Abstract

Although high-tunnelling spin polarization has been observed in soft, ferromagnetic, and predicted for hard, ferrimagnetic Heusler materials, there has been no experimental observation to date of high-tunnelling magnetoresistance in the latter. Here we report the preparation of highly textured, polycrystalline Mn3Ge films on amorphous substrates, with very high magnetic anisotropy fields exceeding 7 T, making them technologically relevant. However, the small and negative tunnelling magnetoresistance that we find is attributed to predominant tunnelling from the lower moment Mn–Ge termination layers that are oppositely magnetized to the higher moment Mn–Mn layers. The net spin polarization of the current reflects the different proportions of the two distinct termination layers and their associated tunnelling matrix elements that result from inevitable atomic scale roughness. We show that by engineering the spin polarization of the two termination layers to be of the same sign, even though these layers are oppositely magnetized, high-tunnelling magnetoresistance is possible.

Similar content being viewed by others

Introduction

Key to the successful development of magnetic random access memory (MRAM), one of the most promising emerging non-volatile memory technologies today, are new magnetic materials for the magnetic tunnel junction (MTJ) memory elements that have sufficient stability against thermal fluctuations to sustain deeply scaled devices. The most promising magnetic materials to date are considered to be magnetic alloys formed from Co, Fe and B, in conjunction with MgO(001) tunnel barriers1,2,3. The magnetic electrodes must possess sufficient perpendicular magnetic anisotropy (PMA) that their magnetizations lie perpendicular to the plane of the MTJ device, since this allows for reduced currents to switch the magnetization of the electrode that forms the memory layer of the device using spin torque3,4. The PMA of Co–Fe–B layers arises from the interfaces between these layers and the tunnel barrier and/or the underlayer on which the Co–Fe–B layer is deposited. Thus, these layers must be made sufficiently thin that the interface PMA overcomes the demagnetization energy that arises from the magnetic volume and increases in proportion with the magnetic volume of the Co–Fe–B layer. In practice, this means that the PMA is too weak to overcome thermal fluctuations when the device has a critical dimension <∼20 nm in size, since the thickness of the magnetic layer has to be below that required to maintain its moment perpendicular, and, below that needed to switch the magnetic layer with reasonable current densities. Magnetic materials in which the PMA is derived from volume magnetocrystalline anisotropy are then needed. One of the most promising class of such materials are the Heusler alloys—compounds having the chemical formula X2YZ or X’X’’YZ, wherein X, X’, X” and Y are transition metals, or lanthanides (rare-earth metals), and Z is from a main group metal5. Some of these compounds are ferromagnetic or ferrimagnetic depending on the exchange interaction between the magnetic moments on the X and/or Y sites. Moreover, while the parent Heusler compounds are cubic and exhibit weak or no significant magnetic anisotropy, the structure of some of these compounds is found to be tetragonally distorted: due to this distortion the magnetization exhibited by these compounds may be aligned along the tetragonal axis. Thus, thin films formed from such materials may exhibit PMA due to a magnetocrystalline anisotropy associated with the tetragonally distorted structure. Some examples of such tetragonal Heusler compounds are Mn3-xGa (ref. 6) and Mn3Ge (ref. 7).

Thin films of these materials have been shown to exhibit large PMA but, to date, all work on these materials has involved films that are grown epitaxially on single crystalline substrates such as SrTiO3(001) or MgO(001) using seed layers formed from a variety of materials but preferably Cr or Pt (refs 7, 8, 9, 10, 11). Such single crystalline substrates are not useful for MRAM applications in which the MTJs must be deposited on wires formed from polycrystalline copper, which may be covered with other layers that are also polycrystalline or amorphous.

Here we show that thin films of ferrimagnetic Mn3Ge with giant PMA can be grown on amorphous substrates (Si(001)/SiO2) using underlayers formed from TaN/IrMn3 (TI). The magnetic properties of these films are comparable or superior to films that we have grown under similar conditions on single crystal MgO(001) substrates using epitaxial Cr(001) underlayers. Very high magnetic anisotropy fields exceeding 7T are found. However, the tunnelling magnetoresistance (TMR) is negative and much smaller than theoretical predictions for tunnel junction devices formed with MgO tunnel barriers. We attribute this to predominant tunnelling from the lower moment Mn–Ge termination layers that are oppositely magnetized to the higher moment Mn–Mn layers. The net spin polarization of the current reflects the different proportions of the two distinct termination layers and their associated tunnelling matrix elements at the tunnel barrier interface, that result from inevitable atomic scale roughness. We have confirmed that a second perpendicularly magnetized Heusler compound, Mn2CuSb, which we identified by computational materials discovery methods, similarly displays small TMR, but that the sign of the spin polarization of each of the termination layers is opposite to that of their magnetization, in contrast to Mn3Ge. Therefore, the low TMR that we have found in Mn3Ge and Mn2CuSb, which we attribute to termination layer compensation, is not an inherent property of ferrimagnetic Heuslers. The spin polarization of the two termination layers can be engineered to be of the same sign even though these layers are oppositely magnetized, therefore providing a path to low magnetization electrodes with high TMR for high density spin transfer torque MRAM applications.

