyne C-H), 2100 (alkyne C-C), 1080 (Si-O).

Synthesis of cyclic co-oligomer (CP2)

Under a dry argon atmosphere, 3-chloropropyldichloromethylsilane (4.1 ml, 26 mmol) and dichlorodimethylsilane (3.1 ml, 26 mmol) in 13 ml of diethyl ether were added dropwise to water (20 ml) at 0 °C. The mixture was stirred for 24 h at ambient temperature. The reaction mixture was extracted with ethyl acetate. The combined organic layer was washed with a saturated sodium hydrogen carbonate aqueous solution several times, dried over anhydrous sodium sulfate and filtered. The filtrate was concentrated under reduced pressure and obtained as a colorless liquid with an yield of 5.25 g (96%). 1H NMR (CDCl3, 400 MHz): δ(p.p.m.)=3.54 (m, 2H, Si(CH2)2CH2), 1.81 (m, 2H, -SiCH2CH2-), 0.65 (m, 2H, -SiCH2-), 0.09 (m, 9H, SiCH3). 13C NMR (CDCl3, 100 MHz): δ(p.p.m.)=47.6, 14.6, 13.4, 0.7, −0.7. IR (NaCl, cm−1): 1079 (Si-O).

Synthesis of random copolymer (P2)

P2 was prepared by a similar method as P1 but using CP2 (5.3 g, 25 mmol). P2 was obtained as brown precipitates with an yield of 2.32 g (45%). The spectral data are shown below. 1H NMR (CDCl3, 400 MHz): δ(p.p.m.)=3.50 (m, 2H, Si(CH2)2CH2), 1.80 (m, 2H, -SiCH2CH2-), 0.64 (m, 2H, -SiCH2-), 0.09 (m, 9H, SiCH3). 13C NMR (CDCl3, 100 MHz): δ(p.p.m.)=47.3, 26.4, 14.7, 0.8, −0.8. IR (NaCl, cm−1): 1080 (Si-O).

Synthesis of quaternized copolymer (PIm2)

PIm2 was prepared by a similar method as PIm1 but using P2 (5.3 g, 25 mmol) and 3. PIm2 was obtained as brown precipitates with an yield of 2.32 g (45%). The spectral data are shown below. 1H NMR ((CD3)2SO, 400 MHz): δ(p.p.m.)=9.7 (br, 1H, imidazole proton), 7.90 (m, 1H, imidazole proton), 7.80 (m, 1H, imidazole proton), 7.47 (m, 4H, phenyl protons), 5.50 (s, 2H, benzyl protons), 4.24 (s, 1H, alkynyl proton), 4.16 (s, 2H, Si(CH2)2CH2N-), 3.53 (s, 2H, Si(CH2)2CH2Cl), 1.71 (m, 4H, SiCH2CH2-), 0.58 (s, 2H, SiCH2(CH2)2Cl, 0.39 (s, 2H, SiCH2(CH2)2N-), 0.03 (s, 12H, SiCH3). 13C NMR (CDCl3, 100 MHz): δ(p.p.m.)=136.7, 135.9, 132.4, 128.8, 122.9, 122.9, 122.3, 83.0, 81.9, 51.6, 47.8, 47.8, 26.4, 23.8, 14.5, 13.5, 1.1, −0.6, −0.6. IR (NaCl, cm−1): 3290 (alkyne C-H), 1080 (Si-O).