Results

Growth of highly textured Mn3Ge on amorphous substrates

Highly textured, polycrystalline and tetragonal Mn3Ge films were grown by either ion-beam deposition or d.c.-magnetron sputtering in an ultra-high vacuum chamber with a base pressure of ∼4 × 10−10 torr on Si(001) substrates covered with 250 Å of amorphous SiO2. We find that seed layers formed from bilayers of TaN/IrMn3 that are first deposited on the SiO2 induce (001) textured Mn3Ge films that are tetragonally distorted. IrMn3 is known to have a L12 structure that is cubic, and which matches one of the sublattices of the structure that Mn3Ge is known to form. Moreover, the lattice mismatch between IrMn3 and Mn3Ge is <1% (ref. 12). The TaN layer that is grown by reactive sputtering, promotes the growth of (001) textured IrMn3, since fcc-IrMn3 favours the (111) out-of-plane orientation when grown directly on amorphous SiO2 surface (Supplementary Fig. 1 and Supplementary Note 1). However, in contrast to theoretical predictions of giant values of TMR6,13,14 for MTJs using Mn3Ge electrodes we find much smaller values experimentally, which we attribute to compensation in the tunnelling spin current polarization from atomic layer variations of the electrode surface termination at the tunnel barrier interface. We propose that this is an inevitable consequence of ferrimagnets with layer-by-layer alternation of magnetization, when the spin polarization of these layers compensates each other. We confirm this conjecture by preparing MTJs using another ferrimagnetic Heusler compound, Mn2CuSb, which also shows high PMA but yet very small TMR.

The structural and magnetic properties of the Mn3Ge films depend sensitively on its composition and atomic order. The latter is strongly influenced by the deposition temperature and subsequent anneal conditions, which also affect the smoothness of the Mn3Ge film. To achieve optimal MTJ performance the electrode must be atomically smooth. We find that the root mean square (r.m.s.) roughness of the Mn3Ge film, rr.m.s., measured using atomic force microscopy, increases significantly when the growth temperature (TG) exceeds modest temperatures of just ∼200 °C, but higher growth temperatures are needed to sustain the Heusler structure, as measured from X-ray diffraction (Supplementary Fig. 2 and Supplementary Note 2). Thus, we find that an optimal growth method, which includes a three-step process for the Mn3Ge electrode, in which an initial 20 Å Mn3Ge layer is grown at 450 °C, followed by a thicker Mn3Ge layer deposited at TG=150 °C, with a final in situ anneal at 450 °C for 1–2 h in vacuum, gives smooth films (rr.m.s.∼3 Å) with high PMA. During the annealing step of Mn3Ge films, there is a substantial inter-diffusion between IrMn3 and Mn3Ge layers (Supplementary Fig. 3), which causes deterioration of the magnetic properties of Mn3Ge. We discovered that this interdiffusion can be prevented by using a thin 10–20 Å TaN barrier between IrMn3 and Mn3Ge layers, as revealed by electron energy loss spectroscopy measurements (Supplementary Note 3). Thus, the preferred underlayer is formed from TaN/IrMn3/TaN (TIT). We note that a single TaN underlayer gives much poorer quality Mn3Ge layers.

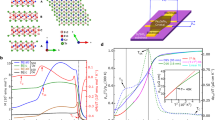

Figure 1 compares the magnetic properties of Mn3Ge films with varying thickness grown on amorphous substrates using the three-step process and on a crystalline MgO(001) substrate with a Cr seed layer (MC). Excellent PMA is observed in all cases but the highest coercive and anisotropy fields are found for structures grown on the TIT underlayer. Coercive fields of 6T and anisotropy fields exceeding 7T are found. Figure 1c summarizes the magnetic moment m, coercivity HC and uniaxial magnetic anisotropy KU for these films. Values of m for Mn3Ge films grown on TIT underlayers are close to those theoretically predicted for bulk Mn3Ge (ref. 15), but m is significantly lowered by ∼15–35% for Mn3Ge films grown using TI underlayers or a MC single crystal substrate. For the latter film, we also find that the magnetic anisotropy KU is substantially lower: we attribute this to the large lattice mismatch (∼7%) between Cr and Mn3Ge.

(a) Magnetization versus field hysteresis loops of Mn3Ge films grown on Si(001)/SiO2 substrate with TI (magenta) and TIT (blue) underlayers and MgO(001) substrate with MC (orange) underlayers. TI (TIT) have the following structure: Si(001)/SiO2/200 Å TaN/200 Å IrMn3 (/10 Å TaN) while MC has the following structure: MgO(001)/20 Å MgO/400 Å Cr. For the TIT films, the thickness of the Mn3Ge layer, deposited using the three-step process, was varied. Out of plane (in-plane) M vs. H loops are shown as solid lines (open squares). b and d are schematics of the MTJ structures grown on Si(001)/SiO2 and MgO(001) substrates, respectively. In some cases a TaN diffusion barrier layer was used as indicated by a dashed line. For characterization of structural, topographical and magnetic properties of the Mn3Ge films, a 30 Å Ta film was used as a capping layer instead of the upper layers shown within the dotted lines. (c) Magnetic moment m, coercive field HC (solid triangles) and uniaxial magnetic anisotropy constant KU (empty squares), extrapolated from Fig. 1a, versus Mn3Ge thickness. The green straight line shows the calculated moment of bulk D022-Mn3Ge (ref. 15). As shown in Fig. 1a, the Mn3Ge magnetization cannot be saturated in-plane using the available magnetic field (7 T); thus, Heff is a lower bound.

Tunnelling magnetoresistance of Mn3Ge-based MTJ devices

MTJ devices were fabricated using standard lithographic techniques from film stacks whose structures are illustrated in Fig. 1b. The reference electrode was formed from the Mn3Ge Heusler compound, and the free electrode from an ultrathin layer of CoFeB with a composition of 20:60:20. Before patterning, these films were post-annealed at 350 °C for 60 min in a high-vacuum chamber using an applied magnetic field of 1T directed out of the plane of the sample. Devices with sizes of 1 × 2 μm2 and ∼30 nm in diameter were fabricated by optical lithography and e-beam lithography, respectively. Only the free layer was patterned to define the junction size while the reference layer was not patterned.

Figure 2a compares TMR versus perpendicular magnetic field H measured at 300 K (smaller squares) and 3 K (larger squares) for patterned MTJ devices (1 × 2 μm2) using TI and TIT underlayers. In each case high applied magnetic fields (±9 T) are needed to align the magnetic moments of the Mn3Ge and CoFeB layers parallel to each other (P state) because of the giant uniaxial anisotropy of Mn3Ge. The junction resistance is higher in the P state compared with the antiparallel (AP) state, obtained when the CoFeB moment switches close to zero field. Thus, the TMR ([(RAP-RP)/RAP] × 100) is negative with values of∼−35% at 300 K and∼−74% at 3 K, where RP and RAP are the junction resistances in the P and AP states, respectively. These are the highest values of TMR reported to date in perpendicularly magnetized MTJ devices using a tetragonally distorted Heusler compound as a magnetic electrode. Nonetheless, these values are much smaller than those predicted by density functional theory (DFT) calculations14, as discussed below.

(a) TMR versus H (perpendicular to the device) measured at 300 K (smaller squares) and 3 K (bigger squares) for MTJ devices grown using TI (magenta) and TIT (blue) underlayers. For the TIT junction, two sets of data were measured at 3 K (blue bigger squares) after cooling down the device from 300 K in a magnetic field of +9 and −9 T, respectively. These data are mirror images of each other, as can be seen in the figure. All the other measurements were performed without field cooling. (b) Temperature dependence of TMR, and RPA and RAPA. (c) MgO thickness dependence of TMR (open symbols) and RAPA product (solid symbols), averaged over >20 devices. Solid and dashed lines are guides to the eye for RAPA and TMR, respectively. RAPA scales exponentially with barrier thickness. (d) HRTEM image of an MTJ device ∼27 nm in size, with the structure: Si/250 Å SiO2/200 Å TaN/200 Å IrMn3/300 Å Mn3Ge/15 Å MgO/15 Å CoFeB/50 Å Ta/50 Å Ru. HRTEM, high-resolution transmission electron microscopy.