The CuAAC reaction and preparation of emulsions

For conjugation with Cy3, PIm1 (9.8 nmol), the azide derivative of Cy3 (20 nmol), tris[(1-benzyl-1-H-1,2,3-triazol-4-yl)methyl]amine (50 nmol) and TACH (5.0 nmol) were added to 0.15 ml of deionized water/dimethyl sulfoxide (v/v=3:1), and the mixture was stirred for 6 h at 27 °C. The conjugation with Alexa Fluor 488 was carried out similarly, except that the reaction mixture was incubated with DE-52 anion-exchange resin in 20 mM Tris–HCl buffer (pH 7.2) for 12 h at ambient temperature three times after the CuAAC reaction to remove unreacted label molecules. Deionized water (1.0 ml) and soybean oil (5.0 μl) were added to the reaction mixture and ultrasonicated for 30 min. The emulsion solution was dialyzed against a 0.55-mM solution of EDTA in deionized water overnight and concentrated by Amicon Ultra-4 Centrifugal Filter Units (molecular weight cutoff: 100 kDa, Merck Millipore, Billerica, MA, USA). For conjugation with cfSGFP2, PIm1 (9.8 nmol), the azide derivative of cfSGFP2 (20 nmol), tris[(1-benzyl-1-H-1,2,3-triazol-4-yl)methyl]amine (50 nmol) and TACH (5.0 nmol) were added to 0.15 ml of 20 mM Tris–HCl buffer (pH 7.0) containing 25% v/v dimethyl sulfoxide and 20% v/v glycerol, and the mixture was stirred for 6 h at ambient temperature. The reaction mixture was dialyzed against a 0.55-mM solution of EDTA in deionized water overnight. Deionized water (1.0 ml) and soybean oil (5.0 μl) were added to the dialyzed reaction mixture and ultrasonicated for 30 min. The emulsion solution was concentrated by centrifuging the solution at 2000 g for 15 min and collecting the emulsion phase in the upper part of the solution. The emulsion fraction was added to 0.5 ml of water and centrifuged again. This concentration process was repeated three times. The CuAAC reactions of PIm2 (16 nmol, 2.9 nmol equiv. of alkyne) and the azide derivatives (5.7 nmol) and preparation of emulsions were also carried out similarly. For the encapsulation of Nile red in the emulsions, soybean oil was mixed with an equal volume of acetone containing 5.62 mg ml−1 of Nile red, and this mixture was used for emulsion formation.

Measurements of average size

Average size distributions of the PIm1 and PIm2 emulsions were estimated by dynamic light scattering using a particle size analyzer (SZ-100, Horiba, Kyoto, Japan) at 25 °C. Scattered light intensity was detected at 90° relative to the incident beam.

Results and Discussion

Synthesis of the polymers

Scheme 1 shows the synthetic pathways for P1 and P2. P1 and P2 were obtained via the anionic ring-opening polymerization of CP1 and CP2, respectively, using tetramethylammonium hydroxide (10% methanol solution) as the initiator.29 CP1 was obtained from 3-chloropropyldichloromethylsilane, and CP2 was obtained from dichlorodimethylsilane and 3-chloropropyldichloromethylsilane via hydrolysis and cyclization reactions.

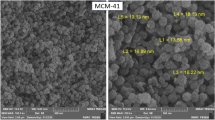

1H and 13C NMR and IR spectroscopy confirmed the structure of P1 and P2. The results of the anionic ring-opening polymerization of CP1 and CP2 are summarized in Table 1. P1 and P2 were soluble in common organic solvents such as tetrahydrofuran, chloroform, dichloromethane and toluene. The formation of CP1, CP2, P1 and P2 was confirmed by size-exclusion chromatography and NMR spectroscopy. The molecular weights of P1 and P2 were much larger than those of CP1 and CP2, respectively, indicating that polymerization was successful. The size-exclusion chromatography profiles of P1 and P2 indicated that the obtained polymers were unimodal and that the low-molecular weight species, such as cyclic dimers or trimers, were mostly removed by reprecipitation in methanol. The 1H and 13C NMR spectra of CP1/P1 and CP2/P2 are shown in Figures 1 and 2, respectively. The 1H and 13C NMR spectra of P1 and P2 were nearly similar to those of CP1 and CP2, respectively, in which each signal was consistently assigned. The integrated ratio of each 1H NMR signal was consistent with the structure of CP1, CP2, P1 and P2 as described in Figures 1 and 2. These results strongly support that no side-reactions occurred during anionic ring-opening polymerization.

Quaternization reaction of the pendent Cl atoms of the polymers

According to Scheme 2, the pendent chlorides of P1 and P2 were functionalized by a quaternized reaction with the imidazole derivative.