For a given MTJ device RAP barely changes, while RP increases monotonically as T decreases, resulting in higher TMR at low temperatures (Fig. 2b). These properties, as well as the dependence of the resistance-area product RAPA and TMR on the barrier thickness (Fig. 2c) are characteristic of a high quality tunnel barrier. A cross-sectional high-resolution transmission electron microscopy image of a typical MTJ device with a width of 27 nm, shown in Fig. 2d, illustrates the high quality of the structure and the device patterning.

Notwithstanding the exceptionally high PMA values exhibited by polycrystalline Mn3Ge films the surprisingly low TMR values lessens their potential importance for MTJ devices. We attribute the low TMR, as discussed below, to their ferrimagnetic structure. This limitation could be overcome by identifying Heusler compounds that display high PMA, and which are ferromagnetic.

Discovery of tetragonal Heuslers by computational methods

To identify potential candidate tetragonal materials we used computational materials discovery methods to calculate the structure and electronic properties of several hundred Heusler compounds (with X=Mn, Fe, Co, Ni, Cu, Ru, Rh, Pd; Y=Sc, Mn, Fe, Co, Ni, Cu, Ru, Rh, Pd, Os, Ir, Pt; and Z=Al, Si, Ga, Ge, In, Sn, Sb) for both the regular and inverse structures and for ferri- and ferromagnetic configurations. Surprisingly, ∼40% of these compounds are calculated to be tetragonal in their ground state. Rank ordering these tetragonal compounds according to the combination of the energy difference between the tetragonal and cubic structures and that between the inverse and regular structures, we identified ∼30 possible candidate tetragonal materials, where the average energy difference exceeded ∼0.3 eV per formula unit. Of these, we prepared eight in thin film form using the same buffer layers and deposition conditions as discussed above. Half of these compounds showed a tetragonal structure and two showed excellent PMA properties, namely, Mn2CuSb and Rh2CoSb. In the other cases, we rationalize that the theoretical predictions were not fulfilled due to atomic disorder on the X and Y sites. This is particularly the case where X and Y have similar chemical properties or atomic size.

Similar magnetic properties were found for Mn2CuSb and Rh2CoSb films grown using either TI underlayers (Supplementary Fig. 4 and Supplementary Note 4) or an MC crystalline substrate but the latter films were typically smoother and better suited for MTJ studies. Results are shown in Fig. 3 for Mn2CuSb. Square magnetic hysteresis loops consistent with PMA are found. The calculated lowest energy configuration of Mn2CuSb is a tetragonal ferromagnetic regular Heusler with a moment of 5.4 μB per formula unit (Table 1). Although we find that the deposited films are tetragonal (Supplementary Fig. 5 and Supplementary Note 5), in agreement with the calculations, the measured c/a ratio is much smaller in the films ( ∼1.1) than that predicted for a fully ordered Mn2CuSb bulk compound (

∼1.1) than that predicted for a fully ordered Mn2CuSb bulk compound ( ∼1.4), and thus only slightly distorted from the cubic phase. Moreover, the magnetization of the films is much too low—∼0.4 μB per formula unit—to be consistent with the predicted ferromagnetic state, as is the TMR, as we discuss below. We rationalize these findings by the likelihood of chemical disorder within the deposited films. We note that the calculations predict that for the cubic phase the structure will be the inverse structure with a ferrimagnetic ordering, with a low moment (Table 1).

∼1.4), and thus only slightly distorted from the cubic phase. Moreover, the magnetization of the films is much too low—∼0.4 μB per formula unit—to be consistent with the predicted ferromagnetic state, as is the TMR, as we discuss below. We rationalize these findings by the likelihood of chemical disorder within the deposited films. We note that the calculations predict that for the cubic phase the structure will be the inverse structure with a ferrimagnetic ordering, with a low moment (Table 1).

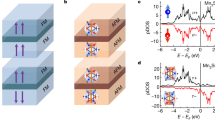

(a) Out-of-plane M versus H hysteresis loops, at 300 K, of 300 Å thick Mn2CuSb films grown on MC MgO(001) substrate at room temperature and post annealed at 300 °C (blue) and 400 °C (orange) for 30 min. The anneal treatments were carried out in a high-vacuum anneal furnace, in an applied magnetic field of 1 T (out-of-plane direction) for 30 min. (b) Out-of-plane M vs. H hysteresis loop of an MTJ film measured before lithography patterning. (c) Two-terminal junction R vs. H loop of a patterned MTJ device (1 × 2 μm2 size). (d) Schematic of a Mn2CuSb-based MTJ, with the structure: MgO(001)/20 Å MgO/400 Å Cr/300 Å Mn2CuSb/25 Å MgO/14 Å CoFeB/4 Å Ta/7 Å CoFeB/7 Å MgO/50 Å Ta/100 Å Ru. The Mn2CuSb electrode was deposited at ambient temperature and in situ annealed at 300 °C before the MgO barrier deposition. The entire stack was then post annealed at 325 °C for 30 min.

MTJ devices were prepared from Mn2CuSb films with the layer stack shown in Fig. 3d and the magnetic hysteresis loop shown in Fig. 3b. The latter shows clear independent switching of the free layer (CoFeB) and the reference layer (Mn2CuSb) but TMR curves measured on 1 × 2 μm2 size devices show only very small TMR values of∼−1% (Fig. 3c).

Termination-layer dependent tunnelling spin polarization

We performed ab initio calculations of the electronic structure and transport properties of Mn3Ge/MgO/Fe and Mn2CuSb/MgO/Fe MTJs (see Methods for details of the calculations). Note that we use bcc Fe rather than CoFeB that is used in the experiments to simplify the calculations. The TMR for Mn3Ge/MgO/Fe MTJs is shown in Fig. 4a as function of the number of MgO layers, NMgO, for NMgO≥2. Two definitions of TMR are shown: (TP−TAP)/min(TP,TAP), that can vary from −∞ to ∞, (that we use for the experimental data) and (TP−TAP)/(TP+TAP), that can vary from −1 to 1. Here TP and TAP are the transmission functions (calculated at zero bias voltage) corresponding to the P and AP states, respectively. The most important result is that the TMR depends sensitively on the atomic configuration of the termination layer in the Mn3Ge adjacent to the MgO tunnel barrier. The calculation gives magnetic moments of +4.08 and −3.12 μB for the Mn–Mn and Mn–Ge termination layers, respectively. The TMR has opposite signs for the two termination layers, Mn–Mn and Mn–Ge, increasing in magnitude with NMgO for Mn–Mn but decreasing in magnitude for Mn–Ge. These results can be understood from the layer dependent, spin-dependent density of states calculated for the bulk electronic structure of Mn3Ge, and the well understood symmetry spin-filtering properties of the MgO/Fe interface. The spin polarization of the native termination layers is negative in both cases but much bigger for Mn–Ge (see Supplementary Fig. 6 and Supplementary Note 6 for more details). A Brillouin zone filtering effect16 arising from the Mn3Ge/MgO interface tends to make the TMR positive for both terminations as the MgO layer thickness is increased. Thus, the TMR is negative for Mn–Ge but positive for Mn–Mn for intermediate MgO thicknesses that are of interest experimentally. The balance between the native spin polarization and the Brillouin zone filtering not only accounts for the dependence of the TMR on NMgO and the termination layer but also the bias voltage (Supplementary Fig. 7 and Supplementary Note 7).

(a) TMR for Mn3Ge/MgO/Fe and Fe/MgO/Fe MTJs versus NMgO. TMR for Mn3Ge/MgO/Fe MTJ with Mn–Mn termination is shown by green line, with Mn–Ge termination by red line and for device with steps (half of the device area has Mn–Mn termination and half of the area has Mn–Ge termination) is shown by blue line. The TMR for Fe/MgO/Fe MTJ calculated in this work by tight-binding linear muffin-tin orbital (TB–LMTO) method is shown by cyan line and calculated by layer Korringa-Kohn-Rostoker (KKR) method (ref. 22) is shown by pink circles. (b) Schematic of atomic step between two distinct terminations with opposite magnetic moments for Mn3Ge. (c) The TMR for Mn2CuSb/MgO/Fe MTJ with Mn–Sb termination is shown by green line, with Mn–Cu termination by red line and for device with steps (half of the device area has Mn–Cu termination and half of the area has Mn–Sb termination) is shown by blue line. (d) Schematic of atomic step between two distinct terminations with opposite magnetic moments for Mn2CuSb. Note that in a and c the TMR for the termination with the larger magnetic moment is shown in green for both Mn3Ge and Mn2CuSb. In b and d the direction of the magnetic moments shown for the different termination layers for the different steps corresponds to the sign of the TMR for that termination layer (that is, arrow pointing up (down) corresponds to positive (negative) TMR).