1H and 13C NMR and IR spectroscopy confirmed the structure of PIm1 and PIm2. 1H NMR confirmed that the conversion of the pendent chlorides to the imidazole derivative was sufficiently quantitative. The 1H NMR signal of P1 at 3.51 p.p.m. for the -CH2Cl protons disappeared and was replaced by a new signal at 4.33 p.p.m. for PIm1, typical of -CH2- imidazole protons (Figure 3a, signal d). Similarly, the 1H NMR signal of P2 at 3.50 p.p.m. disappeared and was replaced by a new signal at 4.16 p.p.m. for PIm2 (Figure 3c, signal i). The degree of quaternization in the PIm1 and PIm2 was estimated by integrating the ratio of the 1H NMR signals between δ=4.33 and 3.51 p.p.m. and between δ=4.16 and 3.50 p.p.m., respectively. The unreacted propyl signals of P2 were detected at 51.6, 26.4 and 14.5 p.p.m. in the 13C NMR spectrum (Figures 3b and d). Table 1 shows the molecular weights of the polymers estimated from the degree of quaternization of the polymers. The degree of quaternization in PIm2 was significantly lower than that of PIm1. As P1 is a homopolymer of (3-chloropropyl)siloxane units, quaternization can occur at every unit of P1. Therefore, the positive charges of the imidazolium salts would be introduced in high density. The electrostatic repulsion caused by positive charges would cause the polymer to adopt an extended structure and expose the reactive groups, thereby facilitating further quaternization reaction and finally resulting in a high degree of quaternization. In contrast, quaternization can occur at only half of the units of P2, which is a random copolymer of (3-chloropropyl)siloxane and dimethylsiloxane units. In this case, the positive charges of the imidazolium salts would be introduced in lower density, which would be insufficient for polymer to adopt an extended structure. As a result, the reactive groups would largely remain unexposed, resulting in a low final quaternization degree.

PIm1 was soluble in polar solvents such as methanol, dimethylformamide, dimethyl sulfoxide and H2O. However, PIm2 was soluble not only in polar but also in organic solvents such as chloroform and dichloromethane. These results are consistent with the higher degree of quaternization in PIm1 than in PIm2.

Thermal characterization of polymers

Tg of PIm1 and PIm2 were determined by DSC and are summarized in Table 1. Figure 4 depicts the DSC thermograms for PIm1 and PIm2 on a second heating scan under a nitrogen atmosphere at a heating rate of 10 °C min−1. The Tg of PIm1 was determined to be 17 °C. However, the Tg of PIm2 was not observed in the DSC thermogram. The Tg of PIm2 is likely not much different from that of PIm1 because PIm2 is as viscous as PIm1 at ambient temperature. As PIm2 is hygroscopic, its glass transition could be hidden under the endothermic changes observed at ∼0 °C because of the solid–liquid transition of water in the polymers. It has been reported that the Tg of a polymer strongly affects its drug release rate.30 The drug diffusivity of the polymer in the rubbery state is much higher than that in the glassy state. Therefore, PIm1 and PIm2 should be satisfactory in drug release upon administration because of their Tg being lower than body temperature. Further, melting temperatures were not observed in the DSC thermograms of PIm1 and PIm2. These results suggest that PIm1 and PIm2 are noncrystalline polymers. This feature would be favored over drug encapsulation because only the amorphous phase in the nanoparticle is likely to accommodate drug molecules.31

The CuAAC reaction and formation of emulsions using the polymers

The CuAAC reaction was performed with the polymers and label molecules (2.0 mol equiv. per polymer). TACH, the Cu (I) complex, was used as a catalyst at a final concentration of 33.3 μM. Tris[(1-benzyl-1-H-1,2,3-triazol-4-yl)methyl]amine, a tris-triazole ligand that facilitates the CuAAC reaction, was added at 10 equiv. of the Cu (I) complex concentration. Scheme 3 shows the synthetic pathways of the labeled polymers using PIm1 and PIm2. As a control experiment, the reaction was carried out without TACH.