These calculations give a natural explanation for the low TMR values found experimentally using Mn3Ge electrodes. Even though the Mn3Ge/MgO interface is very smooth (Fig. 2d) inevitably there will be atomic scale fluctuations in the morphology of the Mn3Ge layer that gives rise to regions with Mn–Mn and Mn–Ge terminations, due to the fundamental underlying structure of the Heusler compound (see illustration in Fig. 4b). The simplest way to model such fluctuations is to average the transmission functions over the different terminations (separately for P and AP states), assuming that the MgO thickness is the same across the device. The TMR calculated from this simple model with an assumption of equal areas occupied by Mn–Ge and Mn–Mn terminations is shown in Fig. 4a. The calculations give a negative TMR since both TP and TAP for the Mn–Ge termination are larger than those for the Mn–Mn termination (for all NMgO considered–ranging from 2 to 12). The negative TMR is consistent with our experimental measurements. Note that due to the large 10.5% lattice mismatch between MgO and Mn3Ge the Brillouin zone filtering effect, which critically depends on the existence of the well-defined 2D Brillouin zone of the Mn3Ge/MgO interface, is likely more suppressed in actual devices as compared with the large negative spin polarization effect that is less sensitive to the existence of the 2D Brillouin zone. Thus, both ideal crystal theoretical simulations (Fig. 4a) and non-ideal crystal arguments predict negative TMR for the Mn3Ge/MgO/Fe system, in agreement with experimental results (at low temperatures the TMR=−75% for ∼27 Å thick MgO: Fig. 2b). We note that the surface energy of the different terminations will very likely not be identical. This could lead to the formation of a more complex surface structure but kinetic considerations will constrain the surface beyond that of the equilibrium structure.

The calculated TMR versus NMgO for Mn2CuSb/MgO/Fe MTJs, where the Mn2CuSb has a tetragonal ferrimagnetic inverse Heusler structure, with Mn–Sb and Mn–Cu terminations at the MgO interface are compared in Fig. 4c. Note that the calculated magnetic moment of the Mn–Sb layer (3.2 μB) is larger than that for the Mn–Cu layer (−2.8 μB). Interestingly, the tunnelling spin polarization from the native termination layers, that is, in the limit of NMgO→0, is of the opposite sign to the magnetic moment direction of these layers, whereas for Mn3Ge the spin polarization is negative for both terminations (Supplementary Fig. 8 and Supplementary Note 8). But for the range of MgO thicknesses of interest for technologically relevant MTJs (2<NMgO≤12), tunnelling spin polarization is parallel and antiparallel, to the magnetic moment of the respective termination layer for Mn3Ge and Mn2CuSb, respectively. Moreover, there is no significant Brillouin zone filtering effect for Mn2CuSb/MgO. In this case the dependence of the TMR on NMgO is due to the symmetry spin filtering effect from MgO/Fe, as can be seen from Fig. 4c by comparing the calculated TMR for Mn2CuSb/MgO/Fe, for both terminations, with that for Fe/MgO/Fe. For the Mn2CuSb/MgO/Fe MTJ a negative TMR is predicted for the termination layer with the largest magnetic moment (Mn–Sb) whereas for Mn3Ge/MgO/Fe the opposite is the case. The TMR calculated for an MTJ with equal areas of Mn–Cu and Mn–Sb terminations is shown in Fig. 4c. The resulting TMR is significantly reduced due to the cancellation of contributions from the different terminations and has an overall negative sign (for NMgO>2). The negative sign of TMR and its small value agrees with our experimental findings.

Discussion

In summary, we have shown a method to grow highly textured ferrimagnetic Heusler films with large perpendicular anisotropy on amorphous substrates, thereby opening a path to their potential use for many applications such as magnetic recording media and rare-earth-free hard magnets. However, we find that the TMR is strongly influenced by unavoidable atomic steps at the tunnel barrier interface. When the two termination layers have opposite tunnelling spin polarizations they compensate one another leading to low TMR, as we have shown is the case for both Mn3Ge and Mn2CuSb. However, the tunnelling spin polarization can be aligned either parallel, as in the case of Mn3Ge, or antiparallel, as in the case of Mn2CuSb, to the magnetization of the termination layers. We conclude that the most interesting and technologically useful ferrimagnetic Heusler materials will have termination layers with the same tunnelling spin polarization, that is, for one termination layer the tunnelling spin polarization is parallel to the magnetization, and for the other it is the opposite. Such materials can be identified by the use of computational techniques.

Methods

Mn3Ge and Mn2CuSb film deposition and characterization

Mn3Ge and Mn2CuSb films were deposited by d.c.-magnetron sputtering or ion-beam deposition at temperatures that were varied from ambient to 550 °C. TaxN films were deposited with different Ar/N2 ratios by reactive magnetron sputtering from a Ta target, and 200 Å IrMn3 films were deposited using ion beam sputtering from a IrMn3 target. TaxN and IrMn3 layers were grown at room temperature. Film compositions were measured by Rutherford back scattering measurements. X-ray diffraction measurements were carried out using a Bruker GADDS or a Bruker D8 Discover system. For the Ar/N2 ratios within the range 95/5–75/25, all IrMn3 films on TaxN had a preferential orientation of (001). IrMn3 film grown on pure Ta underlayer showed a (111) orientation. Atomic force microscopy film characterization was made with a Bruker Icon Dimension with ScanAsyst system. High-resolution transmission electron microscopy and electron energy loss spectroscopy studies were made using a JEOL ARM 200F with a Cold-FEG source operated at 200 keV. Magnetic properties were measured at 300 K using a quantum design superconducting quantum interference device vibrating sample magnetometer (SQUID-VSM) in magnetic fields of up to ±7 T in both in-plane and out-of-plane directions. Uniaxial magnetic anisotropy KU values were calculated from KU=Heff × MS/2+2πMS2 (Heff being the effective magnetic field and MS the saturation magnetization).

Magnetic tunnel junction fabrication and characterization

MTJ devices were encapsulated in Al2O3. Electrical contacts were formed from 50 Å Ru/650 Å Au. TMR of the patterned devices was measured using a Quantum Design DynaCool physical property measurement system and a custom-built probe station with Keithley source metres 2,602 and 2,400. For fast evaluation of TMR, RAP and RP values in Fig. 2c were measured at +0.3 T and −0.3 T, respectively, instead of sweeping the magnetic field from ±9 T.

Calculation details

The electronic structure and transmission functions of Mn3Ge/MgO/Fe, Mn2CuSb/MgO/Fe and Fe/MgO/Fe MTJs were calculated using a tight-binding linear muffin-tin orbital method in the atomic sphere approximation with the local density approximation of DFT for the exchange-correlation energy17,18. For the Mn3Ge/MgO/Fe MTJ, the in-plane lattice constant was fixed to the experimental lattice constant a of bulk tetragonal Mn3Ge (a=3.816 Å and c=7.261 Å (ref. 19)). For Mn2CuSb/MgO/Fe the in-plane lattice constant was fixed to the calculated lattice constant a of the Mn2CuSb tetragonal inverse ferrimagnetic phase a=3.95 Å (Table 1).

Relaxed positions of atoms at the Mn3Ge/MgO and Mn2CuSb/MgO interfaces (for all possible terminations) were determined using the VASP molecular dynamic program20. The O-top configuration was found to be the most stable configuration (as compared with Mg-top and hollow) for both terminations at the Mn3Ge/MgO interface (in agreement with ref. 14), and for both terminations at the Mn2CuSb/MgO interface. For Fe/MgO interface the atomic positions from ref. 21 were used.

Additional information

How to cite this article: Jeong, J. et al. Termination layer compensated tunnelling magnetoresistance in ferrimagnetic Heusler compounds with high perpendicular magnetic anisotropy. Nat. Commun. 7:10276 doi: 10.1038/ncomms10276 (2016).

References

Parkin, S. S. P. MgO Tunnel barriers and method of formation. US patent 8,008,097 (2003).

Parkin, S. S. P. et al. Giant tunneling magnetoresistance at room temperature with MgO (100) tunnel barriers. Nat. Mater. 3, 862–867 (2004).

Ikeda, S. et al. A perpendicular-anisotropy CoFeB-MgO magnetic tunnel junction. Nat. Mater. 9, 721–724 (2010).

Sato, H. et al. Properties of magnetic tunnel junctions with a MgO/CoFeB/Ta/CoFeB/MgO recording structure down to junction diameter of 11 nm. Appl. Phys. Lett. 105, 062403 (2014).

Graf, T., Felser, C. & Parkin, S. S. P. Simple rules for the understanding of Heusler compounds. Prog. Solid State Chem. 39, 1–50 (2011).

Balke, B., Fecher, G. H., Winterlik, J. & Felser, C. Mn3Ga, a compensated ferrimagnet with high Curie temperature and low magnetic moment for spin torque transfer applications. Appl. Phys. Lett. 90, 152504 (2007).

Kurt, H. et al. Magnetic and electronic properties of D022-Mn3Ge (001) films. Appl. Phys. Lett. 101, 132410 (2012).

Sugihara, A., Mizukami, S., Yamada, Y., Koike, K. & Miyazaki, T. High perpendicular magnetic anisotropy in D022-Mn3+xGe tetragonal Heusler alloy films. Appl. Phys. Lett. 104, 132404 (2014).