The polymers, consisting of a polysiloxane chain (hydrophobic) and imidazolium salts (hydrophilic), were assumed to form emulsions in water. The o/w emulsions with soybean oil were prepared by sonication with the polymers as an emulsifier in water, and unreacted label molecules and Cu (I) were removed by extensive dialysis against 0.55 mM EDTA. The diameters of the resulting emulsions were ∼150 nm. The covalent attachment of the ligand to the polymer is not easily confirmed by detecting the formation of the triazole ring as the product of the click reaction because the signals of imidazole overlap with those of the triazole ring in ultraviolet and IR spectra, and the product was not obtained in a sufficient amount for NMR spectroscopy. Hence, conjugation of the fluorescent labels onto the surface of the emulsions was examined by a fluorescence microscope. The microscopy images of the emulsions formed by PIm2 are shown in Figure 5. Similar images were also obtained for the emulsions formed by PIm1 (data not shown). When Cy3 and cfSGFP2 were used as label molecules, fluorescence was observed on the surface of emulsions (Figures 5a and c). In contrast, the emulsions exhibited no fluorescence in the control experiment in which the polymers and azide-functionalized fluorescent labels reacted in the absence of the Cu (I) catalyst (TACH) (data not shown), suggesting that the fluorescent labels were not physically adsorbed to the polymers. From these results, it can be deduced that the fluorescence observed on the surface of the emulsions was caused by the covalently coupled label molecules.23 When Alexa Fluor 488 was conjugated, fluorescence was observed on the surface of emulsions irrespective of the presence of TACH. We hypothesized that the positive charges of imidazolium salts in the polymer attracted Alexa Fluor 488, bearing multiple negative charges. To avoid such an interaction, unreacted label molecules were removed by anion-exchange resin after the CuAAC reaction. As a result, the emulsions formed by resin-treated polymers conjugated with Alexa Fluor 488 successfully exhibited fluorescence (Figure 5b) but no fluorescence was exhibited in the control experiment (data not shown). In addition, aggregation occurred when cfSGFP2 was conjugated, possibly because of the hydrophobic interaction between the polymer and protein. Aggregation was successfully circumvented by adding glycerol in the final concentration of 20% v/v.

The drug encapsulation ability of the emulsion was evaluated using Nile red as a model drug. Nile red is a solvatochromic dye that exhibits strong fluorescence in a nonpolar solvent. When soybean oil containing Nile red was emulsified by PIm2, the resultant emulsions exhibited fluorescence characteristic of Nile red in a nonpolar environment, indicating that Nile red was encapsulated inside the emulsions (Figure 6). Future work will be focused on elucidating the drug-carrying capacity, stability, targeting to cells and drug release properties of this emulsion.

Previously, an alkyne-functionalized poly-(dimethylsiloxane)-poly(2-methyloxazoline) block copolymer was synthesized to form a ‘clickable’ polymersome.18 In this polymer, an alkyne group was introduced at each end. In contrast, the polymers developed in the current study were highly functionalized with alkyne groups. This feature should be advantageous in forming emulsions carrying targeting and labeling molecules in high density, which would lead to effective drug delivery to target cells and sensitive in vivo detection. For such alkyne functionalization in high density, polyacrylate has been used as a hydrophilic block to conjugate alkyne derivatives to polymer side chains by carbodiimide coupling.21 In the current study, alkyne-functionalized amphiphilic polymers can be obtained in a simpler way by simultaneously introducing alkyne functionality and hydrophilicity using a quaternization reaction, which would be advantageous for large-scale preparation of drug carriers. In addition, imidazolium-based polymerized ionic liquids have been shown to possess high binding ability for DNA.25 Therefore, the polymers developed in the current study containing quaternized imidazolium salts would be versatile as carriers for not only drug delivery but also DNA delivery.

Conclusion

The synthesis of poly(dimethylsiloxane) derivatives with quaternized imidazolium salts having an alkyne group (PIm1 and PIm2) was achieved. The introduction of the alkyne group enabled coupling with azide-functionalized fluorescent dyes and green fluorescent proteins using a copper-based catalyst. Fluorescence-labeled o/w emulsions were successfully formed using the labeled polymers. Therefore, PIm1 and PIm2 would be useful for drug delivery by conjugating cell-specific targeting molecules by the click reaction.

Synthetic pathways of P1 and P2.

Synthetic pathways of 3 and quaternization pathways of P1 and P2.

The CuAAC reaction of PIm1 and PIm2 with azide-functionalized fluorescent molecules.

References

Lovelyn, C. & Attama, A. A. Current state of nanoemulsions in drug delivery. J. Biomater. Nanobiotechnol. 2, 626–639 (2011).

Washington, C., Athersuch, A. & Kynoch, D. J. The electrokinetic properties of phospholipid stabilized fat emulsions. IV. The effect of glucose and of pH. Int. J. Pharm. 64, 217–222 (1990).

Abdel-Raouf, M. E.-S. in Crude Oil Emulsions-Composition Stability and Characterization ed. Abdul-Raouf M. E.-S., 183–204 (InTech, New York, NY, USA, 2012).

Clarson, S. J. in Synthesis and properties of silicones and silicone-modified materials eds Clarson S. J., Fitzgerald J. J., Owen M. J., Smith S. D., Van Dyke M. E., 1–10 (American Chemical Society, Washington, DC, USA, 2003).

Mark, J. E. in Silicones and Silicone-Modified Materials eds Clarson S. J., Fitzgerald J. J., Owen M. J., Smith S. D., 1–10 (American Chemical Society, Washington, DC, USA, 2000).

Bergeron, V., Cooper, P., Fischer, C., Giermanska-Kahn, J., Langevin, D. & Pouchelon, A. Polydimethylsiloxane (PDMS)-based antifoams. Colloids Surf. A 122, 103–120 (1997).

Roberts, M., Settel, E., Arlen, M. & Friedman, H. P. Methyl polysiloxane in postoperative gas pains. JAMA 183, 595–597 (1963).

Liu, M., Ragheb, A., Zelisko, P. & Brook, M. A. in Colloidal Biomolecules, Biomaterials, and Biomedical Applications ed. Elaissari A., 309–327 (CRC Press, Boca Raton, FL, USA, 2003).

Fortuniak, W., Rozga-Wijas, K., Chojnowski, J., Labadens, F. & Sauvet, G. Reactions of tertiary hydroxyalkylamines with 3-halogenopropyl substituted polysiloxanes: a route to water soluble and amphiphilic silicones. React. Funct. Polym. 61, 315–323 (2005).

Hou, A. & Shi, Y. Polymerization and surface active properties of water-soluble amphiphilic polysiloxane copolymers modified with quaternary ammonium salts and long-carbon chain groups. Mater. Sci. Eng. B 163, 99–104 (2009).

Xie, K.-L., Hu, K. & Chen, Y. Synthesis of amphiphilic polysiloxanes modified with multi-cationic groups to improve wettability of polyester materials. Iran. Polym. J. 19, 447–455 (2010).

Beppu, K., Kaneko, Y., Kadokawa, J., Mori, H. & Nishikawa, T. Synthesis of sugar-polysiloxane hybrids having rigid main-chains and formation of their nano aggregates. Polym. J. 39, 1065–1070 (2007).

Iwakiri, N., Nishikawa, T., Kaneko, Y. & Kadokawa, J. Synthesis of amphiphilic polysiloxanes and their properties for formation of nano-aggregates. Colloid Polym. Sci. 287, 577–582 (2009).

Prisacaru, A.-I., Grama, S., Durdureanu-Angheluta, A. M., Pinteala, M. & Hurduc, N. Azo-polysiloxane micelles charged with nifedipine. Cent. Eur. J. Chem. 11, 1431–1438 (2013).

Moleavin, I., Grama, S., Carlescu, I., Scutaru, D. & Hurduc, N. Photosensitive micelles based on polysiloxanes containing azobenzene moieties. Polym. Bull. 65, 69–81 (2010).

Broz, P., Benito, S. M., Saw, C., Burger, P., Heider, H., Pfisterer, M., Marsch, S., Meier, W. & Hunziker, P. Cell targeting by a generic receptor-targeted polymer nanocontainer platform. J. Control. Release 102, 475–488 (2005).

Broz, P., Ben-Haim, N., Grzelakowski, M., Marsch, S., Meier, W. & Hunziker, P. Inhibition of macrophage phagocytotic activity by a receptor-targeted polymer vesicle-based drug delivery formulation of pravastatin. J. Cardiovasc. Pharmacol. 51, 246–252 (2008).

Egli, S., Fischer, B., Hartmann, S., Hunziker, P., Meier, W. & Rigler, P. Towards targeted drug delivery by covalent ligand-modified polymeric nanocontainers. Macromol. Symp. 296, 278–285 (2010).

Rostovtsev, V. V., Green, L. G., Fokin, V. V. & Sharpless, K. B. A stepwise Huisgen cycloaddition process: copper(I)-catalyzed regioselective ‘ligation’ of azides and terminal alkynes. Angew. Chem. Int. Ed. 41, 2596–2599 (2002).

Tornøe, C. W., Christensen, C. & Meldal, M. Peptidotriazoles on solid phase: [1,2,3]-Triazoles by regiospecific copper(I)-catalyzed 1,3-dipolar cycloadditions of terminal alkynes to azides. J. Org. Chem. 67, 3057–3064 (2002).