Mizukami, S. et al. Tetragonal D022 Mn3+xGe Epitaxial Films Grown on MgO(100) with a Large Perpendicular Magnetic Anisotropy. Appl. Phys. Expr 6, 123002 (2013).

Li, M., Jiang, X., Samant, M. G., Felser, C. & Parkin, S. S. P. Strong dependence of the tetragonal Mn2.1Ga thin film crystallization temperature window on seed layer. Appl. Phys. Lett. 103, 032410 (2013).

Köhler, A., Knez, I., Ebke, D., Felser, C. & Parkin, S. S. P. Loss of anisotropy in strained ultrathin epitaxial L10 Mn-Ga films. Appl. Phys. Lett. 103, 162406 (2013).

Yamaoka, T. Antiferromagnetism in γ-Phase Mn-Ir Alloys. J. Phys. Soc. Jap. 36, 445–450 (1974).

Winterlik, J. et al. Structural, electronic, and magnetic properties of tetragonal Mn3-xGa: Experiments and first-principles calculations. Phys. Rev. B 77, 054406 (2008).

Miura, Y. & Shirai, M. Theoretical Study on Tunneling Magnetoresistance of Magnetic Tunnel Junctions with D022-Mn3Z (Z= Ga, Ge). IEEE Trans. Magn. 50, 1400504 (2014).

Zhang, D. et al. First-principles study of the structural stability of cubic, tetragonal and hexagonal phases in Mn 3 Z (Z=Ga, Sn and Ge) Heusler compounds. J. Phys. Conds. Matter 25, 206006 (2013).

Faleev, S. V., Parkin, S. S. P. & Mryasov, O. N. Brillouin zone spin filtering mechanism of enhanced TMR and correlation effects in Co(0001)/h-BN/Co(0001) magnetic tunnel junction. Preprint at http://arxiv.org/abs/1504.01017 (2015).

Turek, I., Drchal, V., Kudrnovsky, J., Sob, M. & Weinberger, P. Electronic structure of disordered alloys, surfaces and interfaces Kluwer (1997).

Schilfgaarde, M. v. & Lambrecht, W. R. L. in Tight-binding approach to computational materials science vol. 491, eds Colombo L., Gonis A., Turchi P. 137 (MRS (1998).

Kádár, G. & Krén, E. Neutron diffraction study of Mn3Ge. Int. J. Magn. 1, 143–148 (1971).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys Rev. B 54, 11169–11186 (1996).

Wortmann, D., Bihlmayer, G. & Blügel, S. Ab initio calculations of interface effects in tunnelling through MgO barriers on Fe(100). J. Phys. Condens. Matter 16, S5819–S5822 (2004).

Butler, W. H., Zhang, X.-G., Schulthess, T. C. & MacLaren, J. M. Spin-dependent tunneling conductance of Fe|MgO|Fe sandwiches. Phys. Rev. B 63, 054416 (2001).

Acknowledgements

S.V.F. acknowledges the CNMS User support by Oak Ridge National Laboratory Division of Scientific User facilities. We thank Andrew Kellock, Teya Topuria, Phil Rice, Erik Lara, Leslie Thompson, Eugene Delenia, Brian Hughes and Charles Rettner for their help.

Author information

Authors and Affiliations

Contributions

J.J. and Y.F. prepared the films and performed the experiments. DFT calculations were performed by S.V.F. S.S.P.P. conceived of the study. All authors discussed the results, contributed to the analysis of the data and wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Figures 1-8, Supplementary Notes 1-8 and Supplementary References. (PDF 967 kb)

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Jeong, J., Ferrante, Y., Faleev, S. et al. Termination layer compensated tunnelling magnetoresistance in ferrimagnetic Heusler compounds with high perpendicular magnetic anisotropy. Nat Commun 7, 10276 (2016). https://doi.org/10.1038/ncomms10276

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/ncomms10276

This article is cited by

-

Field-free spin-orbit torque-induced switching of perpendicular magnetization in a ferrimagnetic layer with a vertical composition gradient

Nature Communications (2021)

-

Ultrafast and energy-efficient spin–orbit torque switching in compensated ferrimagnets

Nature Electronics (2020)

-

Effect of insertion layer on electrode properties in magnetic tunnel junctions with a zero-moment half-metal

Scientific Reports (2019)

-

Heusler, Weyl and Berry

Nature Reviews Materials (2018)

-

Chiral domain wall motion in unit-cell thick perpendicularly magnetized Heusler films prepared by chemical templating

Nature Communications (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.