O'Reilly, R. K., Joralemon, M. J., Hawker, C. J. & Wooley, K. L. Facile syntheses of surface-functionalized micelles and shell cross-linked nanoparticles. J. Polym. Sci. Polym. Chem. 44, 5203–5217 (2006).

Lee, S.-M., Chen, H., O'Halloran, T. V. & Nguyen, S. B. T. ‘Clickable’ polymer-caged nanobins as a modular drug delivery platform. J. Am. Chem. Soc. 131, 9311–9320 (2009).

Opsteen, J. A., Brinkhuis, R. P., Teeuwen, R. L. M., Löwik, D. W. P. M. & van Hest, J. C. M. ‘Clickable’ polymersomes. Chem. Comm. 30, 3136–3138 (2007).

van Dongen, S. F. M., Nallani, M., Schoffelen, S., Cornelissen, J. J. L. M., Nolte, R. J. M. & van Hest, J. C. M. A block copolymer for functionalisation of polymersome surfaces. Macromol. Rapid Commun. 29, 321–325 (2008).

Zhang, Y., Chen, X., Lan, J., You, J. & Chen, L. Synthesis and biological applications of imidazolium-based polymerized ionic liquid as a gene delivery vector. Chem. Biol. Drug. Des. 74, 282–288 (2009).

Wan, Y., Wallinder, C., Plouffe, B., Beaudry, H., Mahalingam, A. K., Wu, X., Johansson, B., Holm, M., Botoros, M., Karlen, A., Pettersson, A., Nyberg, F., Fandriks, L., Gallo-Payet, N., Hallberg, A. & Alterman, M. Design, synthesis, and biological evaluation of the first selective nonpeptide AT2 receptor agonist. J. Med. Chem. 47, 5995–6008 (2004).

Suzuki, T., Arai, S., Takeuchi, M., Sakurai, C., Ebana, H., Higashi, T., Hashimoto, H., Hatsuzawa, K. & Wada, I. Development of cysteine-free fluorescent proteins for the oxidative environments. PLoS One 7, e37551 (2012).

Cheng, J., Sun, Y., Wang, F., Guo, M., Xu, J. H., Pan, Y. & Zhang, Z. A copper- and amine-free Sonogashira reaction employing aminophosphines as ligands. J. Org. Chem. 69, 5428–5432 (2004).

Niino, M., Ueno, Y., Araki, T. & Sekine, Y. Binding of methyl orange by water-soluble synthetic polyorganosiloxanes. Polym. Commun. 24, 124–128 (1983).

Yin, J., Noda, Y. & Yotsuyanagi, T. Properties of poly(lactic-co-glycolic acid) nanospheres containing protease inhibitors: camostat mesilate and nafamostat mesilate. Int. J. Pharm. 314, 46–55 (2006).

Chen, C., Yu, C. H., Cheng, Y. C., Yu, P. H. & Cheung, M. K. Biodegradable nanoparticles of amphiphilic triblock copolymers based on poly(3-hydroxybutyrate) and poly(ethylene glycol) as drug carriers. Biomaterials 27, 4804–4814 (2006).

Acknowledgements

We thank Professor Ikuo Wada, Department of Cell Science, Institute of Biomedical Science, Fukushima Medical University School of Medicine for the generous gift of the plasmid for expression of cfSGFP2, Professor Hiroyuki Tanaka, Department of Chemical Biology and Applied Chemistry, College of Engineering, Nihon University for Fourier transform-IR measurements and Ms Satoko Tokiwa and Ms Nami Sugashima, Nihon University College of Engineering Worldwide Research Center for Advanced Engineering and Technology (NEWCAT), for performing NMR measurements. This work is supported in part by the MEXT-Supported Program for the Strategic Research Foundation at Private Universities, 2009–2013, Matching Fund Subsidy for Private Universities from MEXT for 2010 and a Nihon University Multidisciplinary Research Grant for 2011-2012.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kihara, Y., Ichikawa, T., Abe, S. et al. Synthesis of alkyne-functionalized amphiphilic polysiloxane polymers and formation of nanoemulsions conjugated with bioactive molecules by click reactions. Polym J 46, 175–183 (2014). https://doi.org/10.1038/pj.2013.86

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2013.86